Peritectic alloy-like analogue directional solidification crystallizer suitable for working under function of current

A technology of directional solidification and current action, applied in the direction of self-solidification, single crystal growth, crystal growth, etc., can solve the problems of increasing unstable factors, inability to accurately control temperature gradients, and inability to ensure the sealing of the melting area. , to achieve the effect of ensuring sealing, solving directional solidification experiments and real-time observation problems, and avoiding lateral heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

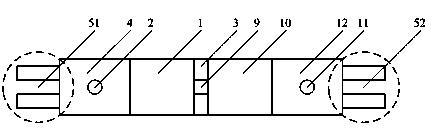

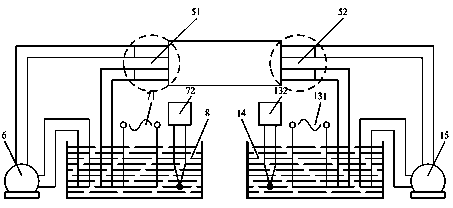

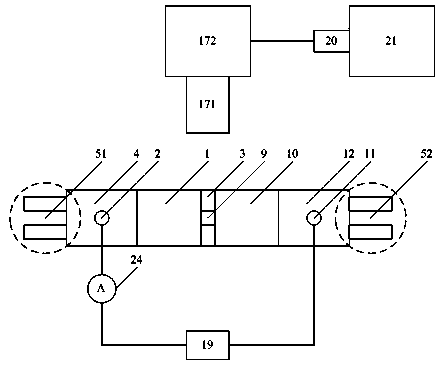

[0028] The structural schematic diagram of the directional solidification crystallizer suitable for peritectic alloy simulants under the action of current in this embodiment is as follows figure 1 As shown, the crystallizer includes a symmetrically arranged copper heat conduction plate 1 at the hot end of the melting zone and a copper heat conduction plate 10 at the cold end of the melting zone. The glass sheet 2 is connected, and the middle part of the glass sheet 2 is provided with a melting area 9; the copper heat conduction plate 1 at the hot end of the melting area is provided with a red copper electrode terminal 3 at the hot end of the melting area, and the end is bonded with silica gel. The hot-end liquid circulation heat transfer block 4, the hot-end liquid circulation heat transfer block 4 is connected to the hot-end liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com