Patents

Literature

47results about How to "Stable temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

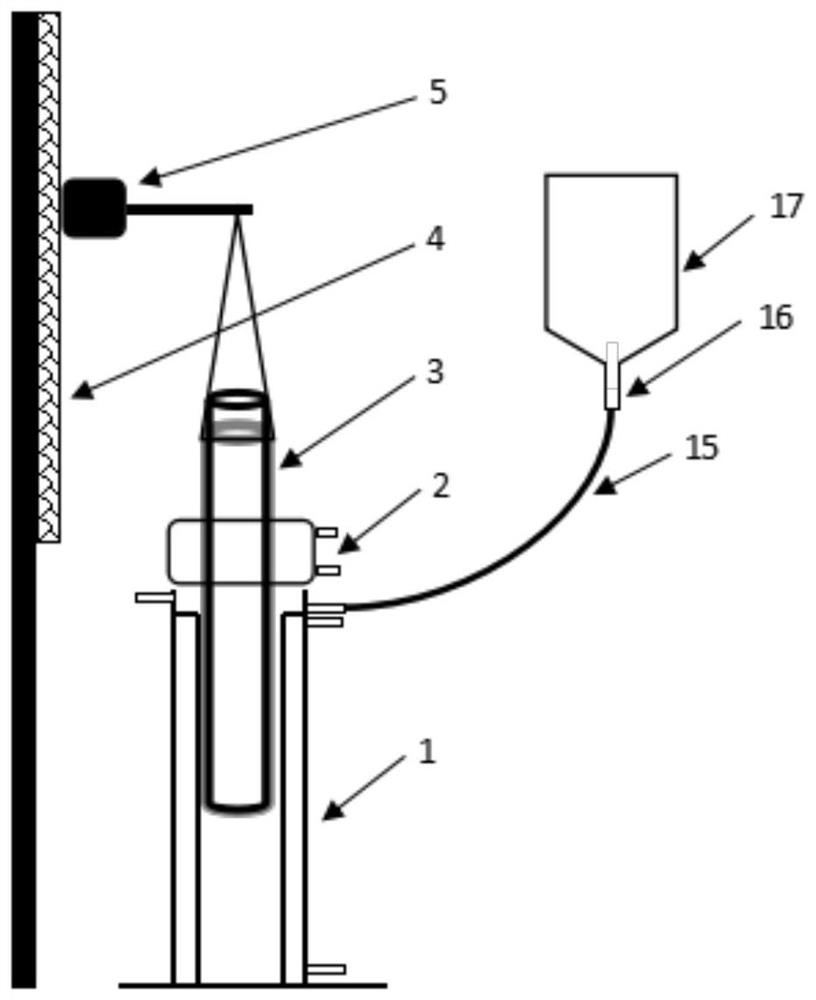

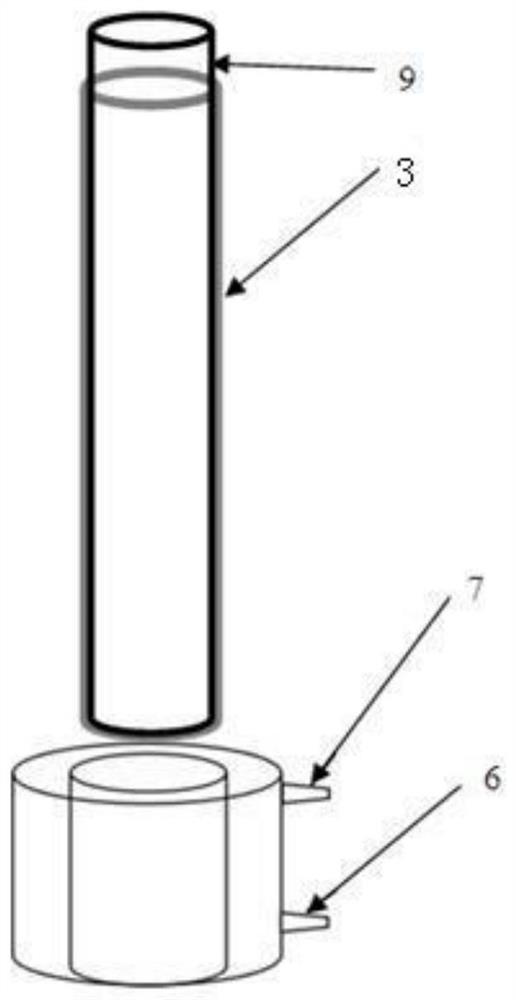

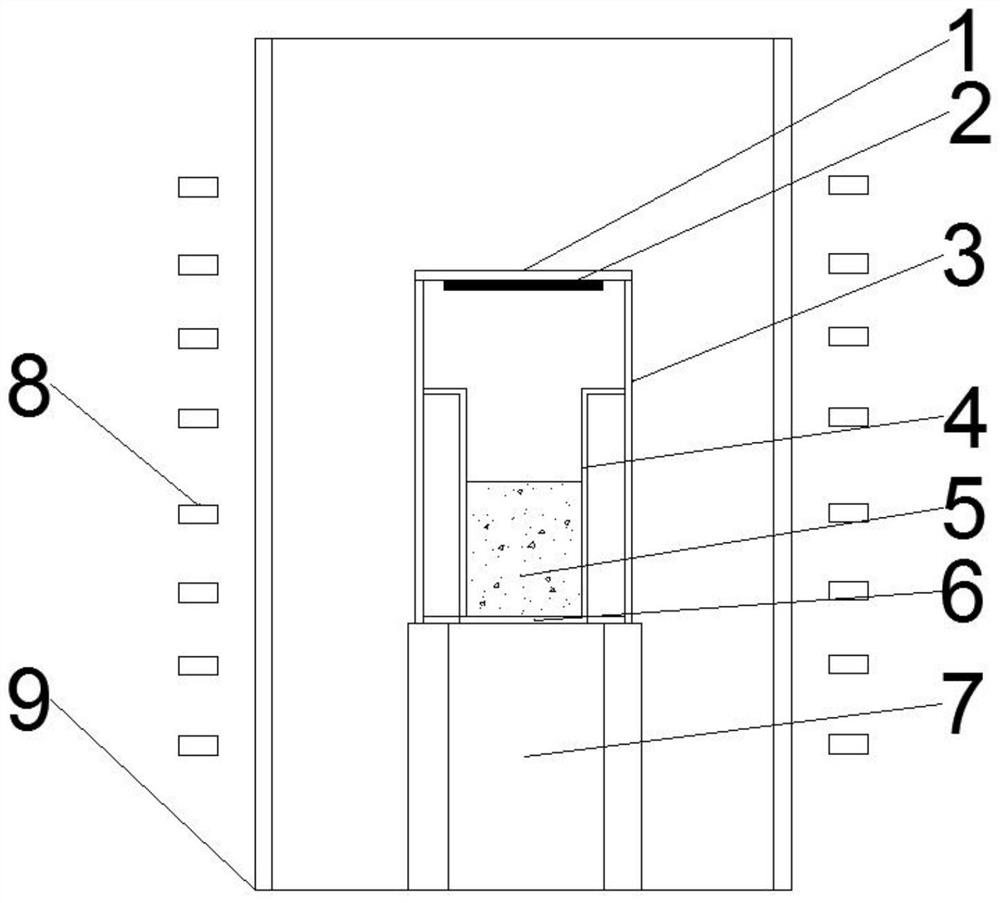

Testing system for deep soil freezing/thawing process

ActiveCN102590468AReduce distractionsMove up and down flexiblyEarth material testingGraduated cylinderCold formed

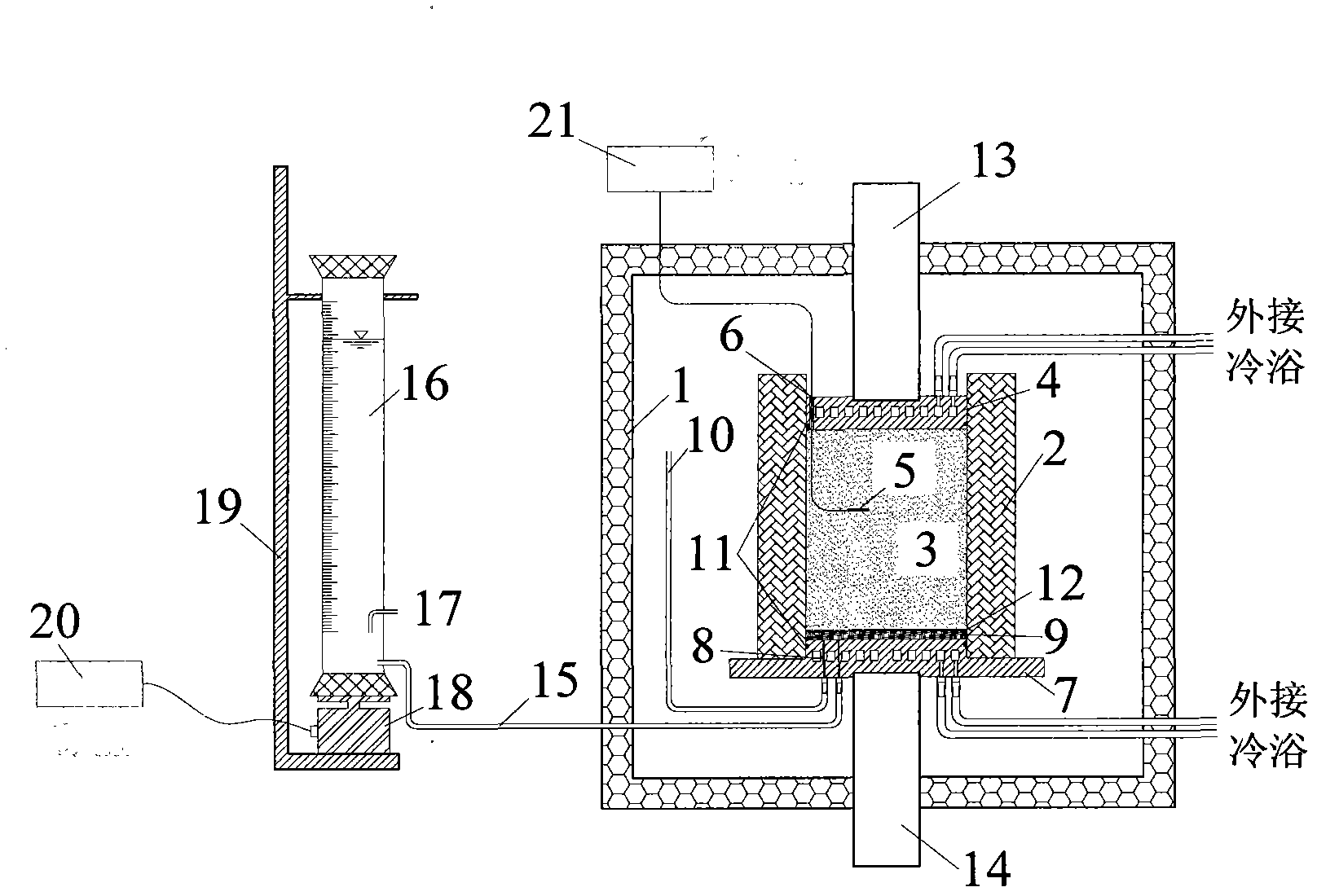

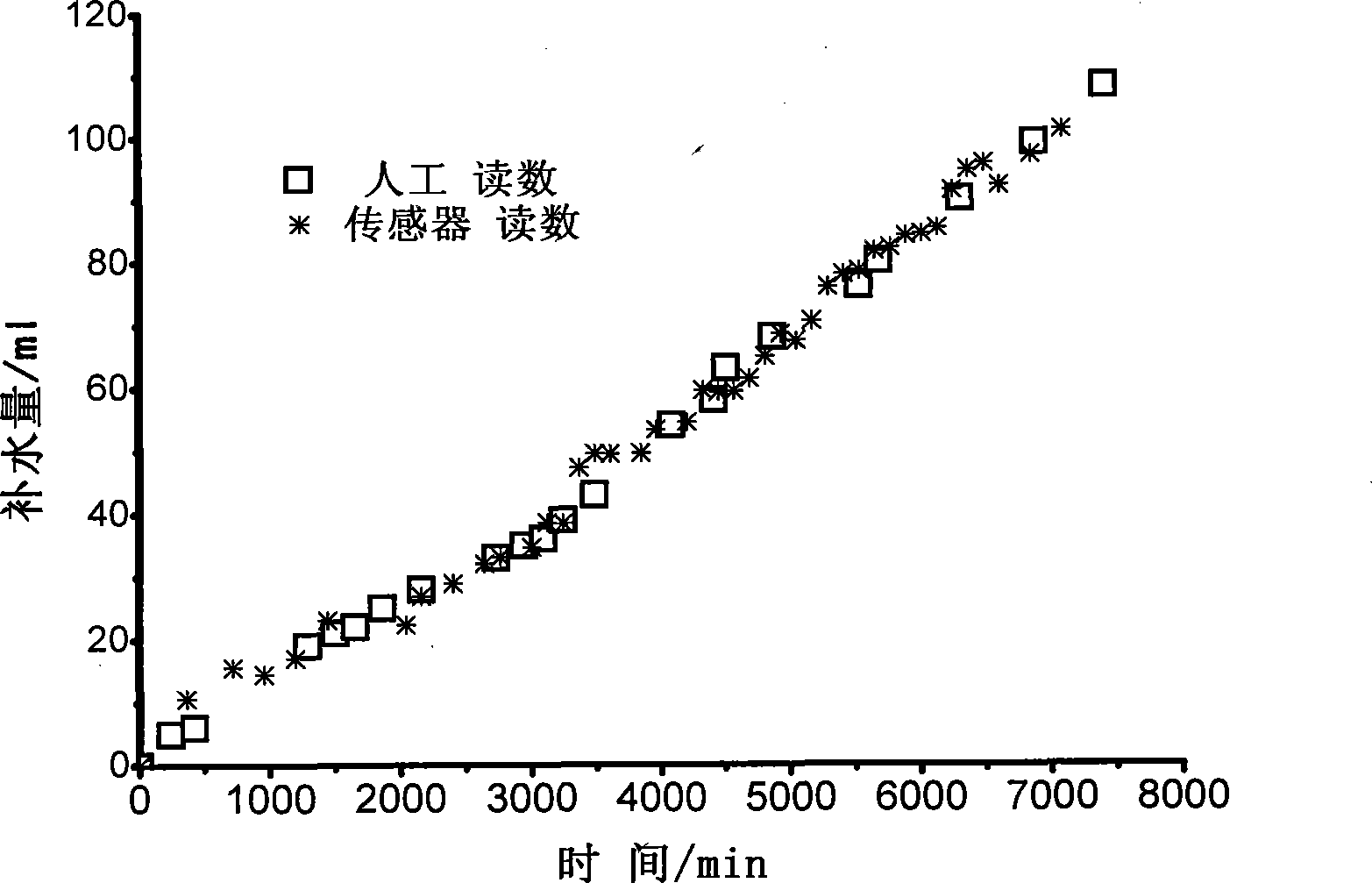

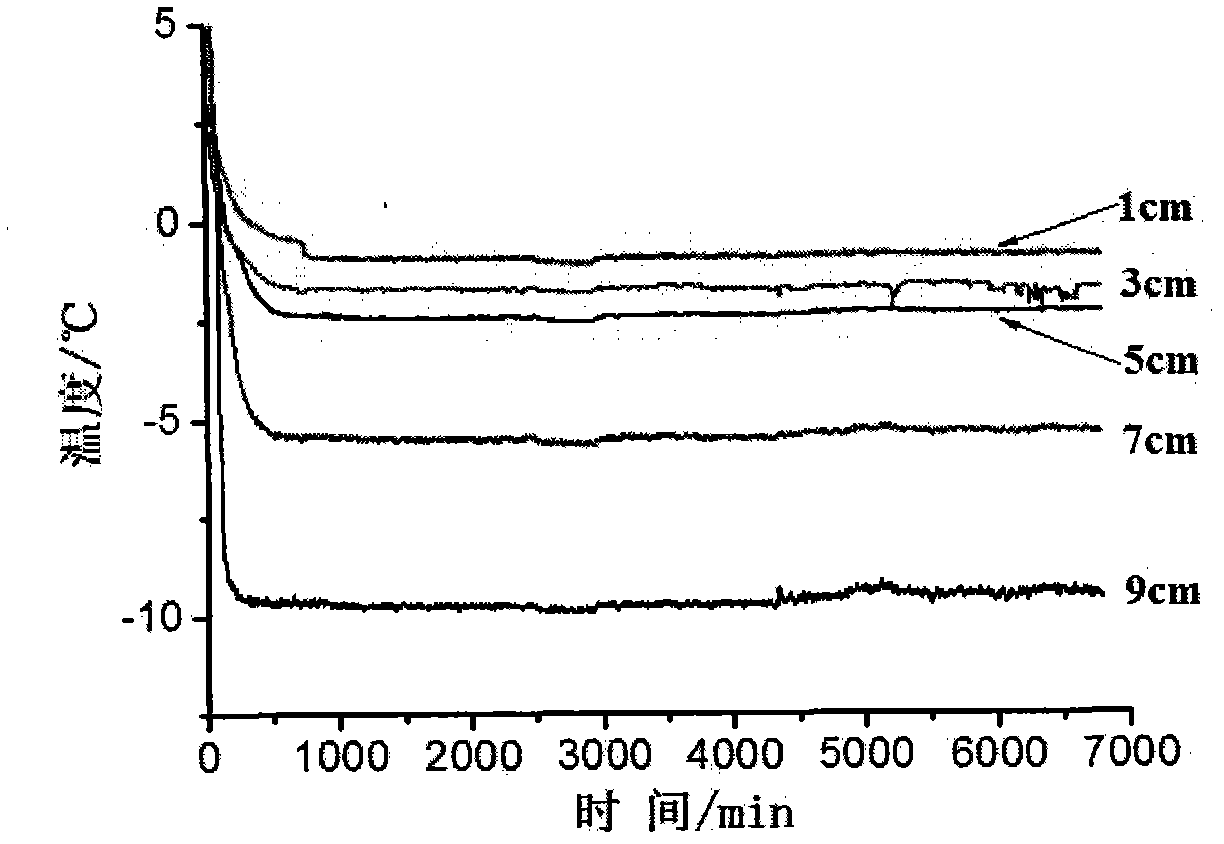

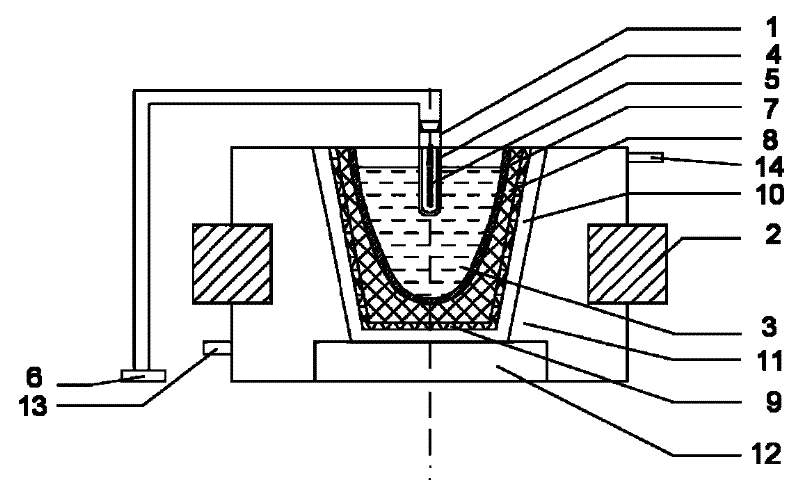

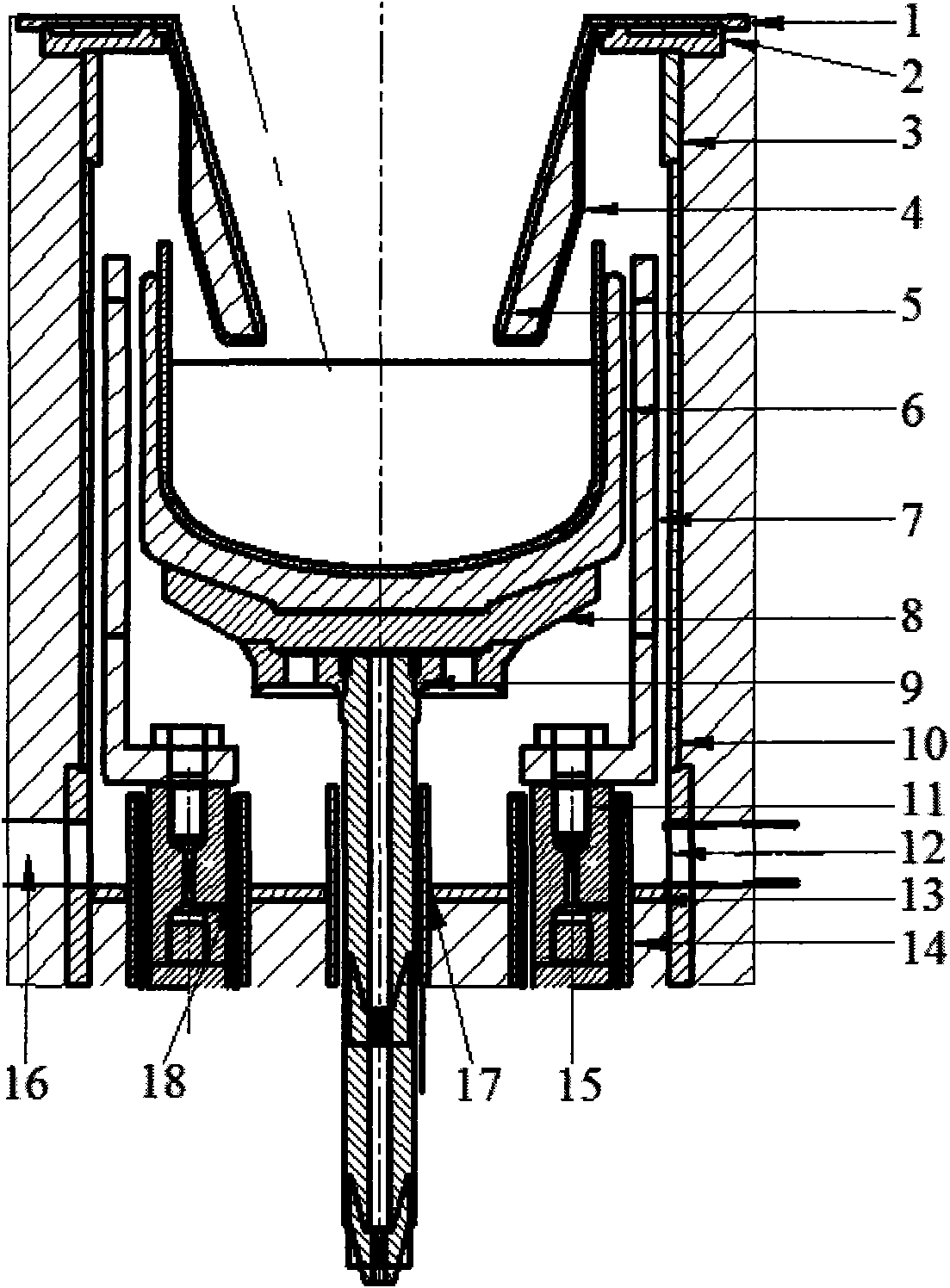

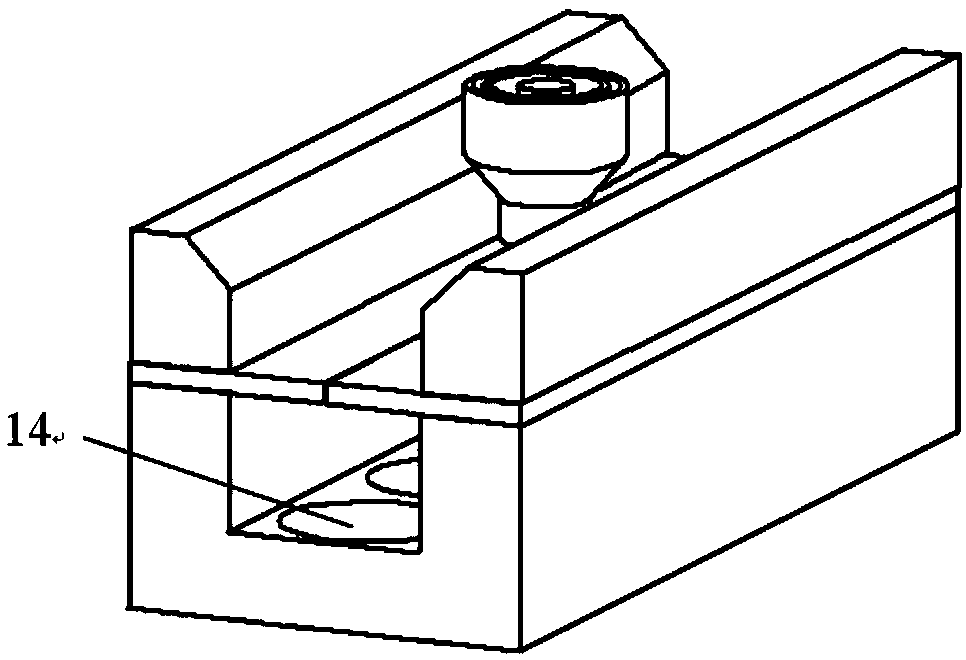

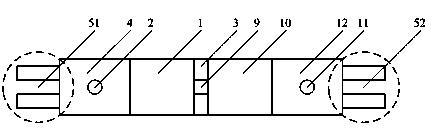

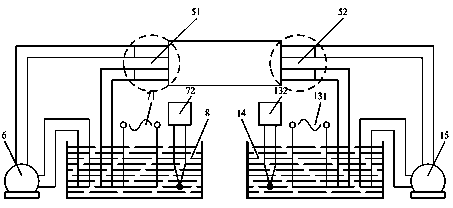

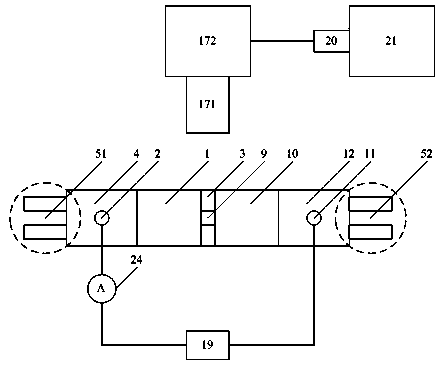

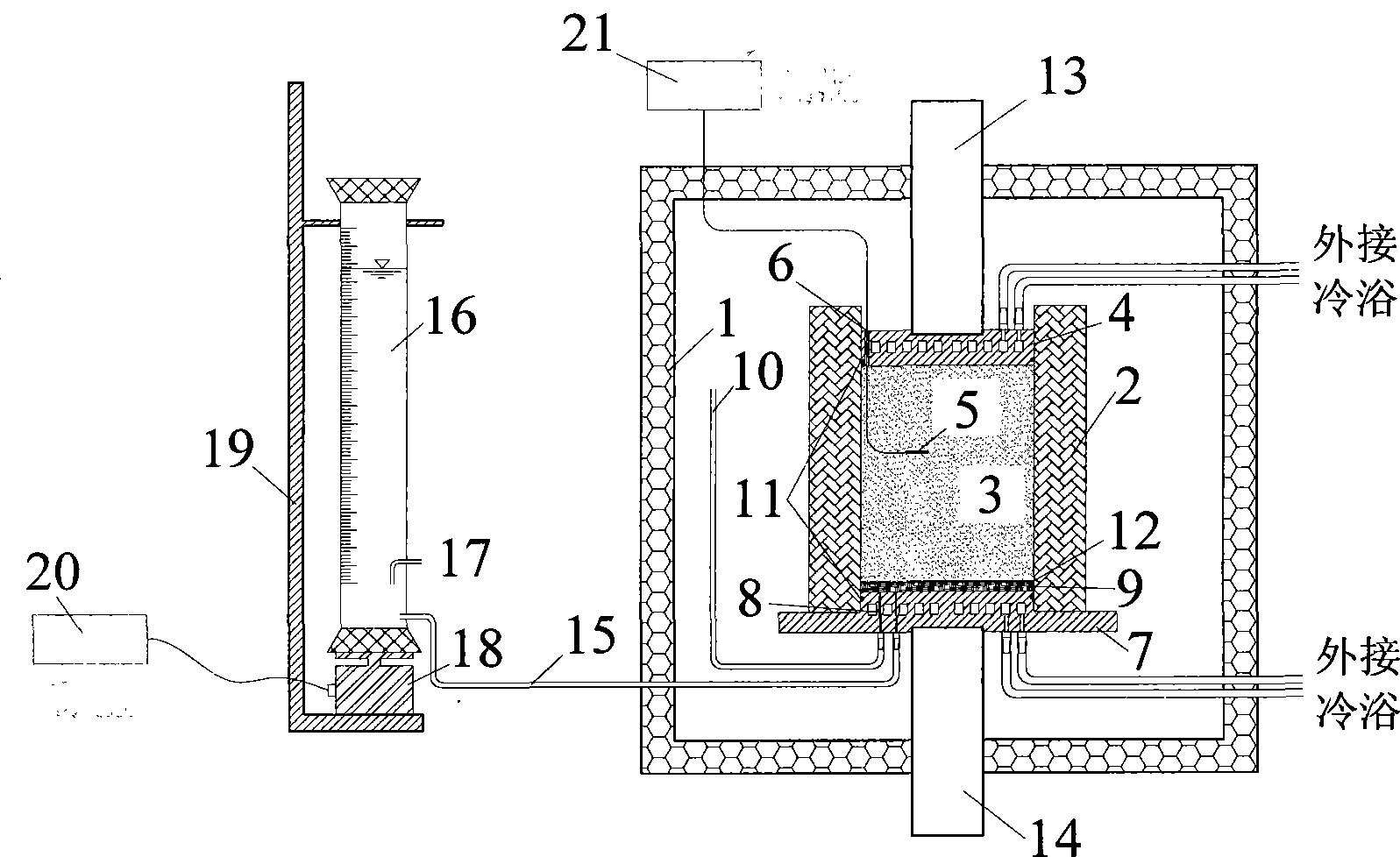

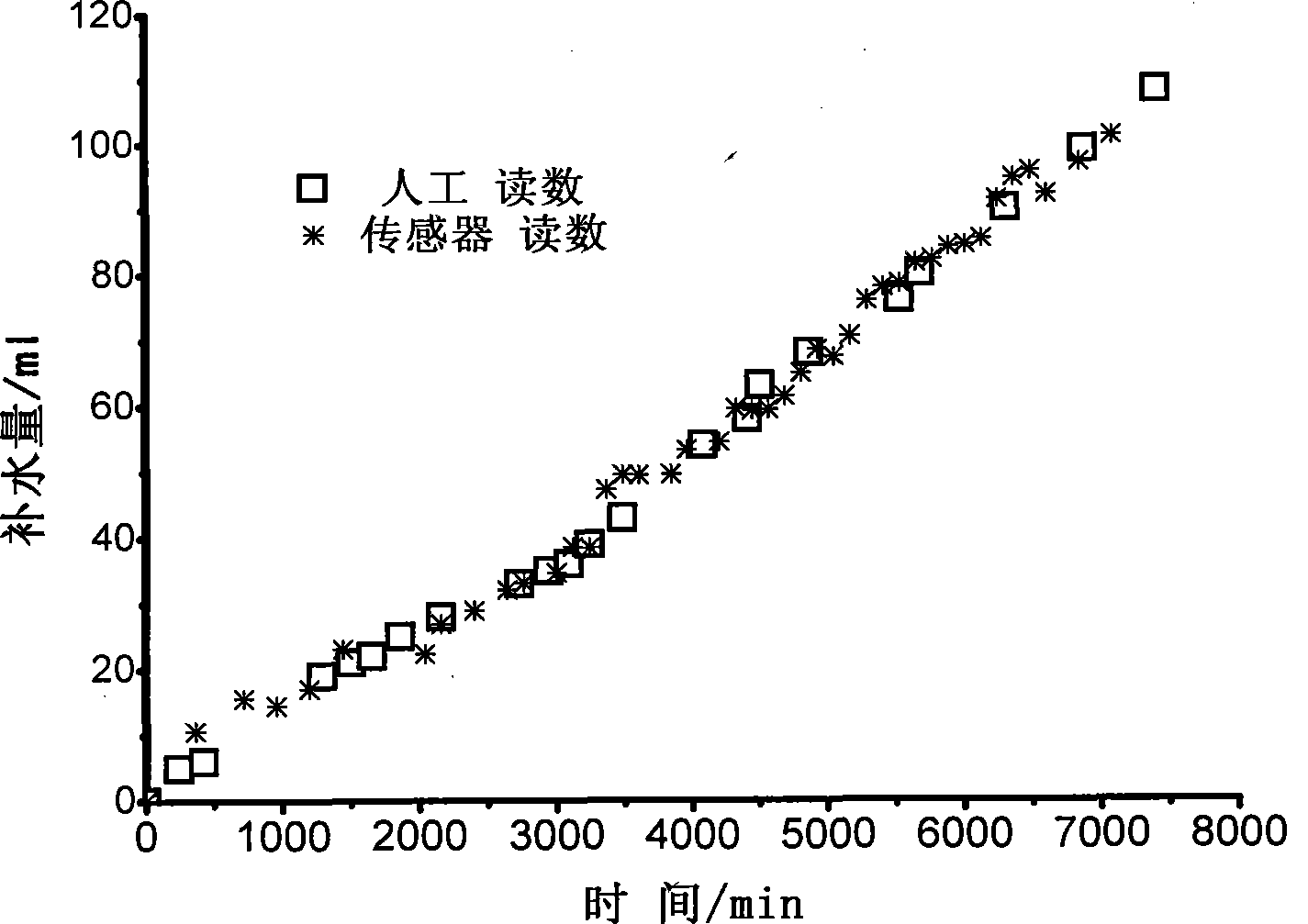

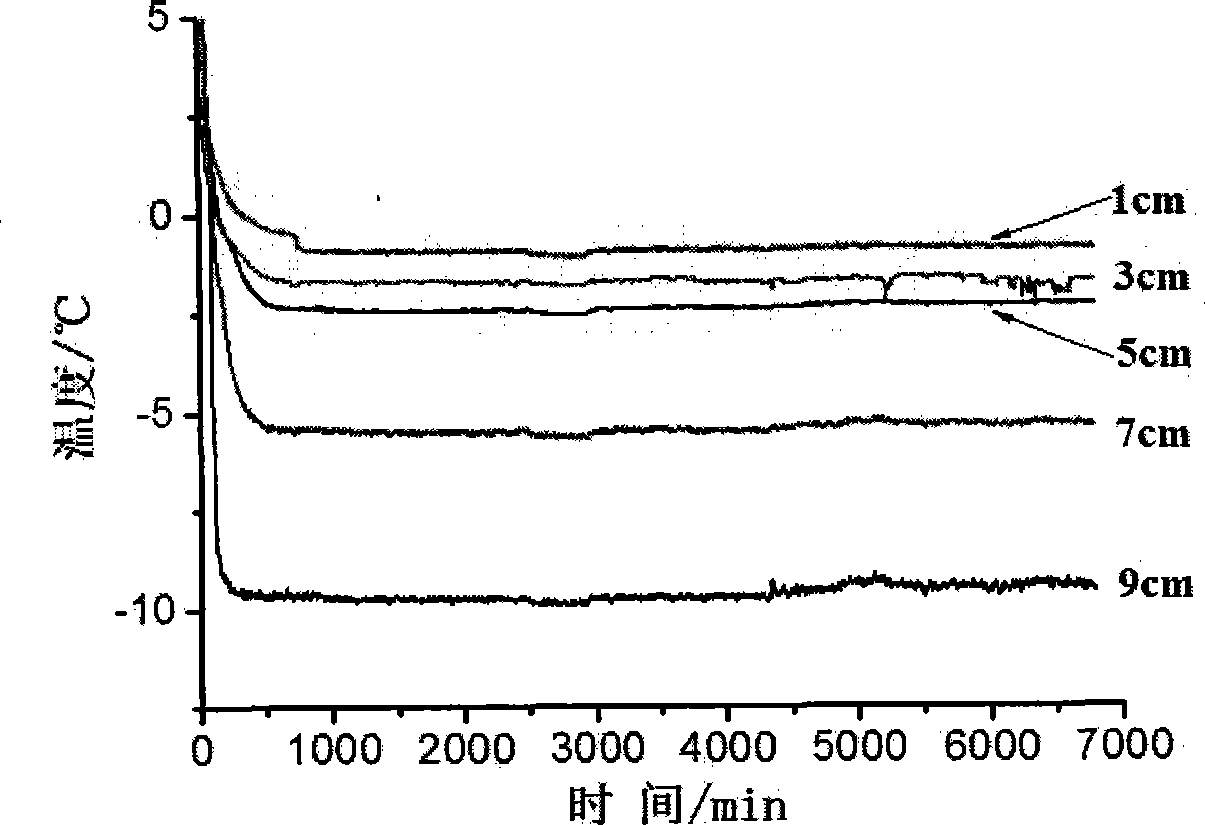

The invention relates to a testing system for deep soil freezing / thawing process, which is structurally characterized in that a temperature-controlled box is connected with an external cold bath; a high pressure-resistant organic glass cylinder is arranged on a temperature-controllable steel base; two small holes are formed in the base, one is connected with a water guide pipe, and the other is connected with a pressure adjusting pipe; a permeable stone, a piece of filter paper and a sample are sequentially arranged at the upper part of the lower base, and a temperature sensor is mounted in the sample; a temperature-controllable upper press head is arranged at the upper part of the sample; a line leading-out hole is formed in the upper press head, and is sealed through sealant after the line is lead out; the upper press head is connected with the transmission rod of a testing machine; a measuring cylinder is connected with the sample through the water guide pipe; and the measuring cylinder is arranged on a weighing sensor and fixed through a bracket. By adopting the testing system, the freezing / thawing process of the deep soil can be rather systematically researched, so as to obtain the frost heaving rate and the water absorbing / draining rate of the deep soil which is in different depths frozen under the different temperature gradients. The testing system provides the technical guarantee for the research in clarifying the action of the external load on the forming processes of the freezing soil and the frozen soil cold-formed structures, and the mutual action of the temperature, the moisture content and the pressure of the soil body in the process of freezing under the high-pressure action.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

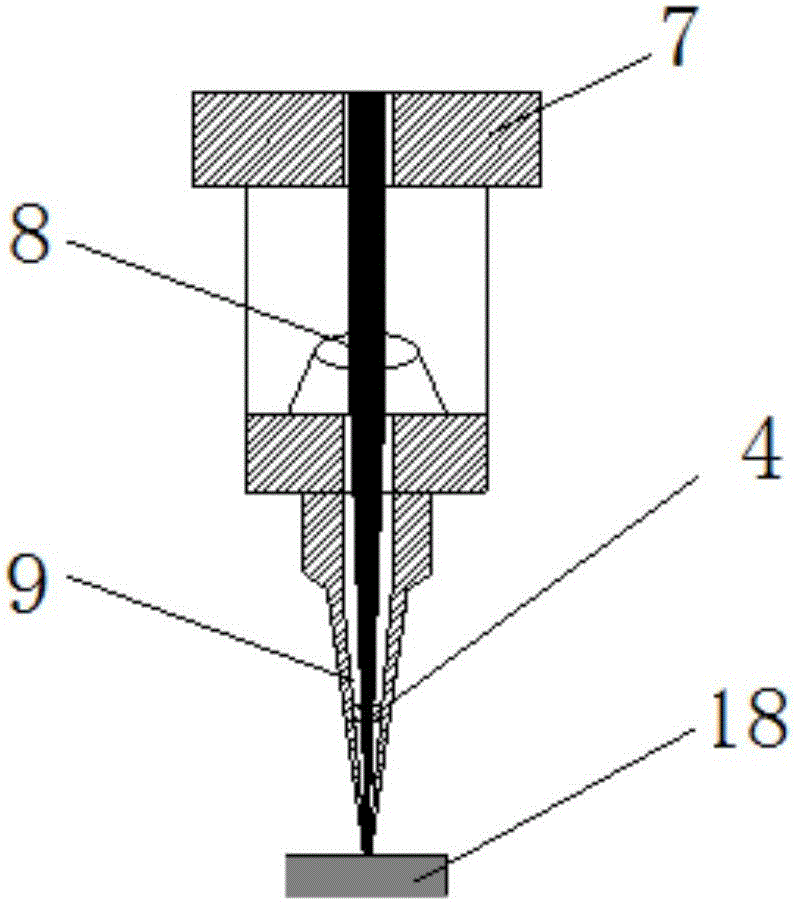

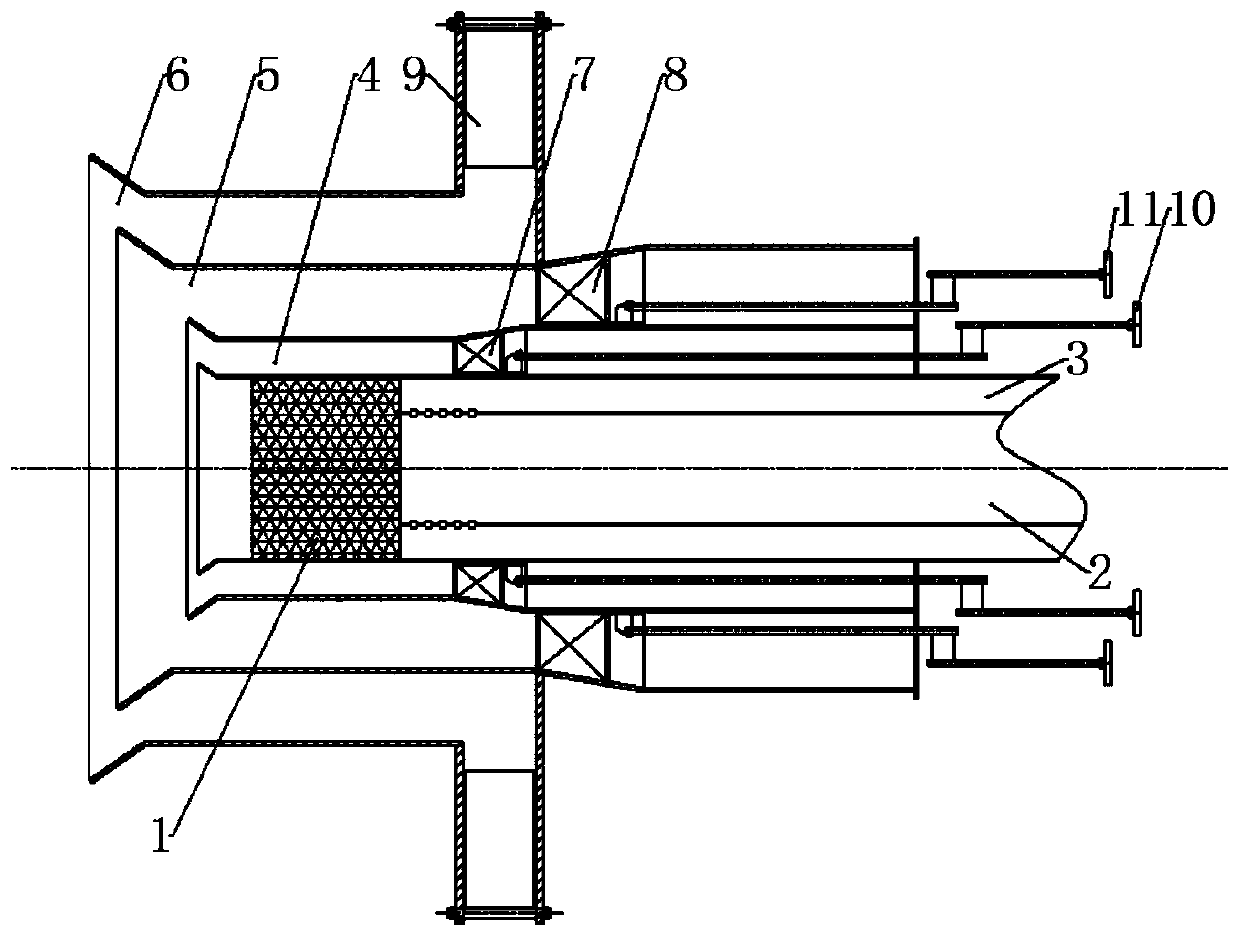

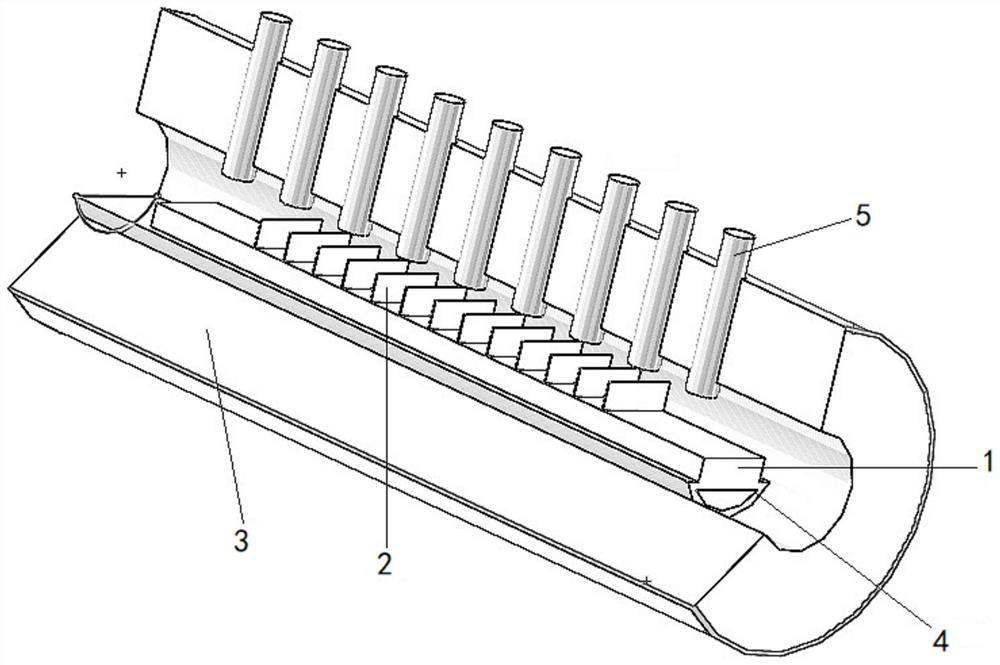

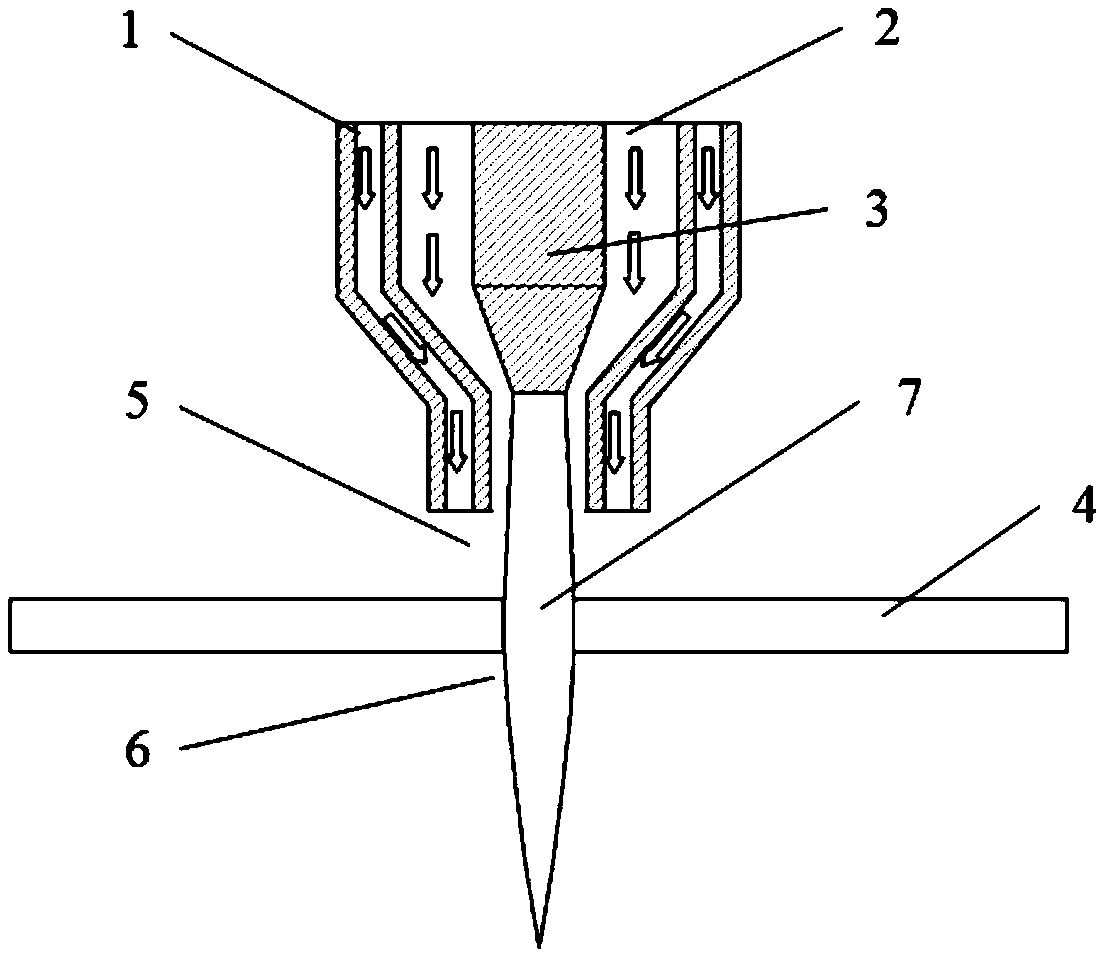

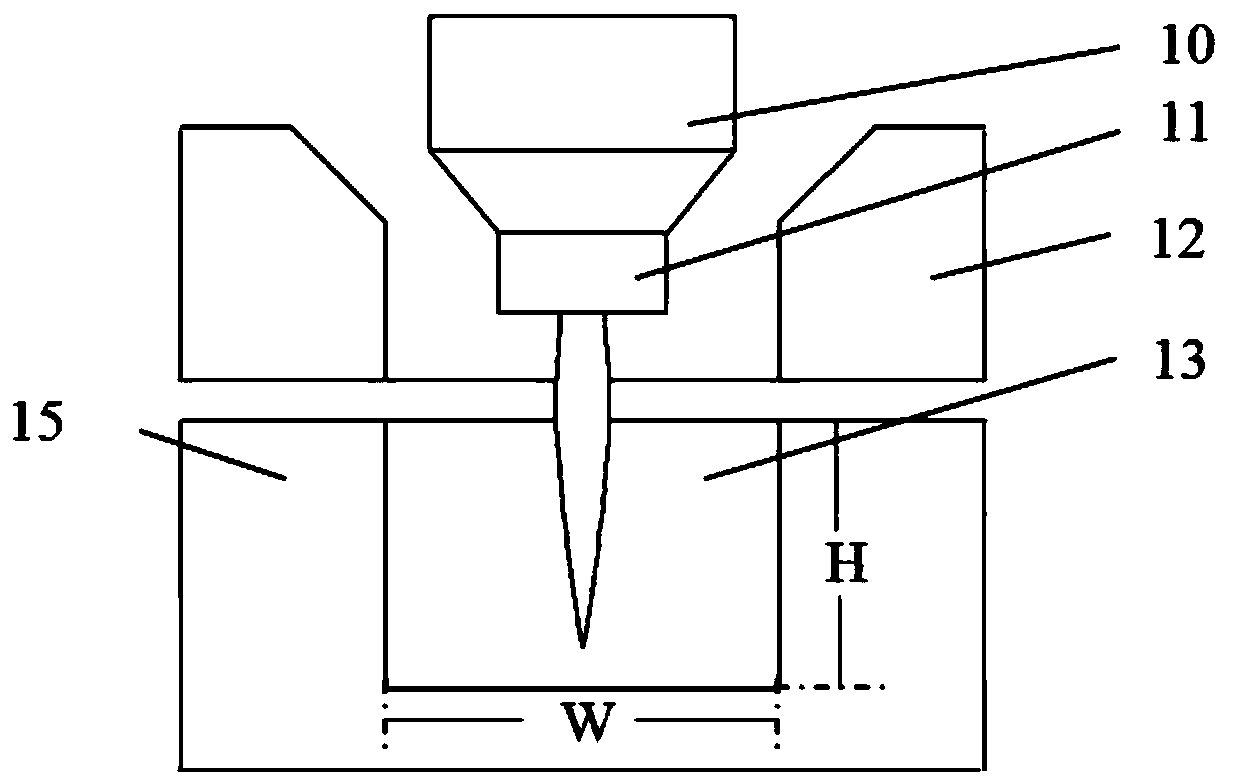

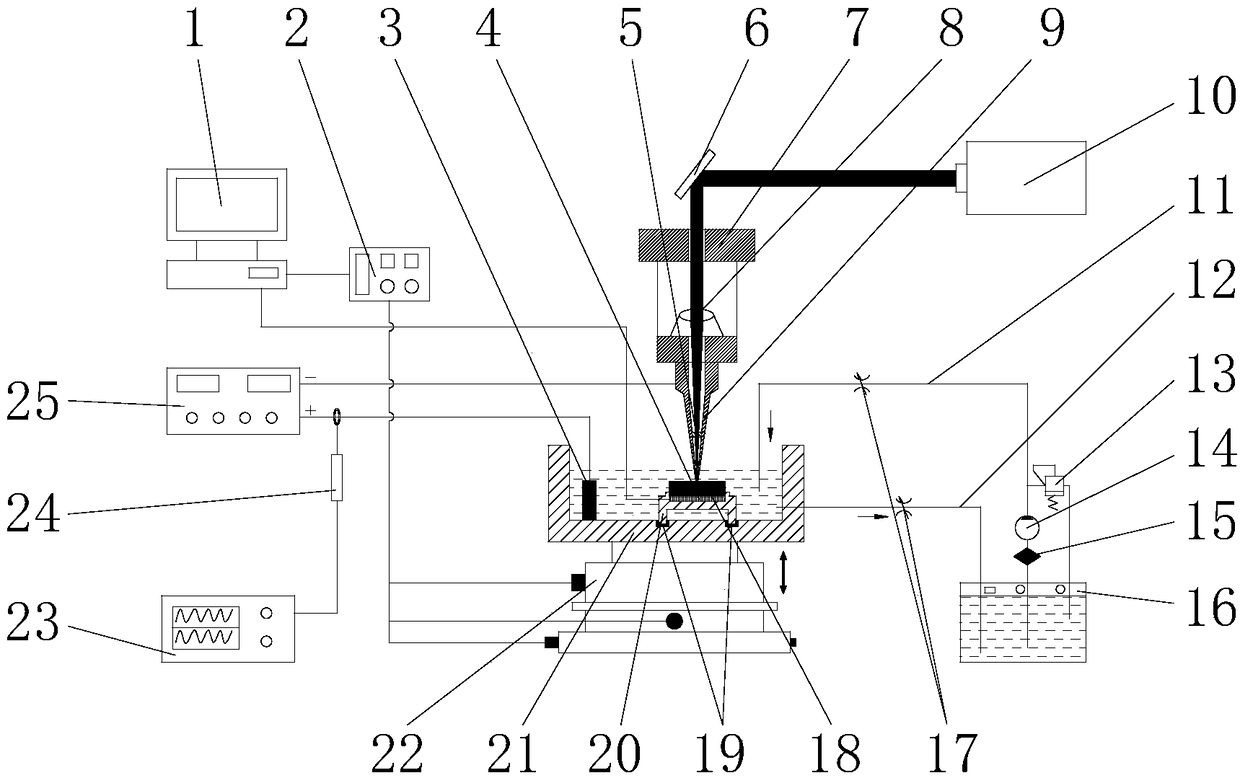

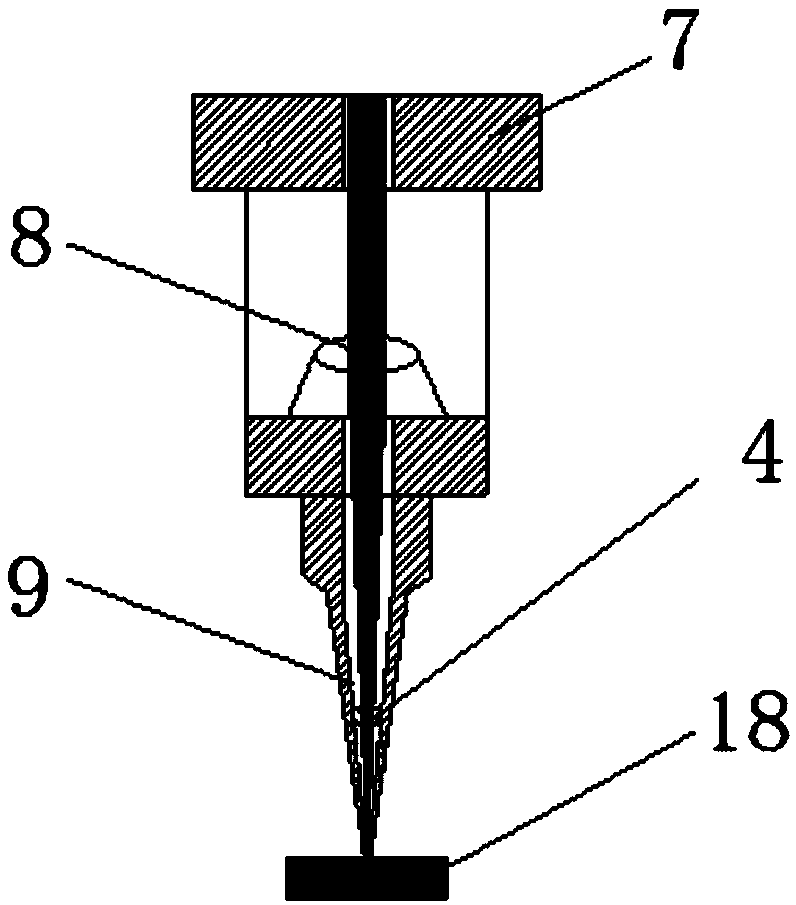

Method and device for coaxial combined machining with tubular electrode discharging and laser irradiation

ActiveCN106424987AImprove processing efficiencyImprove processing localityStress concentrationMaterial defect

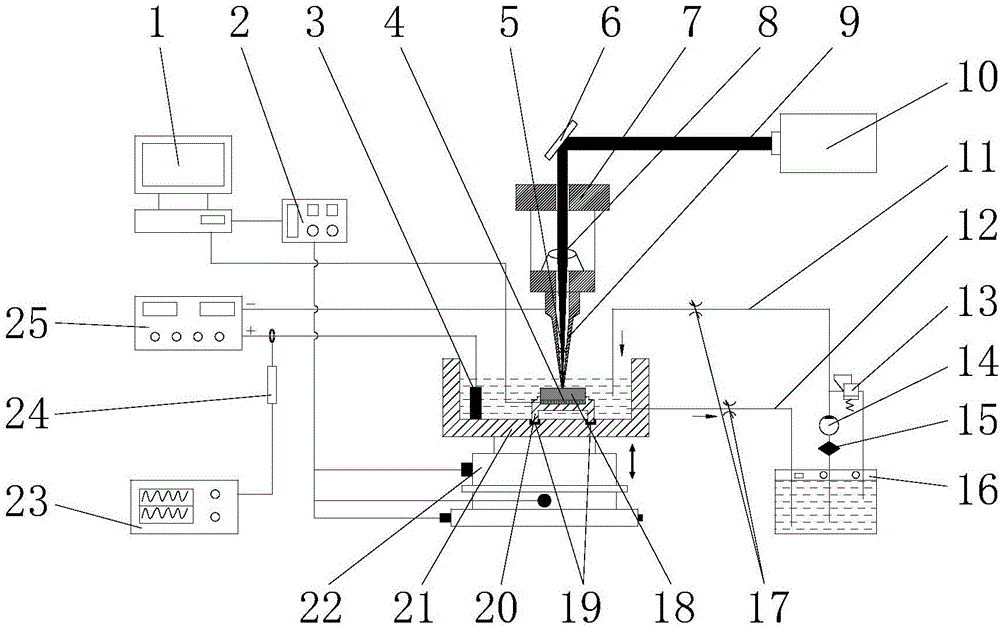

The invention provides a method and a device for coaxial combined machining with tubular electrode discharging and laser irradiation, and belongs to the field of non-traditional machining and combined machining. Micro-etching machining is performed on the surface of an insulating high-hardness brittle material by virtue of a coaxial action of cone-shaped tube electrode discharging and laser irradiation, recessive material defects and stress concentration generated by pulsed laser acting on the surface of a workpiece can attract spark discharge to always act on the current area, and meanwhile, the spark discharge changes the surface shape and physico-chemical property of the current area, then nonlinear absorption of the current area on laser energy is improved, a local field enhancement effect is generated, and pulsed laser focused irradiation can accelerate an electrochemical reaction to promote generation of a stable discharge gas film layer on the surface of a hollow tool electrode; and the interactive cooperation of two types of energy achieves fixed-area micro-etching of the insulating high-hardness brittle material, the machining efficiency is significantly improved, and the machining quality is improved.

Owner:JIANGSU UNIV

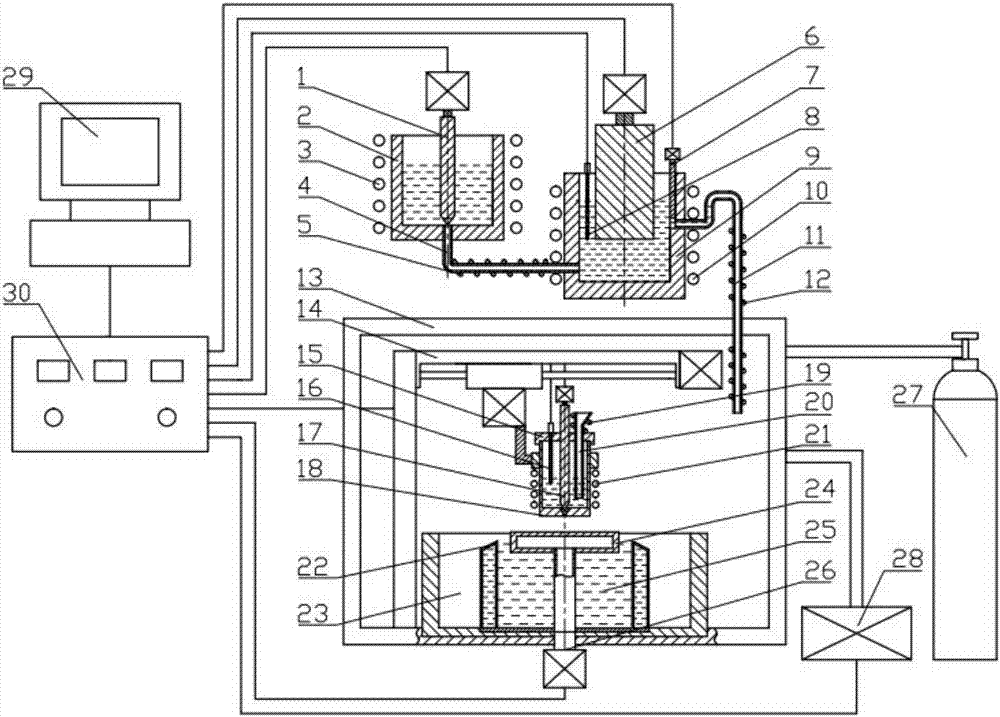

High-efficiency metal 3D printing equipment and method

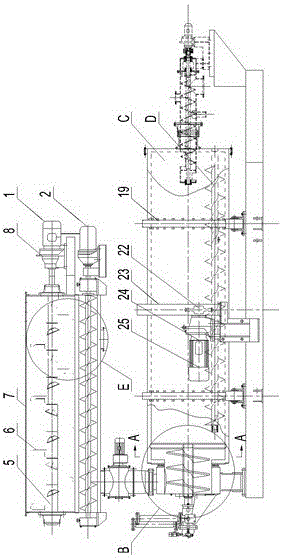

ActiveCN106925783AHigh precisionLow costAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention discloses high-efficiency metal 3D printing equipment and a method, and belongs to the technical field of 3D printing. Through such measures as separation of a supply system of metal 3D printing equipment from a discharge system, separation of a printing forming area from a cooling medium, positioning of the supply system out of a forming room and capability of controlling the size of a discharge port of a nozzle according to sizes of products, based on direct melt supply and cooling medium cooling, the high-efficiency metal 3D printing equipment and method adopt 3D printing to form high-quality metal products with high efficiency and low cost, and in particular, are suitable for high-efficiency formation of large metal products. The 3D printing equipment is flexible in mechanism actions, fast in operating speed, high in flexibility, high in sensitivity and low in manufacturing cost; the 3D printing forming process is high in efficiency; process parameters are liable to control; and the metal products formed by printing are excellent in quality and repeatability and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

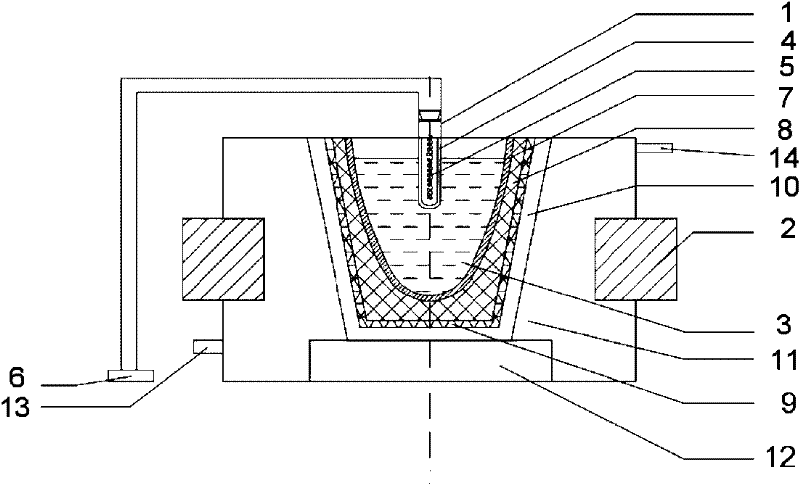

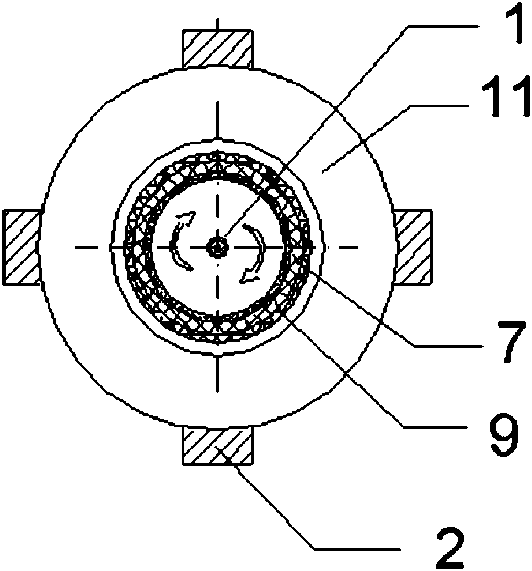

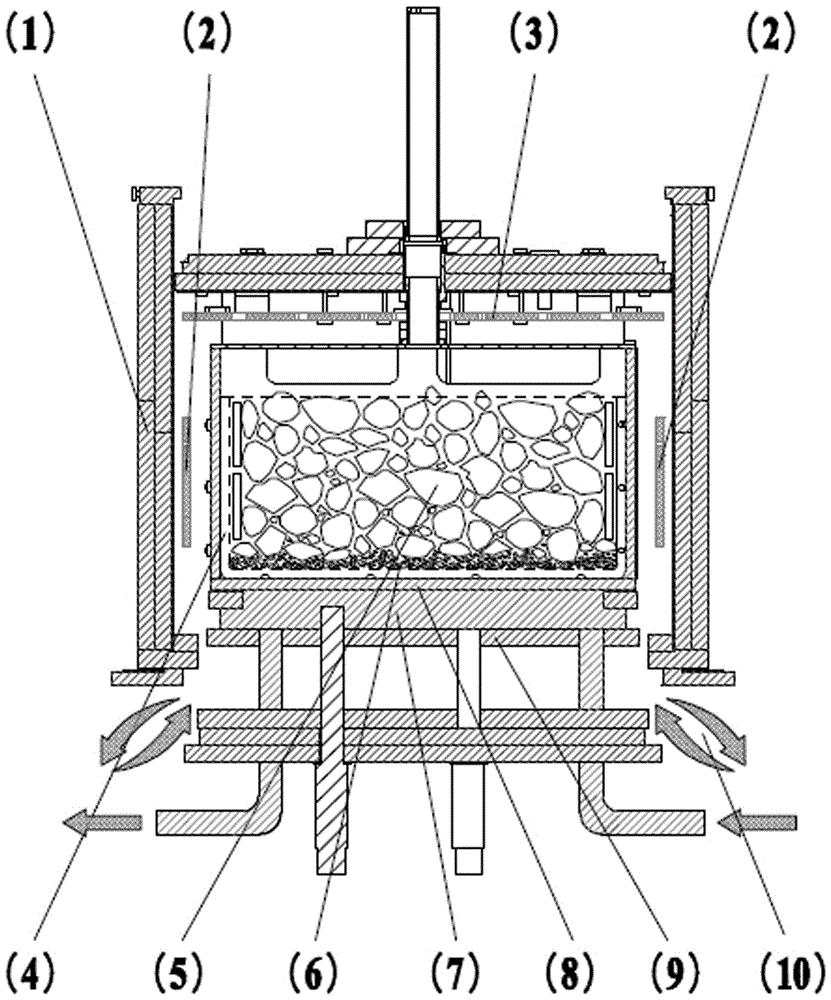

High-purity aluminum purification device based on segregation method

A high-purity aluminum purification device based on segregation method belongs to metal purification technical field and comprises an internal heater, a plurality of electromagnetic stirrers and a purification furnace body. The internal heater is positioned at the center of the purification furnace body and the electromagnetic stirrers are positioned at the periphery of the furnace body and distributed evenly. The invention controls the melt flow field to improve the diffusion and distribution of the impurity elements discharged during the segregation process of the aluminum melt, accordingly accelerates the mixed diffusion of solute elements in the melt, reduces the frontal impurity concentration of the solid-liquid interface and realizes the purpose of improving the aluminum purification efficiency.

Owner:上交赛孚尔(包头)新材料有限公司

Method for preparing highly-uniform synthetic quartz glass weight

ActiveCN104926088AUniform radialUniform axial distributionGlass shaping apparatusSilica particleCombustor

The invention discloses a method for preparing a highly-uniform synthetic quartz glass weight. Preparing is conducted through a vertical depositing furnace based on chemical vapor deposition, raw materials are led into a combustor and chemically reacted in the depositing furnace, silicon dioxide particles are formed, the depositing foundation of the quartz glass weight is a concave depositing pool formed by a bottom face and a side wall, the silicon dioxide particles formed based on chemical vapor synthesis are melted and freely scattered and deposited in the depositing pool, and the temperature gradient of the depositing face is lower than 20 DEG C. According to the method for preparing the highly-uniform synthetic quartz glass weight, the distributing consistency of quartz glass weight components is improved, and the quartz glass weight uniform in radial and axial structure is produced.

Owner:CHINA BUILDING MATERIALS ACAD

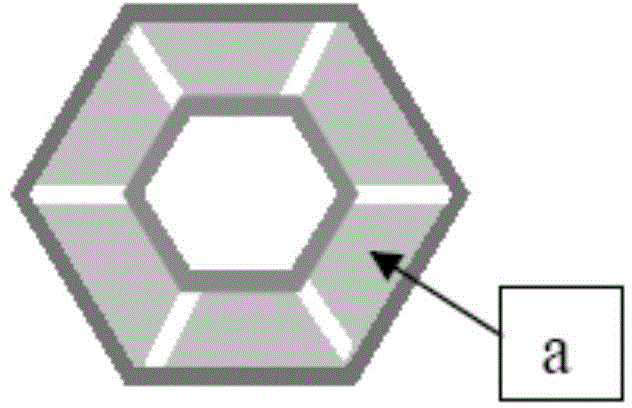

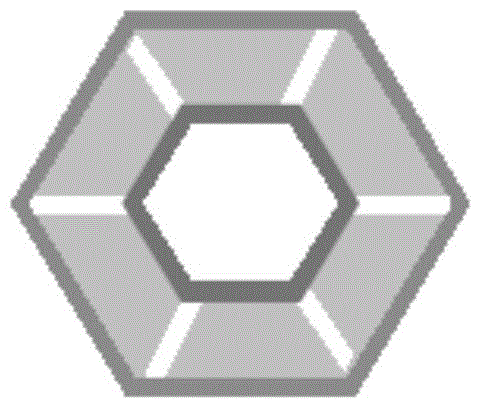

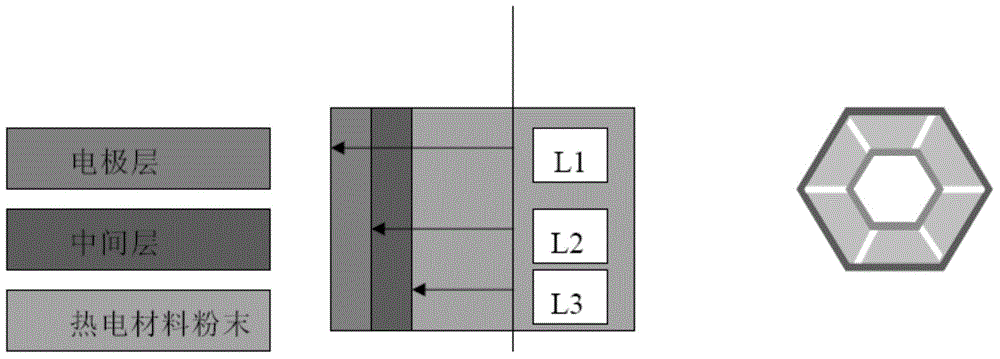

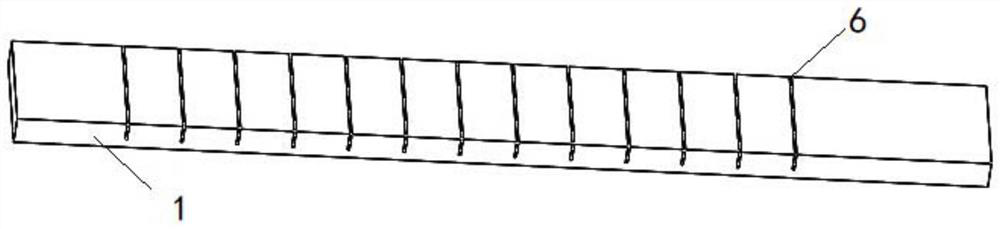

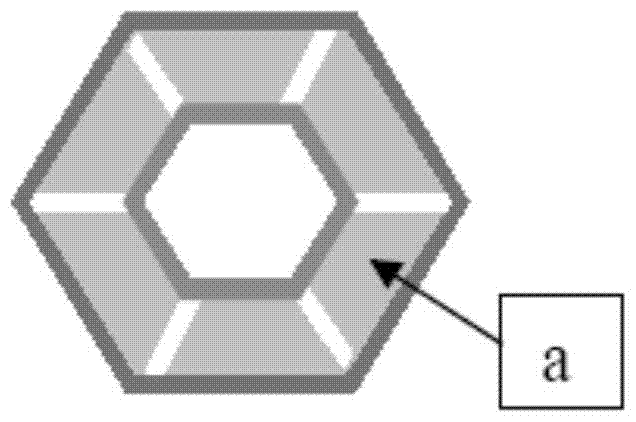

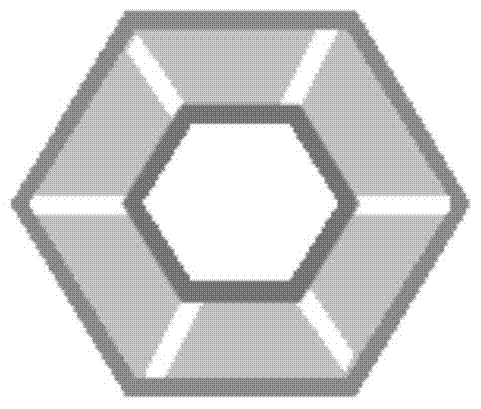

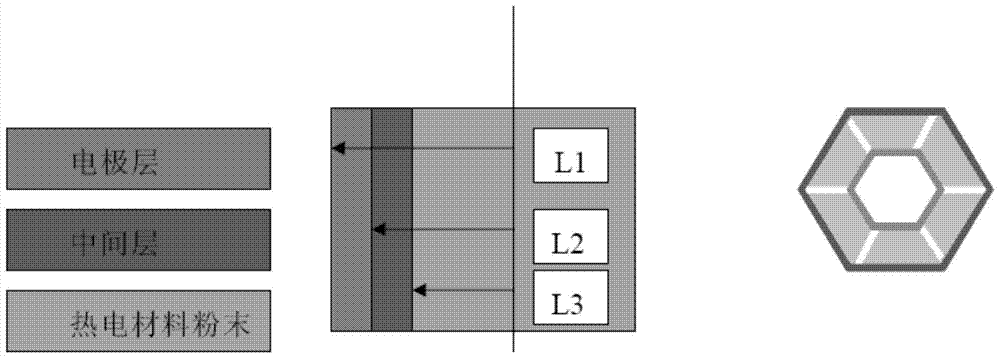

Method for preparing thermoelectric device and thermoelectric device

ActiveCN104638101AIncrease contact areaImprove energy conversion efficiencyThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermoelectric element

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

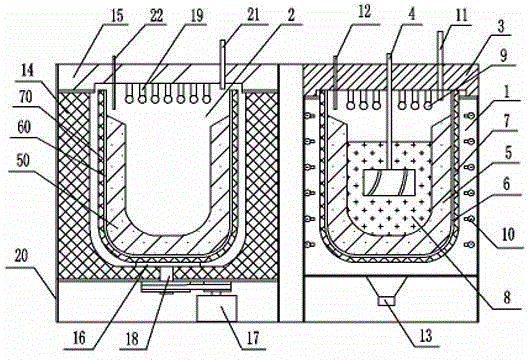

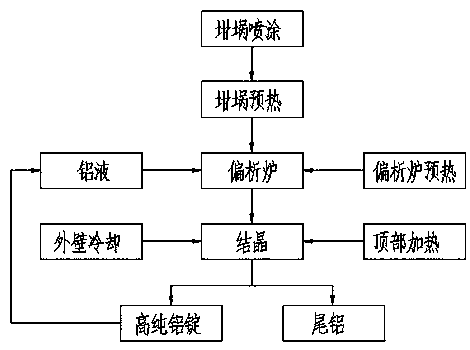

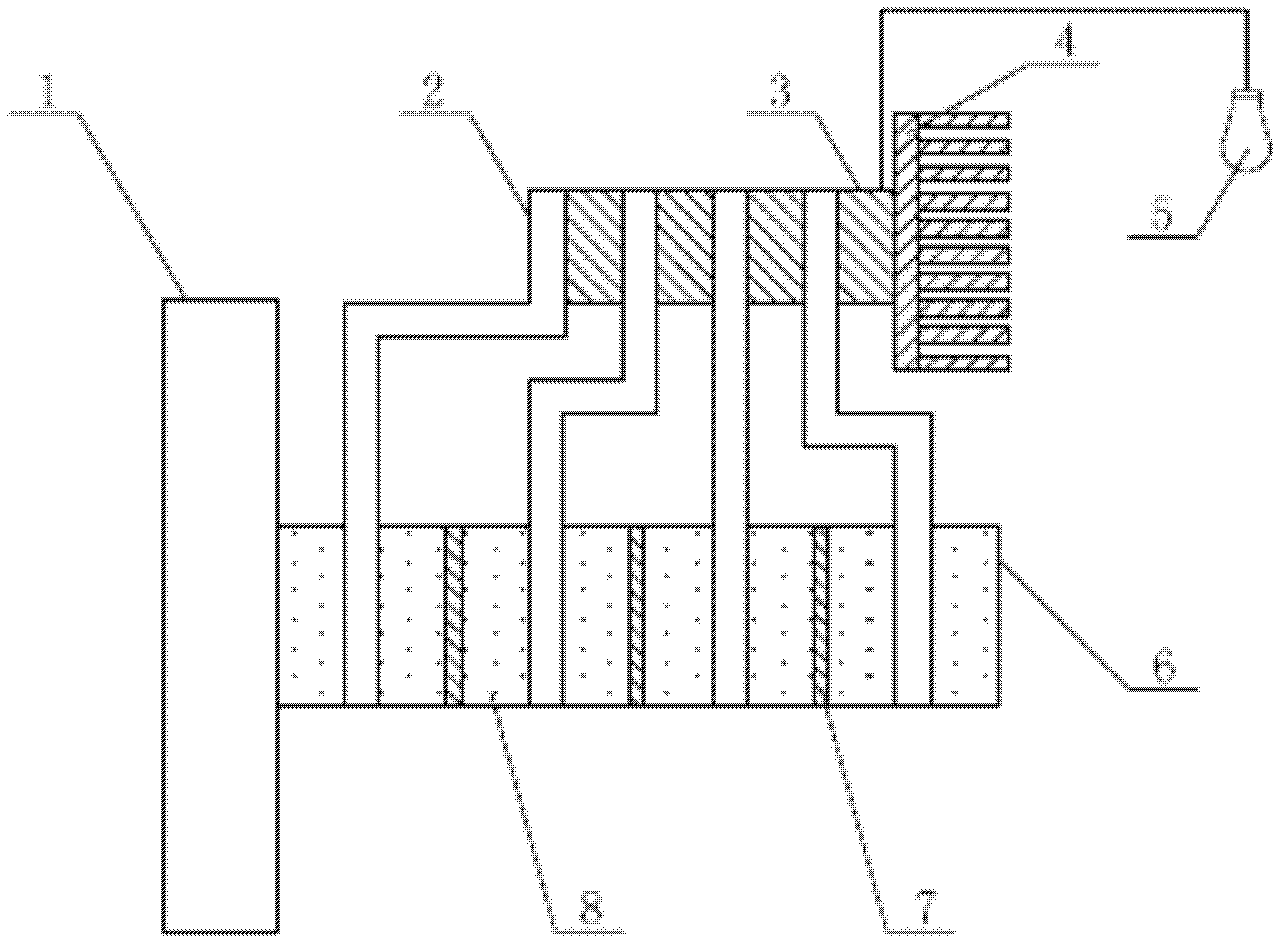

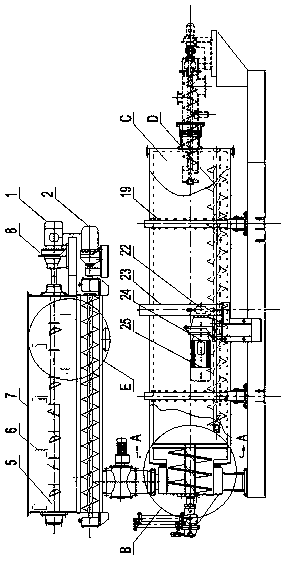

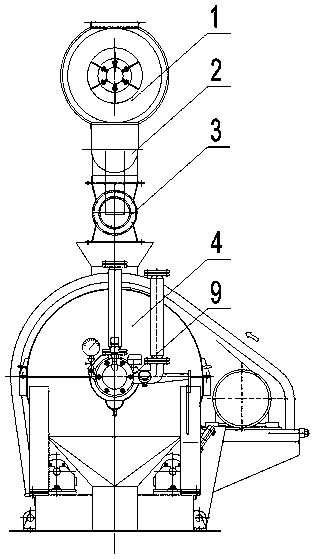

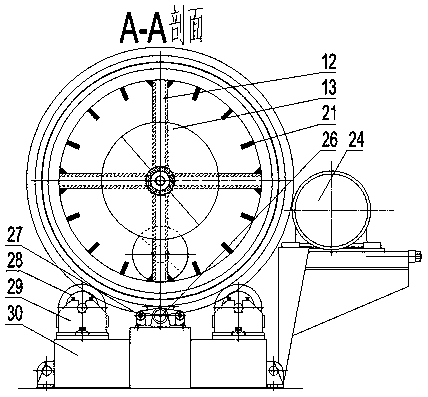

Directional solidification short process purification equipment and purification method of high-purity aluminum

ActiveCN104561591AMelt temperature increases steadilyReduce thicknessProcess efficiency improvementPurification methodsCrucible

The invention discloses directional solidification short process purification equipment and purification method of high-purity aluminum. The purification equipment comprises a purification device and a heating device, which are respectively independent, wherein the purification device comprises a cooling device, a purification heat conduction layer, a purification heat preservation crucible, a stirring device, a purification furnace cover, a vacuumizing device, a first heating mechanism and a temperature measurement device; the heating device comprises a heat insulating layer, a heating heat conduction layer, a heating crucible, a heating furnace cover, a second vacuumizing device, a second heating mechanism and a second temperature measurement device, a rotating platform is arranged at the bottom of the heating crucible, and a rotating mechanism and a transmission mechanism are arranged below the rotating platform. The purification method in which a purification process and a heating process are separately operated is adopted in the invention, so that a solid-liquid interface can be accurately controlled in the purification process to keep a stable temperature gradient and higher purification efficiency and purification quality are kept; afterheat of purified solid aluminum is utilized in the heating process, so that the heating efficiency is more than twice higher than that of conventional heating. The purification equipment disclosed by the invention has the advantages of low energy consumption, large handling capacity, high purification efficiency and high product purity.

Owner:HENAN ZHONGFU IND

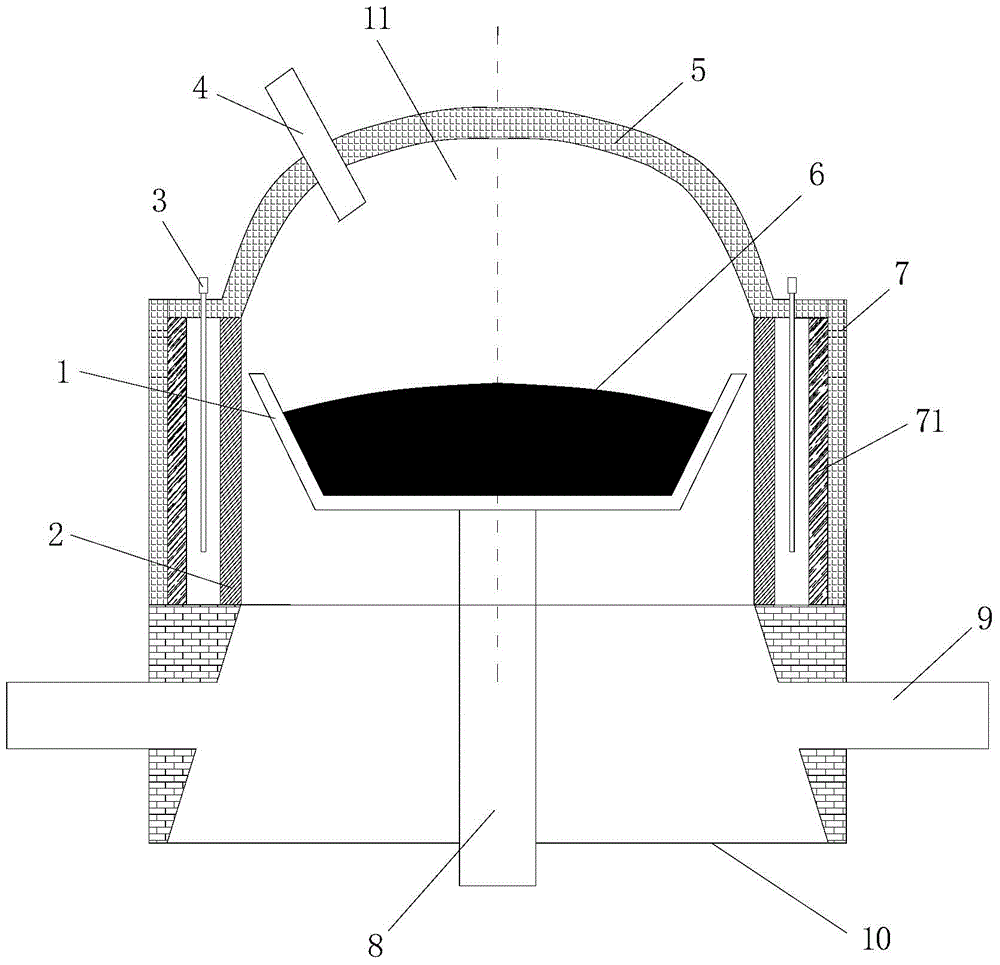

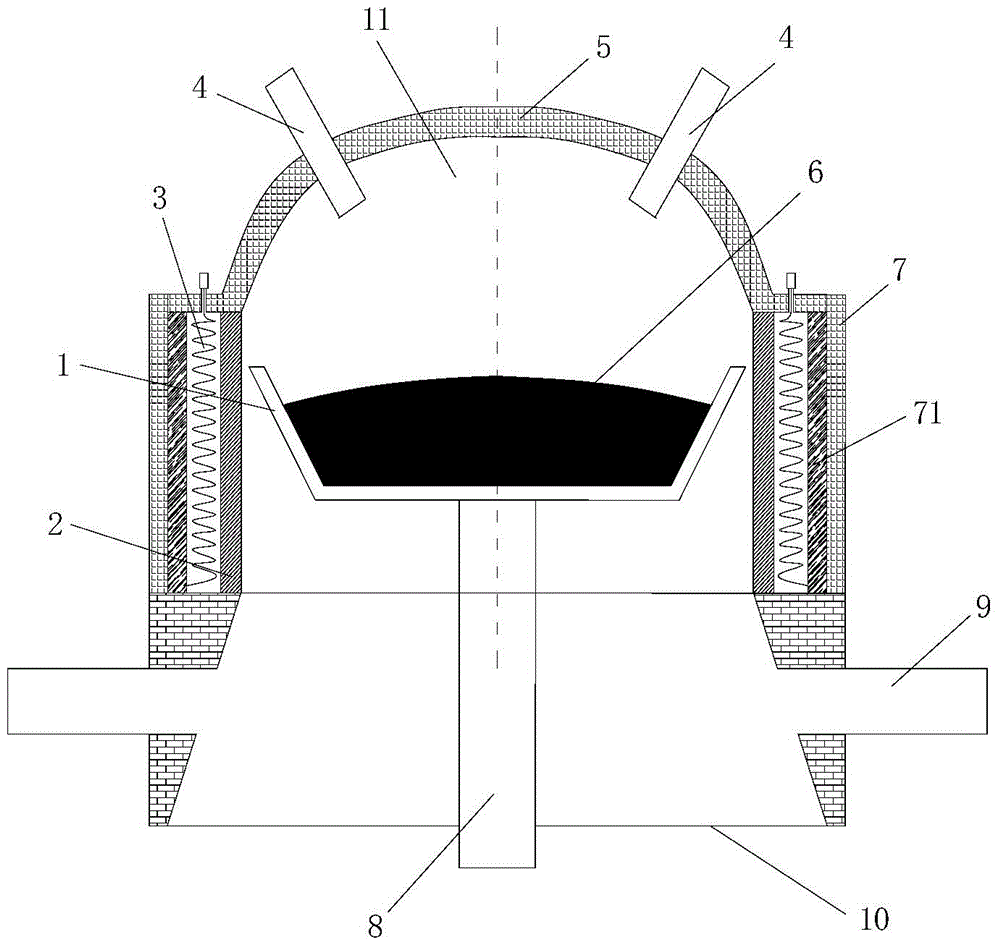

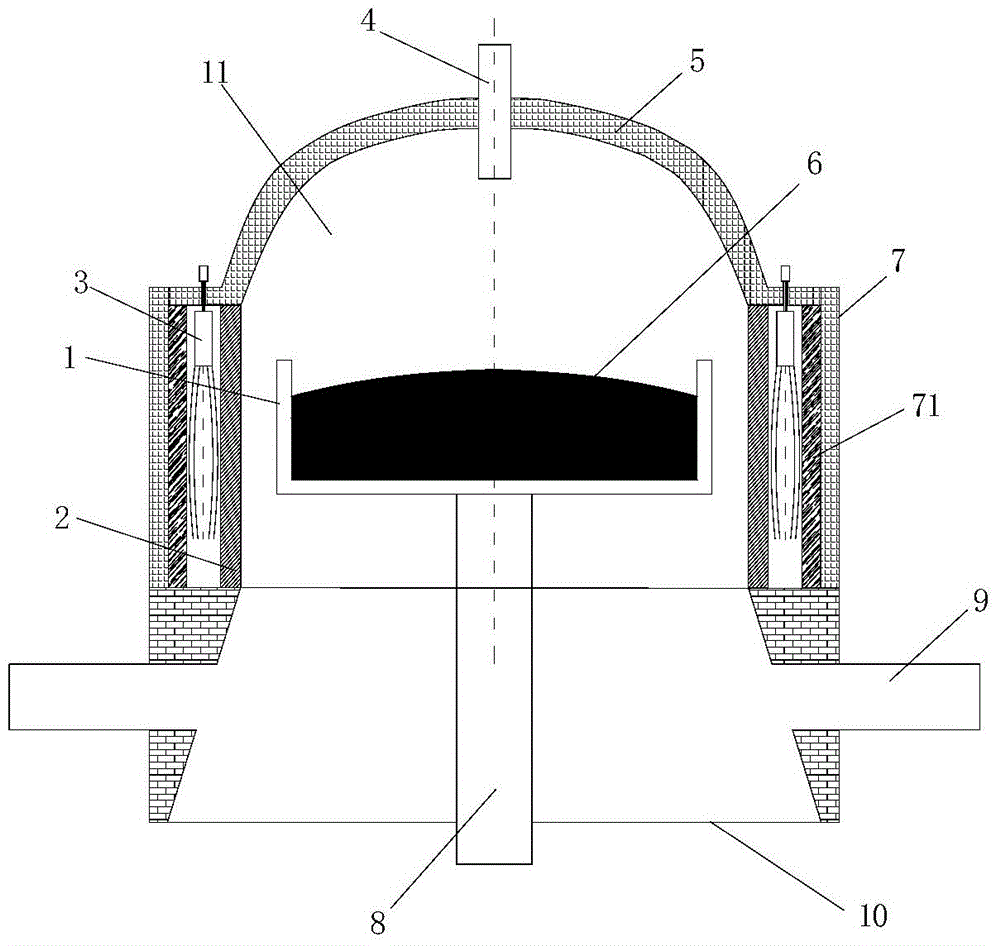

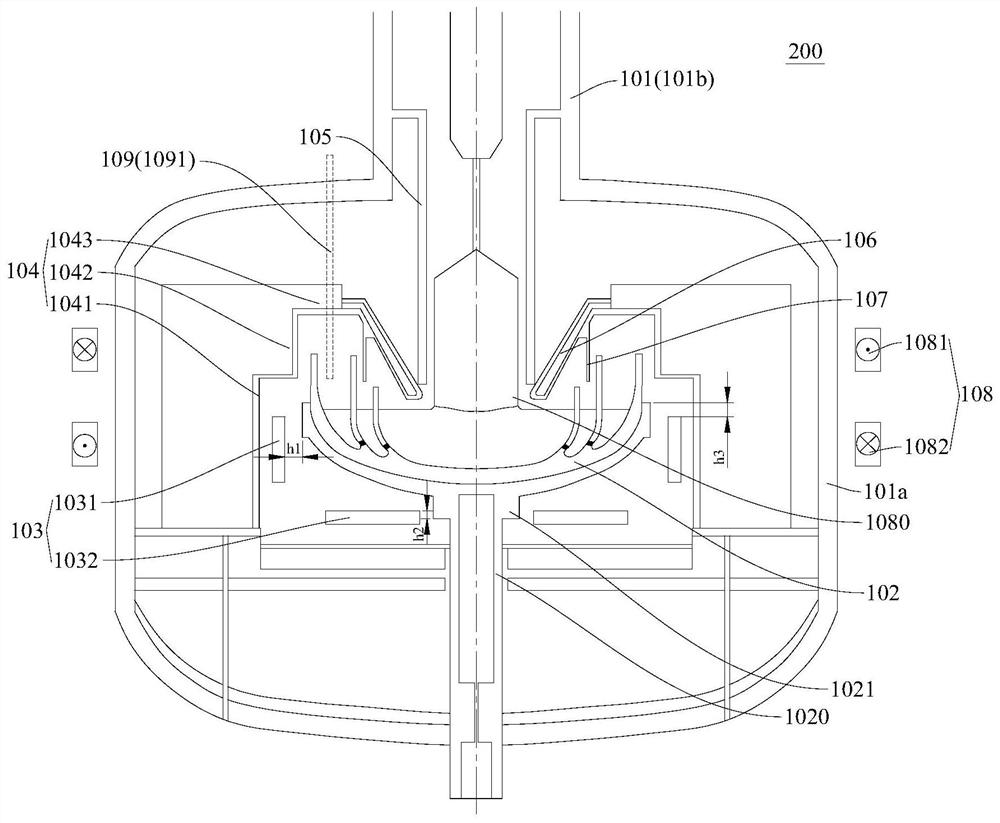

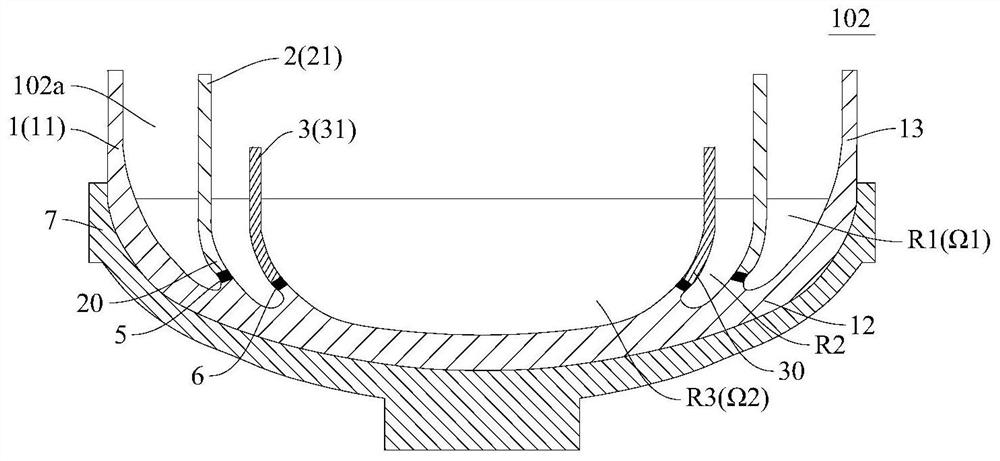

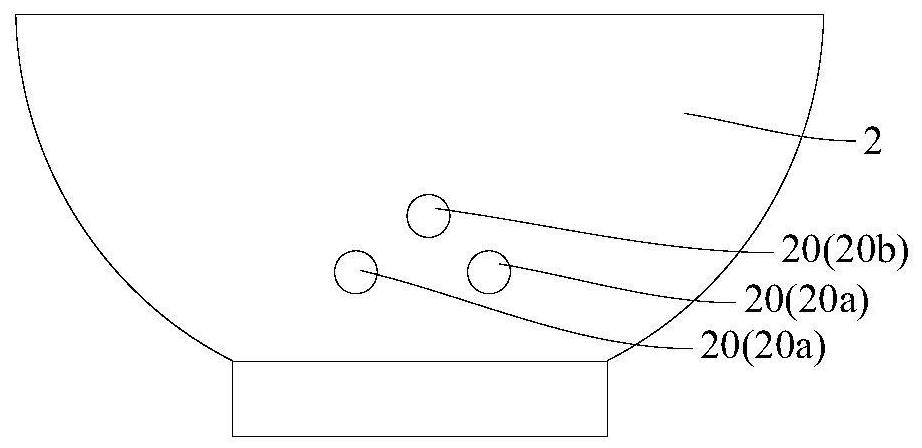

Large-diameter silicon crystal growth device

The invention discloses a large-diameter silicon crystal growth device. The device comprises a heat-preserving system, a heating system, a stream guidance system and a supporting device, wherein the upper part of the heat-preserving system is provided with a heat-preserving cover plate and a furnace bottom heat-preserving structure; the heat-preserving cover plate adopts a double-layer structure, namely, an upper heat-preserving cover plate (1) and a lower heat-preserving cover plate (2) superposed on each other; and a clearance between the upper heat-preserving cover plate (1) and the lower heat-preserving cover plate (2) is filled with a graphite carbon felt. The technical scheme is used for controlling silicon monocrystals of 8 inches and more than 8 inches. Compared with the prior art, the device has the advantages of achieving better energy conservation, consumption reduction and inert gas guidance, improving the heat-preserving effect of the heat-preserving system, reducing heat radiation, changing temperature gradient in a melt, reducing the change of transverse temperature gradient, relatively stabilizing the liquid level temperature of the melt, contributing to the growth of silicon monocrystals, improving an air stream guidance device and preventing gas turbulence.

Owner:芜湖升阳光电科技有限公司

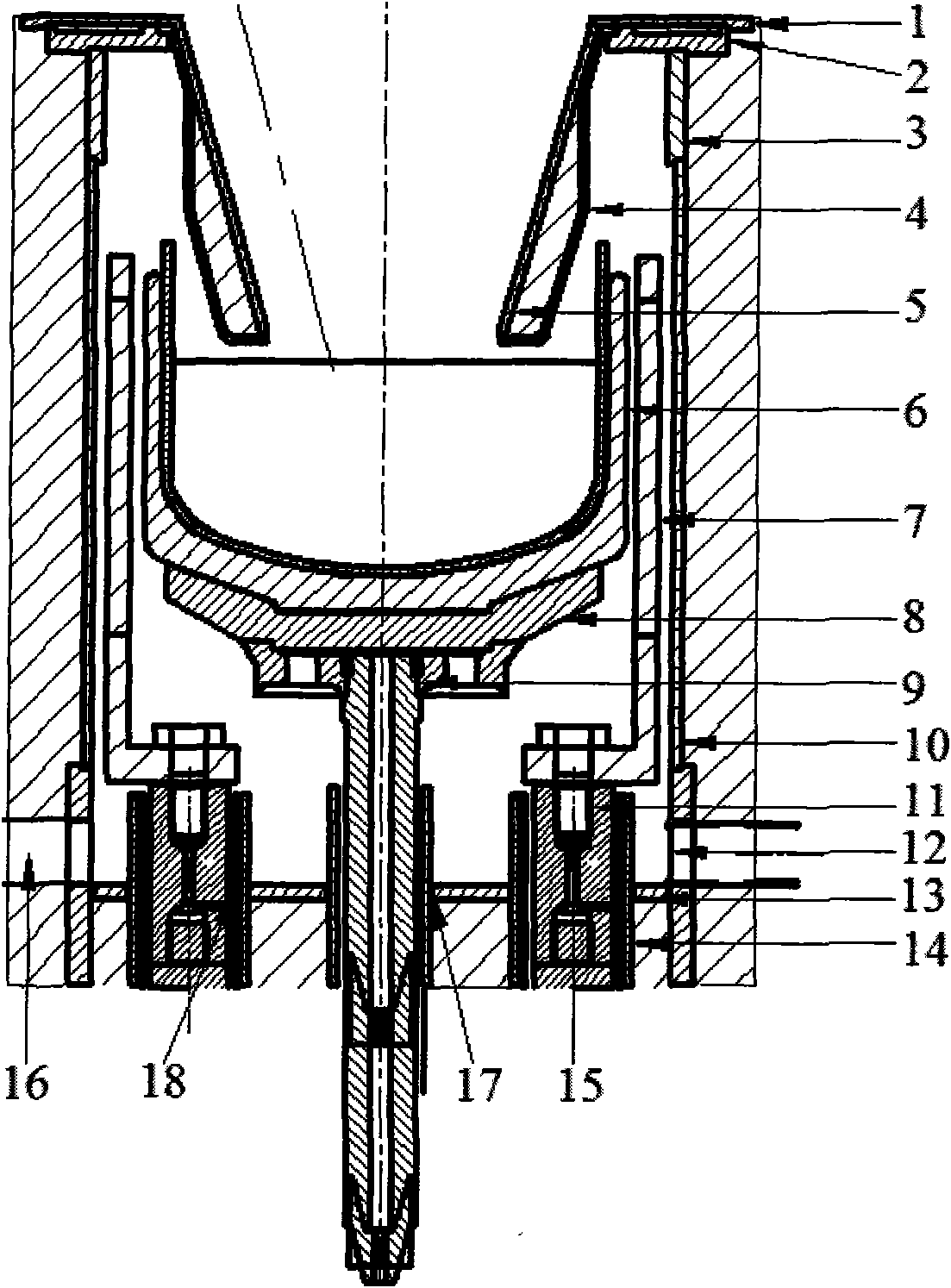

Method for segregation and purification of high-purity aluminum

InactiveCN111378850AStable temperature gradientReduce concentrationProcess efficiency improvementCrucibleHeat conducting

The invention discloses a method for segregation and purification of high-purity aluminum. The method comprises the following steps that a segregation furnace is started up for preheating, a non-stickaluminum coating is sprayed on the inner wall of a crucible, and then the inner wall of the crucible is preheated, the preheated crucible is put unit the segregation furnace, metal molten aluminum orrefined electrolytic aluminum liquid is poured into the crucible, the cooling water on the outer wall of the crucible is opened, when the temperature of the aluminum liquid is reduced to a set value,the upper cover of the segregation furnace is closed, and a heating device, a stirring device and a vacuumizing device of the segregation furnace are opened; during the solidification and growth of an aluminum crystal, the temperature of an aluminum melt is controlled through a temperature measuring device, a purification heat conducting layer is subjected to forced cooling through a cooling device, a temperature gradient of the solid-liquid interface of the aluminum melt in the crucible is controlled between 5 DEG C and 20 DEG C, the growth rate is monitored in real time, and the heating temperature and the cooling water flow of the segregation furnace are adjusted and corrected in real time according to the growth rate. According to the method, the solid-liquid interface can be accurately controlled to maintain a stable temperature gradient, the concentration of impurities in the melt at the front edge of the solid-liquid interface is reduced, thus the solidification process is controlled, and high purification efficiency and quality is maintained.

Owner:HENAN ZHONGFU IND

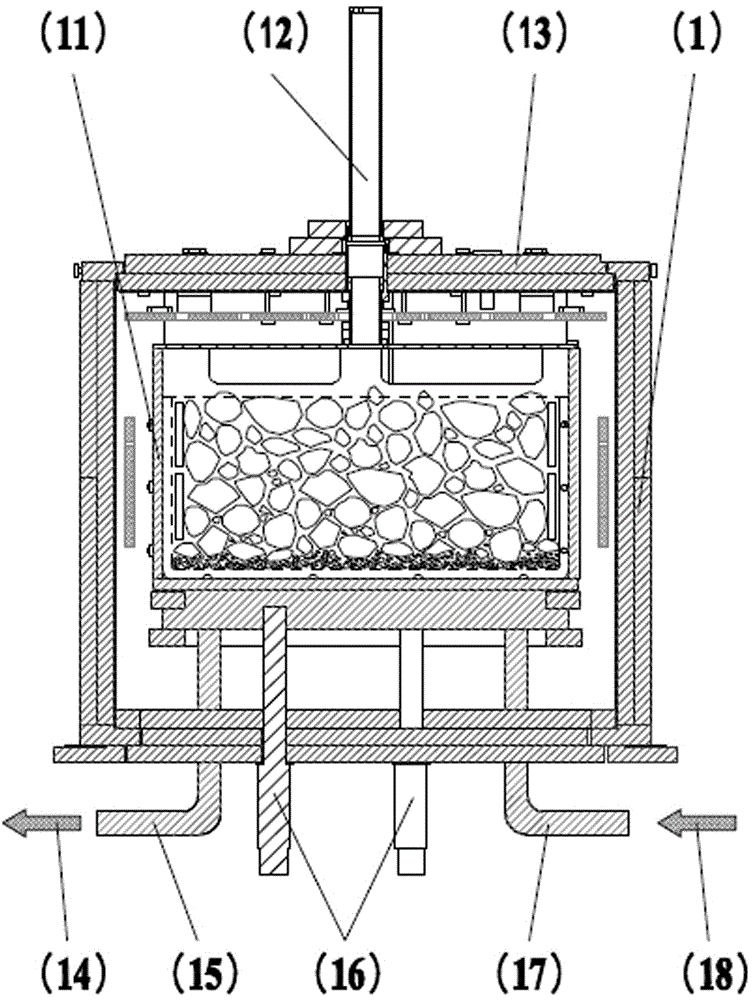

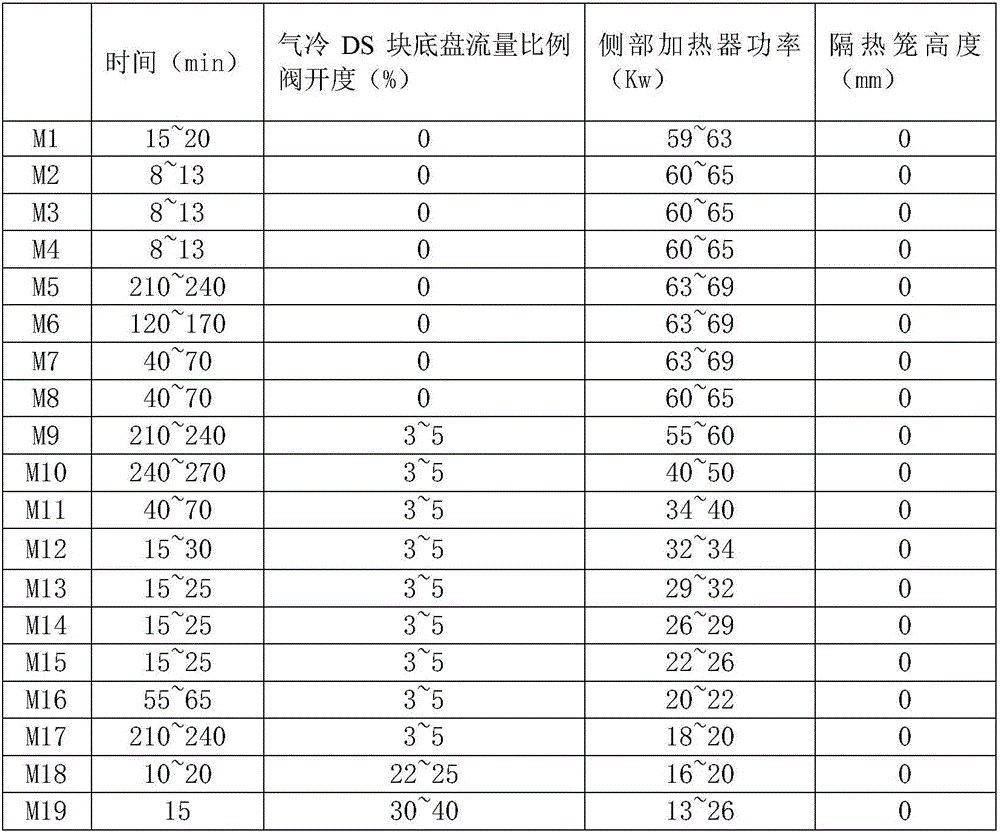

Opening-free heat insulation cage ingot casting device and method

InactiveCN106222741AReduce shockStable retention heightPolycrystalline material growthSingle crystal growth detailsIngot castingEngineering

The invention relates to field of polycrystalline silicon ingot casting, in particular to an opening-free heat insulation cage ingot casting device and method. The device comprises a heat insulation cage, wherein a lateral heater is arranged on the inner side face of the heat insulation cage, a top heater is arranged at the top in the heat insulation cage, and the lateral heater and the top heater are separately controlled by double power supplies. In a melting step, the temperature of an air cooling DS block is controlled not to be higher than 1400 DEG C. In astep of change from melting to crystal growth, the temperature of an air cooling DS block is 1300-1360 DEG C, the temperature of the top heater is 1530-1545 DEG C. In a crystal growth step, the temperature of the top heater is reduced from 1430 DEG C to 1400 DEG C, and the temperature of the air cooling DS block is reduced from 1300 DEG C to 1000 DEG C. By the adoption of the opening-free heat insulation cage ingot casting device, the heat insulation cage cannot be needed to be opened, the subfissurescrap ratio of cut silicon wafers is reduced by about 15%, the dislocation number of silicon ingots in growth is effectively controlled, the photoelectric conversion efficiency of silicon wafer products is high, and the stability is good.

Owner:YICHANG CSG POLYSILICON CO LTD

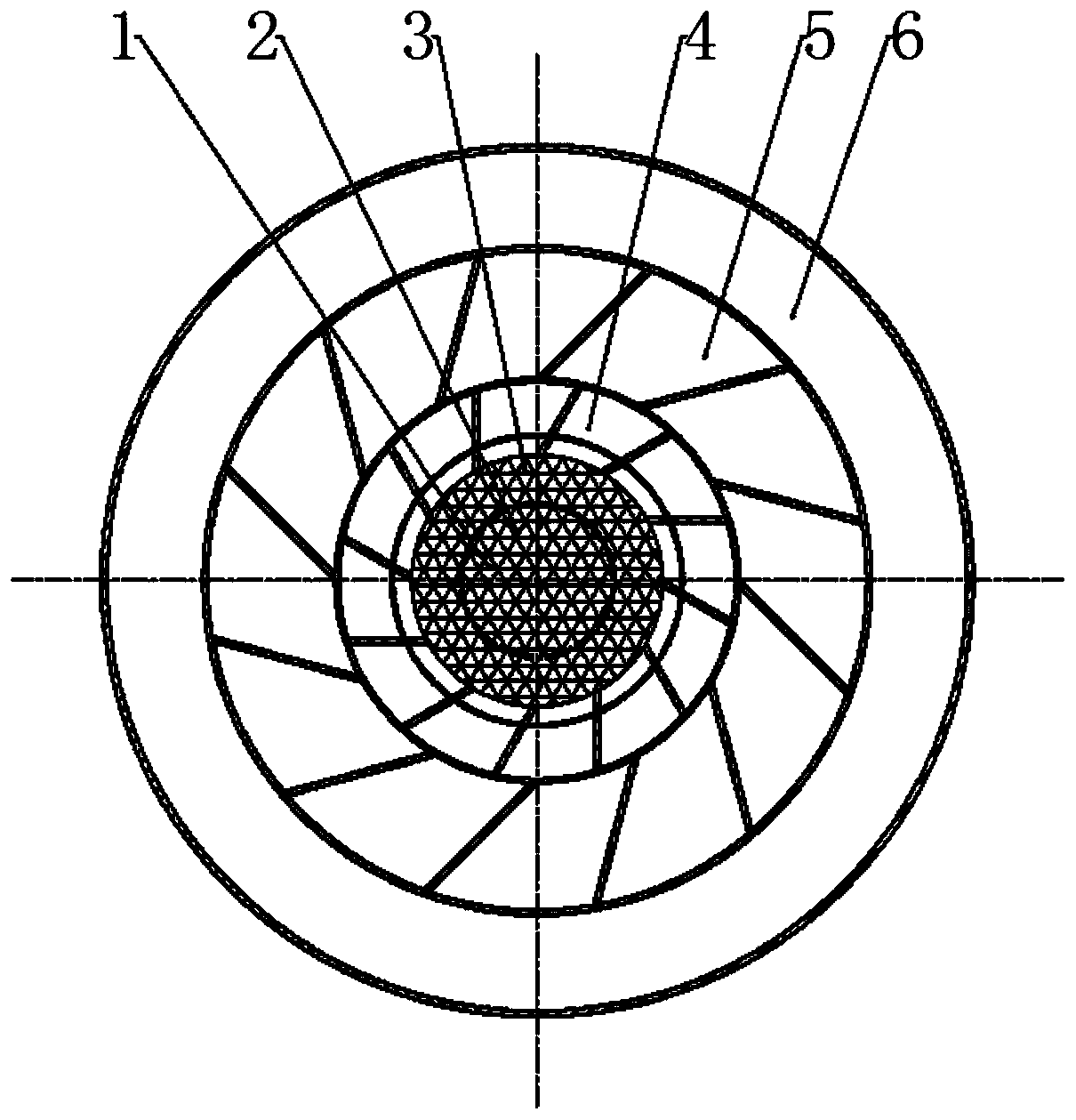

Heat storage premixed biomass gas combustor and using method thereof

PendingCN111396873AReduce incomplete combustion heat lossIncreased turbulenceIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a heat storage premixed biomass gas combustor and a using method thereof. The combustor comprises a porous medium heat storage premixing pipeline, an inner combustion-supporting air pipeline, an outer gas pipeline, an outer combustion-supporting air pipeline, a first sleeve, an inner combustion-supporting air rotational flow adjusting pull rod, a second sleeve, an outer gasrotational flow adjusting pull rod, a plurality of inner combustion-supporting air axial rotational flow blades and a plurality of outer gas axial rotational flow blades. The porous medium heat storage premixing pipeline, the inner combustion-supporting air pipeline, the outer gas pipeline and the outer combustion-supporting air pipeline are sequentially distributed from inside to outside, an outlet of the porous medium heat storage premixing pipeline is filled with a ceramic foam type porous medium, and an inlet of the porous medium heat storage premixing pipeline coaxially communicates witha central gas pipeline and a central combustion-supporting air pipeline. According to the combustor and the using method thereof, the purpose of efficient and low-pollution combustion of biomass gascan be achieved.

Owner:HUANENG POWER INTERNATIONAL +2

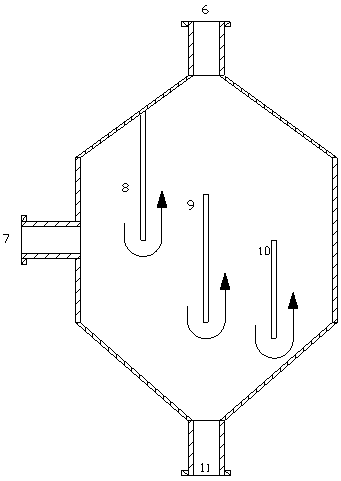

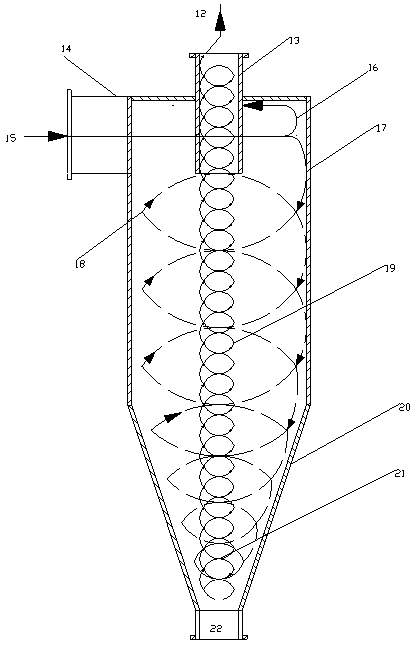

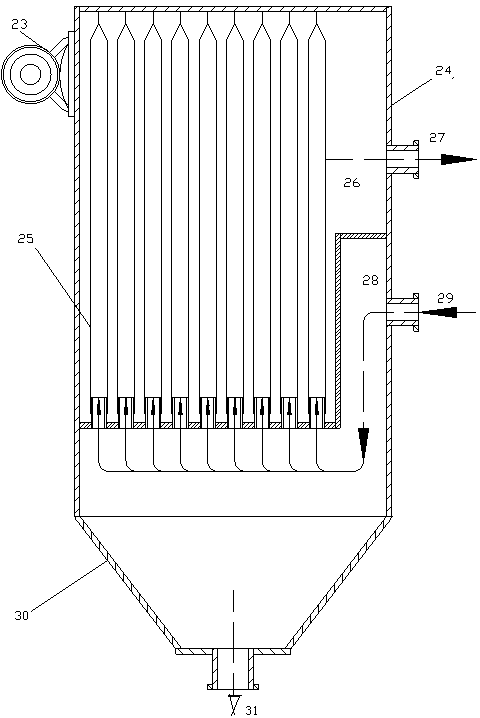

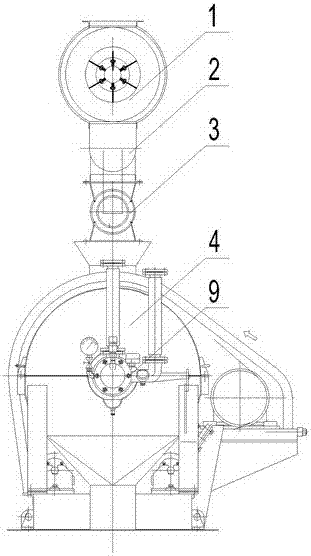

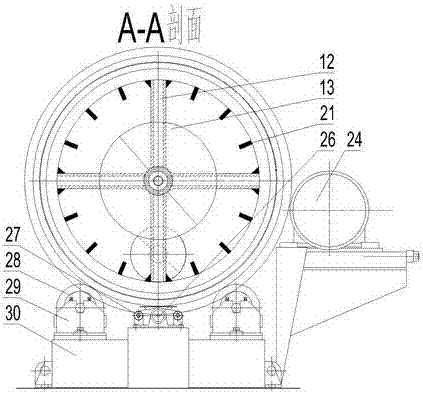

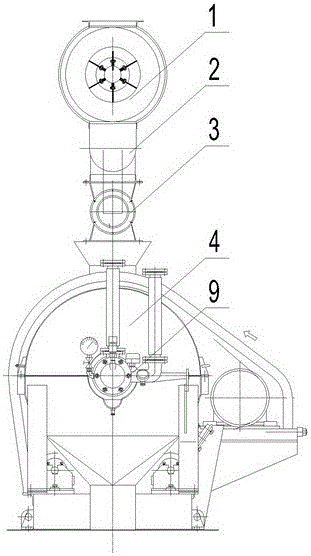

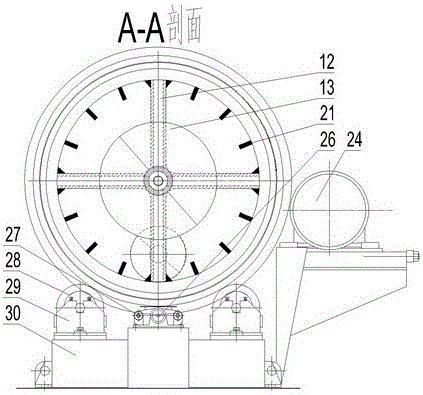

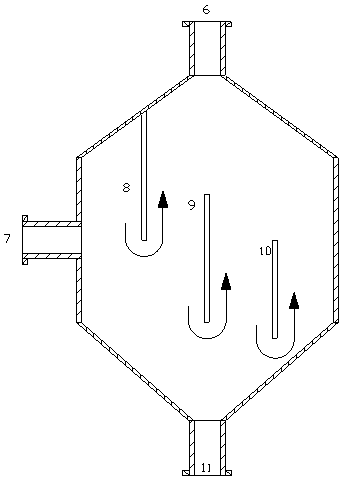

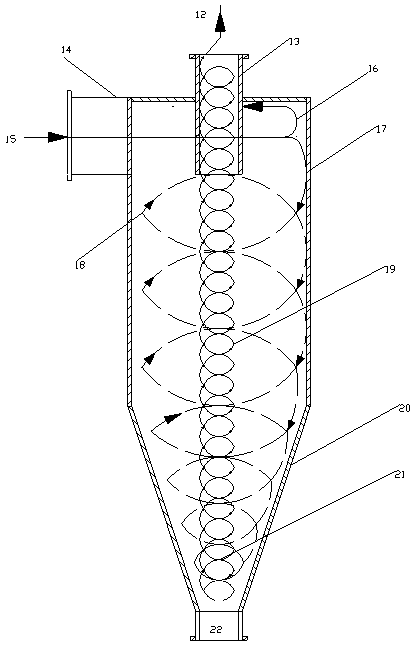

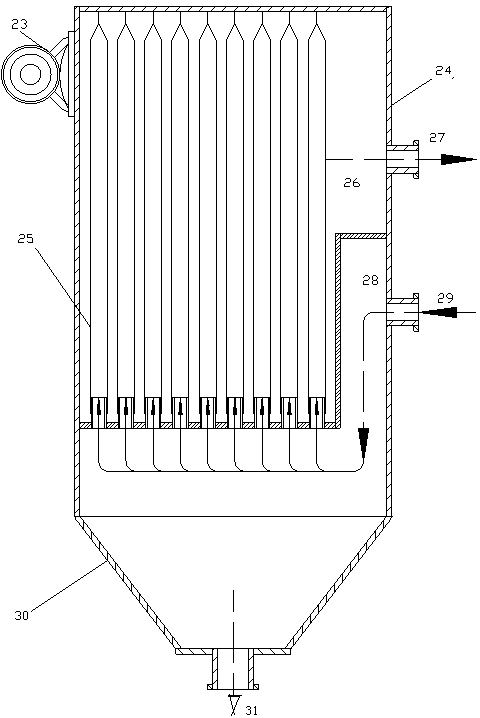

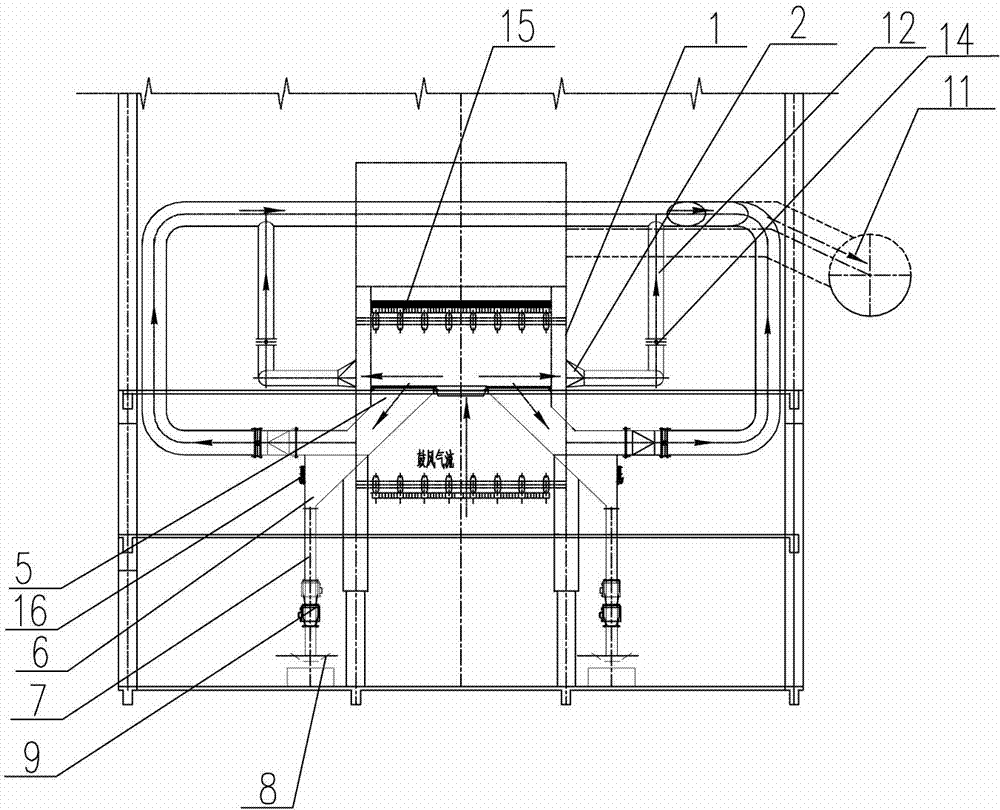

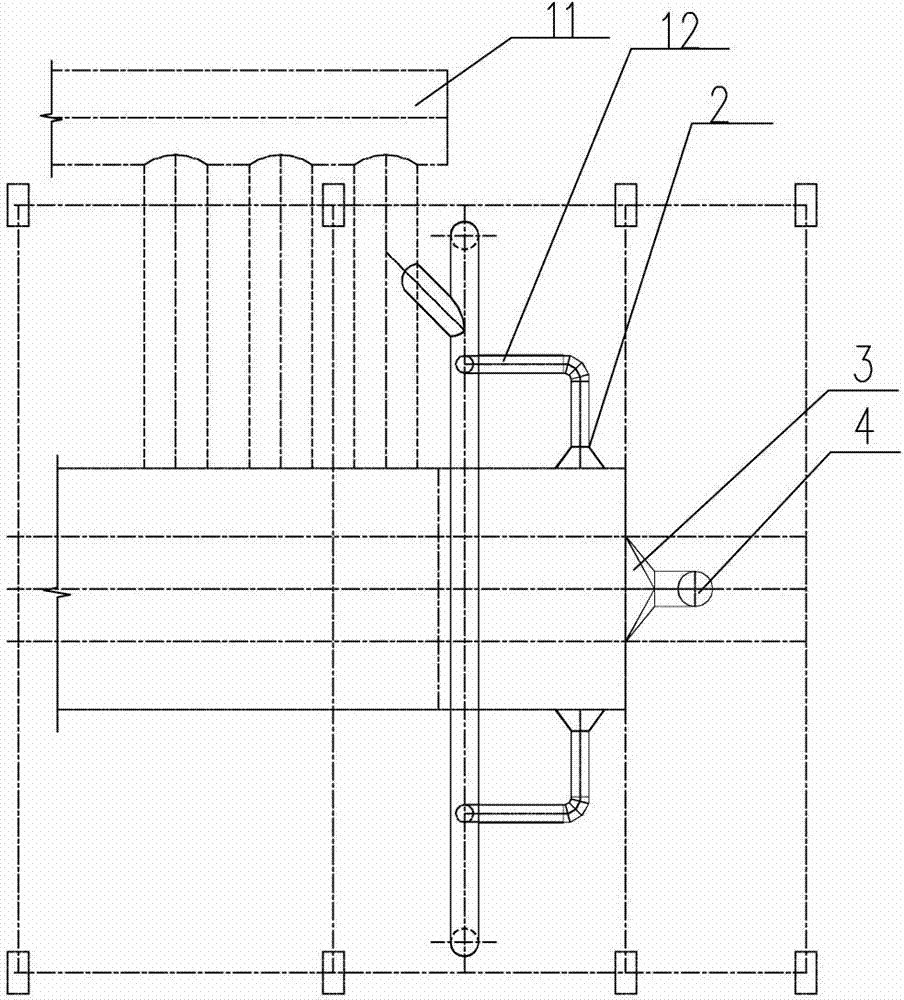

Fine particle thermophoretic deposition dedusting method and system thereof

ActiveCN107261714AStable temperature gradientHigh thermophoretic deposition rateControl systemLithium bromide

The invention relates to a fine particle thermophoretic deposition dedusting method and a system thereof. The system is mainly composed of a thermophoretic deposition deduster, a waste heat lithium bromide refrigeration system, a gas heating device and an electric appliance control system. According to the invention, dust-laden air flow flows into a gas insulating chamber from a dust-laden air-flow inlet, then is introduced into a square plane cold wall pipe under effect of an induced draught fan and performs thermophoretic deposition movement, the air flow flows out from the square plane cold wall pipe and then continuously and downwardly flows due to effects of inertia and negative pressure effects, then the air flow is discharged through an air-flow outlet 69 from a negative pressure chamber until the air flow at the bottom of a conical cylinder is slowly risen, and the air flow is introduced into an inlet of the induced draught fan, so that a purpose of separating gas and dust can be realized. The method takes on-site practical tests as a base, a theoretical equation is taken as a reference, the organic combination of the theoretical equation and the on-site practical tests makes that the control of the thermophoretic deposition system and the practical condition are matched, so that the deduster has high thermophoretic deposition rate. The lithium bromide waste heat is used for refrigeration, so that energy is saved, and the environmental protection is realized.

Owner:盛志方

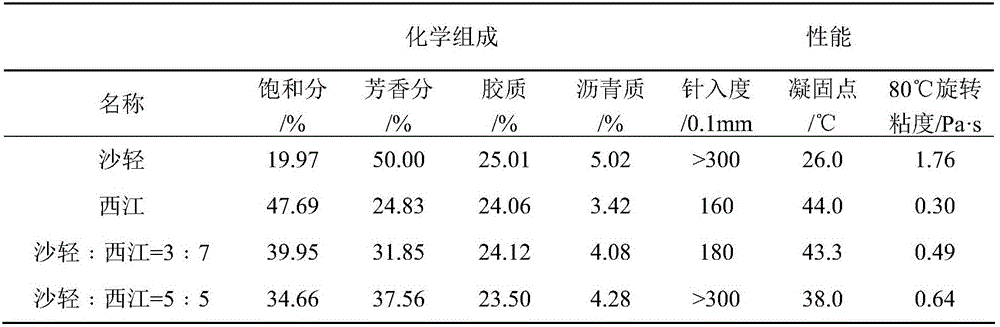

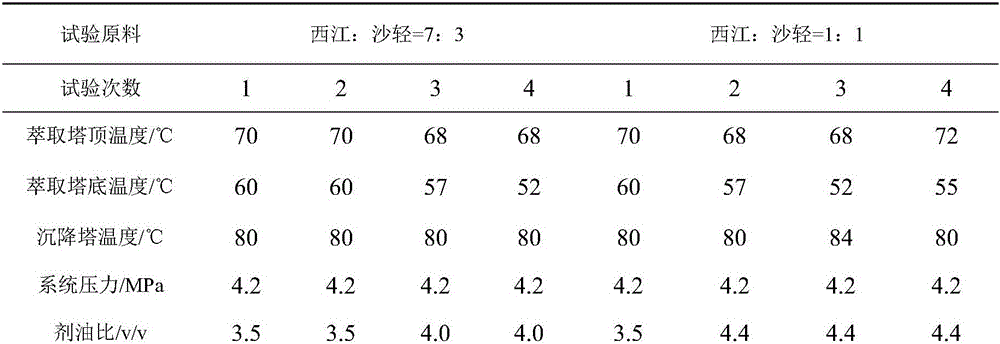

Propane deasphalting method for paraffin-based vacuum residuum with low needle penetration

InactiveCN107523321AWill not cause clogging etc.Enhanced mass transferWorking-up pitch/asphalt/bitumen by selective extractionNeedle penetrationMolten state

The invention discloses a propane deasphalting method for paraffin-based vacuum residuum with low needle penetration. The paraffin-based vacuum residuum with needle penetration lower than 200 / 0.1 mm and intermediate-based vacuum residuum with needle penetration higher than 200 / 0.1 mm are mixed in a molten state and fed into a propane deasphalting device for propane deasphalting treatment, so that deasphalted oil and deoiled asphalt are separated out. According to the method, the paraffin-based vacuum residuum with low needle penetration is modified, so that mixed phase does not appear in an extraction tower during extraction treatment, the deasphalted oil and the deoiled asphalt are separated effectively, and pipeline blocking and other phenomena cannot be caused.

Owner:CHINA PETROLEUM & CHEM CORP

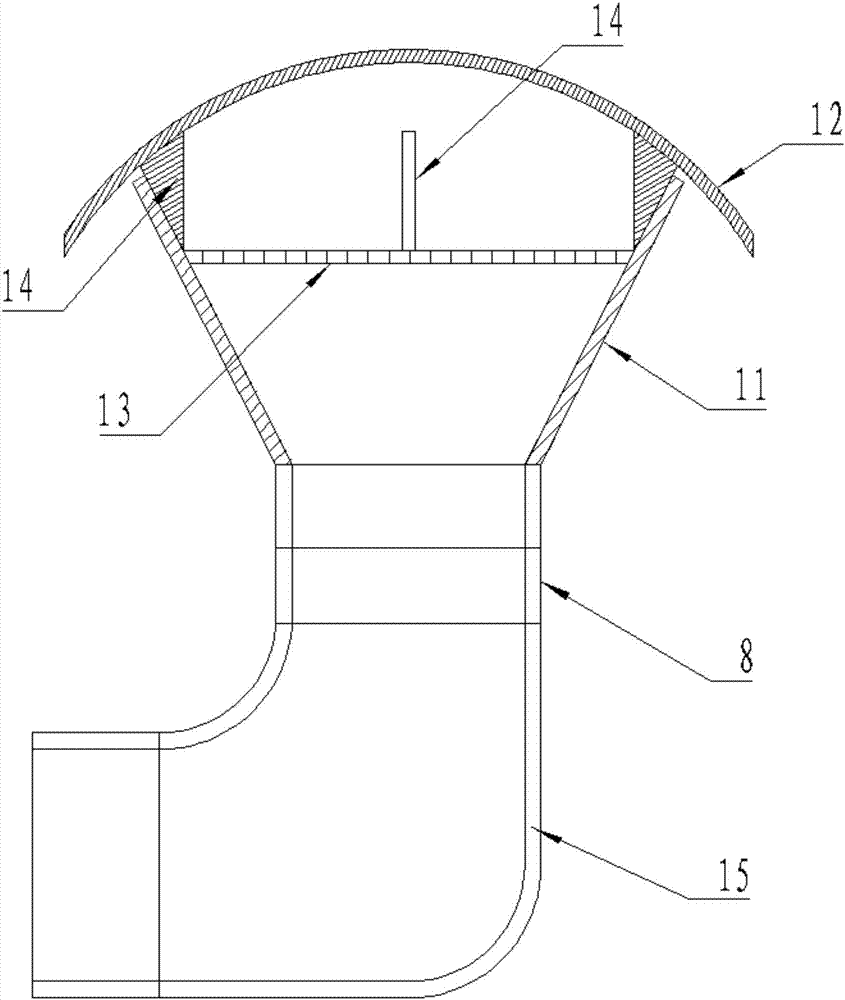

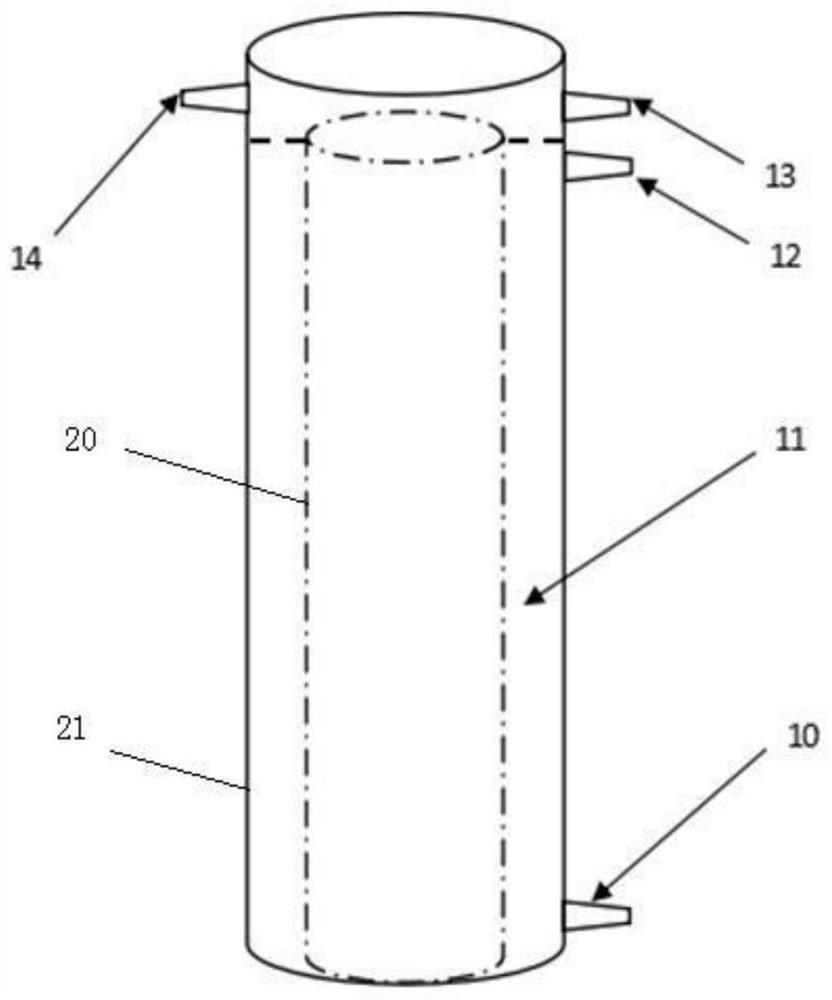

Overflow water distributor and system for uniformly renewing water in water pool

The invention discloses an overflow water distributor and a system for uniformly renewing water in a water pool. The overflow water distributor comprises a water distributor shell (11) and a water distributor cap (12). The water distributor shell (11) is of a conical cylinder structure. The water distributor cap (12) is of a sheet structure. The outer portion of the bottom end of the water distributor shell (11) is covered with the water distributor cap (12). A strip-shaped gap for water flow to pass through is formed between the bottom end of the water distributor shell (11) and the water distributor cap (12). By means of the system for uniformly renewing the water in the water pool, uniformity and stability of an internal circulation system in the water storage pool can be improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

Multilevel power generation system

InactiveCN103138648AReduce lossStable temperature gradientGenerators/motorsElectric energyEngineering

The invention relates to a multilevel power generation system. One end of an insulation box is arranged on the back surface of a vacuum heat collector, clapboards are arranged inside the insulation box, and divide the insulation box into a plurality of mutually independent sealed small space, one end of a heat pipe is inserted inside the insulation box, the other end of the heat pipe is connected with a temperature difference power generation element. Two ends of the temperature difference power generation element are respectively connected with the heat pipe or a radiator, the radiator is arranged on the wall surface of a radiation terminal of the multilevel temperature difference power generation element, heat transfer working medium is filled in the sealed small space inside the insulation box, the vacuum heat collector is used for collecting solar energy, the insulation box and heat conduction oil are used for storing heat, stable temperature gradient can be provided for the multilevel temperature difference power generation element through the insulation box small space formed by the clapboards, the radiator reduces cold side temperature of the multilevel temperature difference power generation element through heat convection, end face temperature difference required in the multilevel temperature difference power generation element is formed, and electrical energy is provided for lamps and lanterns. The multilevel power generation system has the advantages of being compact in design, simple in installation, free of mechanical transmission parts, and high in reliability.

Owner:陕西科林能源发展股份有限公司

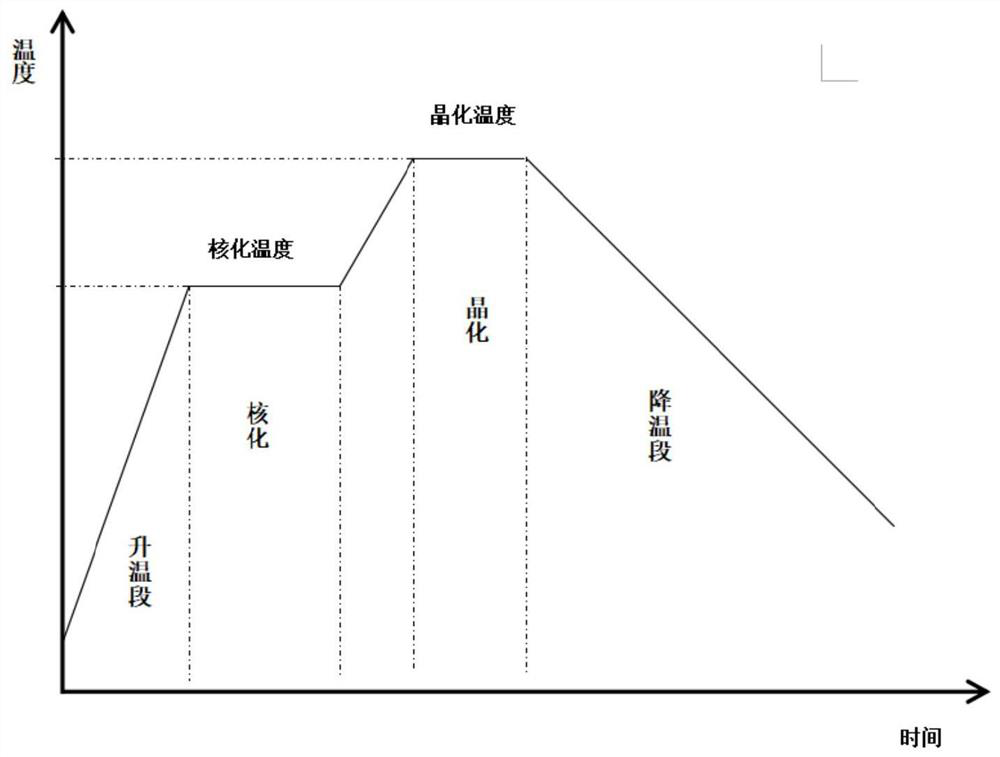

Device and method for efficiently screening microcrystalline glass microcrystallization scheme

InactiveCN112919791AImprove screening efficiencyGuaranteed accuracyEconomic benefitsThermocouple device

The invention discloses a device and a method for efficiently screening a microcrystalline glass microcrystallization scheme. The device comprises a gradient temperature furnace, a thermocouple is arranged on the gradient temperature furnace, the thermocouple extends into an inner cavity of the gradient temperature furnace from the outer wall of the gradient temperature furnace, a D-shaped pipe is arranged in the inner cavity of the gradient temperature furnace, a gradient temperature plate is placed on the D-shaped pipe, a plurality of grooves which are arranged in parallel are formed in the mounting surface of the gradient temperature plate, the grooves are used for inserting microcrystalline glass, and the distances between every two adjacent grooves are the same. A large number of microcrystallization schemes can be experimented by one experiment of the gradient temperature furnace, so that the screening efficiency of the microcrystallization schemes of the microcrystalline glass is greatly improved, the cost is reduced, and the economic benefit is higher.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

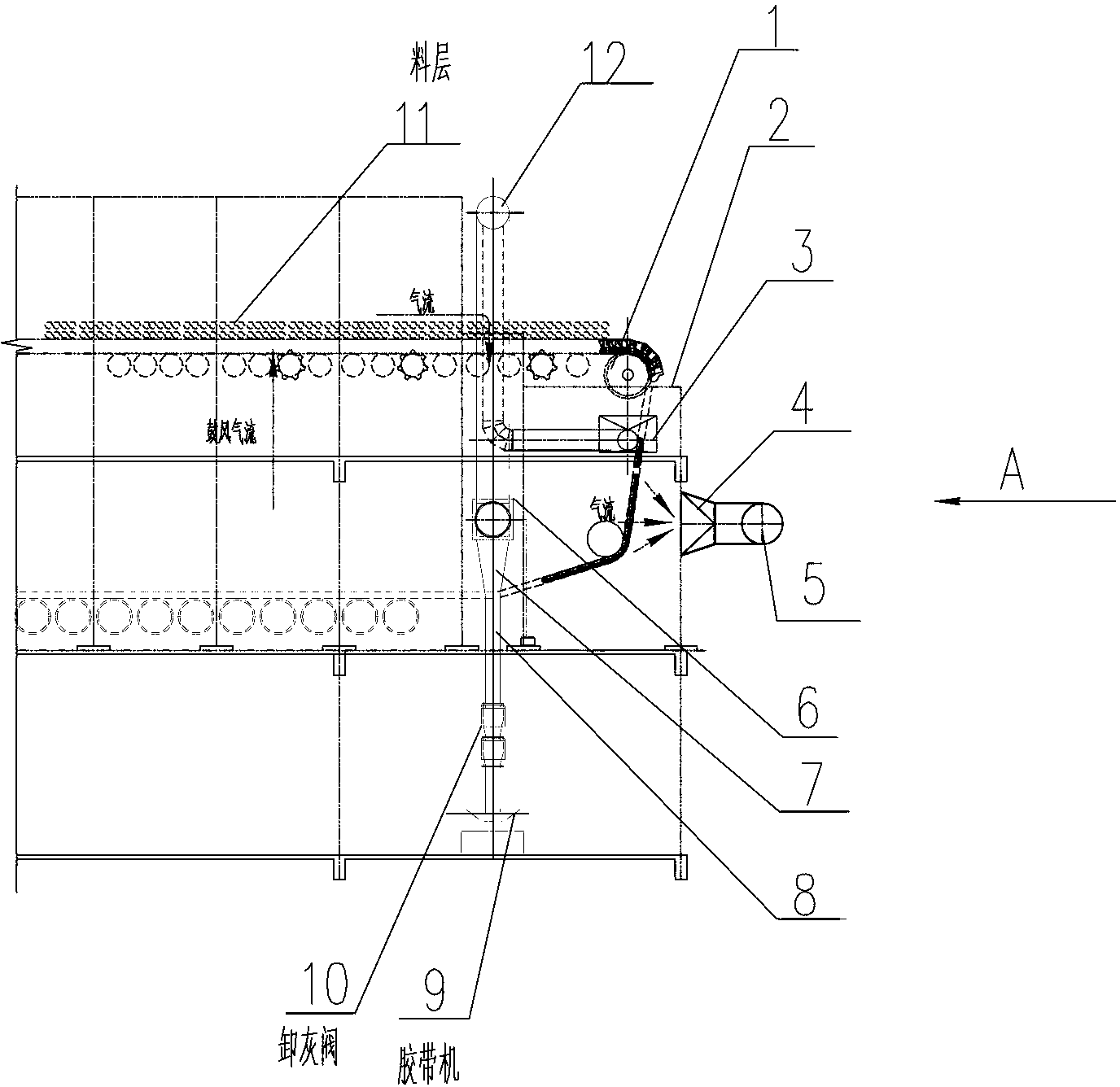

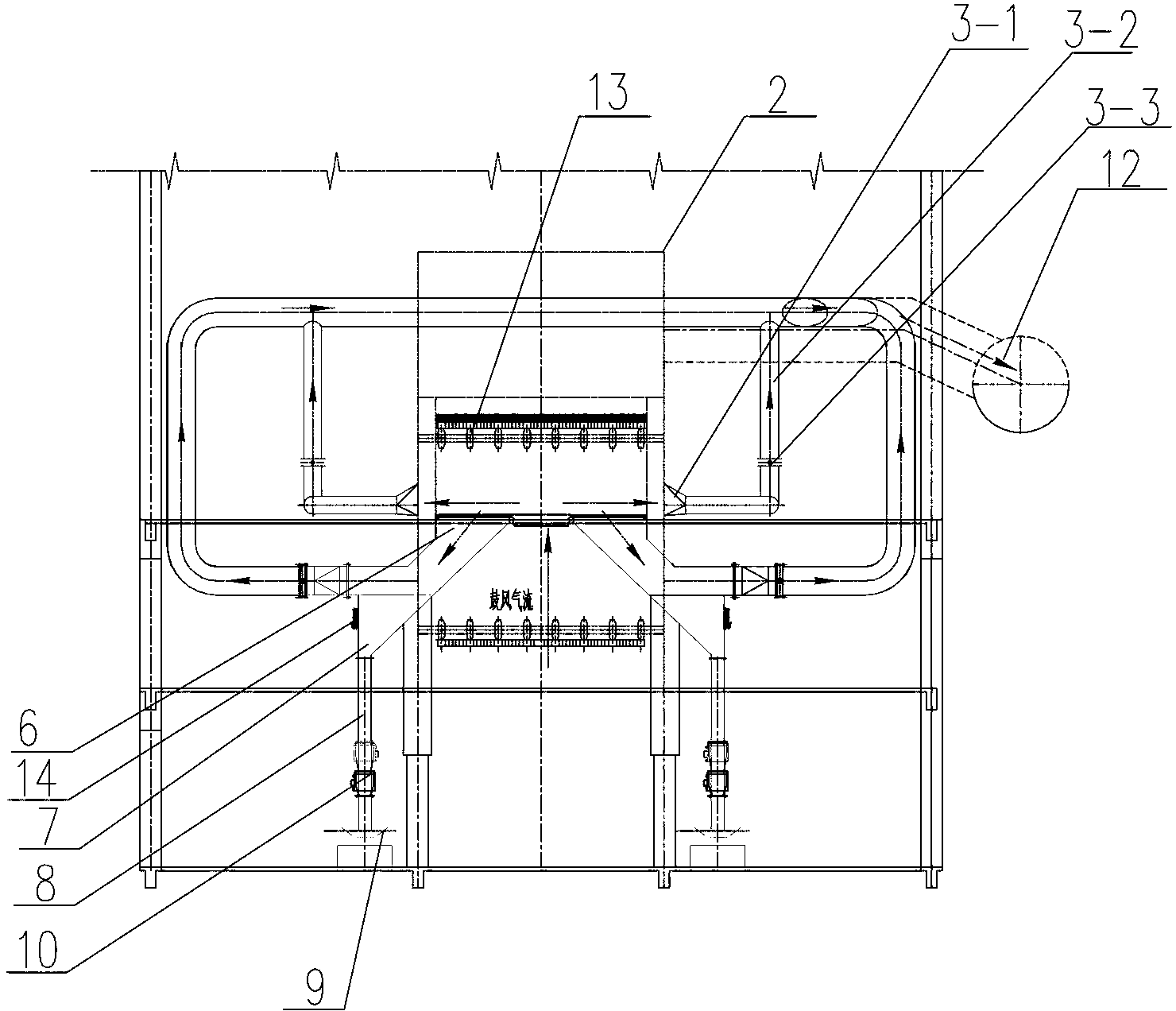

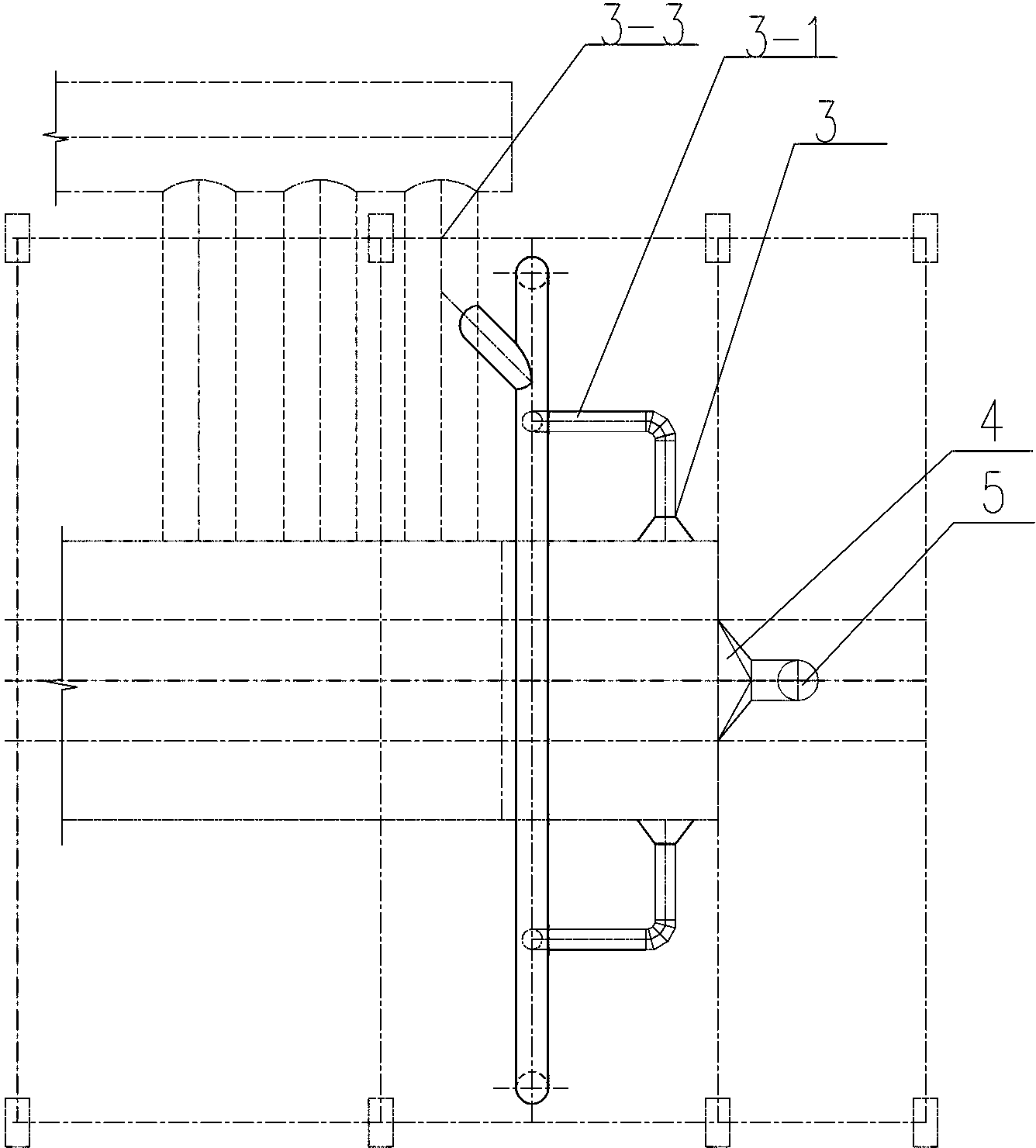

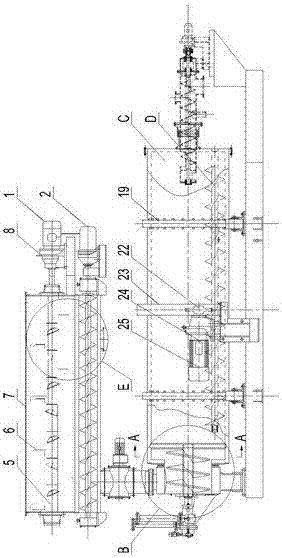

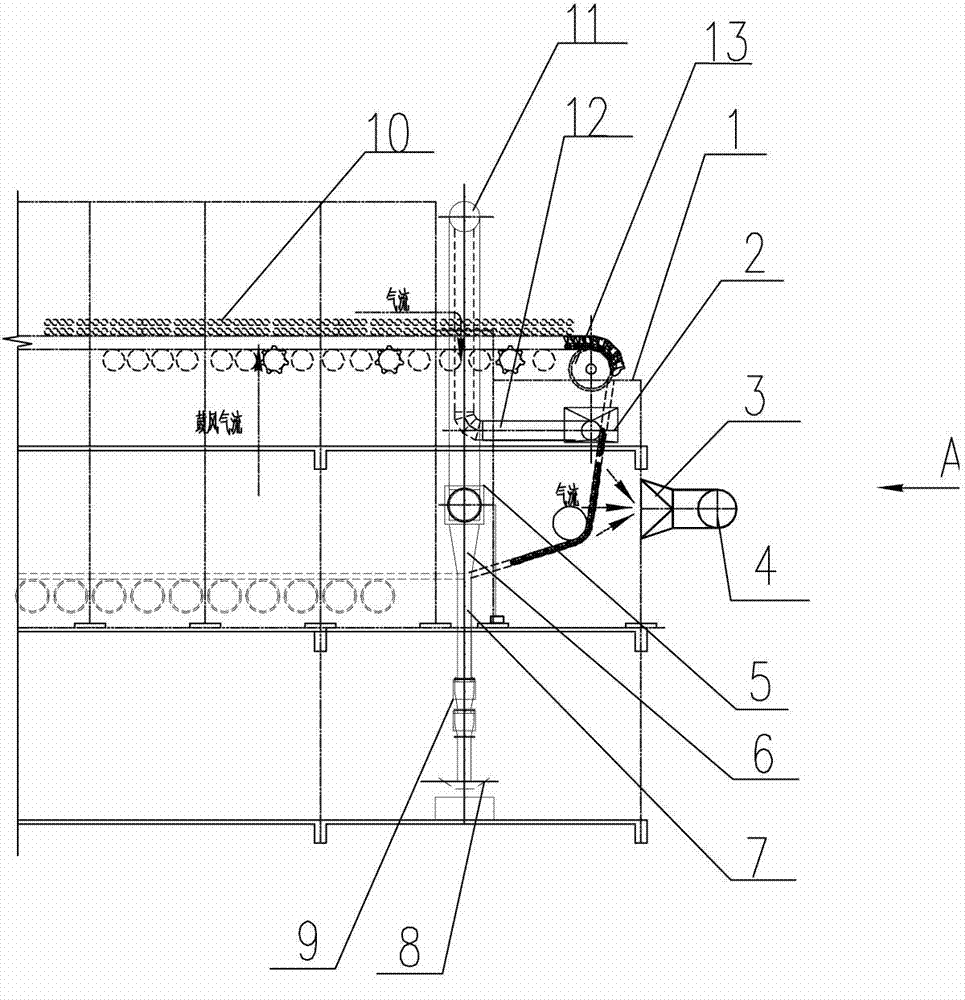

Dust removing system of chain grate machine tail part

InactiveCN103075892APrevent spillageReduce maintenanceWaste heat treatmentEngineeringTemperature gradient

The invention relates to a dust removing method in the production process of metallurgical pellets, in particular to a dust removing system of a chain grate machine tail part. The dust removing system comprises a chain grating machine tail part mechanism with a chain grate machine wheel and a chain grate machine tail wheel return device; the dust removing system is characterized in that a machine tail seal cover is arranged on the chain grate machine tail part mechanism; chain grate machine tail wheel return segment dust removing devices are arranged on the upper part of the machine tail seal cover; an overall chain grate machine tail dust removing device is arranged in the middle part of the machine tail seal cover; and a tail sealing wind box dust removing device of the chain grate machine is arranged at the end part of the lower return of the chain grate machine tail. According to the dust removing system provided by the invention, as the chain grate machine tail wheel return segment dust removing devices are arranged at the three main dust-raising spots of the chain grate machine tail mechanism, and are connected with external exhaust fans by pipelines, thereby forming a negative pressure environment; the three dust removing systems are compensated to one another and are linked with one another, so that the high temperature waste gas can be effectively prevented from overflowing, the tail machine environment of the chain grate machine workshop can be improved, the service life of the heat resistant parts of the equipment can be ensured; and moreover, the temperature gradients of the materials are smoothed, and the mine return quantity of the cured pellets can be reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Method for using slag cooler special for heat storage secondary combustion purifying device for treating solid waste for adsorbing VOCs waste gas

ActiveCN107013929AReduce heat lossStable temperature gradientLighting and heating apparatusIndefinite timeCombustion

The invention relates to the technical field of volatile organic compound waste gas treatment, in particular to a method for using a slag cooler special for a heat storage secondary combustion purifying device for treating solid waste for adsorbing VOCs waste gas. The method is characterized in that the slag ash slagging temperature ranges from 850 DEG C to 950 DEG C, and therefore a two-stage cooling technical scheme including jacket type air cooling spiral conveyor first-stage air cooling and roller slag cooling assembly second-stage water cooling is adopted, and it is guaranteed that gradient descent of the slag ash temperature is stable and gentle; therefore, it is guaranteed that when slagging is carried at indefinite time intervals, spiral blades in a jacket type air cooling spiral conveyor have no the problems that local temperature changes are large, and the spiral blades and the inner wall of an air cooling jacket are locked after thermal expansion; and a spiral slag crushing ream is designed to roll on the circumferential face of a rotary roller along with rotation of the rotary roller, scale on the inner wall of the rotary roller is swept in cycles, and the rotary roller is prevented from heat conducting coefficient reducing and local high temperature deformation.

Owner:山东天盛纤维素股份有限公司

Crystal growth furnace and crystal production process

The invention discloses a crystal growth furnace and a crystal production process. The crystal growth furnace comprises a furnace body, a crucible assembly, a heating assembly and a heat insulation assembly, the crucible assembly comprises a first crucible, a second crucible and a third crucible, a first cavity is suitable for being constructed into a raw material discharging area, and a third cavity is suitable for being constructed into a crystal growth area; the heating assembly comprises a first heater and a second heater, the first heater is arranged around the crucible assembly, and thesecond heater is arranged under the crucible assembly; the heat insulation assembly comprises a first heat insulation part, a second heat insulation part and a third heat insulation part, the first heat insulation part is arranged around the first heater, the second heat insulation part is arranged at the upper end of the first heat insulation part and extends inwards to exceed the first heater soas to surround the crucible assembly, the third heat insulation part is arranged at the upper end of the second heat insulation part and located above the crucible assembly, and the third heat insulation part at least extends inwards to the radial inner side of the first crucible. According to the crystal growth furnace, production of defect-free crystals is facilitated.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

Variable-polarity plasma arc wake flame guide tool and welding method

ActiveCN109396622AAvoid Welding DefectsGood drainagePlasma welding apparatusEngineeringWelding process

The invention relates to a variable-polarity plasma arc wake flame guide tool. The variable-polarity plasma arc wake flame guide tool comprises an upper pressing plate (12) and a lower weighing plate(15), wherein the upper pressing plate (12) and the lower weighing plate (15) are respectively located on both sides of an external butt material (4); the upper pressing plate (12) is connected with the lower weighing plate (15) so as to fix the external butt material (4); the lower weighing plate (15) is in a shape of a U-shaped groove; the weld width of the external butt material (4) is w; and the ratio of the width W of the U-shaped groove of the lower weighing plate (15) to the weld width w is 2 to 4, and the ratio of the width of the groove of the upper pressing plate (12) to the diameterof an external gun head (11) is 1.2 to 2.5. The variable-polarity plasma arc wake flame guide tool is used for preferably guiding the welding wake flame; in the welding process of a large complex camber structure, the structure of the tool and a welding method are optimized, so that the large complex camber structure is welded, and the welding quality and the welding precision are guaranteed.

Owner:BEIJING SATELLITE MFG FACTORY

Peritectic alloy-like analogue directional solidification crystallizer suitable for working under function of current

ActiveCN103510152AGuaranteed tightnessSolve real-timePolycrystalline material growthFrom frozen solutionsPower flowSilica gel

The invention provides a peritectic alloy-like analogue directional solidification crystallizer suitable for working under the function of current and belongs to an experimental apparatus for peritectic alloy-like analogue directional solidification under the function of current. A melting-zone hot-end red copper heat-transfer plate and a melting-zone cold-end red copper heat-transfer plate are connected through glass sheets which are bonded with silica gel, so that the leak tightness of a melting zone is guaranteed to facilitate the formation of a stable temperature gradient GT at two ends of the melting zone, and the lateral heat dissipation is avoided. Besides, compared with the crystallizers manufactured by mechanical connection in the prior art, the crystallizer can control the temperature gradient in the directional solidification process more accurately, and provides the support for the experiment and real-time observation on directional solidification of high-melting point peritectic alloy-like analogues under the function of current.

Owner:HARBIN INST OF TECH

Deep soil freeze-thaw process test system

ActiveCN102590468BReduce distractionsMove up and down flexiblyEarth material testingGraduated cylinderCold formed

The invention relates to a testing system for deep soil freezing / thawing process, which is structurally characterized in that a temperature-controlled box is connected with an external cold bath; a high pressure-resistant organic glass cylinder is arranged on a temperature-controllable steel base; two small holes are formed in the base, one is connected with a water guide pipe, and the other is connected with a pressure adjusting pipe; a permeable stone, a piece of filter paper and a sample are sequentially arranged at the upper part of the lower base, and a temperature sensor is mounted in the sample; a temperature-controllable upper press head is arranged at the upper part of the sample; a line leading-out hole is formed in the upper press head, and is sealed through sealant after the line is lead out; the upper press head is connected with the transmission rod of a testing machine; a measuring cylinder is connected with the sample through the water guide pipe; and the measuring cylinder is arranged on a weighing sensor and fixed through a bracket. By adopting the testing system, the freezing / thawing process of the deep soil can be rather systematically researched, so as to obtain the frost heaving rate and the water absorbing / draining rate of the deep soil which is in different depths frozen under the different temperature gradients. The testing system provides the technical guarantee for the research in clarifying the action of the external load on the forming processes of the freezing soil and the frozen soil cold-formed structures, and the mutual action of the temperature, the moisture content and the pressure of the soil body in the process of freezing under the high-pressure action.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Special slag cooler for heat storage secondary combustion purification plants for treating and adsorbing VOCs (volatile organic compounds) waste gas and solid waste

ActiveCN106838948AThe temperature gradient drops and stabilizesReduce air leakage coefficientLighting and heating apparatusVolatile organic compoundSlag

The invention relates to the field of technologies for treating volatile organic compound waste gas, in particular to a special slag cooler for heat storage secondary combustion purification devices for treating and adsorbing VOCs (volatile organic compounds) waste gas and solid waste. The special slag cooler is characterized by comprising an ash blowing machine, a jacket type air-cool spiral conveyor, an air shutdown valve and a drum type slag cooling assembly. According to the technical scheme of secondary slag ash cooling, the special slag cooler has the advantages that stable and gentle temperature gradient descent of slag ash can be guaranteed by primary air cooling of the jacket type air-cool spiral conveyor and secondary water cooling of the drum type slag cooling assembly, and accordingly the problems of great local temperature variation of spiral blades in existing jacket type air-cool spiral conveyors during irregular interval slag discharge and locking of the spiral blades and the inner wall of air-cool jackets after the spiral blades are thermally expanded can assuredly solved; designed spiral slag breaking hinges can roll in circumferential surfaces of rotary drums along with rotation of the rotary drums, accordingly, slag on the inner walls of the rotary drums can be cleaned in cycles, and reduction of heat conductivity coefficients of the rotary drums and local high-temperature deformation of the rotary drums can be prevented.

Owner:FAREAST KINGSTAR CHEM

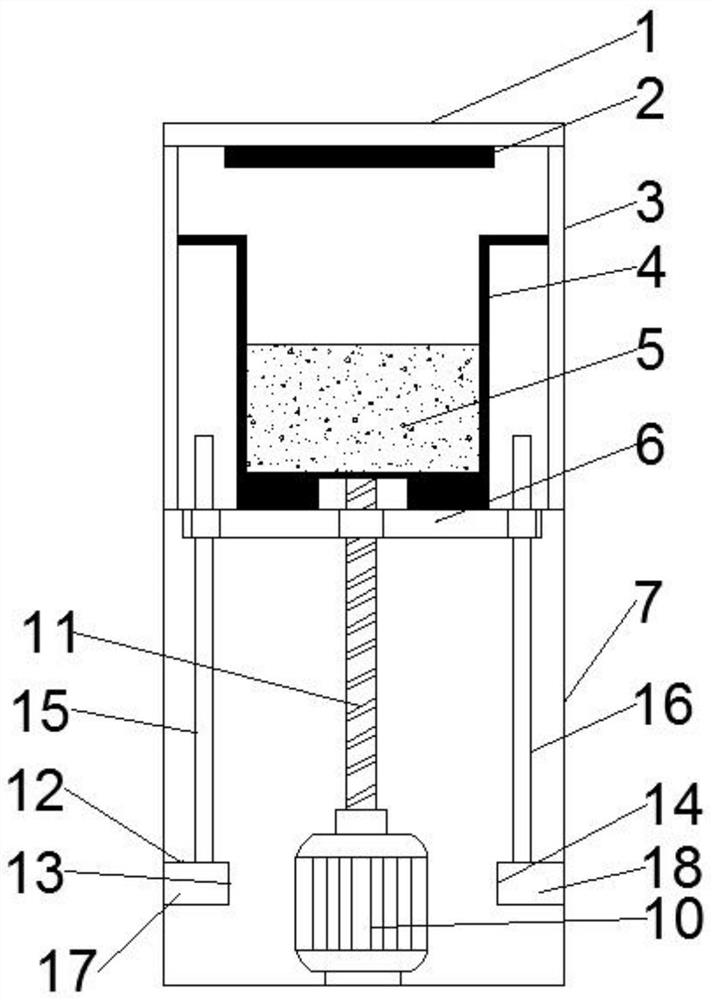

A device and method for removing s impurities in yellow phosphorus by directional solidification through full melting

ActiveCN112813503BLow costPrevention of Accidental Leakage and DeflagrationAfter-treatment apparatusPolycrystalline material growthHazardous substanceElectric machine

The invention relates to a device and method for removing S impurities in yellow phosphorus through directional solidification through full melting, which includes a vertical heating device and a yellow phosphorus carrier, and also includes an annular cooler, and the annular cooler is located above the vertical heating device And it fits closely with the top of the vertical heating device. The yellow phosphorus carrier passes through the annular cooler from top to bottom and is inserted into the vertical heating device. The top of the yellow phosphorus carrier is hung on the motor shaft, and the motor is connected to the vertical slide. On the rail, a liquid level maintaining device is arranged on the upper part of the device, and the liquid level maintaining device is connected to the vertical heating device through a hose. The method and device melt all the materials to be removed, then let the materials solidify gradually from one end, use the difference in the segregation coefficient of impurities to enrich the impurities at both ends of the material, and finally remove the two ends of the material. The sulfur impurity removal rate in phosphorus is over 95%. The method and device have good sulfur removal effect, simple device, easy production, high safety, and no harmful substance discharge.

Owner:贵州威顿晶磷电子材料股份有限公司

Device and method for reducing generation of 4H-SiC polymorphic defects

InactiveCN113684538AStable growth rateConsistent speedPolycrystalline material growthFrom condensed vaporsCrucibleCrystal growth rate

The invention discloses a device and a method for reducing generation of 4H-SiC polymorphic defects, and belongs to the field of crystal growth devices. The crystal growth device solves the problems that an existing crystal growth device for growing 4H-SiC crystals is prone to generating multiple crystal forms in the crystal growth process, and the crystal growth quality is poor. The device comprises a crucible upper cover, an outer crucible, an inner crucible, a connecting plate, a supporting table, an induction coil and a quartz tube, the outer crucible is arranged on the upper side of the supporting table, the inner crucible is sleeved with the outer crucible, the crucible upper cover is arranged on the outer crucible, seed crystals are arranged on the inner wall of the crucible upper cover, the inner crucible is filled with raw materials, the inner crucible is arranged on the connecting plate, the connecting plate is in threaded connection with the threaded rod, the threaded rod is arranged in the supporting table and penetrates through the connecting plate to be connected with the inner crucible, the supporting table and the outer crucible are arranged in the quartz tube, and the induction coil is arranged on the outer side of the quartz tube. According to the crystal growth device and method, the stable crystal growth rate is realized, and the generation of crystal growth defects is reduced.

Owner:哈尔滨科友半导体产业装备与技术研究院有限公司

A method of using a special cold slag machine for treating adsorption vocs waste gas solid waste heat storage secondary combustion purification device

ActiveCN107013929BReduce heat lossStable temperature gradientLighting and heating apparatusHeat conductingSlag

The invention relates to the technical field of volatile organic compound waste gas treatment, in particular to a method for using a slag cooler special for a heat storage secondary combustion purifying device for treating solid waste for adsorbing VOCs waste gas. The method is characterized in that the slag ash slagging temperature ranges from 850 DEG C to 950 DEG C, and therefore a two-stage cooling technical scheme including jacket type air cooling spiral conveyor first-stage air cooling and roller slag cooling assembly second-stage water cooling is adopted, and it is guaranteed that gradient descent of the slag ash temperature is stable and gentle; therefore, it is guaranteed that when slagging is carried at indefinite time intervals, spiral blades in a jacket type air cooling spiral conveyor have no the problems that local temperature changes are large, and the spiral blades and the inner wall of an air cooling jacket are locked after thermal expansion; and a spiral slag crushing ream is designed to roll on the circumferential face of a rotary roller along with rotation of the rotary roller, scale on the inner wall of the rotary roller is swept in cycles, and the rotary roller is prevented from heat conducting coefficient reducing and local high temperature deformation.

Owner:山东天盛纤维素股份有限公司

Coaxial compound processing method and device for tube electrode discharge and laser irradiation

ActiveCN106424987BImprove processing efficiencyImprove processing localityMaterial defectElectrochemical response

Owner:JIANGSU UNIV

Method for preparing thermoelectric components and thermoelectric components

ActiveCN104638101BIncrease contact areaImprove energy conversion efficiencyThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermoelectric element

The present invention relates to a method for preparing thermoelectric components and thermoelectric components, and provides a method for preparing thermoelectric components, the method comprising: (a) providing a large number of thermoelectric material sheets or thermoelectric element sheets, each sheet having at least one predetermined shape; (b) arranging a plurality of thermoelectric material sheets or thermoelectric element sheets into a predetermined combination, and connecting the plurality of thermoelectric material sheets or thermoelectric element sheets to form a thermoelectric material segment or thermoelectric element segment; (c) repeating steps (b) to produce a plurality of segments; and (d) joining said plurality of segments together to produce a predetermined configuration for the thermoelectric component. A thermoelectric element is also provided.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

A kind of dust removal method and system for thermophoretic deposition of fine particles

ActiveCN107261714BStable temperature gradientHigh thermophoretic deposition rateControl systemLithium bromide

The invention relates to a fine particle thermophoretic deposition dedusting method and a system thereof. The system is mainly composed of a thermophoretic deposition deduster, a waste heat lithium bromide refrigeration system, a gas heating device and an electric appliance control system. According to the invention, dust-laden air flow flows into a gas insulating chamber from a dust-laden air-flow inlet, then is introduced into a square plane cold wall pipe under effect of an induced draught fan and performs thermophoretic deposition movement, the air flow flows out from the square plane cold wall pipe and then continuously and downwardly flows due to effects of inertia and negative pressure effects, then the air flow is discharged through an air-flow outlet 69 from a negative pressure chamber until the air flow at the bottom of a conical cylinder is slowly risen, and the air flow is introduced into an inlet of the induced draught fan, so that a purpose of separating gas and dust can be realized. The method takes on-site practical tests as a base, a theoretical equation is taken as a reference, the organic combination of the theoretical equation and the on-site practical tests makes that the control of the thermophoretic deposition system and the practical condition are matched, so that the deduster has high thermophoretic deposition rate. The lithium bromide waste heat is used for refrigeration, so that energy is saved, and the environmental protection is realized.

Owner:盛志方

Dust removal system at the tail of the chain grate machine

ActiveCN103697711BGuaranteed service lifePrevent spillageWaste heat treatmentEngineeringTemperature gradient

The invention relates to a dust removing method in the production process of metallurgical pellets, in particular to a dust removing system of a chain grate machine tail part. The dust removing system comprises a chain grating machine tail part mechanism with a chain grate machine wheel and a chain grate machine tail wheel return device; the dust removing system is characterized in that a machine tail seal cover is arranged on the chain grate machine tail part mechanism; chain grate machine tail wheel return segment dust removing devices are arranged on the upper part of the machine tail seal cover; an overall chain grate machine tail dust removing device is arranged in the middle part of the machine tail seal cover; and a tail sealing wind box dust removing device of the chain grate machine is arranged at the end part of the lower return of the chain grate machine tail. According to the dust removing system provided by the invention, as the chain grate machine tail wheel return segment dust removing devices are arranged at the three main dust-raising spots of the chain grate machine tail mechanism, and are connected with external exhaust fans by pipelines, thereby forming a negative pressure environment; the three dust removing systems are compensated to one another and are linked with one another, so that the high temperature waste gas can be effectively prevented from overflowing, the tail machine environment of the chain grate machine workshop can be improved, the service life of the heat resistant parts of the equipment can be ensured; and moreover, the temperature gradients of the materials are smoothed, and the mine return quantity of the cured pellets can be reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com