Control system and control method for outlet temperature of novel coal mill

A technology of outlet temperature and control system, which is applied in combustion methods, block/powder fuel preparation, grain processing, etc., can solve the problem of inability to adapt to frequent changes of coal mills and the operating value of coal mill outlet temperature is low, and achieves The effect of reducing the heat loss of pulverized coal incomplete combustion, stabilizing boiler combustion, and reducing the heat loss of incomplete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

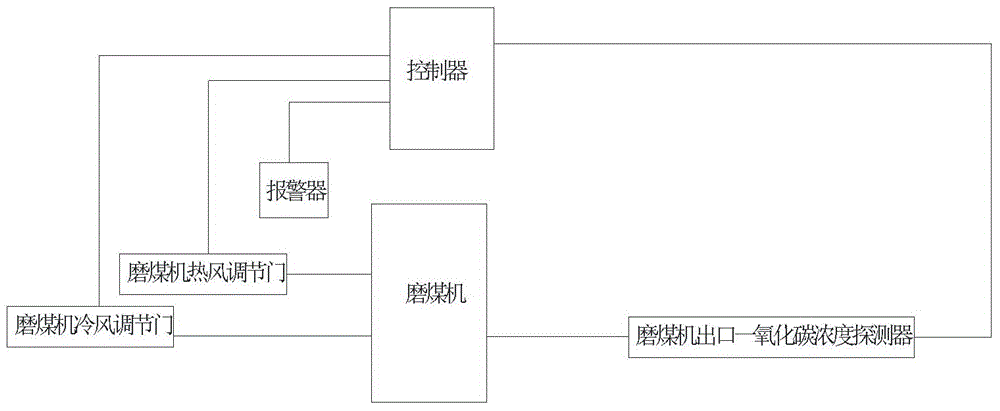

[0041] The structure of the control system of this embodiment is as follows: figure 1 As shown, the algorithm flow chart is as follows Figure 4 As shown, the details are as follows:

[0042] 1) The carbon monoxide concentration measurement signal at the coal mill outlet is connected to the coal mill outlet temperature control system as a parameter for controlling the coal mill outlet temperature;

[0043] 2) If the carbon monoxide concentration measuring point at the coal mill outlet measures the average carbon monoxide concentration at the coal mill outlet to be 0PPm, the controller issues an instruction to increase the opening of the hot air control door at the coal mill inlet and decrease the opening of the cold air control door at the coal mill inlet. When the carbon monoxide concentration measuring point at the outlet of the coal mill measures the concentration of carbon monoxide at the outlet of the coal mill is greater than 0PPm, immediately lock the opening of the ho...

Embodiment 2

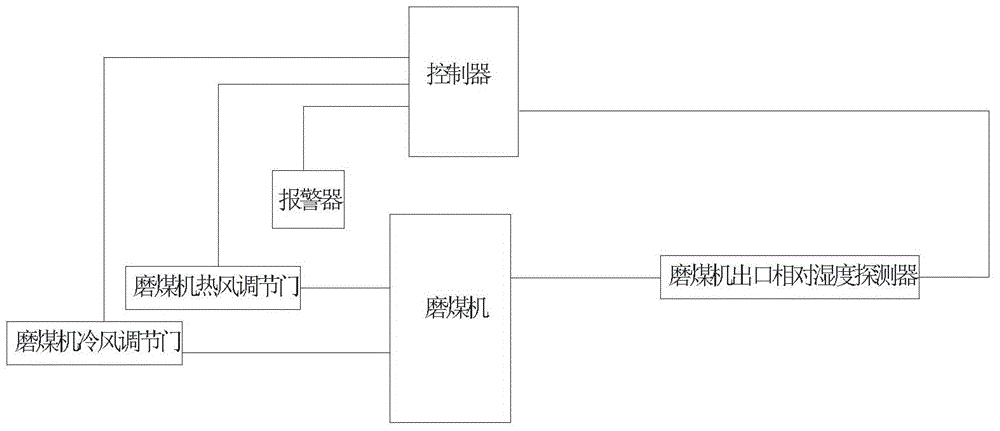

[0048] The structure of the control system of this embodiment is as follows: figure 2 As shown, the algorithm flow chart is as follows Figure 5 As shown, the details are as follows:

[0049] 1) The relative humidity measurement signal of the air-powder mixture at the outlet of the coal mill is connected to the temperature control system at the outlet of the coal mill as a parameter for controlling the outlet temperature of the coal mill;

[0050] 2) If the relative humidity of the air-powder mixture at the outlet of the coal mill is greater than 0.52 measured at the relative humidity of the air-powder mixture at the outlet of the coal mill, the controller issues an instruction to increase the opening of the hot air door at the inlet of the coal mill and reduce the opening of the cold air door opening until the relative humidity of the air-powder mixture at the outlet of the coal mill is 0.52;

[0051] 3) If the relative humidity of the air-powder mixture at the outlet of t...

Embodiment 3

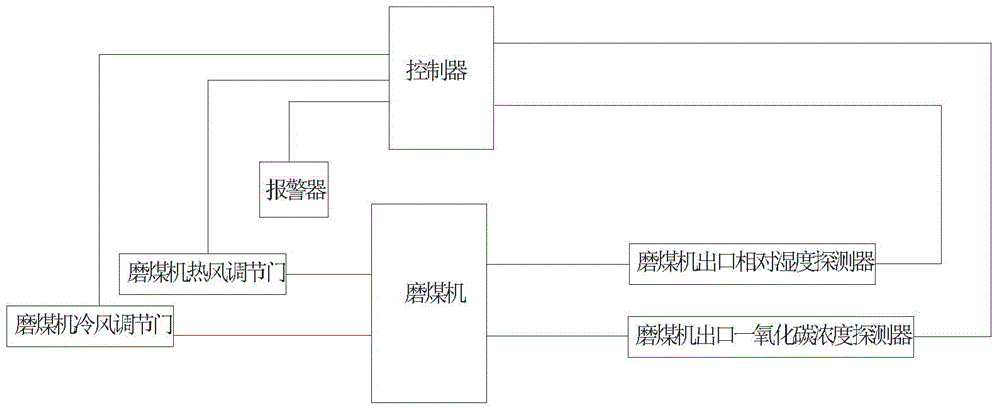

[0056] The structure of the control system of this embodiment is as follows: image 3 As shown, the algorithm flow chart is as follows Figure 6 As shown, the details are as follows:

[0057] 1) The carbon monoxide concentration measurement signal at the coal mill outlet and the relative humidity measurement signal of the air-powder mixture at the coal mill outlet are connected to the coal mill outlet temperature control system as parameters for controlling the coal mill outlet temperature;

[0058] 2) If the carbon monoxide concentration measuring point at the coal mill outlet measures the carbon monoxide concentration at the coal mill outlet as 0PPm, and the relative humidity of the air-powder mixture at the coal mill outlet is greater than 0.52, increase the opening of the hot air control door at the coal mill inlet and reduce the Adjust the opening of the cold air door at the coal machine inlet until the relative humidity at the coal mill outlet is 0.52 or the carbon mono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com