A kind of dust removal method and system for thermophoretic deposition of fine particles

A dedusting system and thermophoretic technology, which are applied in the field of thermophoretic deposition and dedusting of fine particles and its systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

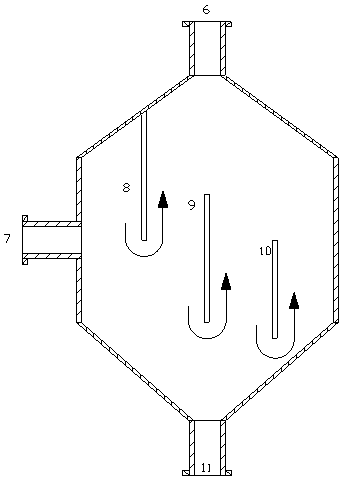

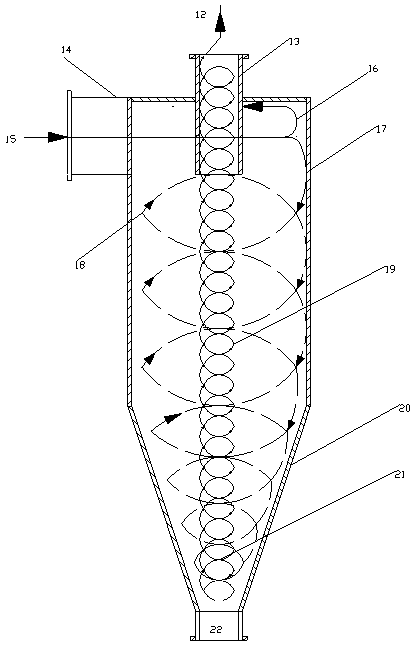

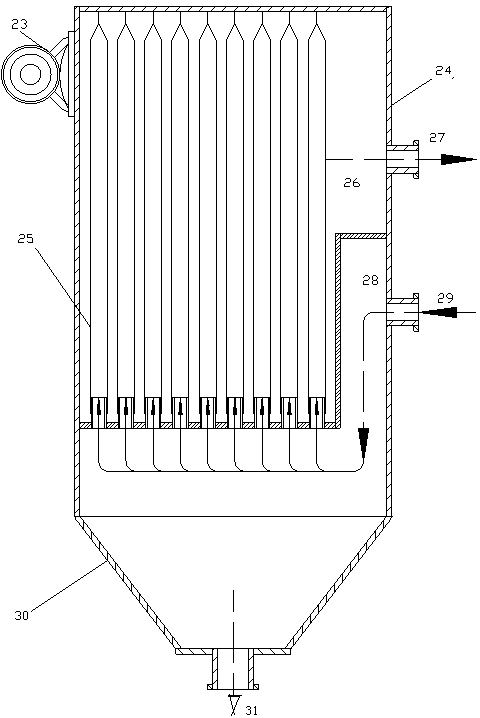

[0250] The following is a detailed description of some specific operation methods:

[0251] (1) Qualitative analysis of thermophoretic deposition:

[0252] Thermophoresis means that when fine particles are suspended in a fluid with a temperature gradient, due to the difference in the momentum transmitted when the molecules in the hot zone and the molecules in the cold zone collide with the particles, the overall performance is that they are subjected to a force opposite to the temperature gradient, so that the fine particles produce the same force as the particle. The speed of motion against the temperature gradient. This creates movement and separation. Make full use of thermophoresis to make the particles in the fluid generate a directional velocity. And it is deposited and collected, which is the development direction of fine particle dust removal.

[0253] Although the physical change process of thermophoresis has not been fully understood by people. The various physic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com