Heat storage premixed biomass gas combustor and using method thereof

A gas burner and biomass gas technology, which is applied in the directions of gas fuel burners, combustion methods, burners, etc., can solve the problems of no open burners and low pollutant emissions, so as to improve turbulence and strengthen internal radiation. Heat transfer and reduction of fire heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

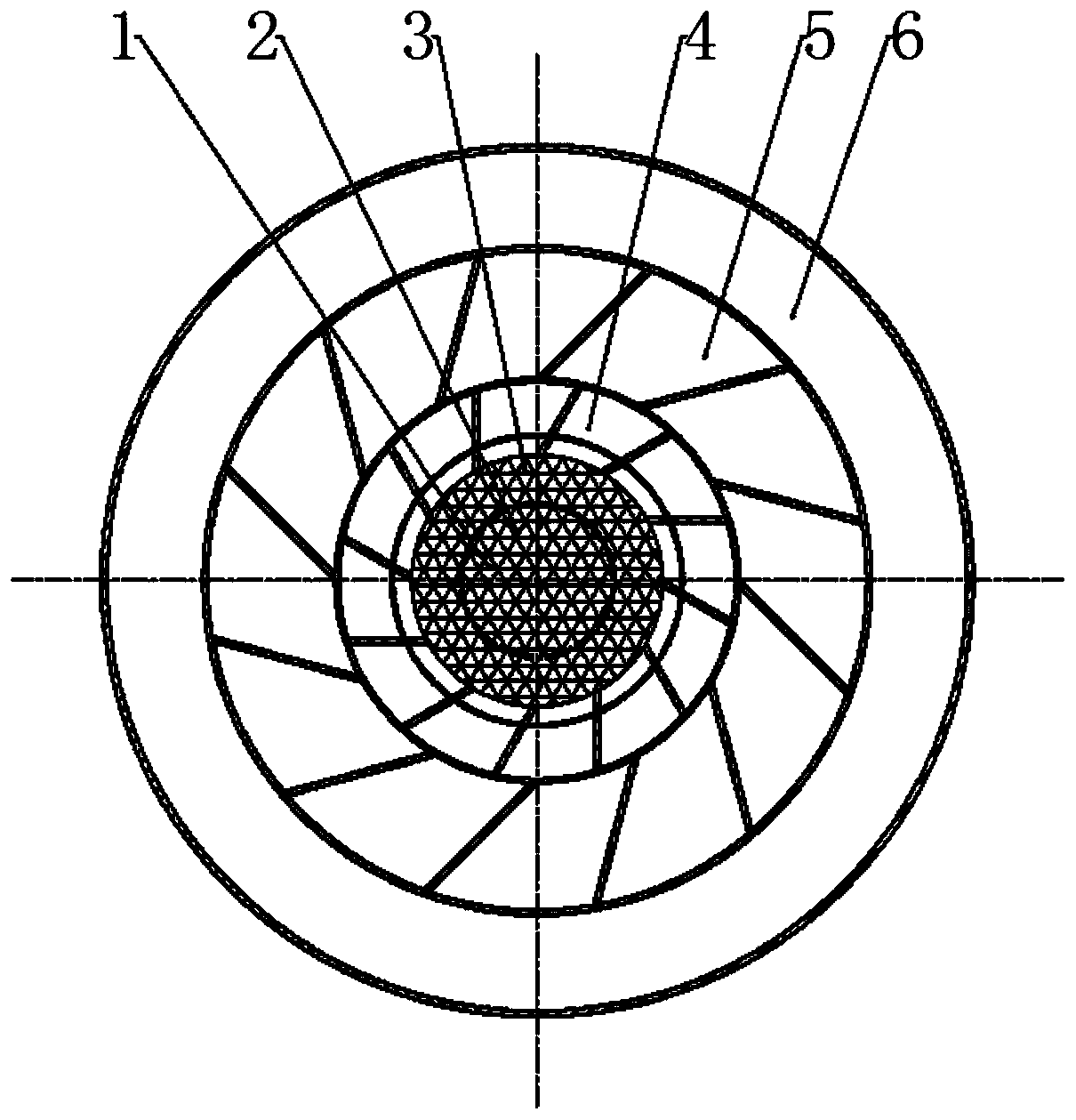

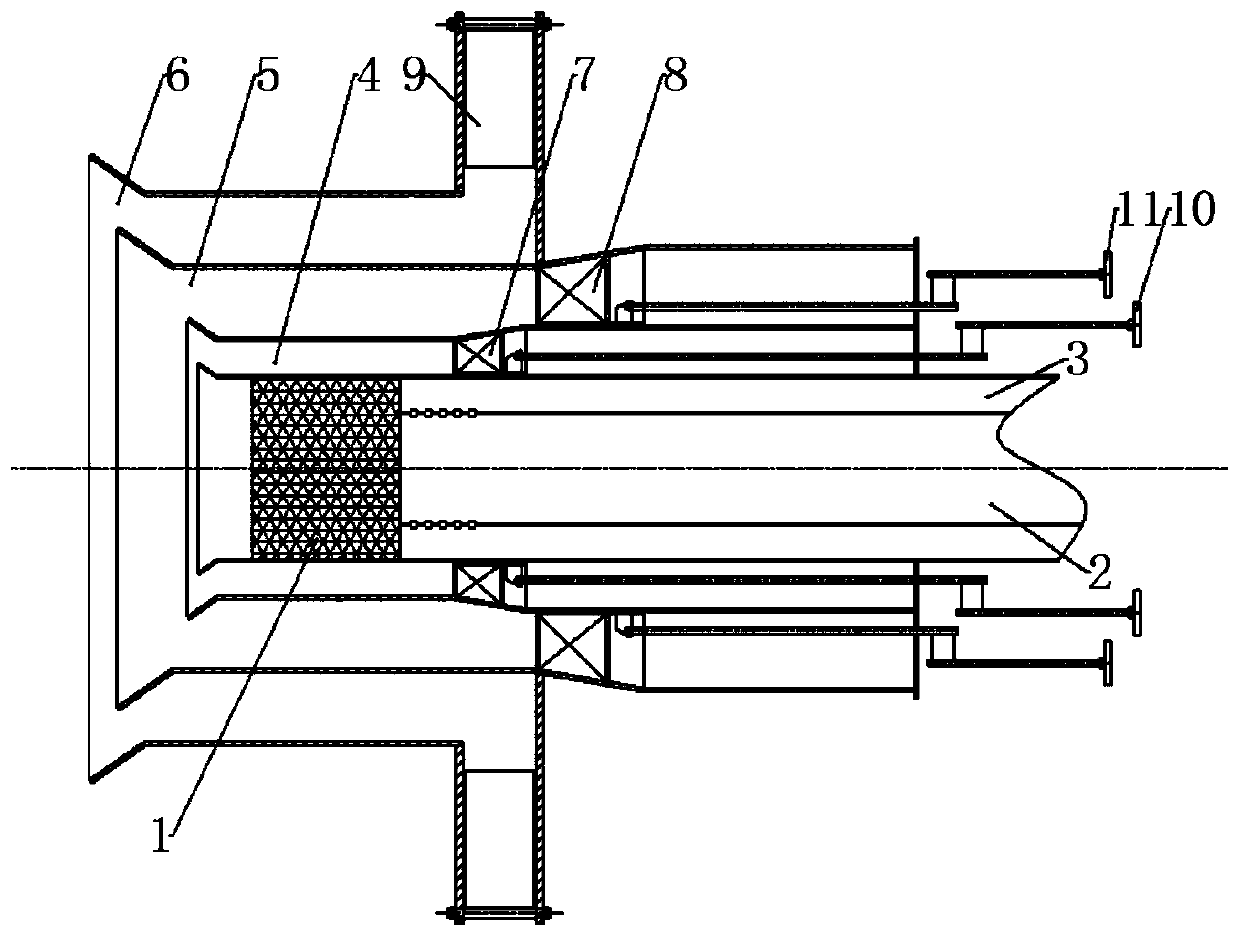

[0022] refer to figure 1 and figure 2 , the thermal storage premixed biomass gas burner of the present invention includes a porous medium thermal storage premixing pipeline 1, an internal combustion air pipeline 4, an external gas pipeline 5, an external combustion air pipeline 6, a first sleeve, and an internal combustion air pipeline. swirl adjustment rod 10, second sleeve, external gas swirl adjustment rod 11, a number of internal combustion air axial swirl blades 7 and a number of external gas axial swirl blades 8; porous media heat storage premixing pipe 1, inner The combustion-supporting air pipeline 4, the external gas pipeline 5 and the external combustion-supporting air pipeline 6 are distributed sequentially from the inside to the outside, and the outlet of the porous medium heat storage premix pipeline 1 is filled with ceramic foam-type porous media, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com