Patents

Literature

35results about How to "Control temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

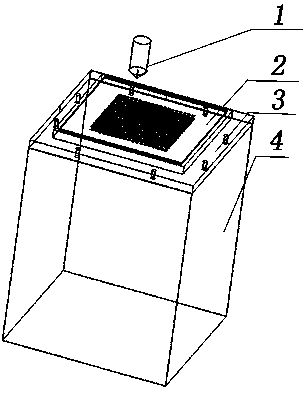

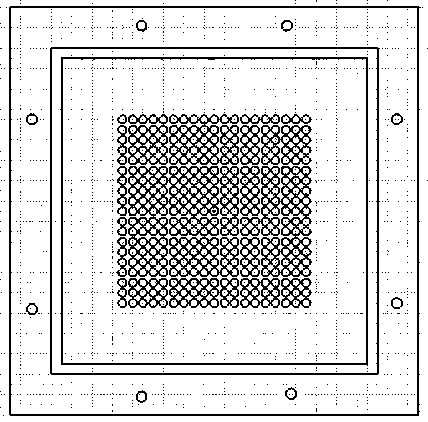

High-energy beam additive manufacturing method and equipment with high powder raw material utilization rate

ActiveCN104668563AReduce dosageImprove manufacturing efficiencyIncreasing energy efficiencyAbnormal shapedMetal powder

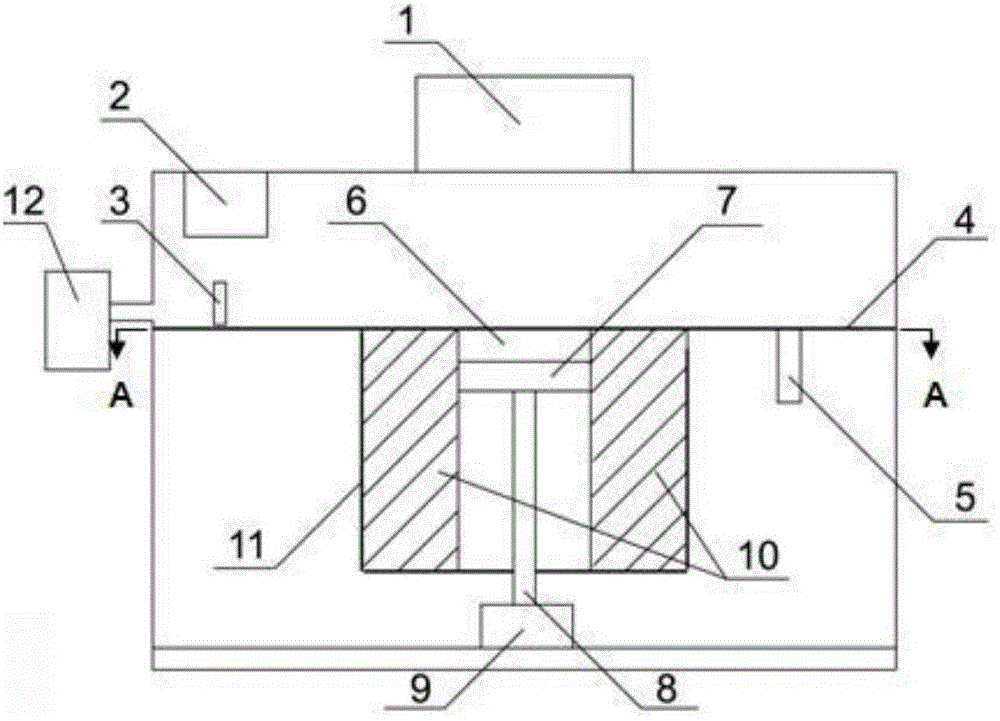

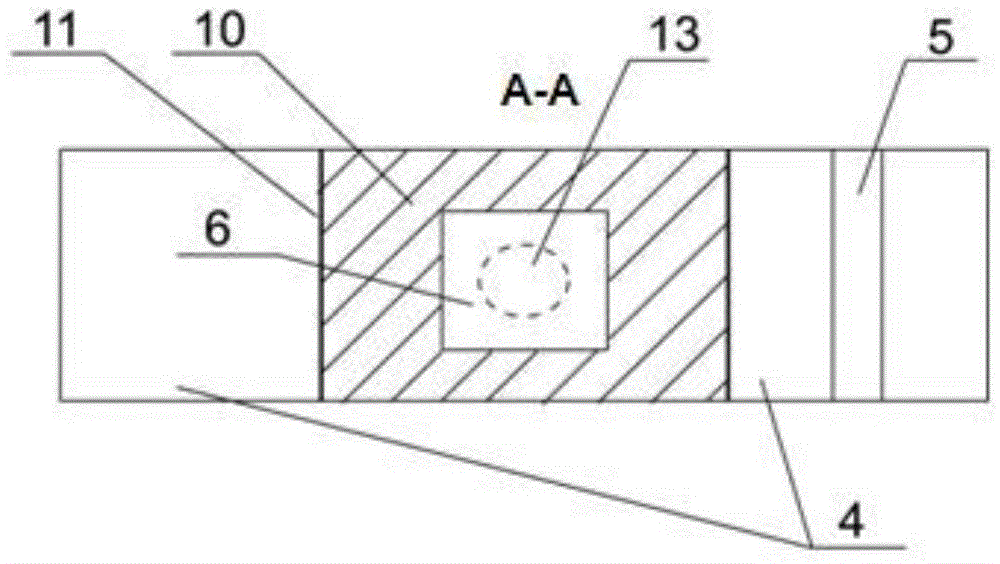

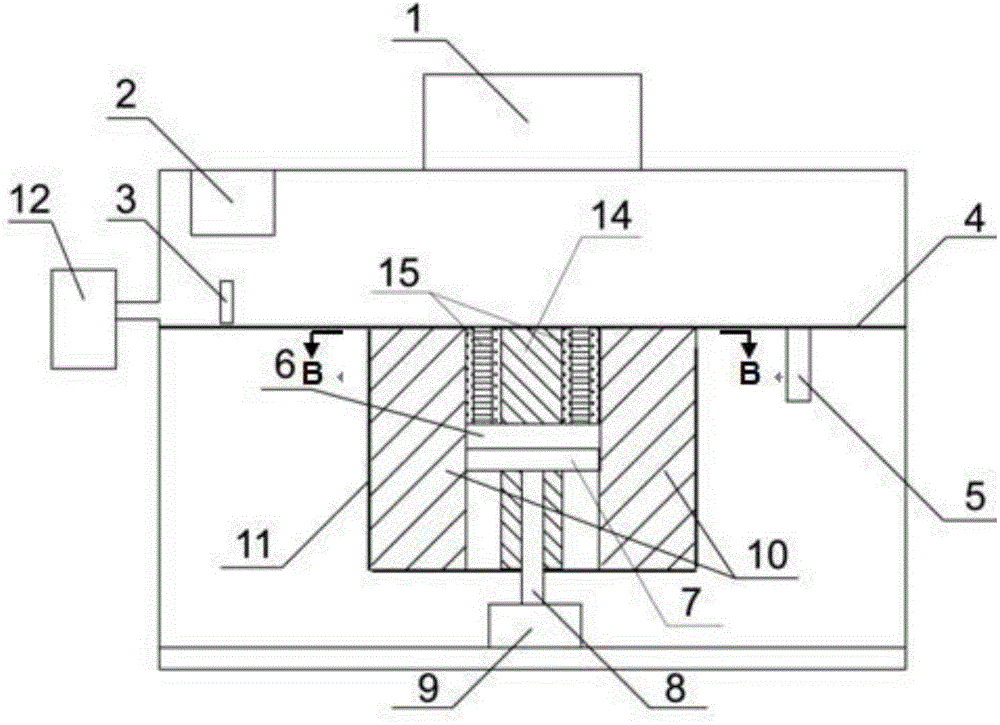

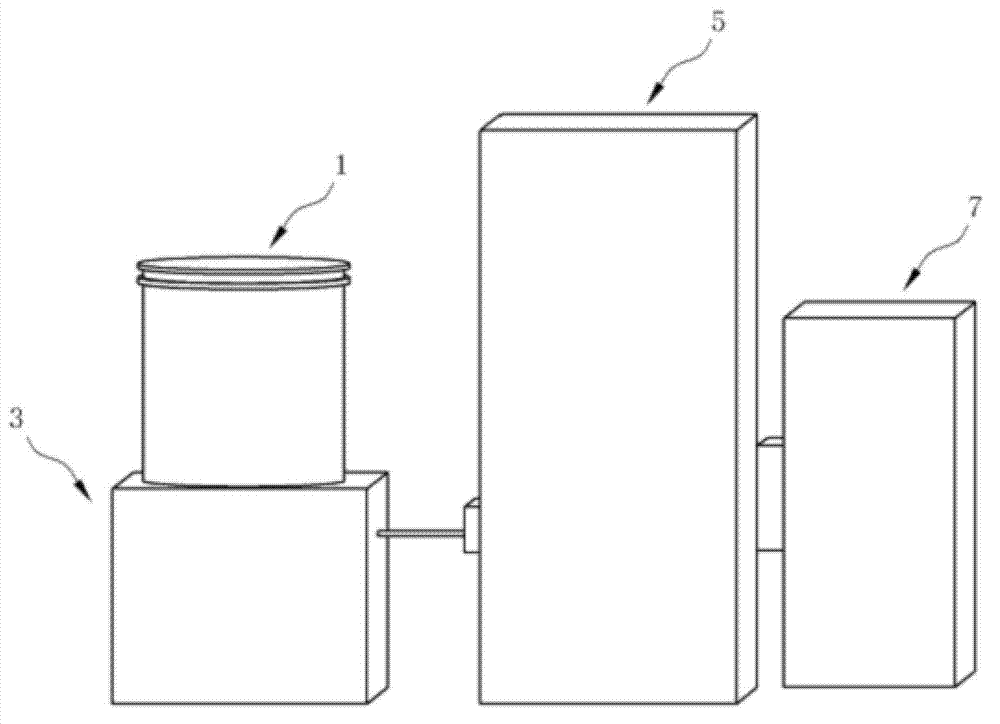

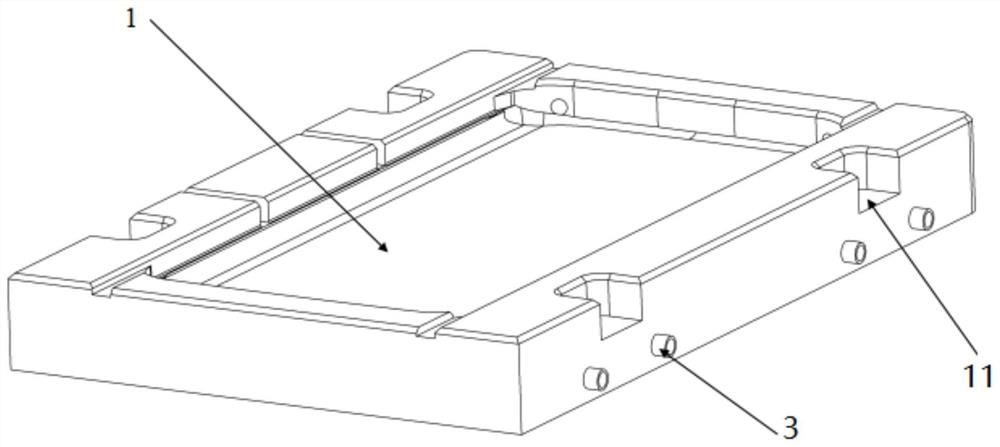

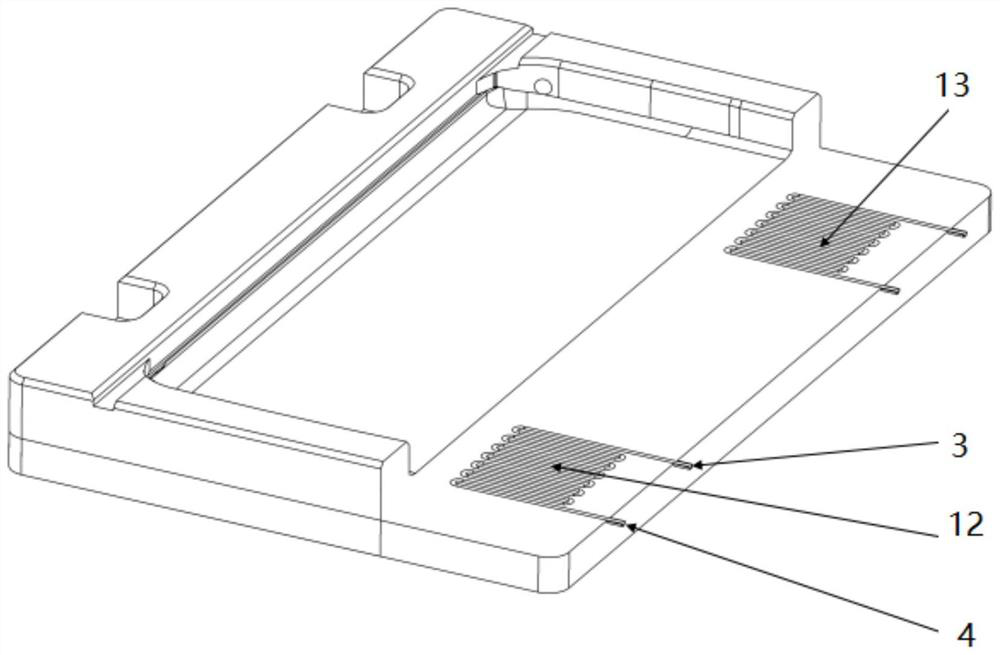

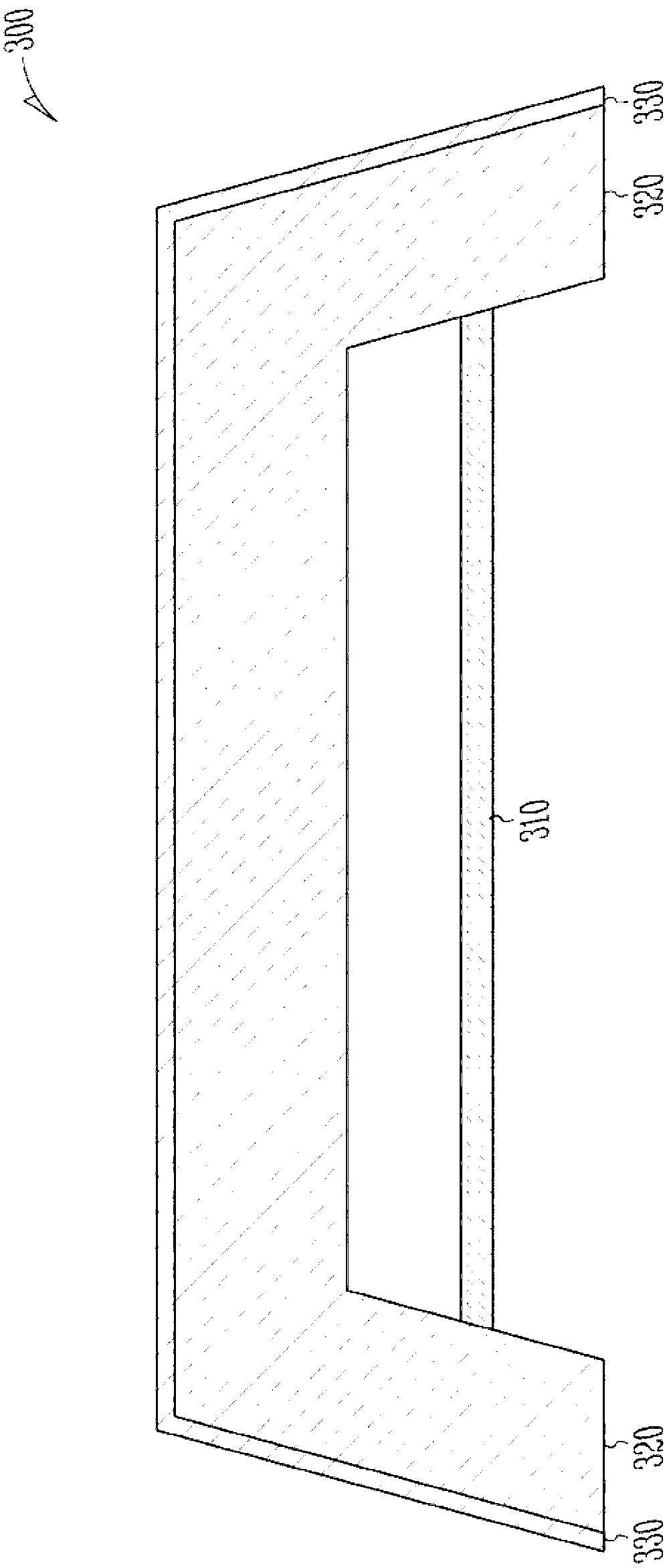

The invention discloses a high-energy beam additive manufacturing method and equipment with high powder raw material utilization rate. The method comprises the following step of according to the outline shape of a to-be-molded metal component slice, determining the internal structure of a molding cylinder, wherein metal powder of each powder paving layer is only positioned in an area corresponding to the outline shape of the to-be-molded metal component slice, so that the using amount of the metal powder is greatly reduced, and the function and effect of manufacturing the high-energy beam increasing material is improved. The equipment comprises one or more molding cylinders, wherein the internal structures of the molding cylinders are matched with the outline shape of the to-be-molded metal component slice. Due to the fact that an insert and a special-shaped substrate which adapts to the outline shape of the metal component slice are used, rebuilding of the molding cylinders for different metal component structure characteristics is realized, and the defect that redundant powder is too much in the traditional high-energy beam increasing material manufacturing process is successfully avoided. High-quality and High-effective molding of various metal components with complex structures and different sizes can be finished under the condition of high powder utilization rate.

Owner:HUAZHONG UNIV OF SCI & TECH +1

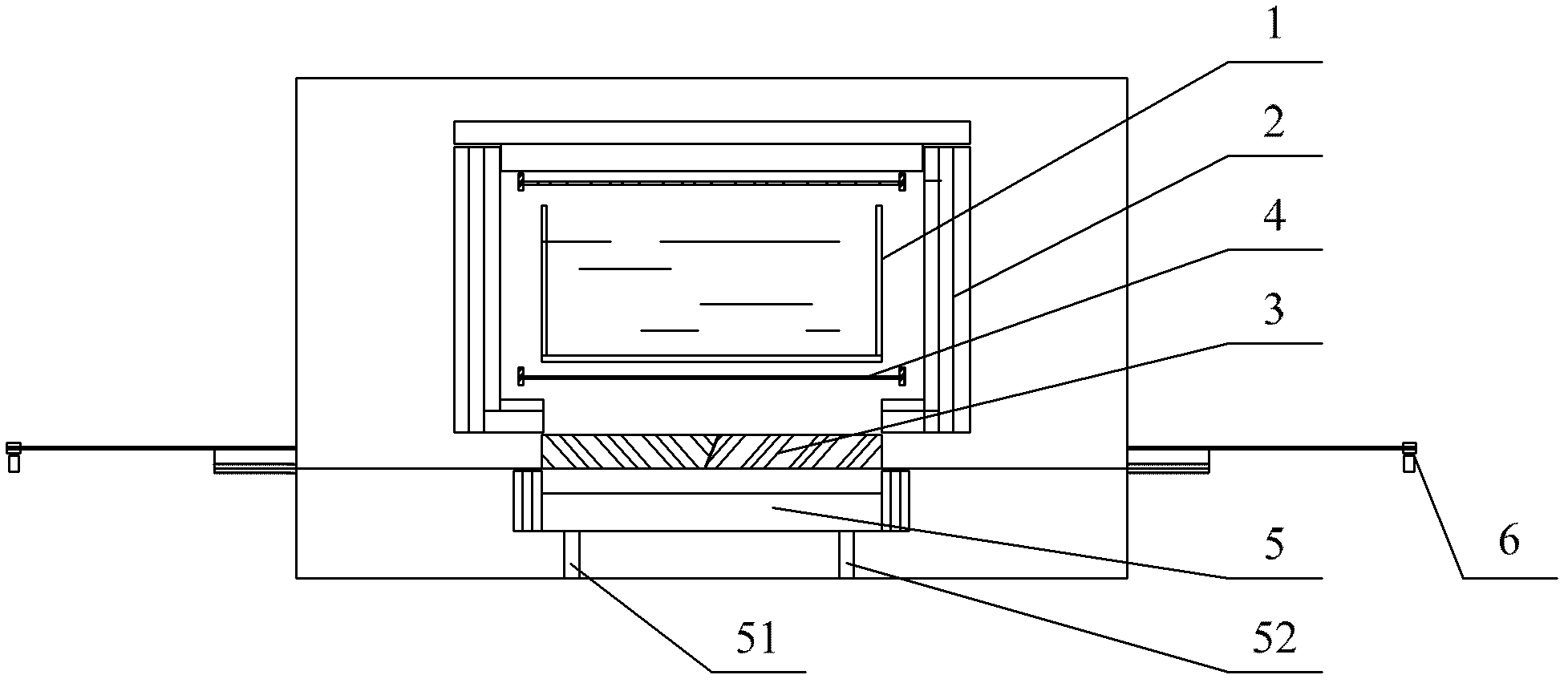

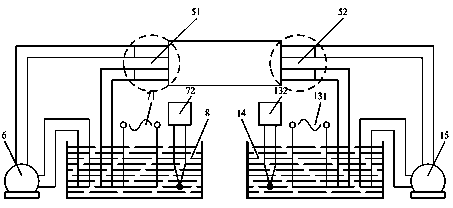

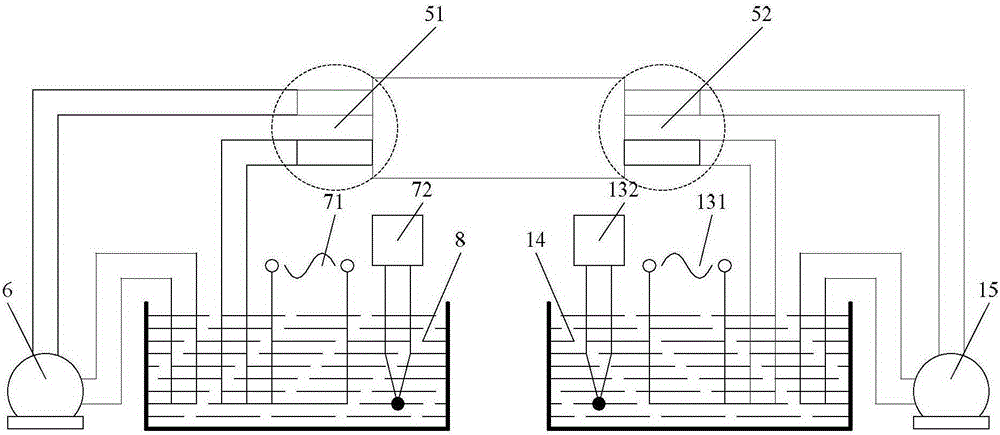

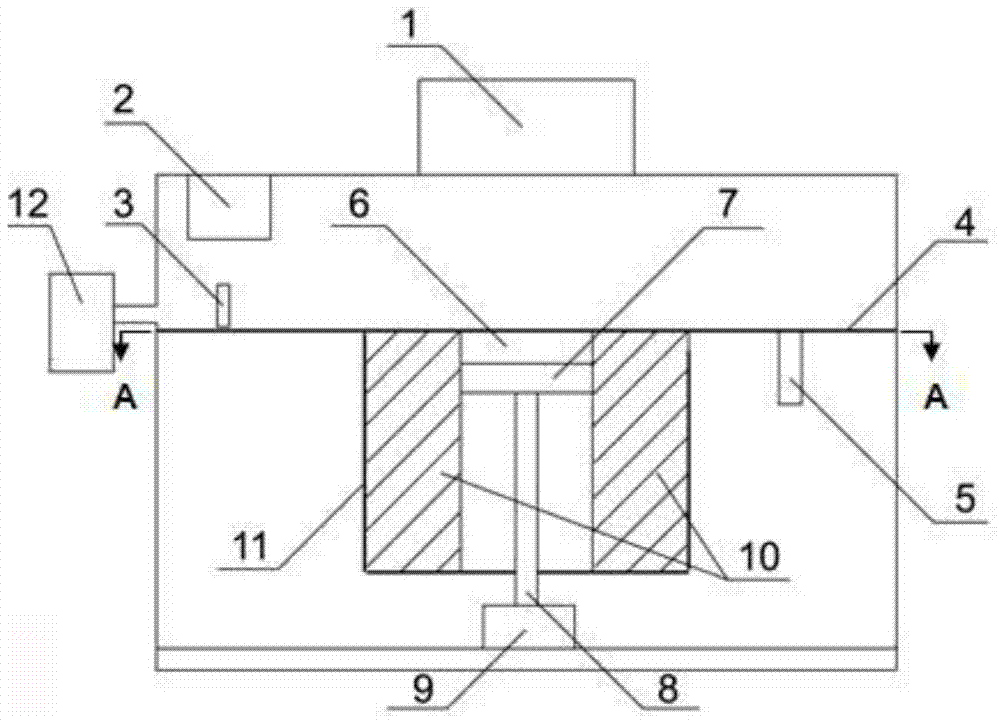

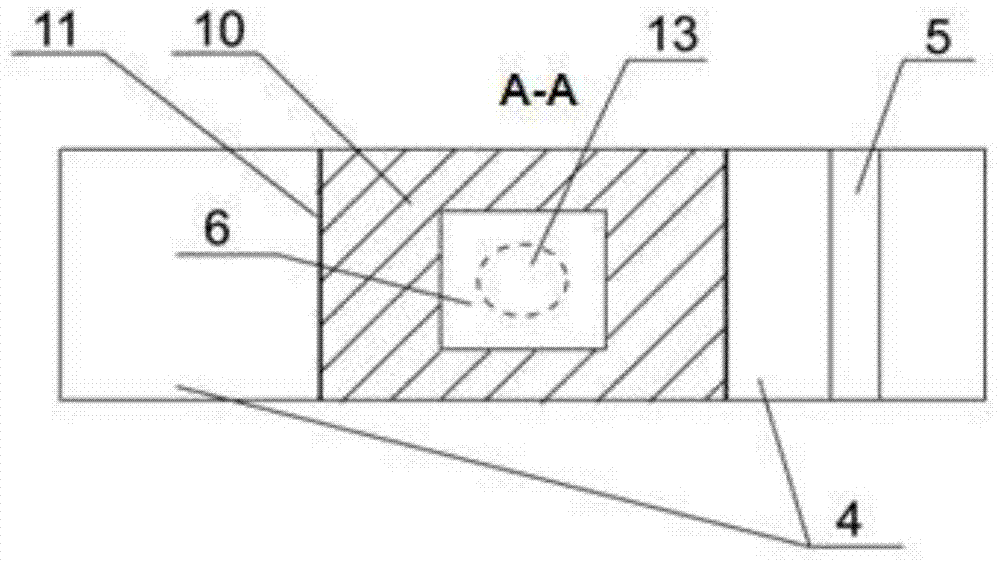

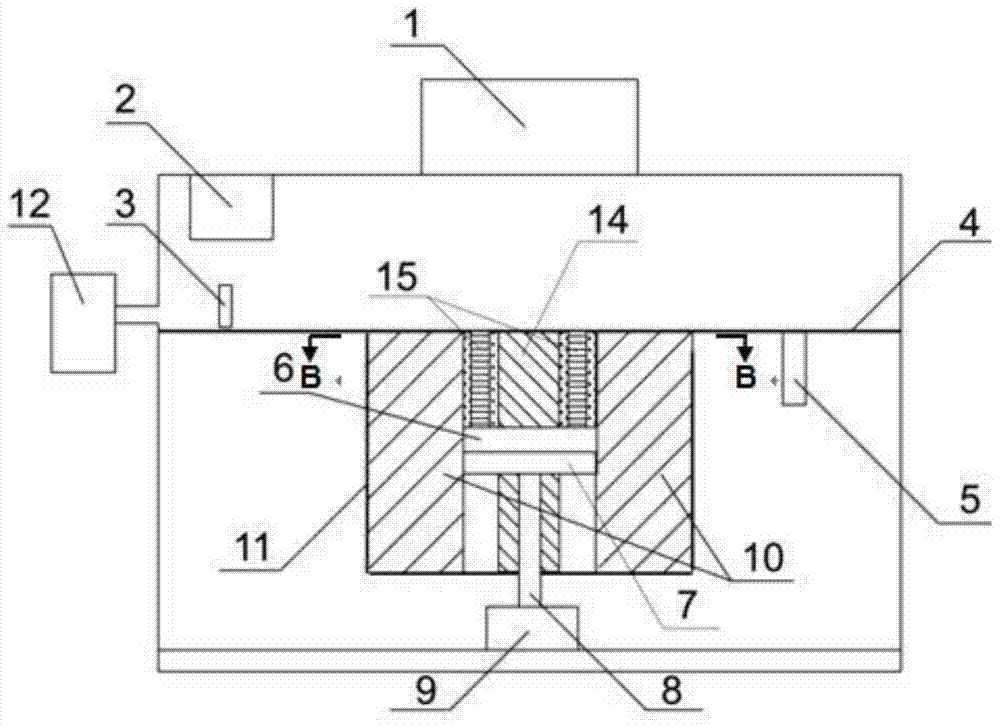

Device and method for testing deformation and water transfer characteristics of soil body under temperature gradient effect

ActiveCN103344748AHighlight substantiveAvoid disturbanceEarth material testingWater bathsTemperature control

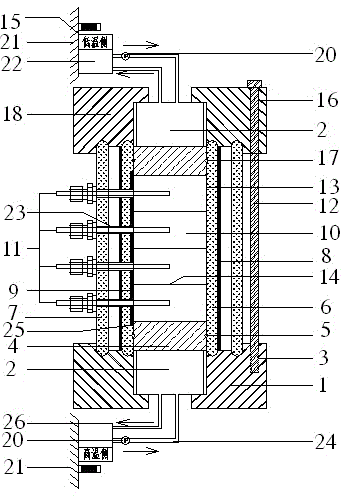

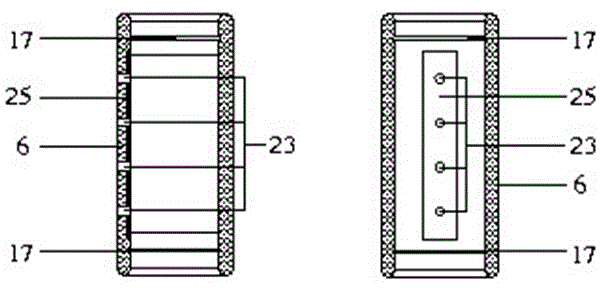

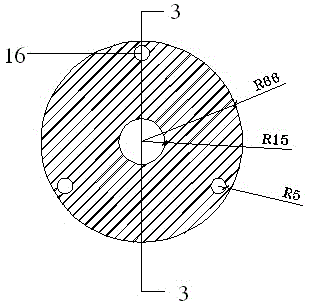

The invention discloses a device and method for testing deformation and water transfer characteristics of a soil body under a temperature gradient effect. The device comprises a sample chamber, a temperature gradient control device and a temperature and water content collecting device, wherein the sample chamber comprises an dual-layer hollow organic glass interlayer sleeve and a cover plate; a high-temperature control device and a low-temperature control device are arranged at the upper end and the lower end of the temperature gradient control device respectively, and the temperature gradient control device comprises a constant-temperature water bath, a heating chamber inside the sample chamber, heat transfer plates at two ends of a sample, and a full-closed circulating pipeline. The device for testing the water and temperature of the soil body can be used for testing the water content and the temperature of the soil body synchronously in real time. The device provided by the invention is convenient, simple and light in design, convenient to operate, good in integration performance, and high in testing precision.

Owner:SHANGHAI UNIV

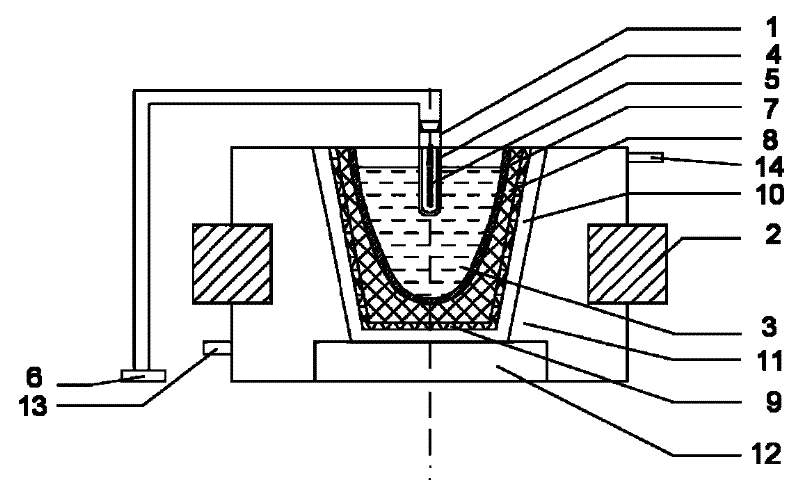

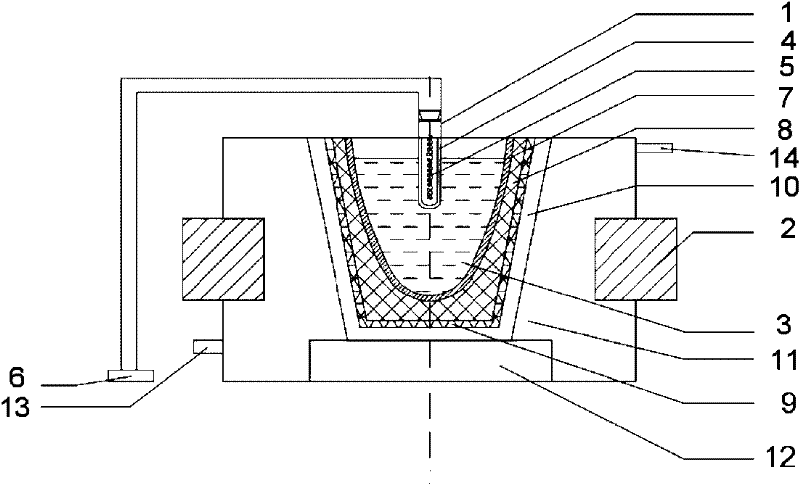

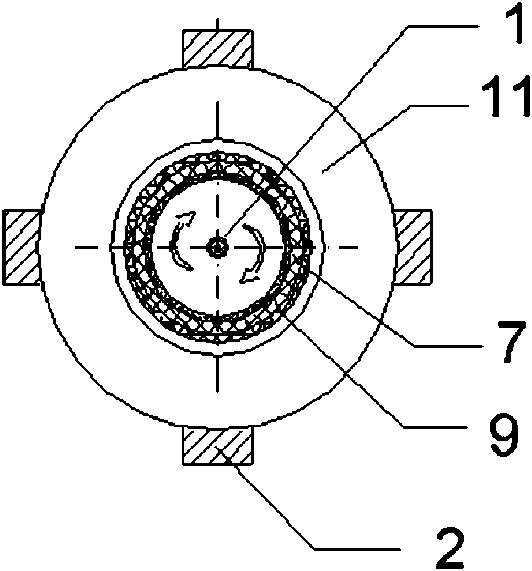

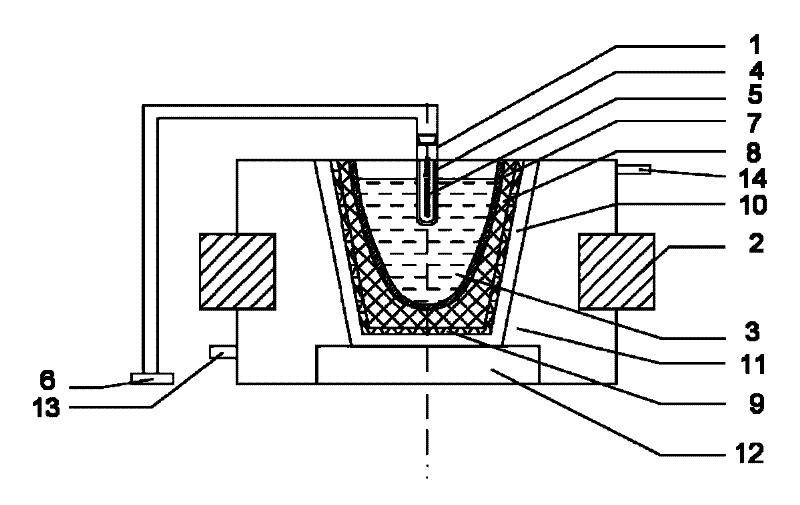

High-purity aluminum purification device based on segregation method

A high-purity aluminum purification device based on segregation method belongs to metal purification technical field and comprises an internal heater, a plurality of electromagnetic stirrers and a purification furnace body. The internal heater is positioned at the center of the purification furnace body and the electromagnetic stirrers are positioned at the periphery of the furnace body and distributed evenly. The invention controls the melt flow field to improve the diffusion and distribution of the impurity elements discharged during the segregation process of the aluminum melt, accordingly accelerates the mixed diffusion of solute elements in the melt, reduces the frontal impurity concentration of the solid-liquid interface and realizes the purpose of improving the aluminum purification efficiency.

Owner:上交赛孚尔(包头)新材料有限公司

Soil body temperature gradient and moisture movement test device

InactiveCN104237483ASubstantiveAvoid disturbanceEarth material testingWater bathsTemperature control

The invention discloses a soil body temperature gradient and moisture movement test device. The device comprises a sample chamber, a temperature gradient control device and a temperature and moisture content acquisition device. The sample chamber is composed of an organic glass double-layer hollow interlayer sleeve and a cover plate. The upper end and the lower end of the temperature gradient control device are respectively provided with a high temperature control device and a low temperature control device, and the temperature gradient control device comprises a constant temperature water bath box, a heating chamber placed inside the sample chamber, heat transfer plates arranged on both ends of a sample and a full-closed circulating pipeline. By using the soil body moisture and temperature test device, the moisture content and the temperature of a soil body are synchronously real-timely measured. The temperature gradient and moisture movement test device is simple, light and handy in design, convenient to operate, good in integration performance and high in test precision.

Owner:SHANGHAI UNIV

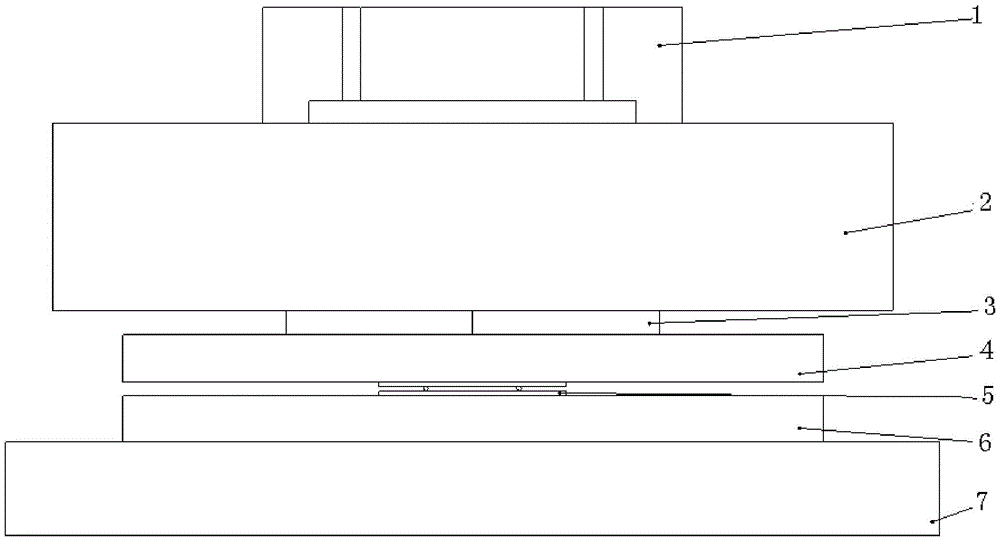

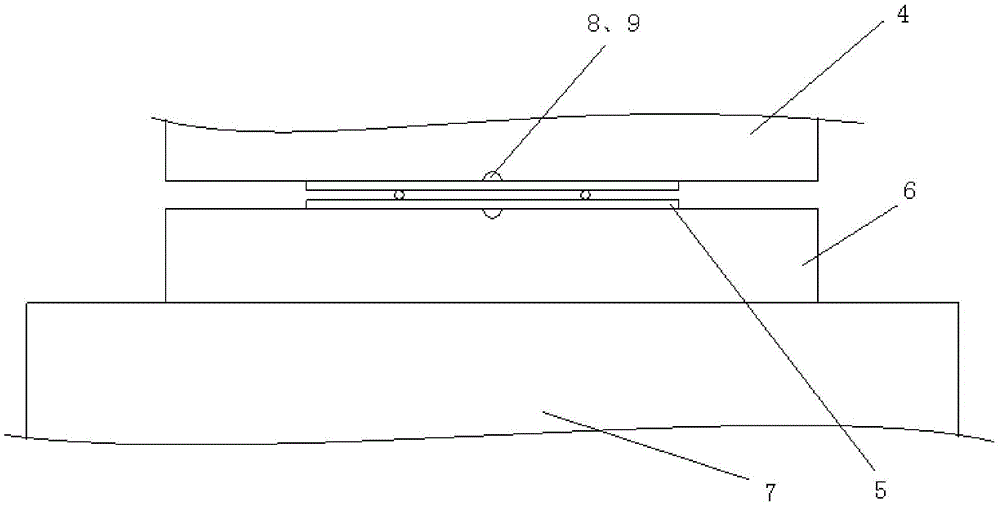

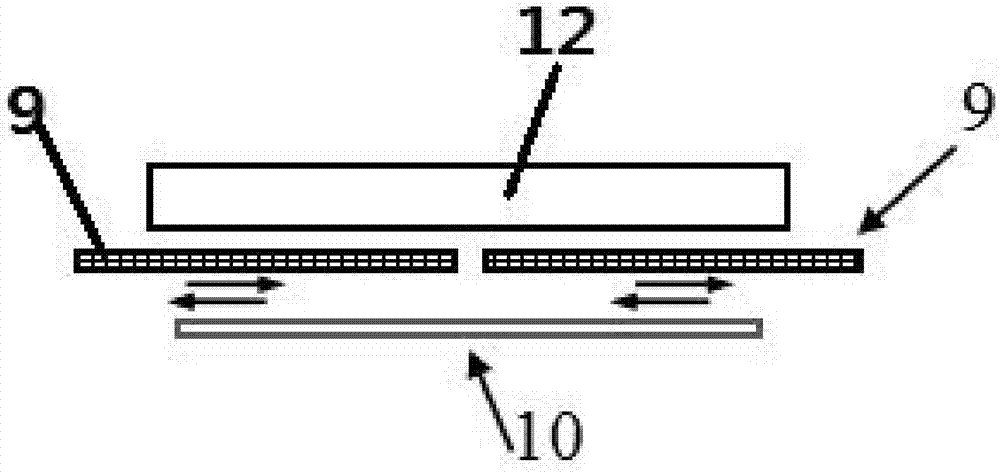

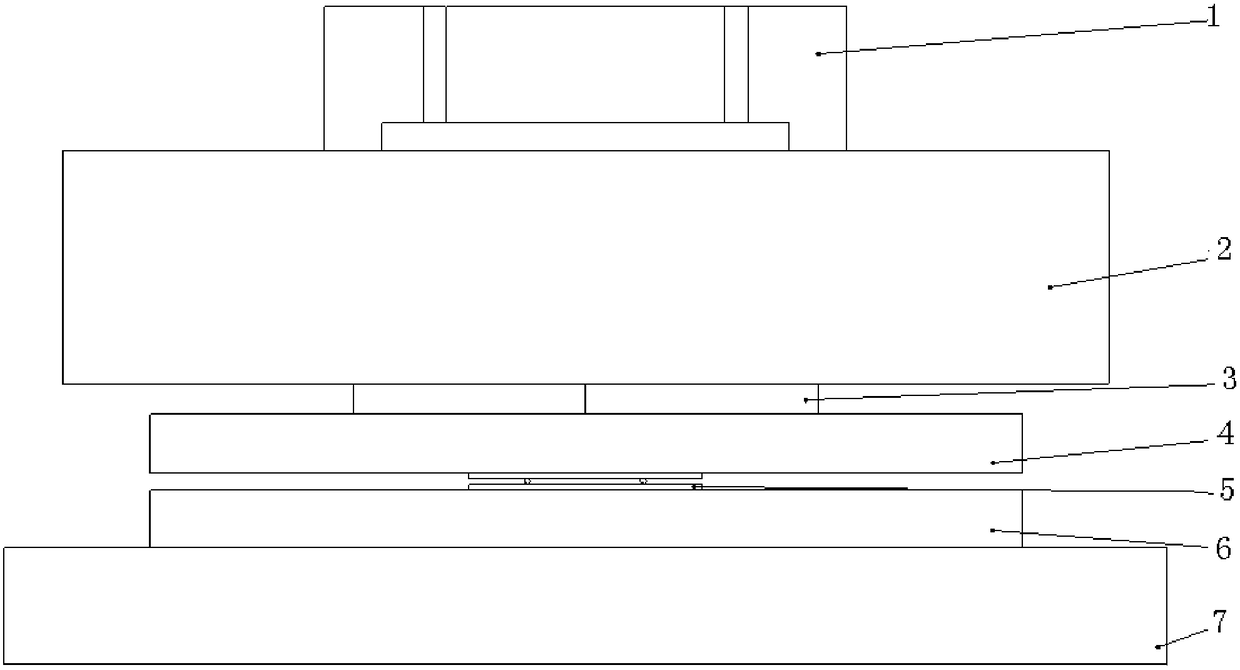

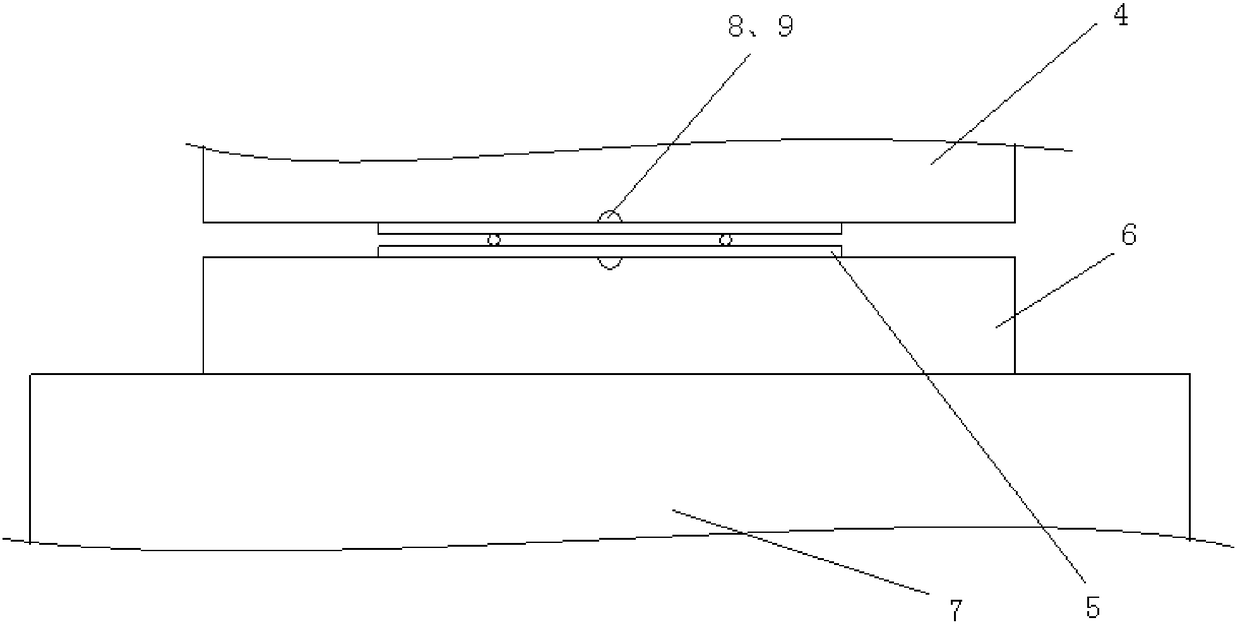

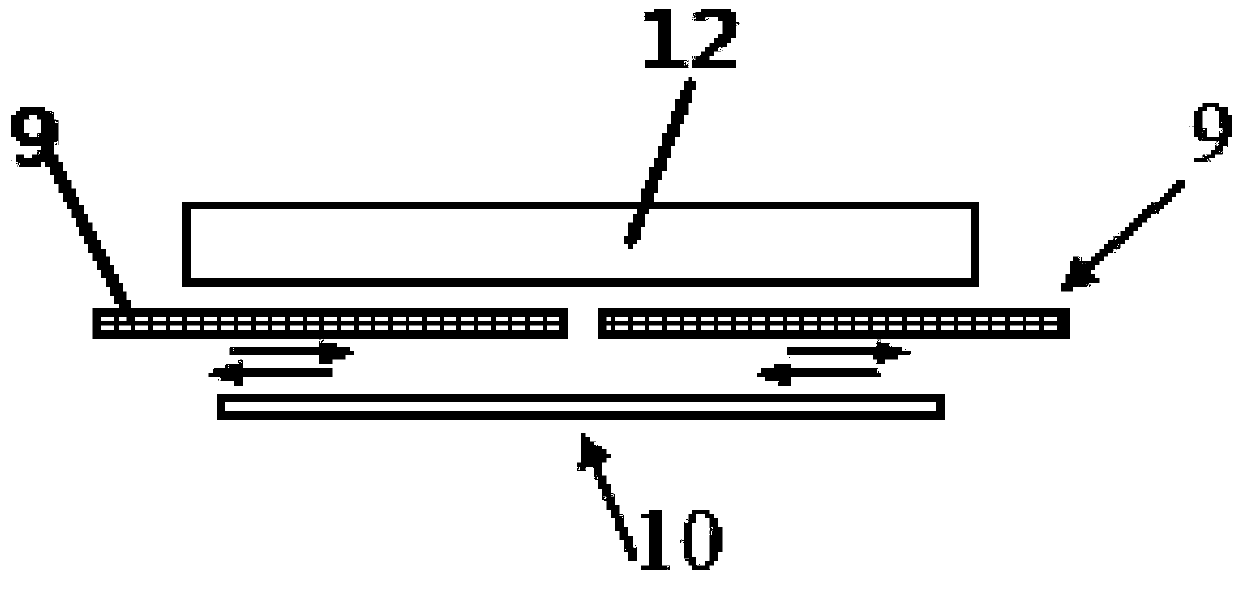

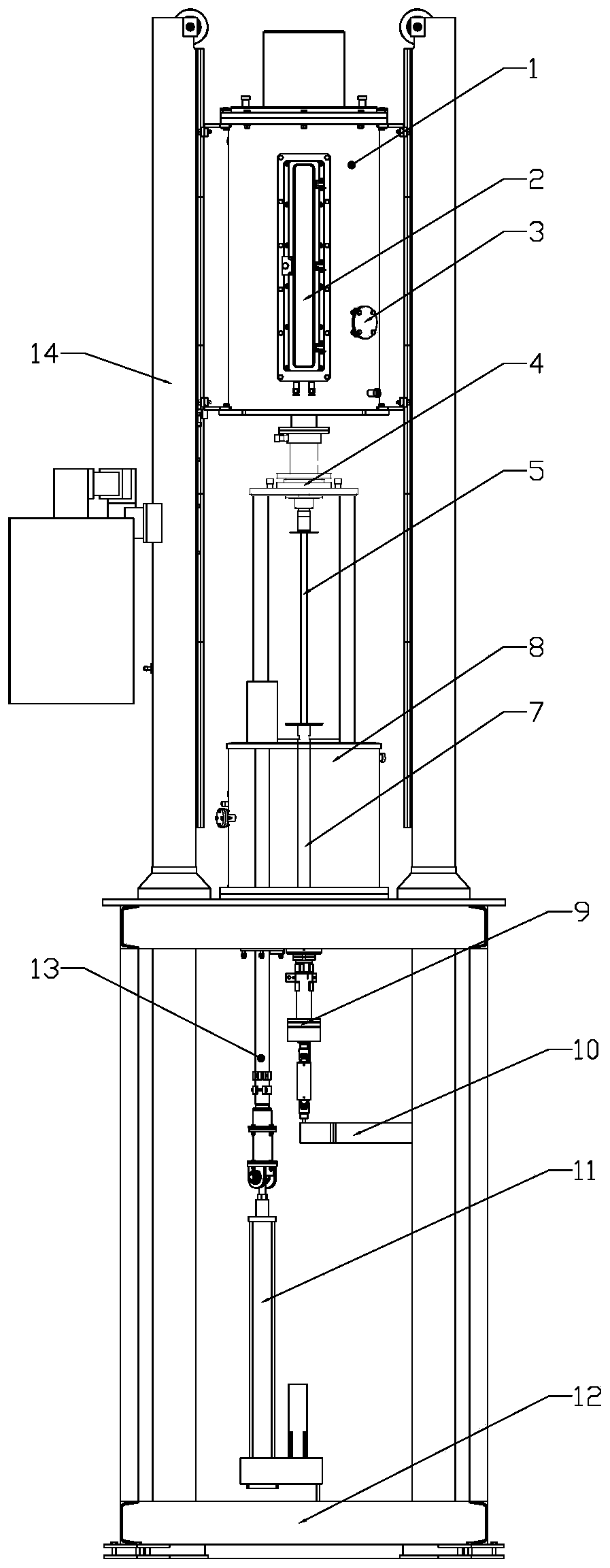

Device and method for detecting thermal migration performance of interconnected welding spots

InactiveCN105606647AGood safety and reliabilitySimple structureMaterial heat developmentPreparing sample for investigationTemperature controlAir volume

The invention discloses a device and a method for detecting the thermal migration performance of interconnected welding spots. The device sequentially comprises a cooling mechanism, an upper heat conduction plate, a lower heat conduction plate and a heating plate from top to bottom, namely, the cooling mechanism is arranged at the upper part of the upper heat conduction plate and the lower heat conduction plate is arranged at the upper part of the heating plate; and a sample is arranged in a space between the upper heat conduction plate and the lower heat conduction plate. A temperature control device of the heating plate is adjusted to obtain the temperature required by the heating plate; a rotating speed adjusting device of a cooling fan is adjusted to adjust the air volume of the fan so as to change the temperature of the hot and cold ends of the sample, and the required temperature gradient can be obtained according to the height of the welding spot. The device and the method have high safety reliability, the structure is simple and can be operated easily, the cost is low, popularization can be realized easily, electromigration interference can be effectively avoided, and the temperature gradient can be effectively controlled by control of the temperature difference of the cold and hot ends.

Owner:SOUTH CHINA UNIV OF TECH

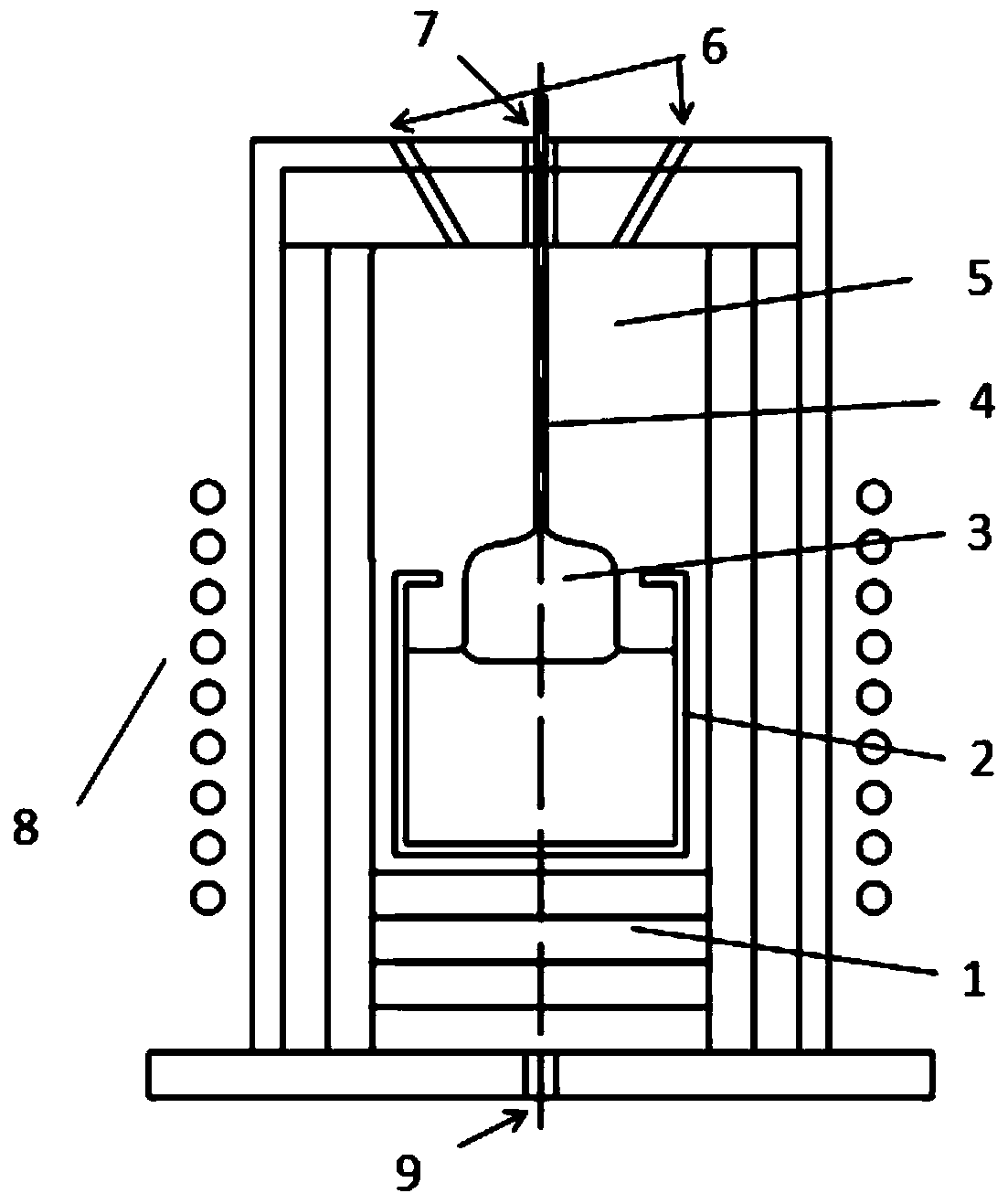

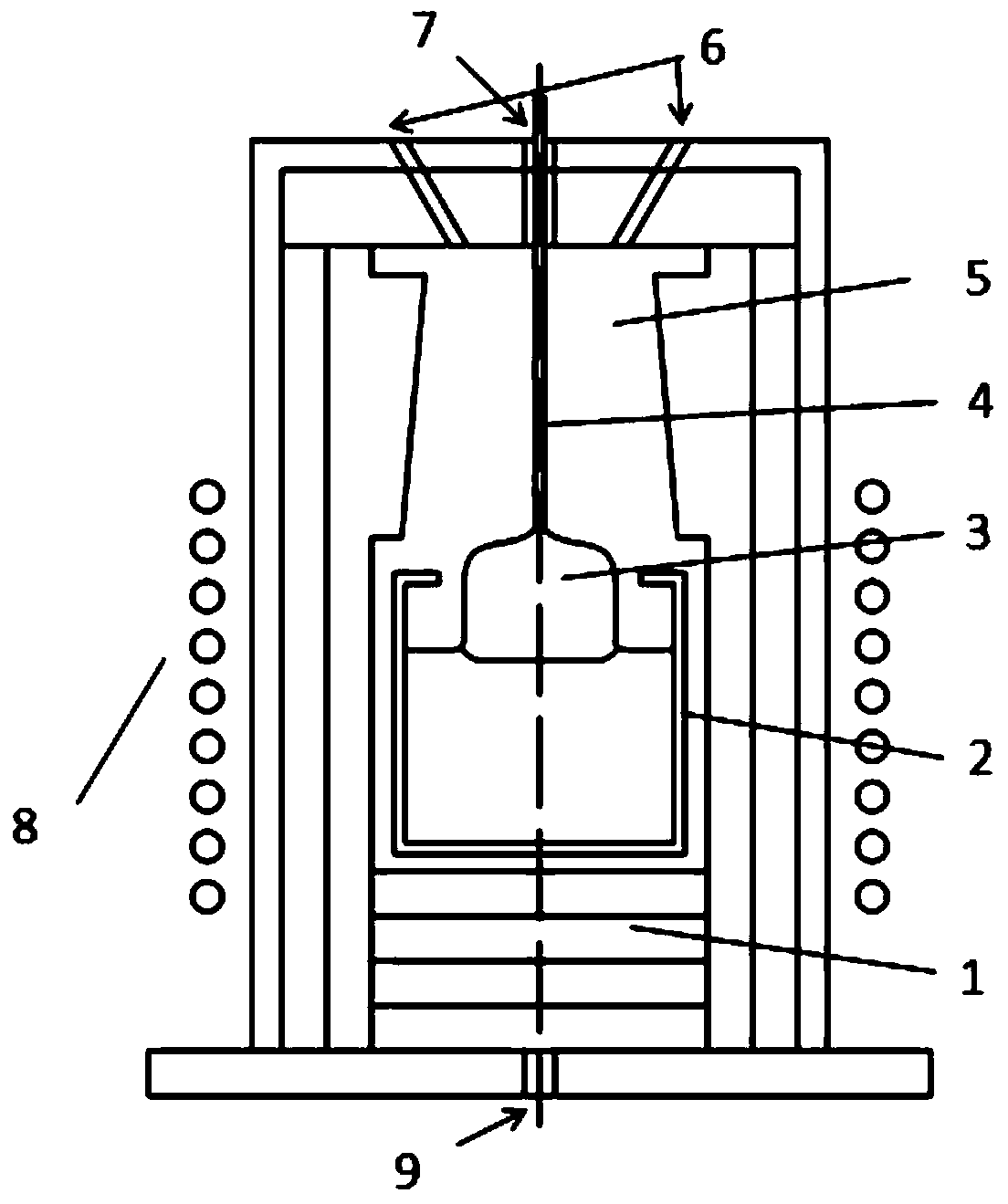

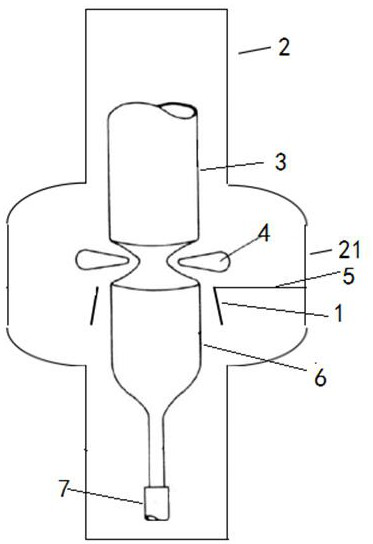

Pulling method crystal growth furnace

InactiveCN103741208AReduce the likelihood of breakageControl flow stateBy pulling from meltRound tableDislocation

The invention discloses a pulling method crystal growth furnace. The pulling method crystal growth furnace is characterized by comprising a furnace body and a crucible (2), wherein the interior of the furnace body is hollow so as to form a furnace cavity (5), the crucible (2) is arranged at the center of the furnace cavity (5), and the crucible (2) is connected with a seed crystal rod (4) which is coaxially arranged in the furnace cavity (5) and used for growing crystals (3) in the crucible (2); and the pulling method crystal growth furnace is characterized in that the inner wall of the furnace cavity (2) at the upper part of the crucible (2) has a certain conicity and a round table cylinder structure is further formed. The growth furnace disclosed by the invention can effectively control the three-dimensional effect of flow and heat transfer in the pulling method furnace cavity, organize a relatively good temperature environment around the crystals and simultaneously form a relatively good temperature gradient at a solid-liquid interface in the growth process of the crystals. The novel furnace cavity structure can reduce the production of dislocation or rupture in the growth process of the crystals and improve the quality of the crystals.

Owner:HUAZHONG UNIV OF SCI & TECH

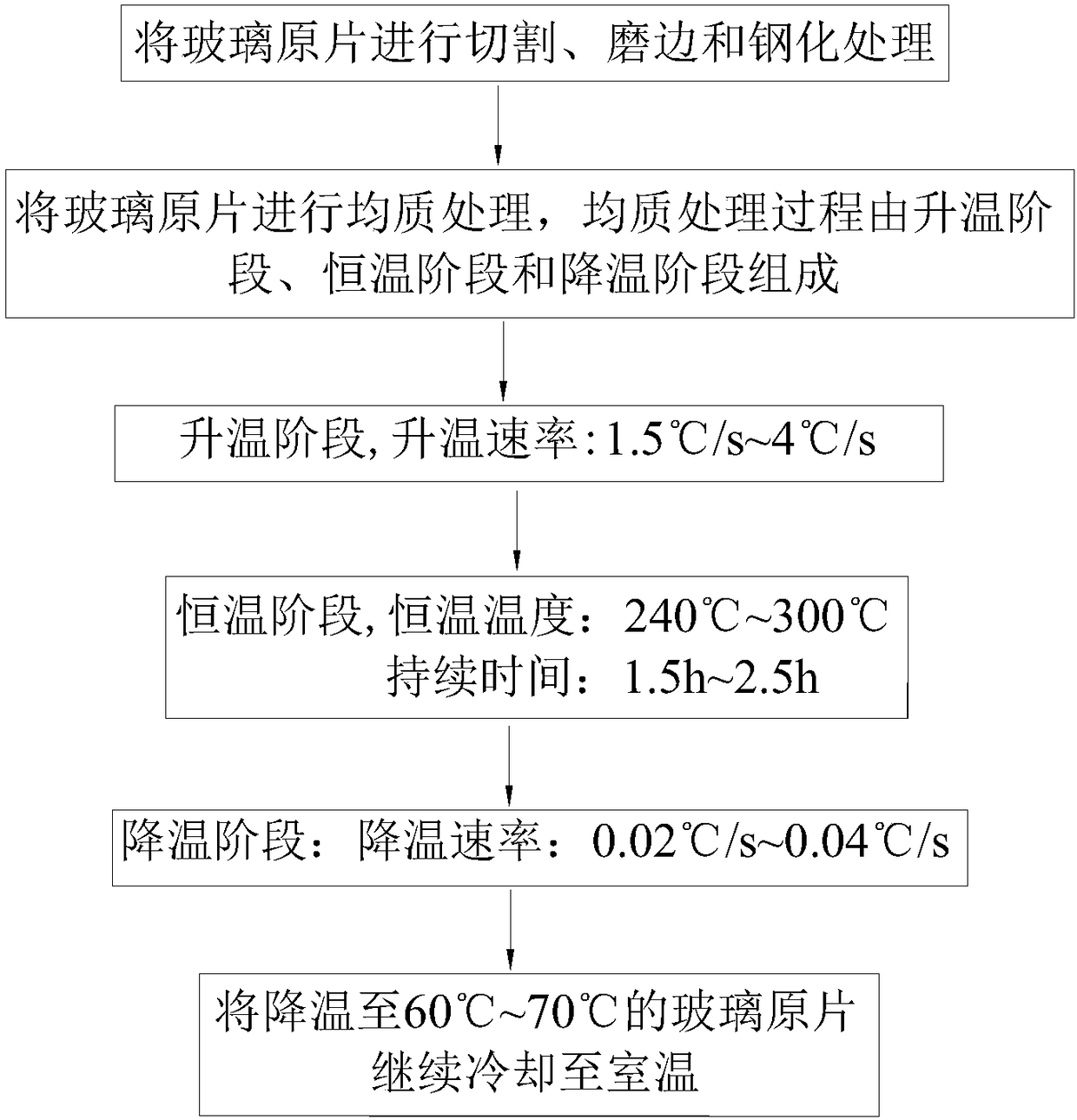

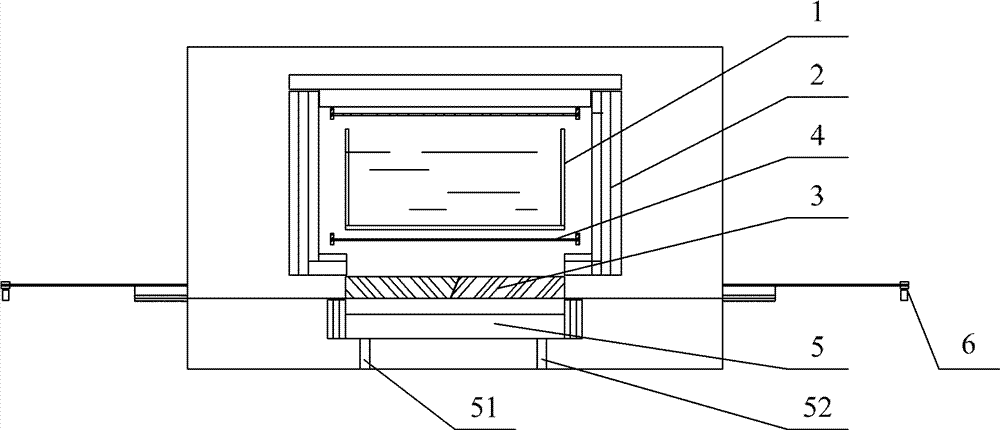

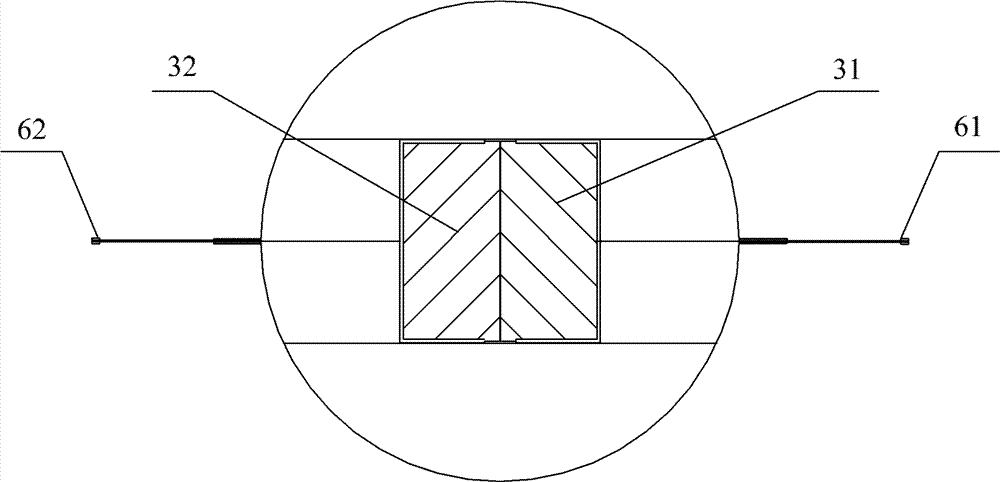

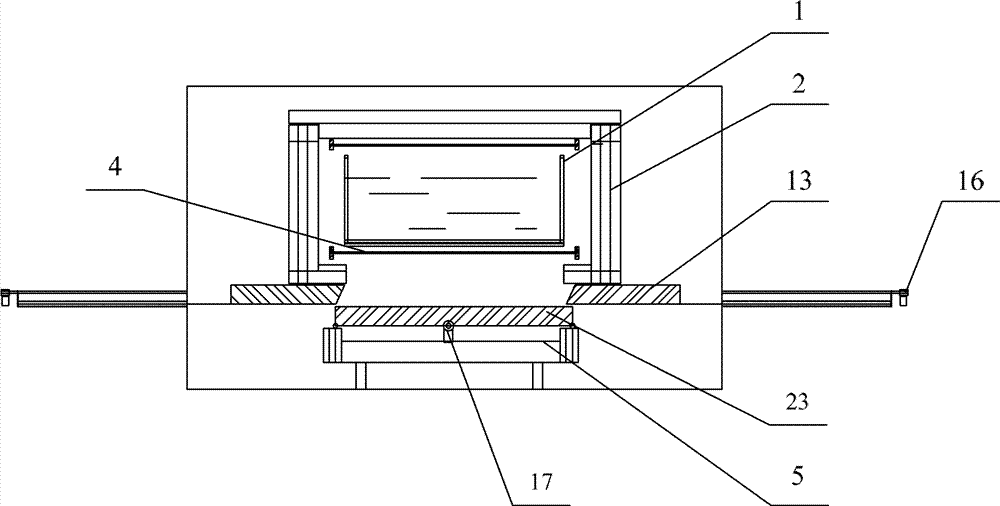

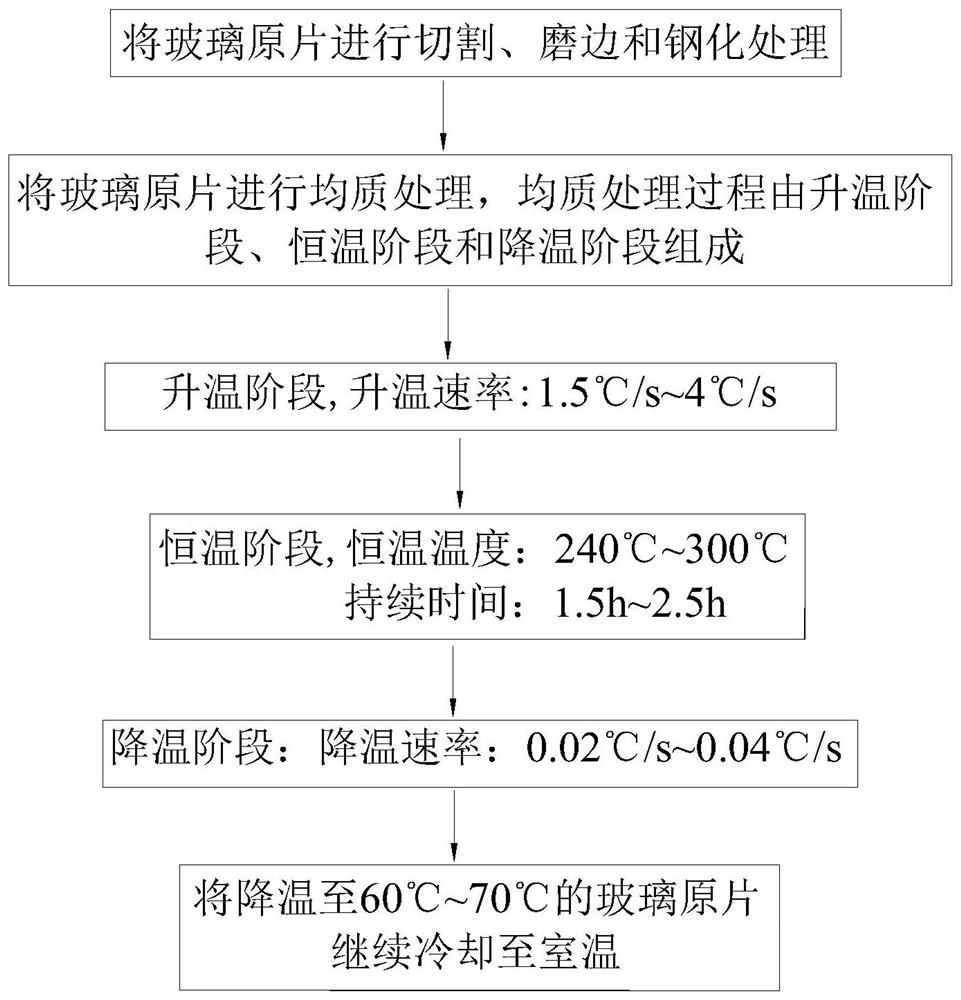

Homogenization processing method for tempered glass and tempered glass

ActiveCN108328913AQuality assuranceControl temperature gradientGlass tempering apparatusRoom temperatureToughened glass

The invention belongs to the technical field of tempered glass preparation methods, and particularly relates to a homogenization processing method for tempered glass and the tempered glass. The homogenization processing method for the tempered glass comprises the following steps: S1: providing a glass original sheet, and performing the cutting, edging and toughening treatment on the glass originalsheet; S2: performing the homogenization treatment on the glass original sheet, wherein a homogenization treatment process is formed by a temperature rising stage, a constant temperature stage and atemperature reducing stage; S3: setting a temperature rising rate in the temperature rising stage as 1.5 DEG C / s to 4 DEG C / s, setting a temperature in the constant temperature stage as 240 DEG C to 300 DEG C, wherein the duration time is 1.5 h to 2.5 h, and setting a temperature reducing rate in the temperature reducing stage as 0.02 DEG C / s to 0.04 DEG C / s; and S4: moving out the glass originalsheet of which the temperature is reduced to 60 DEG C to 70 DEG C from a homogenizing furnace and continuously cooling to a room temperature. The above method is capable of, through accurately limiting homogenization treatment technological parameters, effectively controlling a temperature gradient in the homogenizing furnace, and guaranteeing the quality of the tempered glass after the homogenization treatment.

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

Single crystal growth device and method

InactiveCN103710741APrevent cracks or breaksAvoid deformationPolycrystalline material growthSemiconductor/solid-state device manufacturingChemistrySingle crystal growth

The invention provides a single crystal growth device and a method. The temperature gradient in the crucible can be accurately and actively controlled, and by strengthening the structure of the vacuum chamber, the deformation after the long-time use can be prevented, and therefore the residual stress of the single crystal in the length direction during the single crystal growth can be reduced to the greatest extent, the cracks or the breaking can be prevented, and the single crystal growth diameter can be increased. The single crystal growth device comprises a crucible 30 capable of moving upwardly and downwardly in a chamber 10, a side part heating device 22 disposed on the side of the crucible 30, a lower heater 24 disposed on the lower part of the crucible 30, a cooling rod 40 capable of penetrating the chamber10 and the lower heater 24 to reach the crucible 30, and capable of moving upwardly and downwardly, a driving unit 50 used for driving the cooling rod 40, and a power distribution device capable of controlling the heating conditions of the side heater 22 and the lower heater 24, and the up-down moving condition of the cooling rod 40.

Owner:BIAM

Dual-power adaptive control technology applied to polycrystalline silicon ingot casting

InactiveCN103541002AImprove photoelectric conversion efficiencyReduce lossPolycrystalline material growthSingle crystal growth detailsMetallurgyTransformer

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

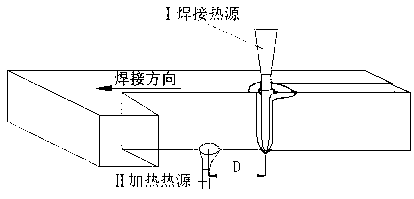

Welding deformation and joint quality control method

InactiveCN110340559AControl temperature gradientImprove welding stress stateWelding/cutting auxillary devicesAuxillary welding devicesThick plateQuality control

The invention discloses a welding deformation and joint quality control method. At present, the invention relates to the field of great equipment manufacturing, the welding of the metal material component with the large surface and the long welding line is limited due to the fact that the weight or the size of the component is greatly limited, or is limited by the structural form of a welding joint, so that the problems that the welding deformation of the component is large, and the welding joint easily has defects such as cracks and air holes are solved. According to the welding deformation and joint quality control method, a heating heat source is additionally arranged on the back surface of a welding heat source, the back heating heat source can offset or reduce welding deformation caused in the welding process, meanwhile, the heat source is arranged at the front part of the welding heat source, so that the preheating effect is achieved, welding defects such as cracks, air holes andthe like during welding of high-strength, crack-sensitive materials and thick plate materials can be greatly reduced, so that good welding quality is obtained. The welding deformation and joint quality control method is applied to welding deformation and joint quality control methods.

Owner:哈尔滨现代焊接技术有限公司

Polycrystalline ingot furnace and its hot door device

InactiveCN102828228AEffective growth controlReduce consumptionPolycrystalline material growthFrom frozen solutionsThermal energyEngineering

The invention discloses a hot door device which comprises: a first hot door apparatus which is provided with at least two oppositely-arranged first door bodies; a first drive unit which is used to drive each first door body to move towards each other or away from each other; a second hot door apparatus which is arranged on the downside of the first hot door apparatus and is provided with at least two oppositely-arranged second door bodies, wherein there is an included angle between the opening direction of the second hot door apparatus and the opening direction of the first hot door apparatus; and a second drive unit which is used to drive each second door body to move towards each other or away from each other. Through at least two split-level hot door apparatuses, when the two hot door apparatuses simultaneously open, an opening area gradually expands from the center to the periphery so as to form a temperature conducting area, opening degree of which can be controlled. Therefore, crystal growth more accords with technological requirements. By the adoption of the hot door device, temperature gradient of a crystal growth area is effectively controlled, temperature radiation quantity is controlled, consumption of heat energy is minimized, and the purpose of saving electric energy is achieved. The invention also discloses a polycrystalline ingot furnace with the above hot door device.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

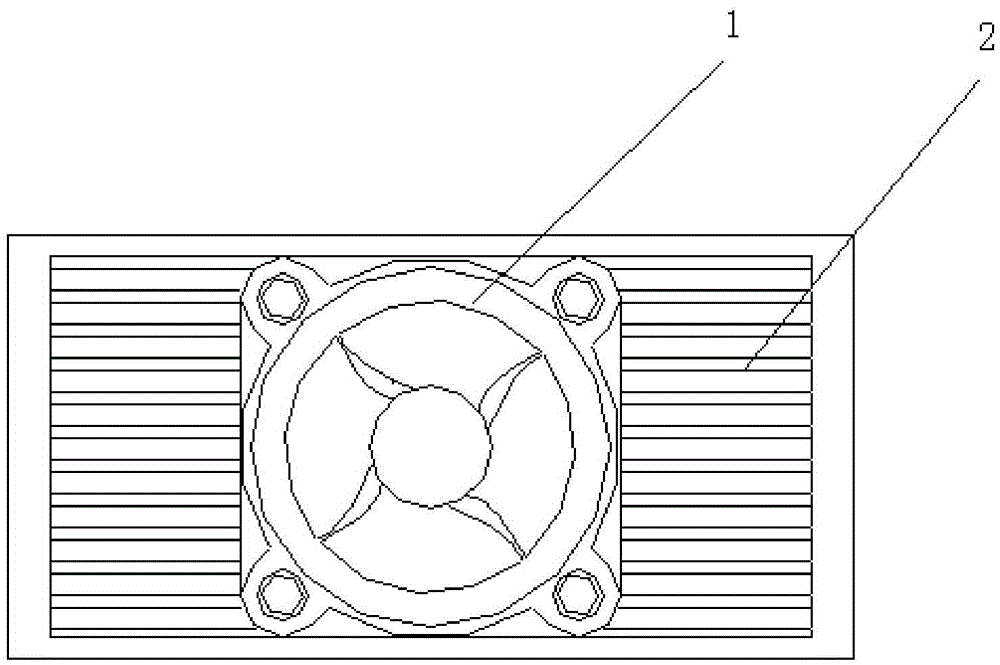

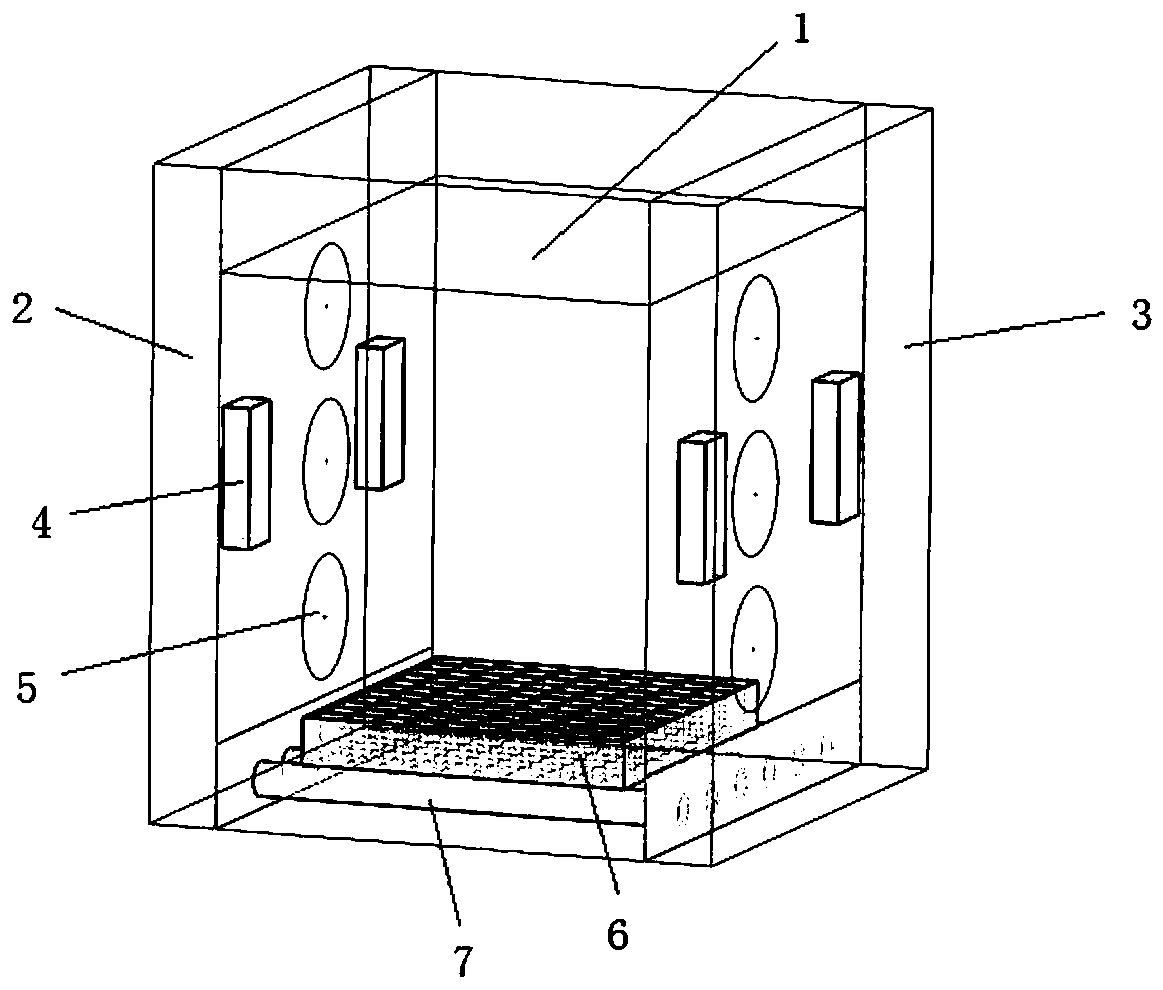

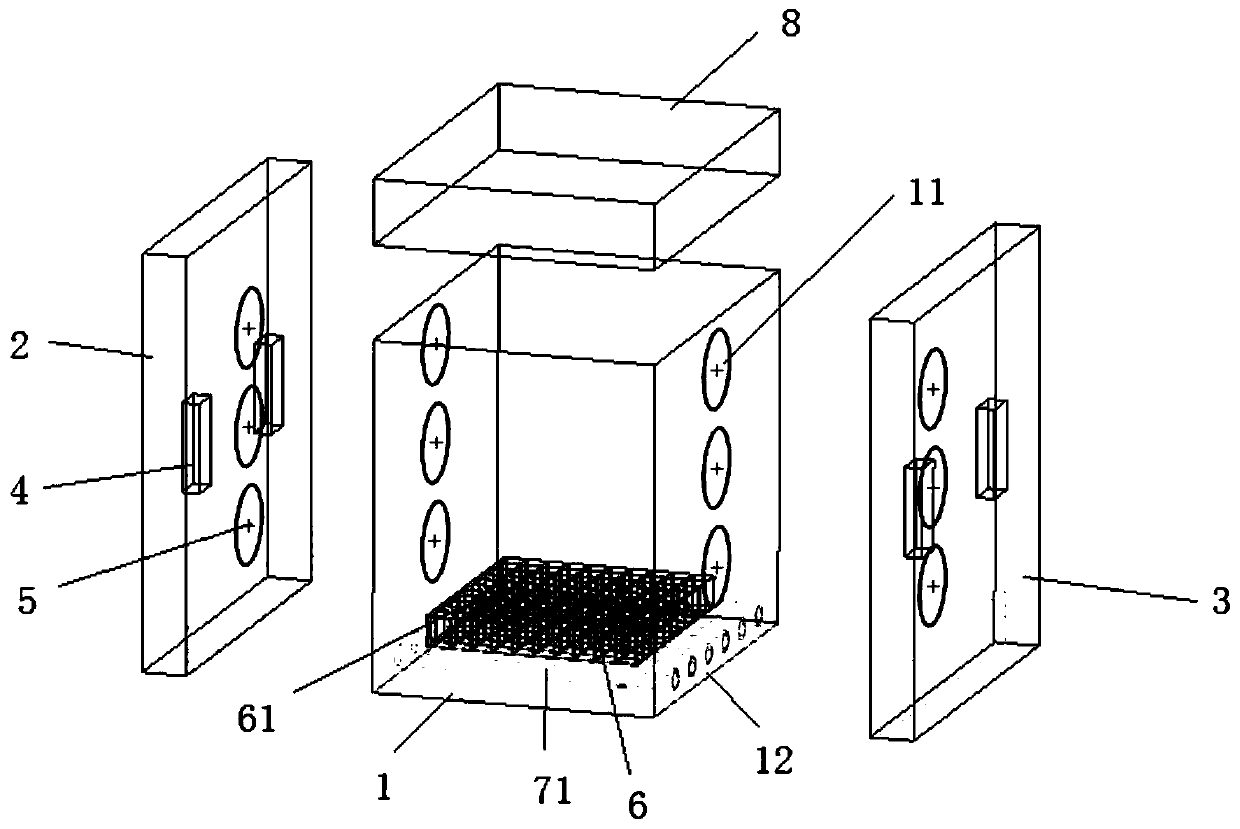

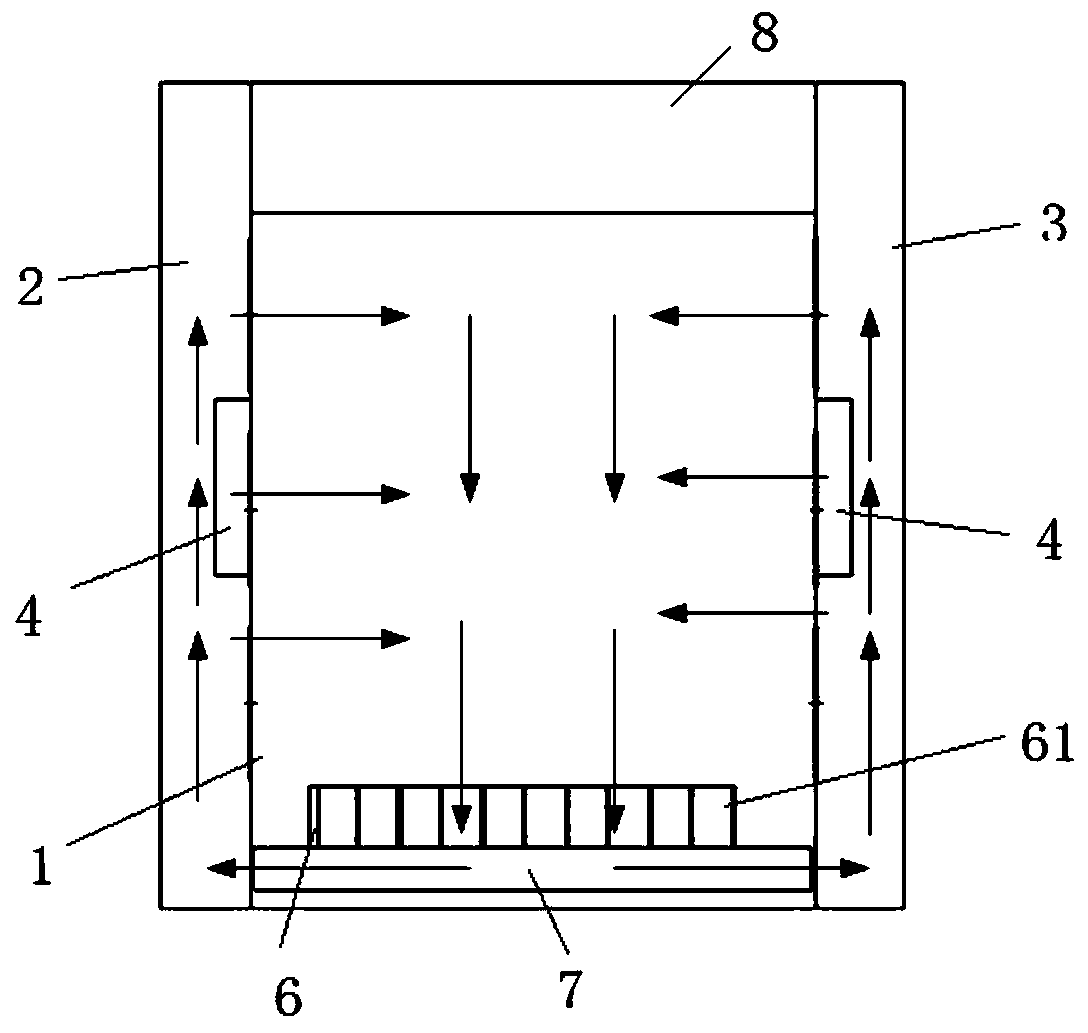

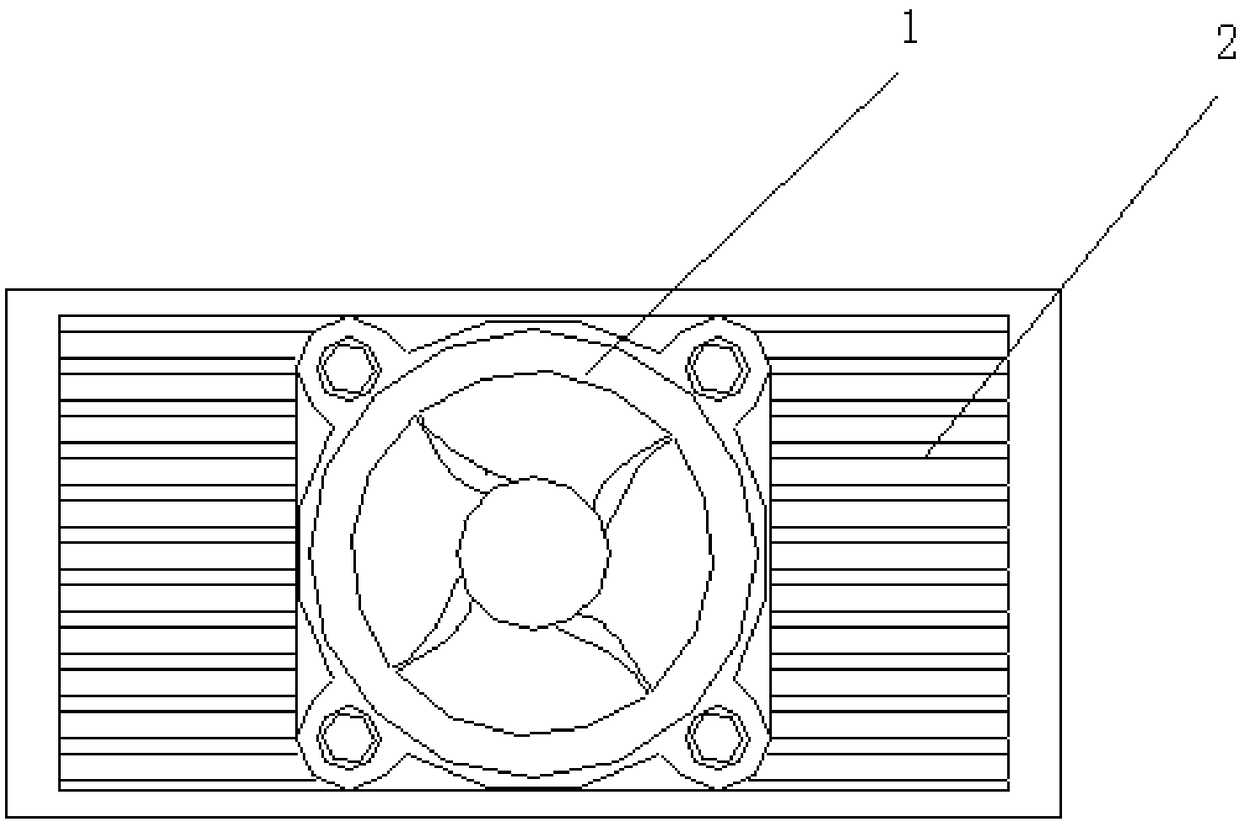

Air-heated internal circulation oven for insulator curing

InactiveCN110459372ASimple structureAchieve temperature controlInsulatorsTemperature controlEngineering

The invention relates to an air-heated internal circulation oven for insulator curing, which comprises a box body. The left and right sides of the box body are provided with a left air duct plate anda right air duct plate which are hollow internally; the left air duct plate and the right air duct plate are internally provided with heating devices and fans; the box body is provided with an air inlet hole corresponding to the fan; the bottom of the box body is provided with a rolling mechanism and a base placed on the rolling mechanism for mounting an insulator mold; and the lower end of the box body is provided with an air outlet communicated with the left air duct plate and the right air duct plate. According to the air-heated internal circulation oven for insulator curing disclosed in the invention, the structure is simple, temperature control in the box body can be realized conveniently, and due to the symmetrical fan design, hot air is blown to the insulator mold at different windspeeds to achieve control on the temperature gradient.

Owner:HEFEI UNIV OF TECH +3

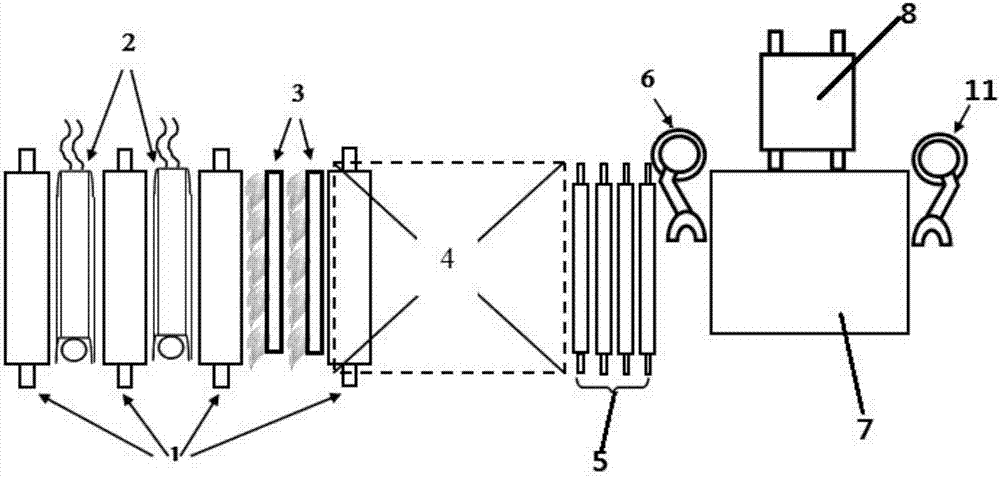

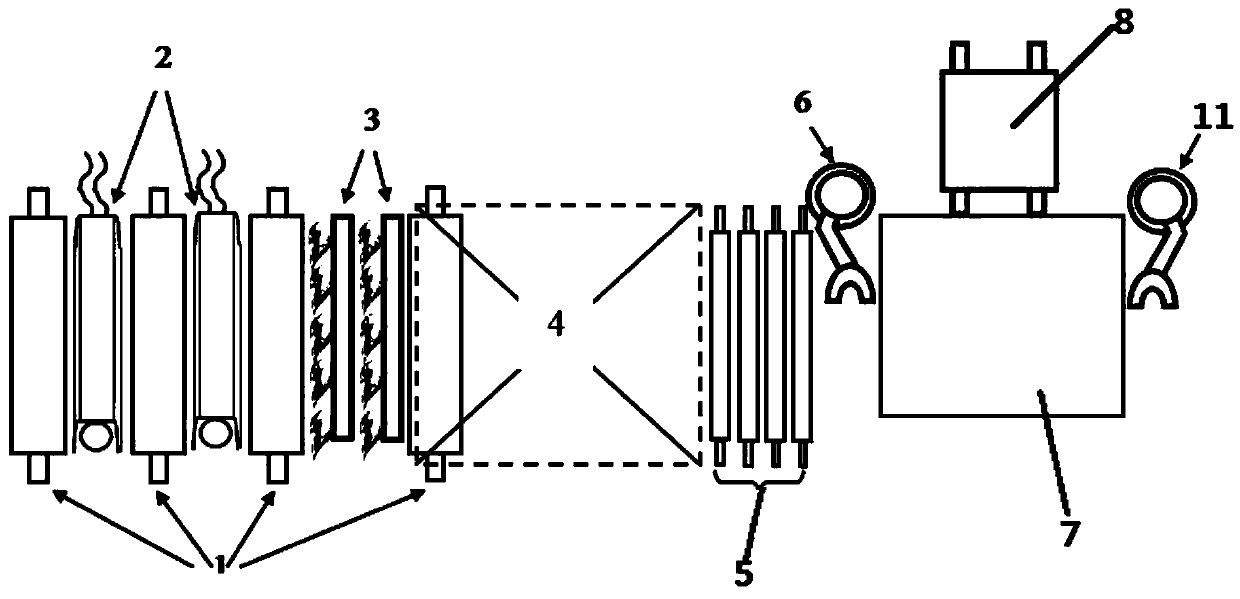

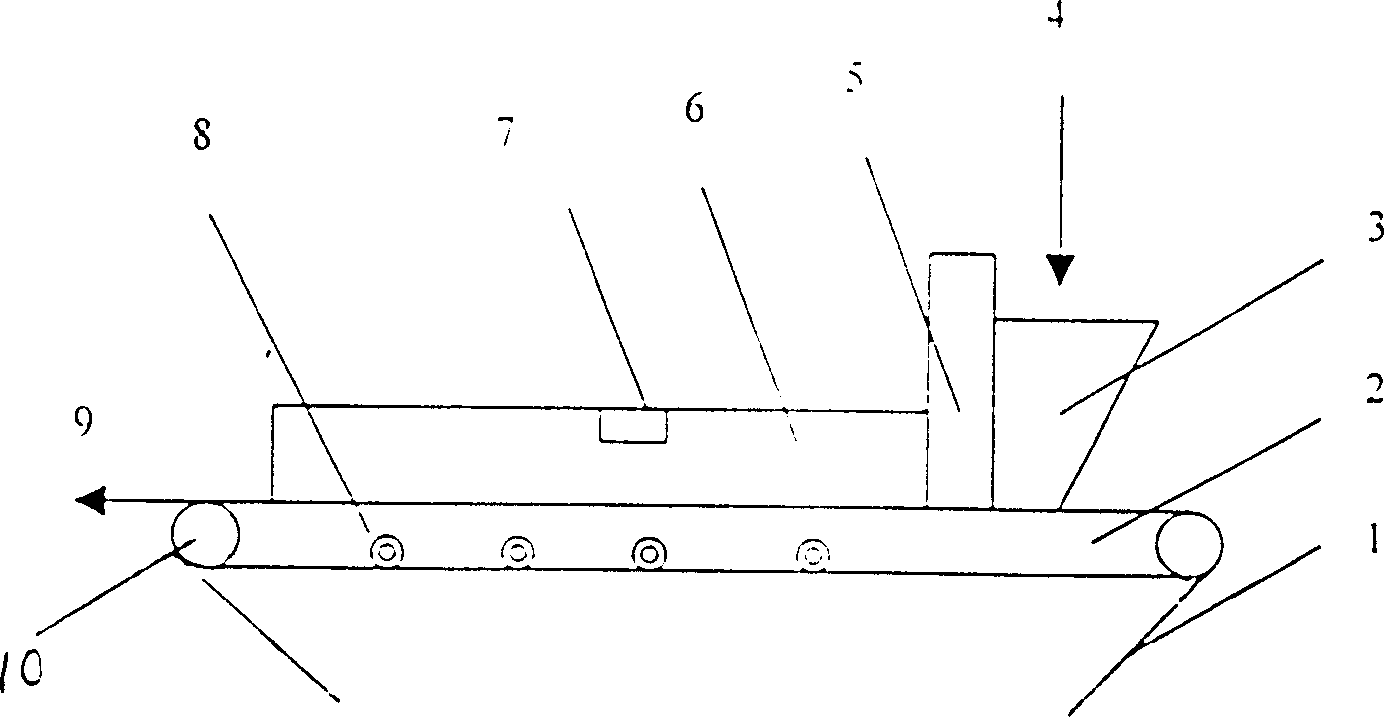

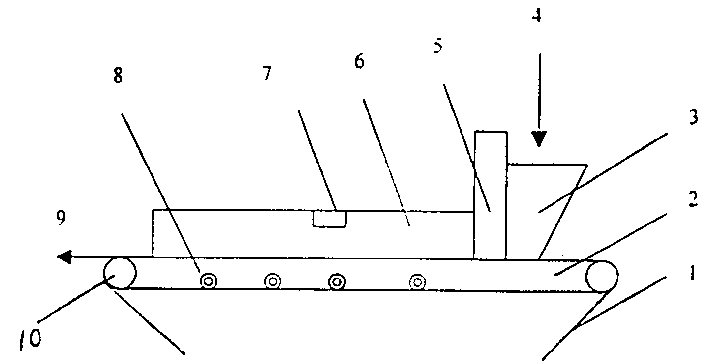

Short-process hot stamping forming production line equipment and production technology thereof

ActiveCN106944555ASmall footprintReduce heatingShaping toolsMetal-working feeding devicesProduction lineHot stamping

The invention discloses short-process hot stamping forming production line equipment and a production technology thereof. The production line equipment comprises a ceramic pinch roller set, a roller hearth furnace, a conveying roller set, a feeding robot, a hydraulic machine system and a discharging robot which are sequentially arranged from the feeding direction to the discharging direction. Rapid heating devices are arranged between adjacent ceramic pinch rollers in the ceramic pinch roller set. The production technology includes the steps that a blank is put on the ceramic pinch rollers and then conveyed along with the ceramic pinch rollers, and the rapid heating devices are used for rapidly heating and the warming the blank; and afterwards, the blank enters the roller hearth furnace to be heated, and the heated blank is pinched to a mold station of the hydraulic machine system through the feeding robot for hot stamping forming. According to the short-process hot stamping forming production line equipment and the production technology thereof, the mode of combining rapid heating with roller hearth furnace heating is adopted, through the rapid warming means of the rapid heating devices, the technical purpose of shortening the heating process of the blank is achieved, the floor area of the roller hearth furnace is decreased, and the manufacturing cost of heating equipment is reduced.

Owner:东营布鲁特新材料有限公司

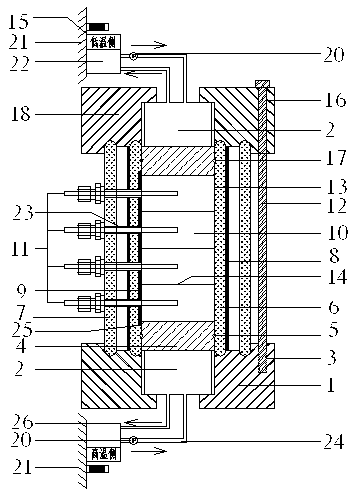

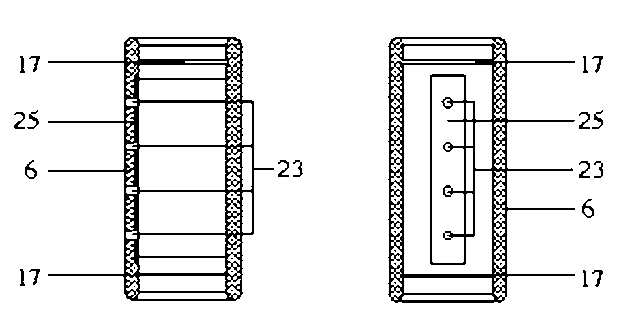

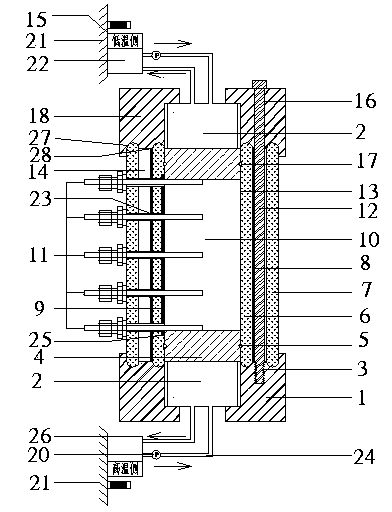

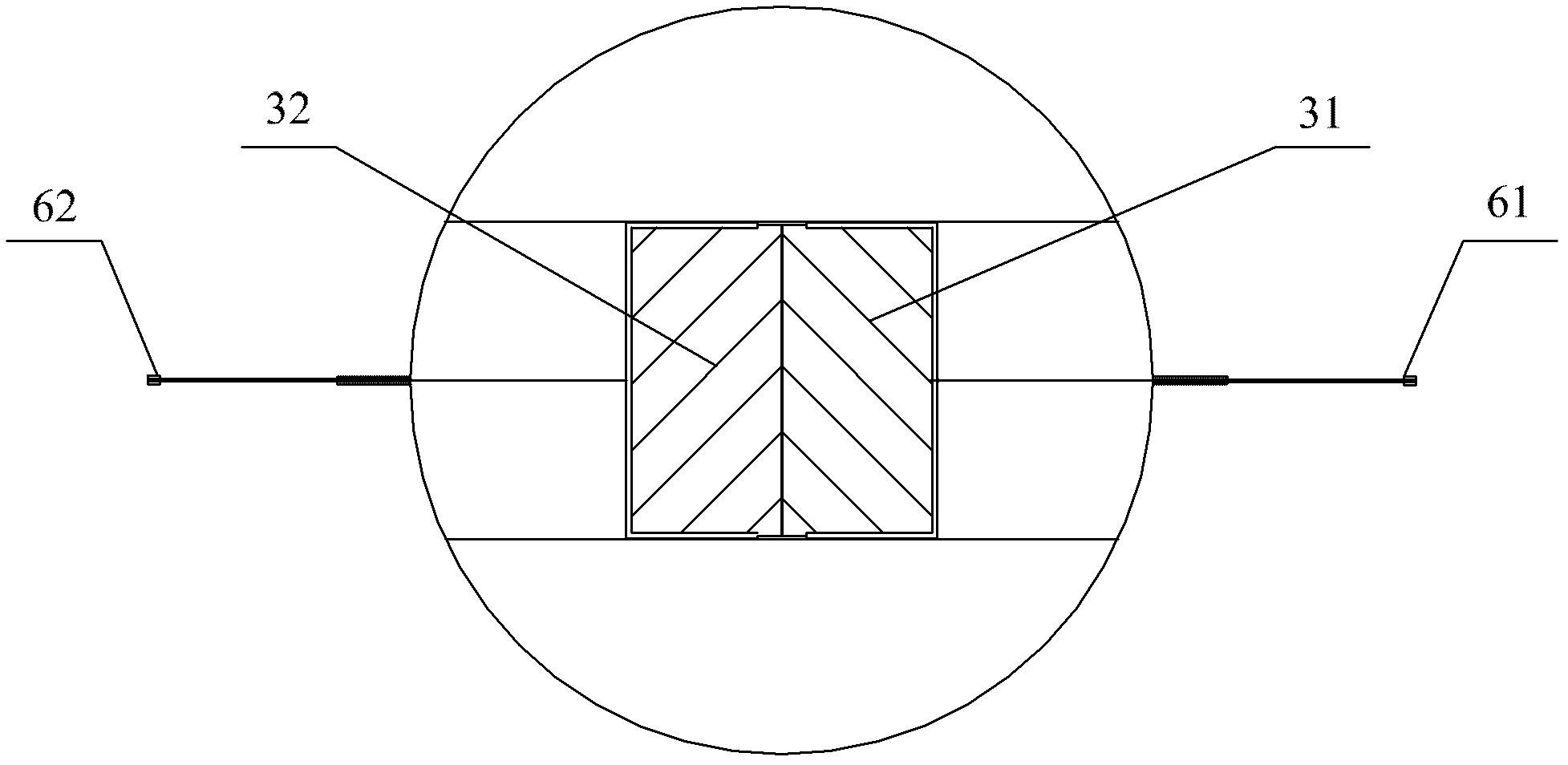

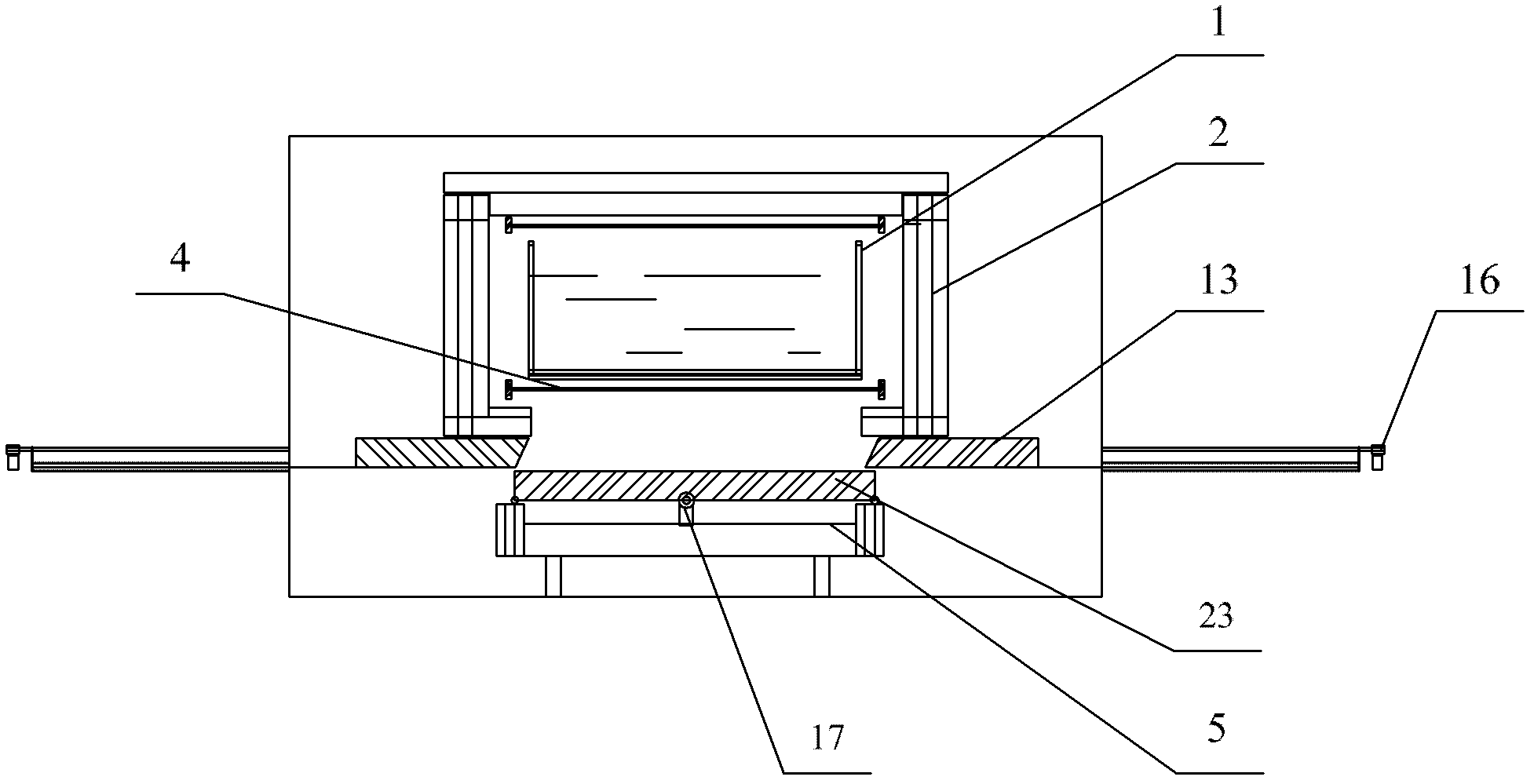

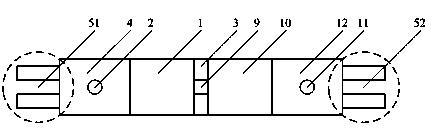

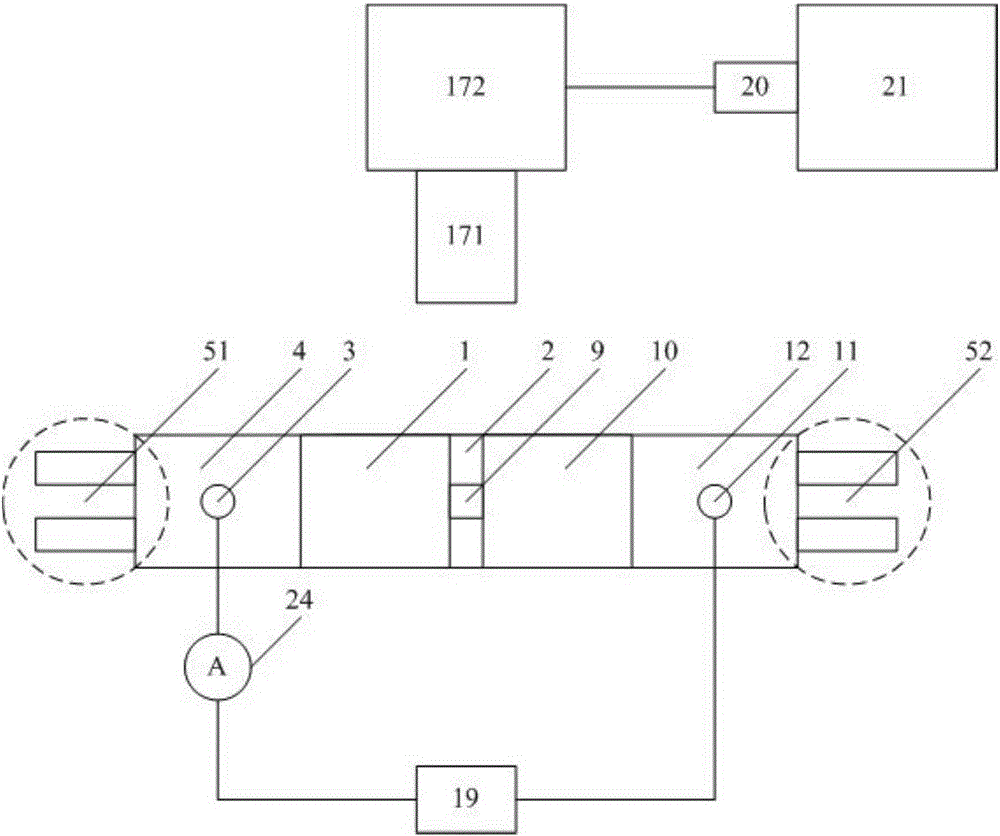

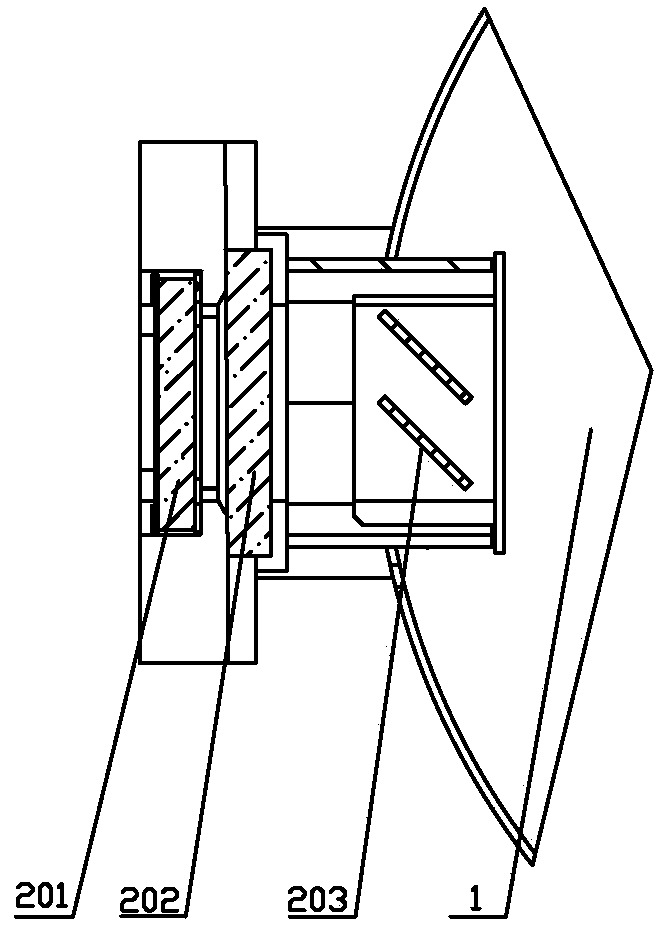

Peritectic alloy-like analogue directional solidification crystallizer suitable for working under function of current

ActiveCN103510152AGuaranteed tightnessSolve real-timePolycrystalline material growthFrom frozen solutionsPower flowSilica gel

The invention provides a peritectic alloy-like analogue directional solidification crystallizer suitable for working under the function of current and belongs to an experimental apparatus for peritectic alloy-like analogue directional solidification under the function of current. A melting-zone hot-end red copper heat-transfer plate and a melting-zone cold-end red copper heat-transfer plate are connected through glass sheets which are bonded with silica gel, so that the leak tightness of a melting zone is guaranteed to facilitate the formation of a stable temperature gradient GT at two ends of the melting zone, and the lateral heat dissipation is avoided. Besides, compared with the crystallizers manufactured by mechanical connection in the prior art, the crystallizer can control the temperature gradient in the directional solidification process more accurately, and provides the support for the experiment and real-time observation on directional solidification of high-melting point peritectic alloy-like analogues under the function of current.

Owner:HARBIN INST OF TECH

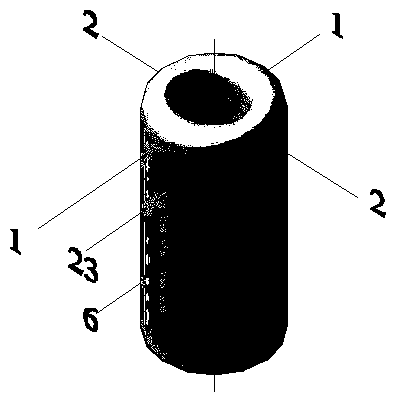

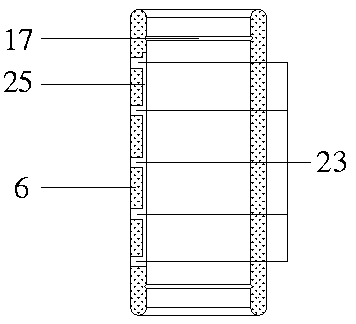

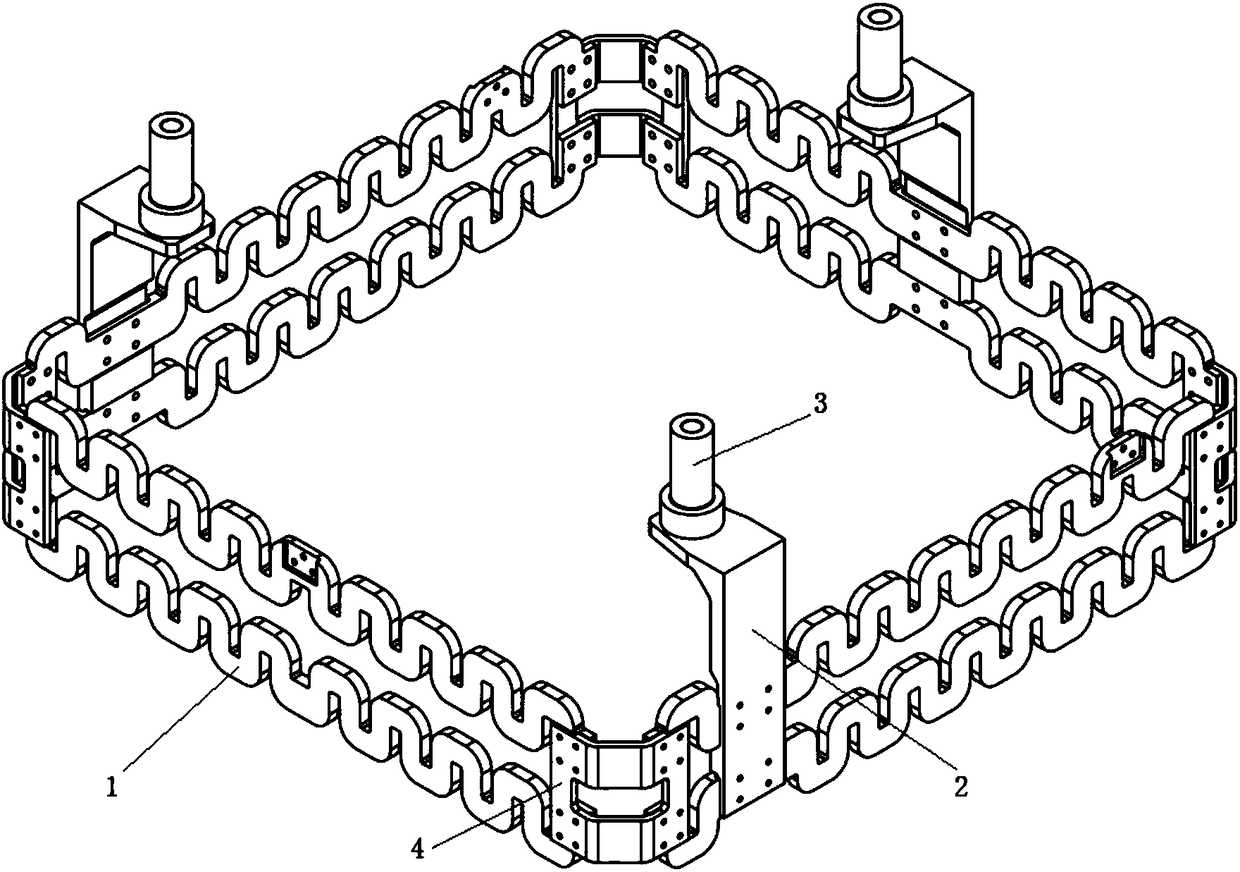

Graphite side heater of layered serpentine polycrystalline silicon ingot furnace

PendingCN108221048AEnhanced convectionImprove flatnessPolycrystalline material growthSingle crystal growth detailsOptoelectronicsIngot

The invention discloses a graphite side heater of a layered serpentine polycrystalline silicon ingot furnace, and relates to the technical field of photovoltaic equipment ingot. The graphite side heater comprises 8 side heater monomers, 3 lifting arms, 3 electrodes and 4 corner connecting plates. The side heater monomers are serpentine, an upper layer side heater comprises four side heater monomers, a lower layer side heater comprises four side heater monomers, the lower middle sections of the lifting arms are connected with the upper layer side heater and the lower layer side heater, so thatthe upper layer side heater and the lower layer side heater are connected in parallel, the lifting arms divide the side heater into equal three phases, the electrodes are connected with the top ends of the lifting arms, and the corner connecting plates connect the upper layer side heater monomers and the lower layer side heater monomers, and connect left-right adjacent side heater monomers in eachsame layer. The graphite side heater is designed as an in-parallel upper-lower two-layer structure, the resistance of the side heater can be effectively reduced, the peak power of the side heater canbe improved, and double requirements of G8 and a larger size ingot furnace on the power and the thickness of the graphite side heater can be balanced.

Owner:江苏美科太阳能科技股份有限公司

Glass hot bending mold and glass hot bending method

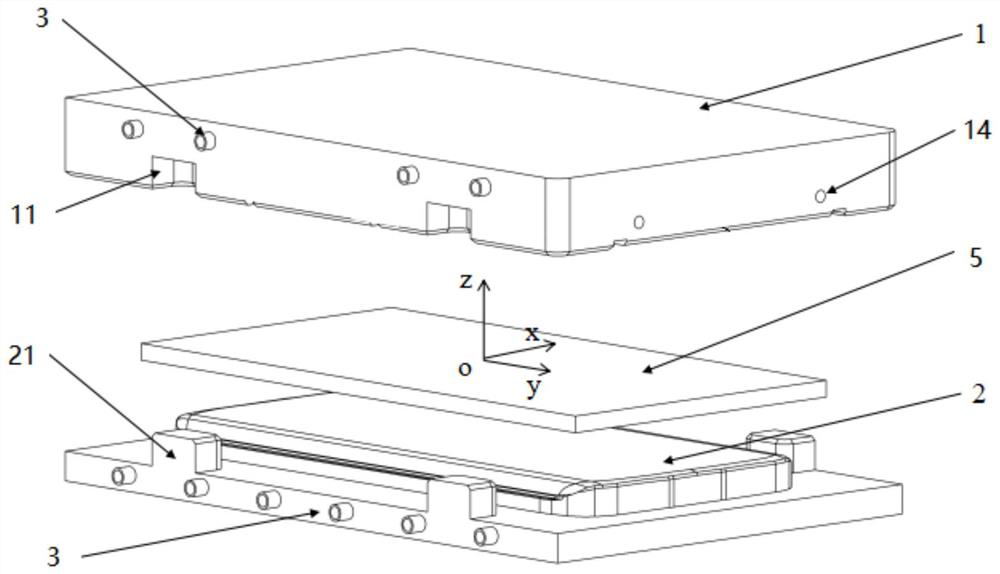

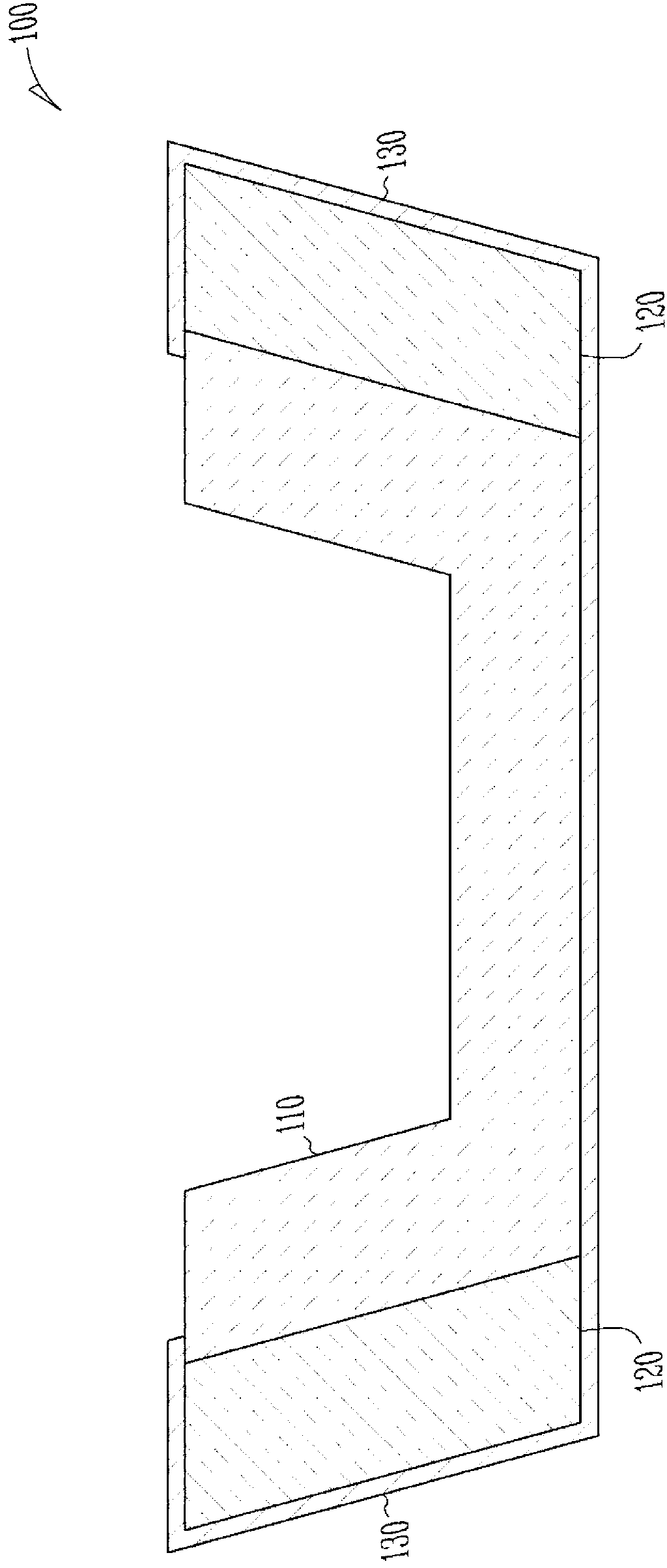

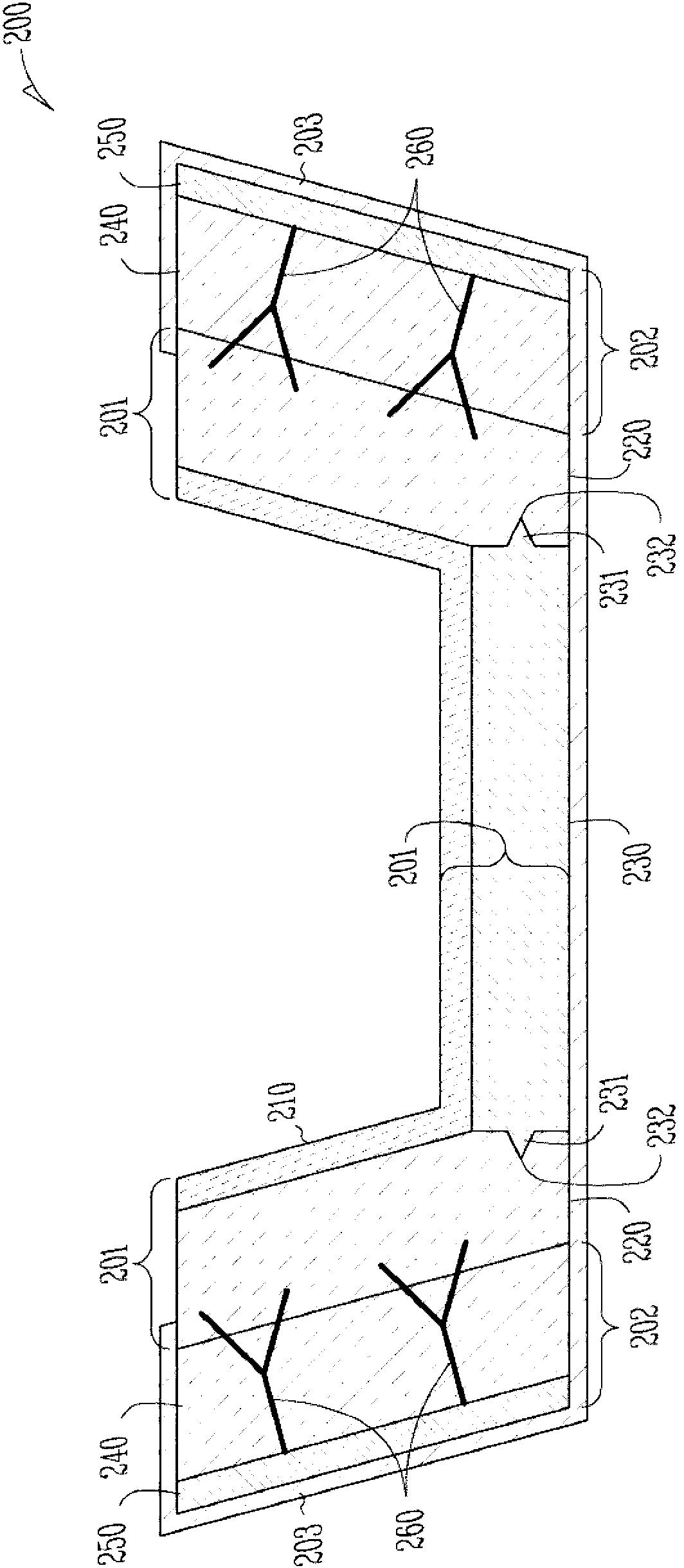

PendingCN114212979AUniform temperature distributionEliminate temperature gradientsGlass reforming apparatusGlass productionComposite materialTemperature control

The invention belongs to the technical field of glass processing molds, and particularly relates to a glass hot bending mold and a glass hot bending method. The glass hot bending mold comprises a mold body, and the mold body comprises an upper mold and a lower mold; the upper mold and the lower mold are closed to form a sealing cavity; the upper mold and the lower mold respectively comprise a plurality of groups of mutually independent temperature control assemblies; the temperature control assembly comprises an air supply device and a micro-channel arranged in the upper mold or the lower mold; and the gas supply device is connected with the micro-channel and is used for supplying gas for adjusting the temperature into the micro-channel. The glass hot bending mold provided by the invention can eliminate the temperature gradient of the glass blank due to non-uniform heat transfer of the mold in the hot bending process.

Owner:GUANGDONG HUST IND TECH RES INST

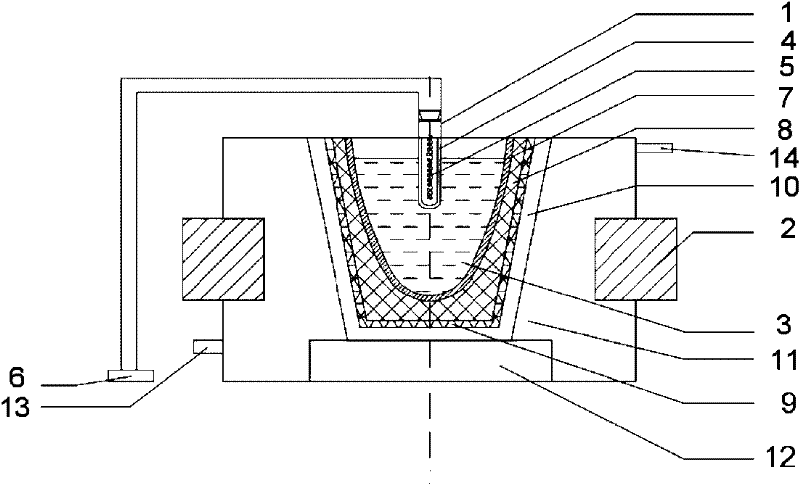

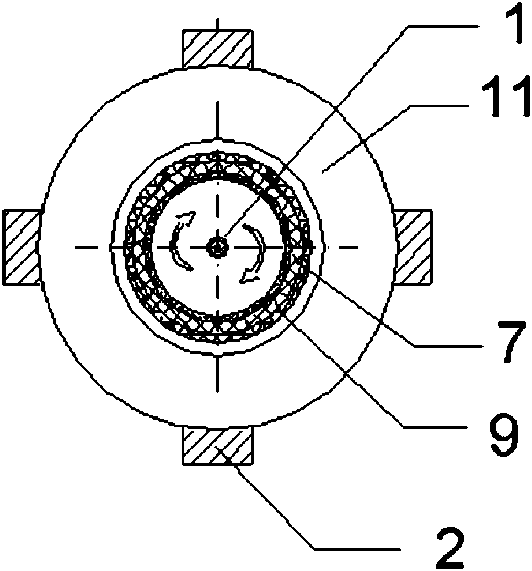

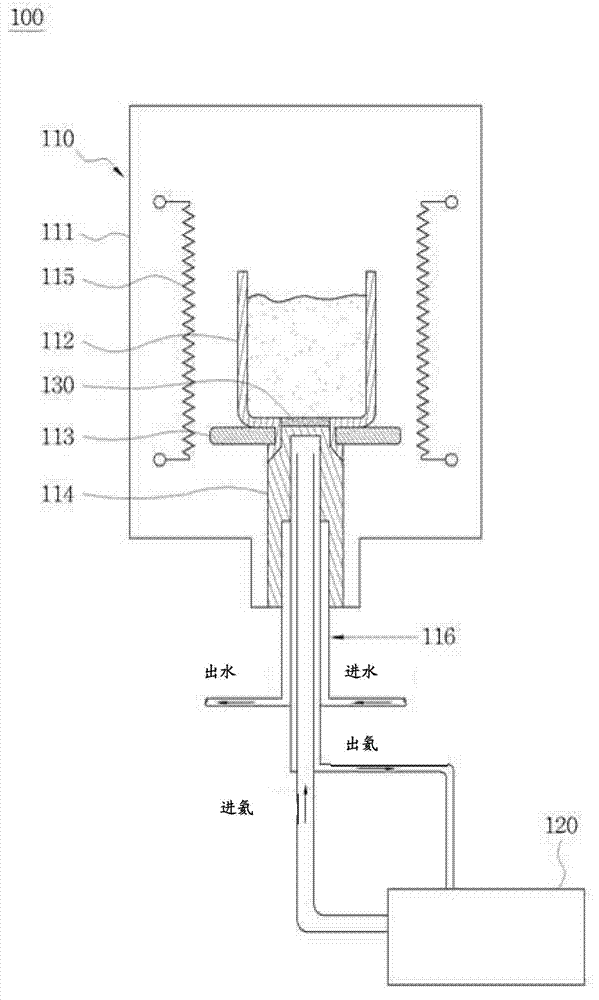

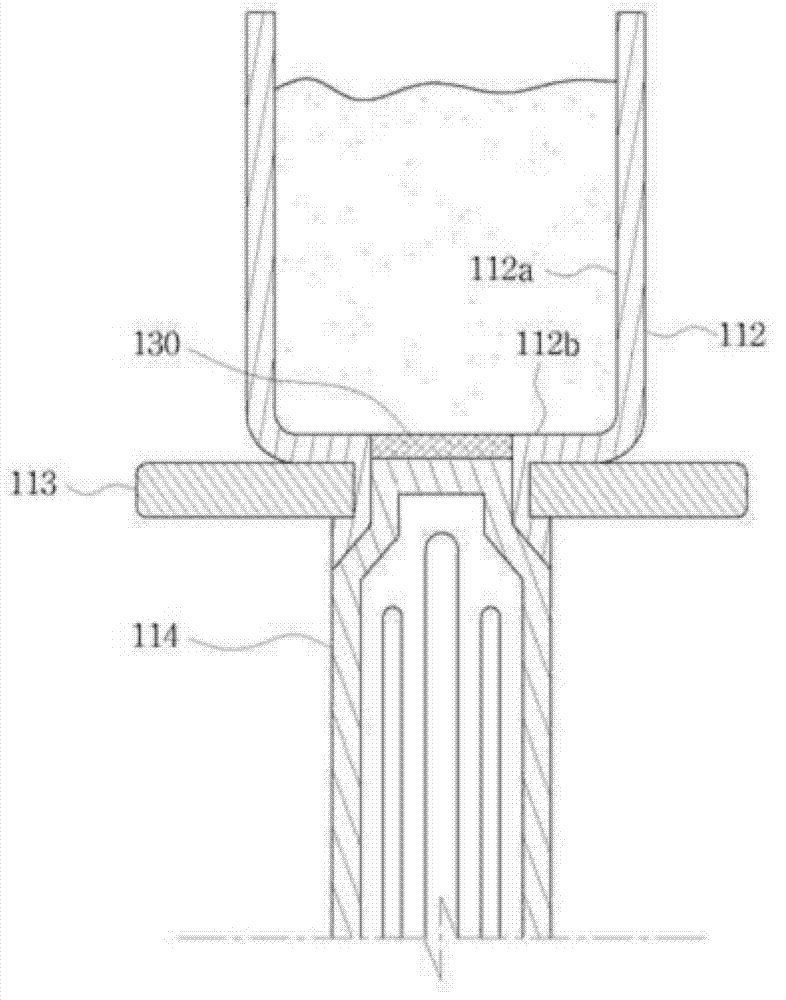

Apparatus and method for directional solidification of silicon

ActiveCN103261493AGuaranteed temperatureControlled coolingPolycrystalline material growthFrom frozen solutionsDirectional solidificationSolar cell

The present invention relates to an apparatus and method for purifying silicon using directional solidification. The apparatus can be used more than once for the directional solidification of silicon without failure. The apparatus and method of the present invention can be used to make silicon crystals for use in solar cells.

Owner:SILICOR MATERIALS INC

Device and method for testing soil deformation and moisture migration characteristics under temperature gradient

ActiveCN103344748BAvoid disturbanceAvoid hysteresisEarth material testingWater bathsTemperature control

The invention discloses a device and method for testing deformation and water transfer characteristics of a soil body under a temperature gradient effect. The device comprises a sample chamber, a temperature gradient control device and a temperature and water content collecting device, wherein the sample chamber comprises an dual-layer hollow organic glass interlayer sleeve and a cover plate; a high-temperature control device and a low-temperature control device are arranged at the upper end and the lower end of the temperature gradient control device respectively, and the temperature gradient control device comprises a constant-temperature water bath, a heating chamber inside the sample chamber, heat transfer plates at two ends of a sample, and a full-closed circulating pipeline. The device for testing the water and temperature of the soil body can be used for testing the water content and the temperature of the soil body synchronously in real time. The device provided by the invention is convenient, simple and light in design, convenient to operate, good in integration performance, and high in testing precision.

Owner:SHANGHAI UNIV

Polycrystalline ingot furnace and its hot door device

InactiveCN102828228BEffective growth controlReduce consumptionPolycrystalline material growthFrom frozen solutionsEngineeringCrystal growth

The invention discloses a hot door device which comprises: a first hot door apparatus which is provided with at least two oppositely-arranged first door bodies; a first drive unit which is used to drive each first door body to move towards each other or away from each other; a second hot door apparatus which is arranged on the downside of the first hot door apparatus and is provided with at least two oppositely-arranged second door bodies, wherein there is an included angle between the opening direction of the second hot door apparatus and the opening direction of the first hot door apparatus; and a second drive unit which is used to drive each second door body to move towards each other or away from each other. Through at least two split-level hot door apparatuses, when the two hot door apparatuses simultaneously open, an opening area gradually expands from the center to the periphery so as to form a temperature conducting area, opening degree of which can be controlled. Therefore, crystal growth more accords with technological requirements. By the adoption of the hot door device, temperature gradient of a crystal growth area is effectively controlled, temperature radiation quantity is controlled, consumption of heat energy is minimized, and the purpose of saving electric energy is achieved. The invention also discloses a polycrystalline ingot furnace with the above hot door device.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Tempered glass homogeneous treatment method and tempered glass

ActiveCN108328913BQuality assuranceControl temperature gradientGlass tempering apparatusToughened glassCeramic materials

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

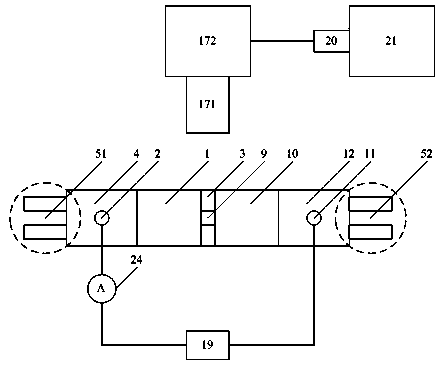

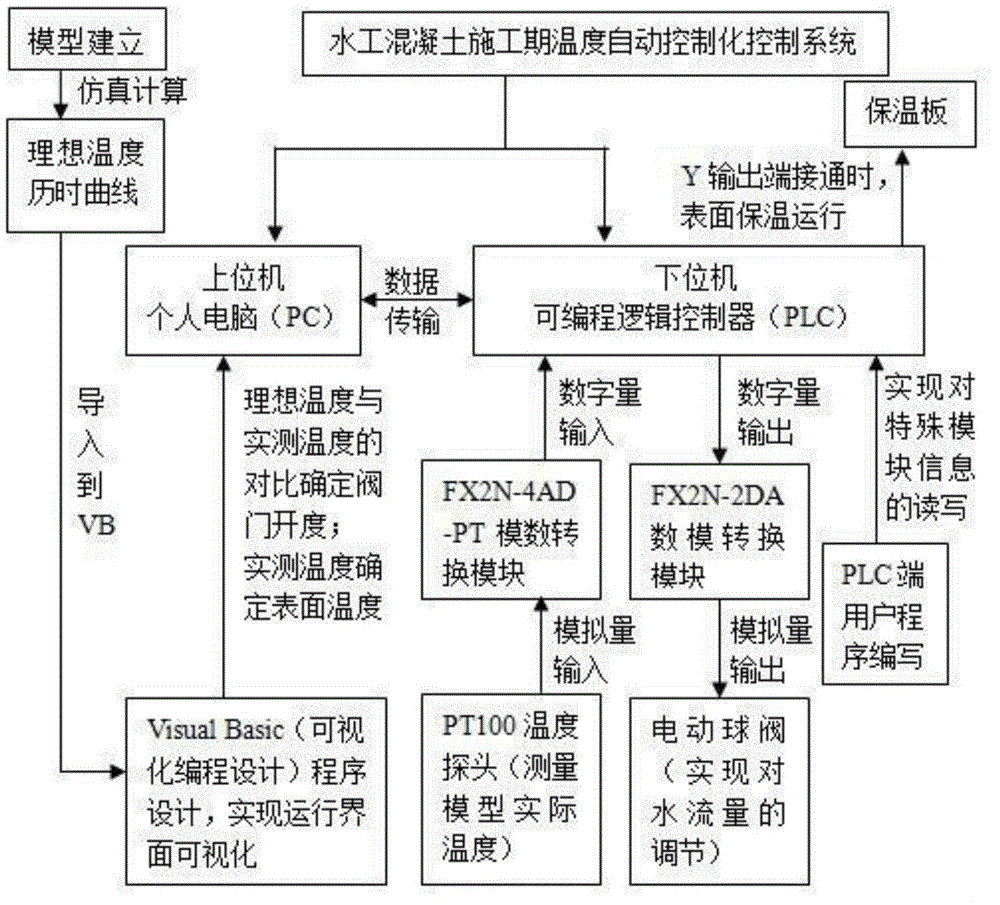

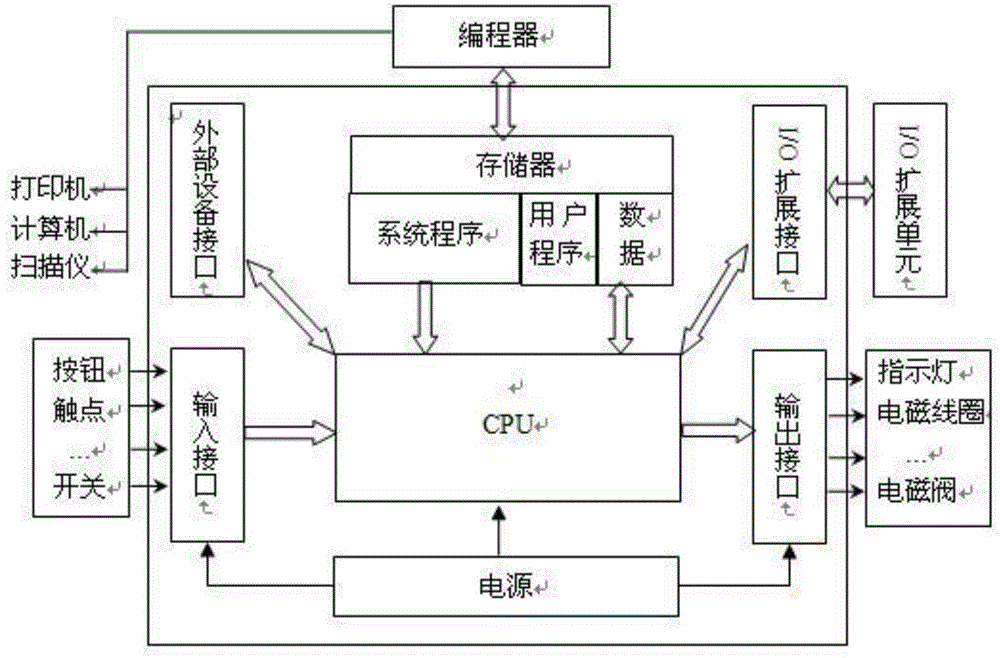

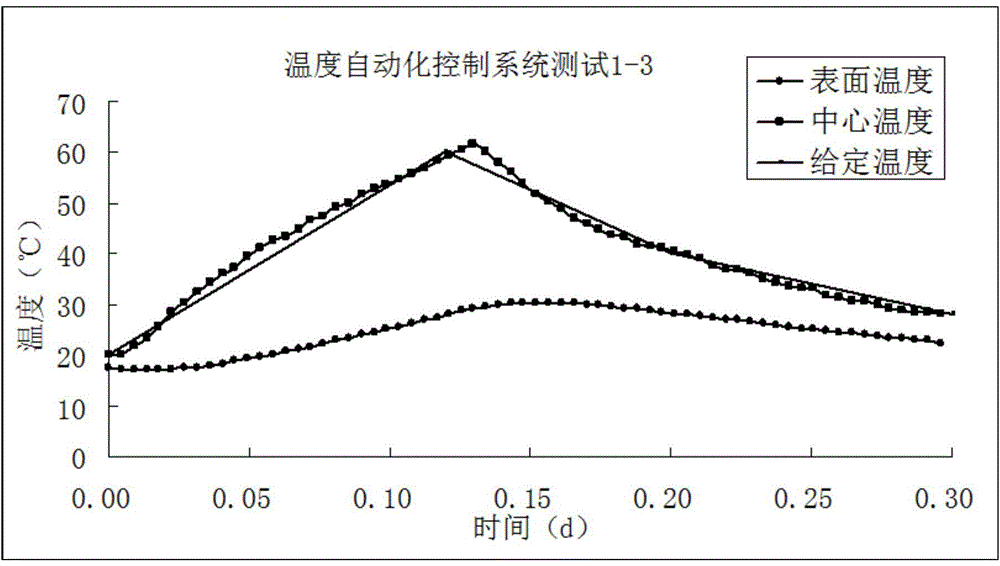

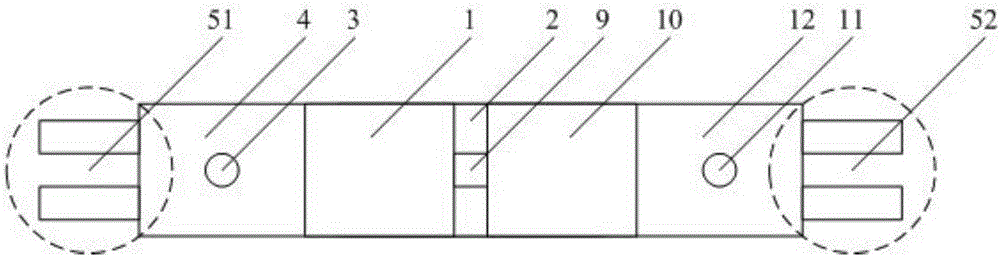

System for automatically controlling temperatures in concrete construction periods

InactiveCN104950937APrecise control of temperature gradientsAvoid it happening againHumidity controlInternal temperatureValve opening

The invention discloses a system for automatically controlling temperatures in concrete construction periods. The system is characterized in that detected actual temperature data are converted by the aid of an FX2N-4AD-PT analog-digital conversion module, then are transmitted a programmable logic controller by a temperature sensor and are transmitted to a personal computer by the programmable logic controller, measured temperature duration curves are compared to preliminarily given temperature duration curves by visual control system software in the personal computer, valve opening values can be obtained by means of feedback, are transmitted back to the programmable logic controller and then are converted into current signals by an FX2N-2AD digital-analog conversion module, and valve opening of electric ball valves can be controlled. The system has the advantages that the internal temperatures of concrete can be automatically developed along with the optimal temperature duration curves under the precise control of the system, temperatures of surface steel formworks can be controlled, and accordingly temperature gradient of concrete surface layers can be within set ranges under the precise control of the system.

Owner:HOHAI UNIV

A crystallizer suitable for directional solidification of peritectic alloy simulants under the action of electric current

ActiveCN103510152BGuaranteed tightnessSolve real-timePolycrystalline material growthFrom frozen solutionsCopperDirectional solidification

The invention provides a peritectic alloy-like analogue directional solidification crystallizer suitable for working under the function of current and belongs to an experimental apparatus for peritectic alloy-like analogue directional solidification under the function of current. A melting-zone hot-end red copper heat-transfer plate and a melting-zone cold-end red copper heat-transfer plate are connected through glass sheets which are bonded with silica gel, so that the leak tightness of a melting zone is guaranteed to facilitate the formation of a stable temperature gradient GT at two ends of the melting zone, and the lateral heat dissipation is avoided. Besides, compared with the crystallizers manufactured by mechanical connection in the prior art, the crystallizer can control the temperature gradient in the directional solidification process more accurately, and provides the support for the experiment and real-time observation on directional solidification of high-melting point peritectic alloy-like analogues under the function of current.

Owner:HARBIN INST OF TECH

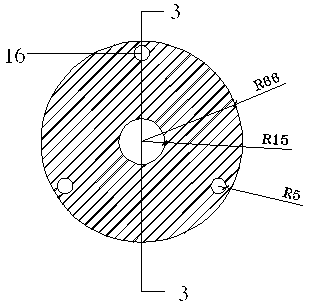

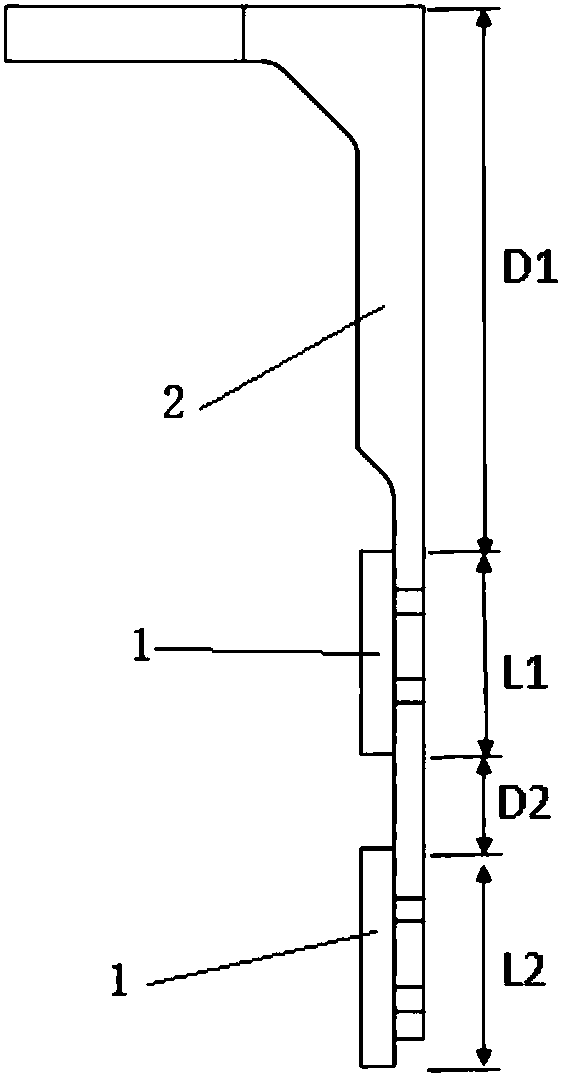

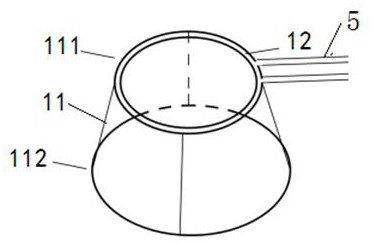

Method for drawing six-inch zone-melting silicon single crystal and used heat shield

PendingCN114574940ADissipate quicklyGuaranteed temperature gradientPolycrystalline material growthBy zone-melting liquidsPhysical chemistrySingle crystal

The invention relates to a method for drawing a six-inch zone-melting silicon single crystal and a heat shield used in the method. A heat shield is arranged at a position 40mm below a heating coil in a middle furnace chamber of the zone-melting single crystal furnace, the diameter of the upper edge of the heat shield is 90mm, the diameter of the lower edge of the heat shield is 215mm, the height of the heat shield is 40mm, and the pressure of cooling water in a condensation pipeline is 3.2 bar; when the procedures of shoulder expansion, shoulder rotation, equal diameter and ending are carried out, the silicon single crystal moves downwards along with the lower shaft and enters the heat shield area, heat reflected by the heat shield acts on the lower portion of the silicon single crystal, and the phenomenon that due to the fact that the temperature gradient is too large or too small, the silicon single crystal explodes or melts back, and crystal forming fails is avoided.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

A device and method for detecting thermal migration performance of interconnection solder joints

InactiveCN105606647BEasy to readThermal Migration Performance JudgmentMaterial heat developmentPreparing sample for investigationTemperature controlAir volume

The invention discloses a device and a method for detecting the thermal migration performance of interconnected welding spots. The device sequentially comprises a cooling mechanism, an upper heat conduction plate, a lower heat conduction plate and a heating plate from top to bottom, namely, the cooling mechanism is arranged at the upper part of the upper heat conduction plate and the lower heat conduction plate is arranged at the upper part of the heating plate; and a sample is arranged in a space between the upper heat conduction plate and the lower heat conduction plate. A temperature control device of the heating plate is adjusted to obtain the temperature required by the heating plate; a rotating speed adjusting device of a cooling fan is adjusted to adjust the air volume of the fan so as to change the temperature of the hot and cold ends of the sample, and the required temperature gradient can be obtained according to the height of the welding spot. The device and the method have high safety reliability, the structure is simple and can be operated easily, the cost is low, popularization can be realized easily, electromigration interference can be effectively avoided, and the temperature gradient can be effectively controlled by control of the temperature difference of the cold and hot ends.

Owner:SOUTH CHINA UNIV OF TECH

A short-process hot stamping production line equipment and its production process

ActiveCN106944555BSmall footprintReduce heatingShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses short-process hot stamping forming production line equipment and a production technology thereof. The production line equipment comprises a ceramic pinch roller set, a roller hearth furnace, a conveying roller set, a feeding robot, a hydraulic machine system and a discharging robot which are sequentially arranged from the feeding direction to the discharging direction. Rapid heating devices are arranged between adjacent ceramic pinch rollers in the ceramic pinch roller set. The production technology includes the steps that a blank is put on the ceramic pinch rollers and then conveyed along with the ceramic pinch rollers, and the rapid heating devices are used for rapidly heating and the warming the blank; and afterwards, the blank enters the roller hearth furnace to be heated, and the heated blank is pinched to a mold station of the hydraulic machine system through the feeding robot for hot stamping forming. According to the short-process hot stamping forming production line equipment and the production technology thereof, the mode of combining rapid heating with roller hearth furnace heating is adopted, through the rapid warming means of the rapid heating devices, the technical purpose of shortening the heating process of the blank is achieved, the floor area of the roller hearth furnace is decreased, and the manufacturing cost of heating equipment is reduced.

Owner:东营布鲁特新材料有限公司

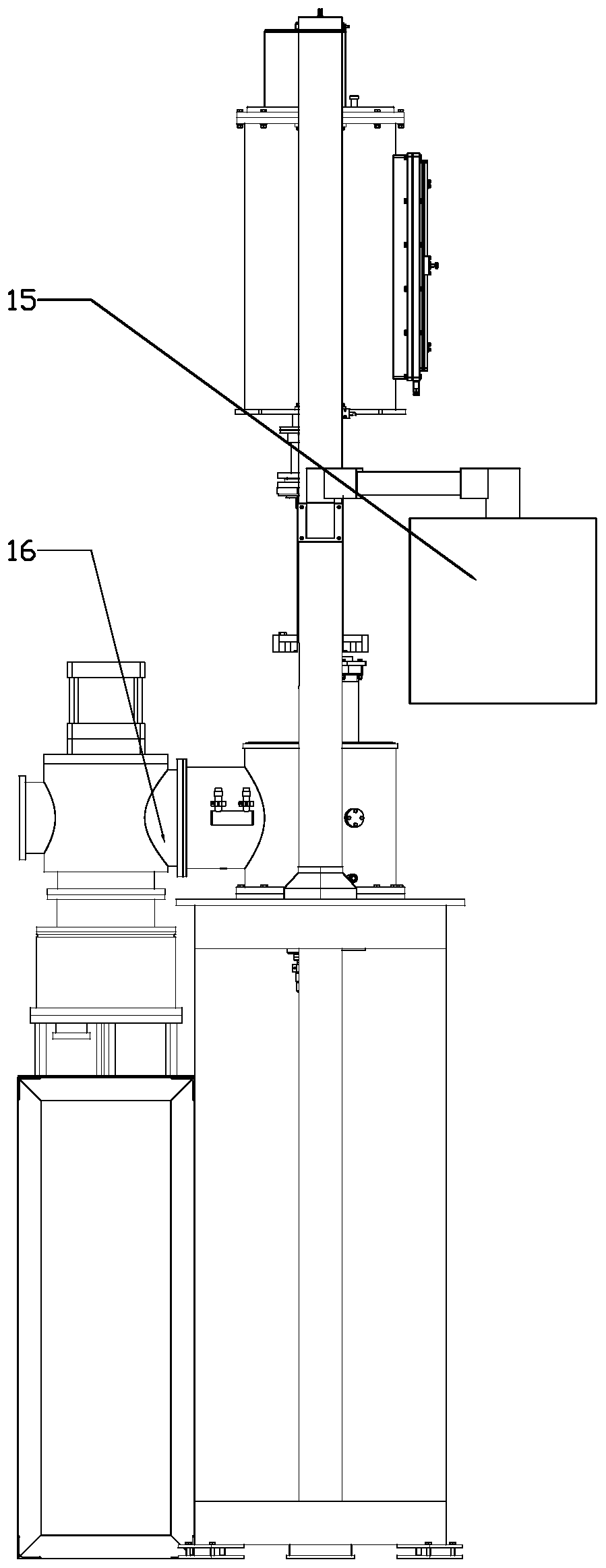

An electron beam suspension zone melting furnace and melting method

ActiveCN106929909BAvoid facing directlyEliminate pollutionBy zone-melting liquidsHigh energyZone melting

The invention discloses an electron-beam floating zone smelting furnace and a smelting method. The electron-beam floating zone smelting furnace comprises a furnace body and an argon filled fast cooling system, a water cooling system and a high-vacuum unit which are matched with the furnace body, wherein the furnace body comprises an upper furnace chamber and a lower furnace chamber, and the upper furnace chamber and the lower furnace chamber are in longitudinal and sealed butt joint in a working state; a loading fixing device for fixing a material bar is fixedly mounted in the working area of the furnace body, the working area of the furnace body is provided with a ring-type electron gun, the ring-type electron gun is provided with an electron gun moving system, narrow-area melting of the raw material bar is achieved under high-energy heat, gas is separated out, impurities are evaporated and single crystals are generated in the whole complex physical and chemical process, and smelting is achieved.

Owner:GRIMAT ENG INST CO LTD

A high energy beam additive manufacturing method and equipment with high powder raw material utilization rate

ActiveCN104668563BImprove powder utilizationReduce dosageIncreasing energy efficiencyMetallurgyMetal powder

The invention discloses a high-energy beam additive manufacturing method and equipment with high powder raw material utilization rate. The method comprises the following step of according to the outline shape of a to-be-molded metal component slice, determining the internal structure of a molding cylinder, wherein metal powder of each powder paving layer is only positioned in an area corresponding to the outline shape of the to-be-molded metal component slice, so that the using amount of the metal powder is greatly reduced, and the function and effect of manufacturing the high-energy beam increasing material is improved. The equipment comprises one or more molding cylinders, wherein the internal structures of the molding cylinders are matched with the outline shape of the to-be-molded metal component slice. Due to the fact that an insert and a special-shaped substrate which adapts to the outline shape of the metal component slice are used, rebuilding of the molding cylinders for different metal component structure characteristics is realized, and the defect that redundant powder is too much in the traditional high-energy beam increasing material manufacturing process is successfully avoided. High-quality and High-effective molding of various metal components with complex structures and different sizes can be finished under the condition of high powder utilization rate.

Owner:HUAZHONG UNIV OF SCI & TECH +1

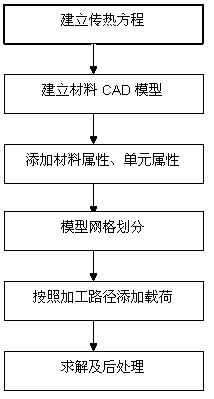

A method of 3D printing metal materials with controllable temperature gradient in the solidification process

ActiveCN106021795BImprove mechanical propertiesImprove high temperature mechanical propertiesDesign optimisation/simulationSpecial data processing applicationsControl signalElement analysis

The invention relates to a method for 3D printing metal materials with controllable temperature gradient in the solidification process. The steps are: 1) Establish the CAD model of metal material parts; 2) Select the processing technology; 3) Single-pass cladding experiment; 4) Model slicing and processing trajectory design; 5) Use finite element analysis software to simulate the temperature field in the processing process ;6) Divide the processing area; 7) Fit the temperature-time curve of the feature point; 8) Set the temperature gradient; 9) Solve the control signal of each resistance wire on the platform; 10) Laser 3D printing. The present invention can control the temperature gradient of the forming process in the processing process, obtain metal materials with low residual stress and good mechanical properties, and greatly save costs; the temperature gradient of the processing process can also be set according to requirements, so as to prepare metal materials in a directional manner .

Owner:NANCHANG HANGKONG UNIVERSITY

Continuous doctor-blading shaping method and equipment of water-base gel for raw thin wafer of ceramic device

A continuous doctor-blading process for preparing thin wafer blank of ceramic device includes such steps as mixing and dissolving organic monomer, cross-linking agent and water to obtain pre-prepared liquid, adding ceramic powder and disperser, ball grinding, removing bubbles, adding polymerization trigger of monomer and catalyst, uniform stirring, and solidifying on doctor-blading machine. Its advantages are less consumption of organic substance, less environmental pollution, low cost, high filming speed and continuous production.

Owner:TSINGHUA UNIV

High-purity aluminum purification device based on segregation method

A high-purity aluminum purification device based on segregation method belongs to metal purification technical field and comprises an internal heater, a plurality of electromagnetic stirrers and a purification furnace body. The internal heater is positioned at the center of the purification furnace body and the electromagnetic stirrers are positioned at the periphery of the furnace body and distributed evenly. The invention controls the melt flow field to improve the diffusion and distribution of the impurity elements discharged during the segregation process of the aluminum melt, accordinglyaccelerates the mixed diffusion of solute elements in the melt, reduces the frontal impurity concentration of the solid-liquid interface and realizes the purpose of improving the aluminum purification efficiency.

Owner:上交赛孚尔(包头)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com