Device and method for reducing generation of 4H-SiC polymorphic defects

A 4h-sic, defect technology, applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as poor crystal growth quality, achieve crucible stability, save investment, and reduce crystal growth defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

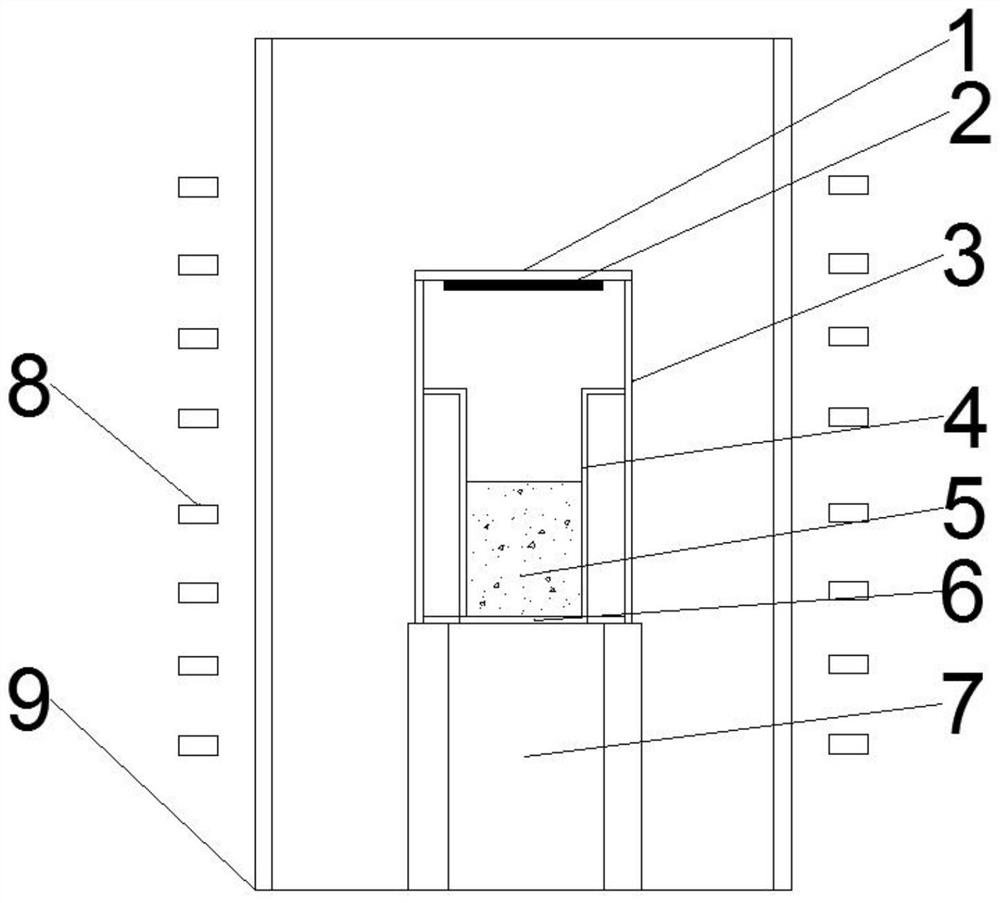

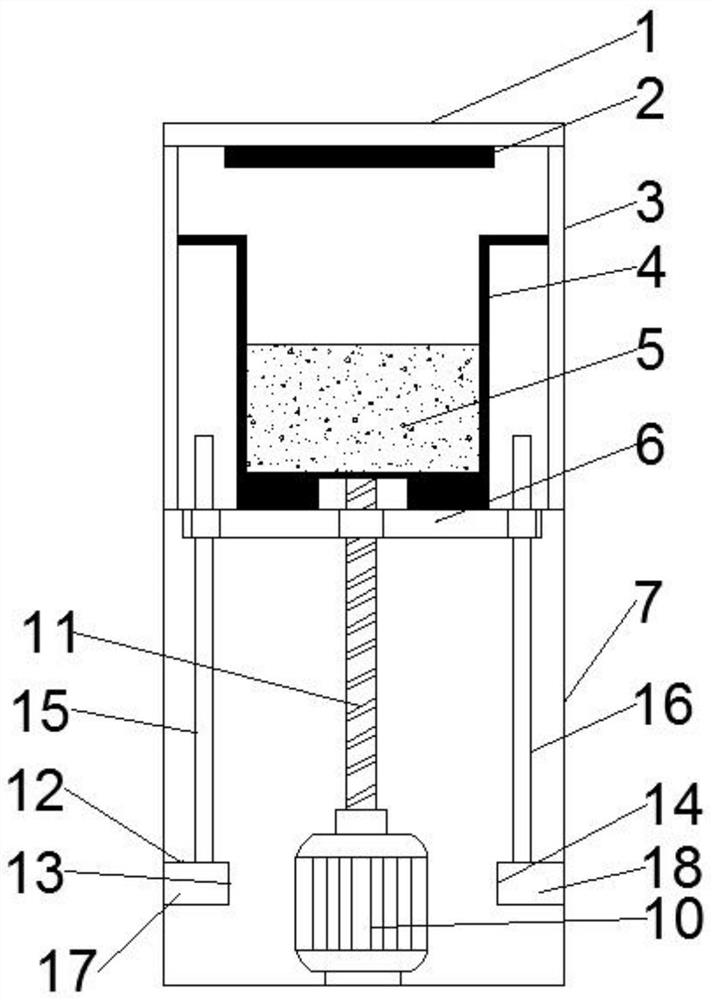

[0027] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, a device for reducing the occurrence of 4H-SiC polytype defects in this embodiment, including a crucible upper cover 1, an outer crucible 3, an inner crucible 4, a connecting plate 6, a support table 7, an induction coil 8 and a quartz tube 9. The outer crucible 3 is set on the upper side of the support platform 7, the inner crucible 4 is set inside the outer crucible 3, the crucible upper cover 1 is arranged on the outer crucible 3, the seed crystal 2 is arranged on the inner wall of the crucible upper cover 1, and the inner crucible 4 Filled with raw material 5, the inner crucible 4 is arranged on the connection plate 6, the connection plate 6 is threadedly connected with the threaded rod 11, the threaded rod 11 is arranged in the support platform 7 and connected with the inner crucible 4 through the connection plate 6, the support platform 7 is connected with the inner crucible 4 T...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, a device for reducing the generation of 4H-SiC multi-type defects in this embodiment, also includes a motor 10, the motor 10 is arranged in the support table 7, the motor 10 is connected to one end of the threaded rod 11, and the threaded rod 11 passes through The motor 10 drives the rotation, and the threaded rod 11 can also be driven to rotate by a hand wheel or other ways that those skilled in the art can think of.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, a device for reducing the occurrence of 4H-SiC multi-type defects in this embodiment, a lifting device 12 is installed on the inner wall of the support table 7, and the lifting device 12 includes a first lifting device 13 and a second lifting device 14 , the first lifting device 13 and the second lifting device 14 are connected to the connecting plate 6 respectively, the first lifting device 13 includes a first fixing part 17 and a first lifting rod 15, and the first fixing part 17 is fixedly installed on the supporting platform 7 On the inner wall of the inner crucible, the first fixing member 17 is provided with a first lifting rod 15, and the first lifting rod 15 passes through the connecting plate 6 and is arranged at the gap between the outer crucible 3 and the inner crucible 4, and the second lifting device 14 includes a second Fixing piece 18 and the second lifting rod 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com