Coaxial compound processing method and device for tube electrode discharge and laser irradiation

A composite processing and laser irradiation technology, which is used in the fields of electrochemical discharge and laser irradiation coaxial composite processing of insulation, brittle materials, and high hardness. It is difficult to achieve micro-localized processing and other problems, and achieve the effect of improving processing efficiency, improving processing localization, and constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

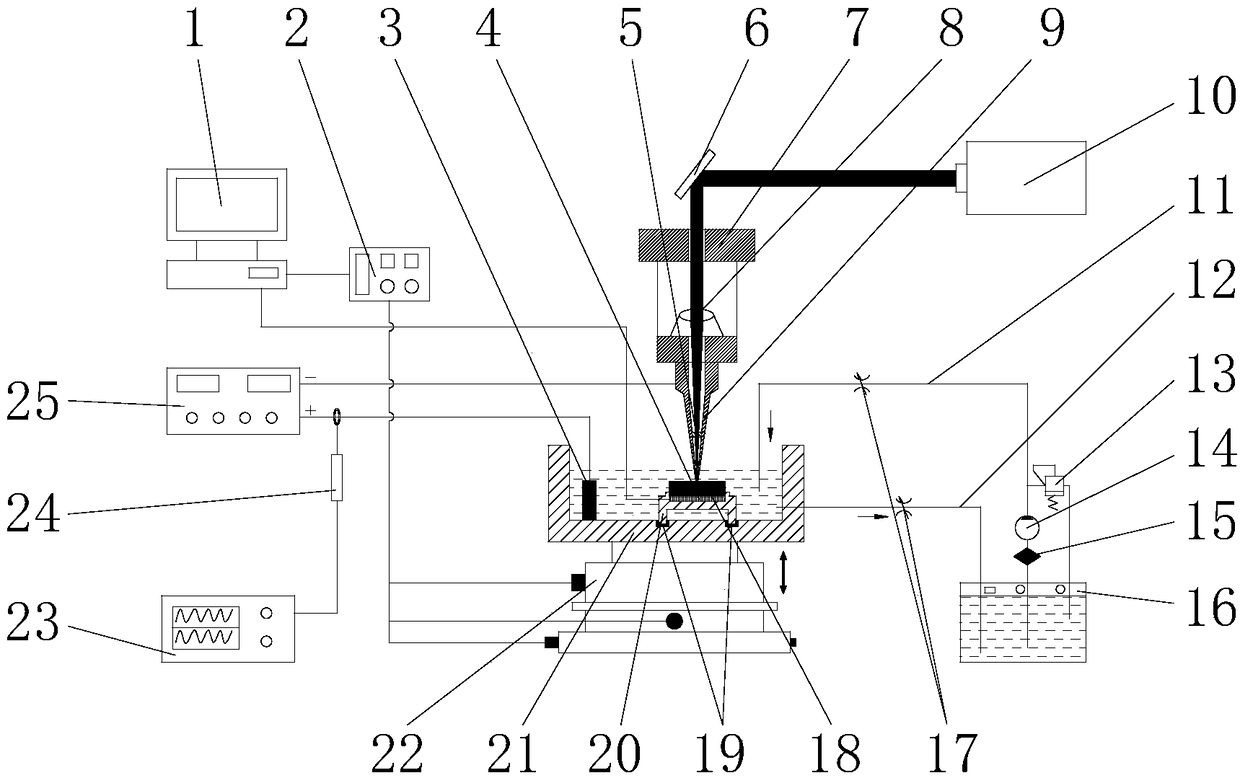

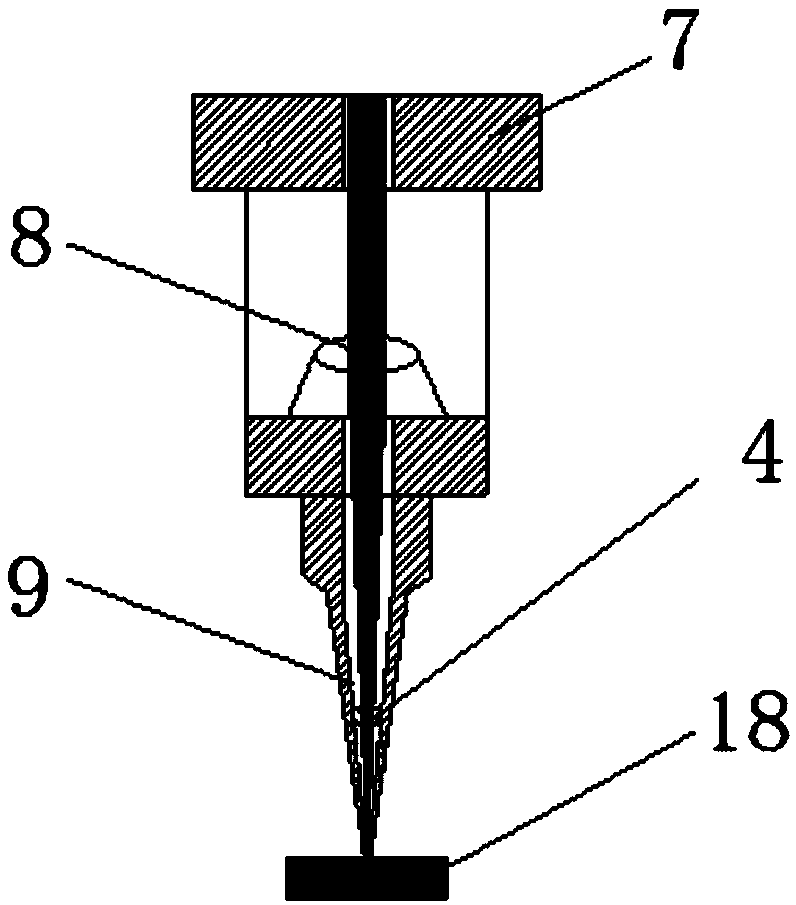

[0029] Such as figure 1The coaxial composite processing device of tube electrode discharge and laser irradiation shown includes electrochemical discharge and laser composite processing system, motion control system, and electrolyte circulation system. The combined electrochemical discharge and laser processing system includes a hollow tool electrode 9, an electrochemical discharge processing device 7, an auxiliary electrode 3, an adjustable pulse power supply 25, a working chamber 21, a laser 10, a mirror 6, a focusing lens 8, and a protective lens 5. The hollow tool electrode 9 is fixedly installed on the electrochemical discharge machining device 7, and there is an electrolyte in the working chamber 21, and the bottom of the hollow tool electrode 9 and the auxiliary ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com