Continuous doctor-blading shaping method and equipment of water-base gel for raw thin wafer of ceramic device

A water-based gel and ceramic technology, applied in the field of material science, can solve problems such as high cost, solvent toxicity, and serious environmental pollution, and achieve the effects of low production cost, less usage, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

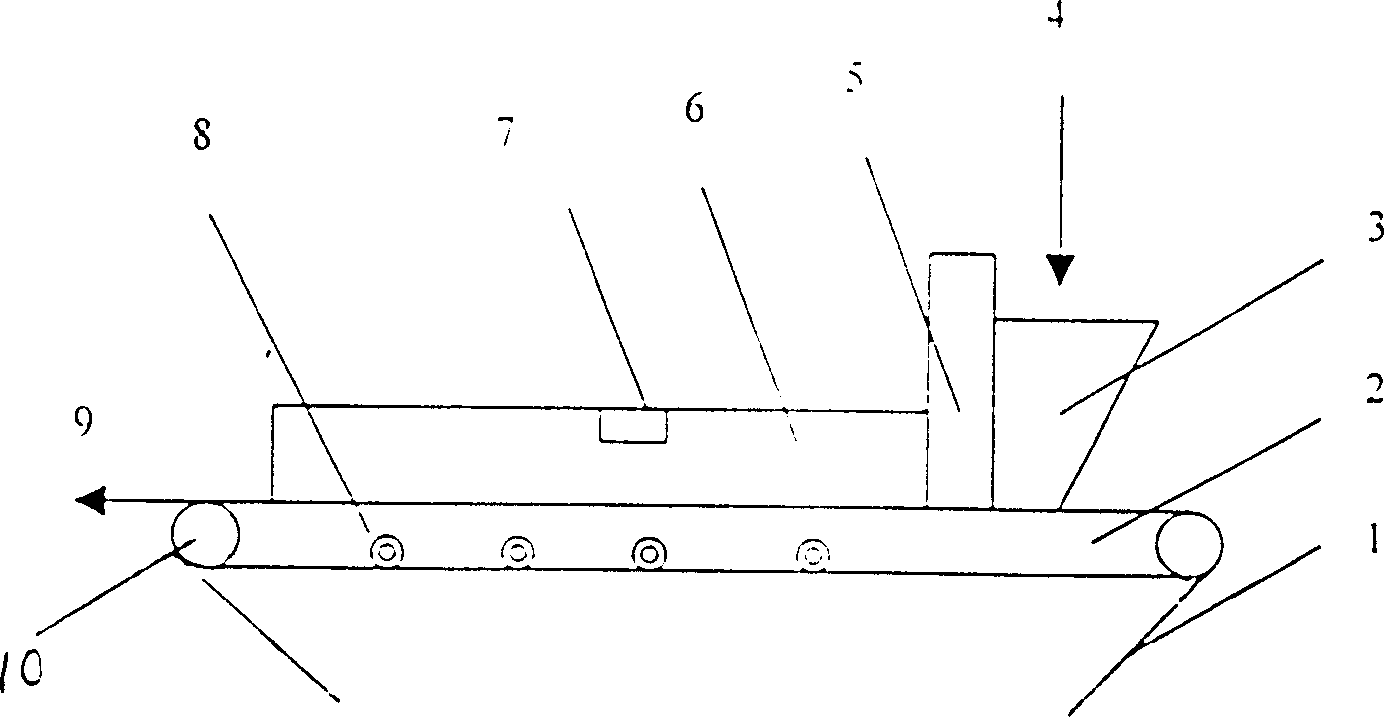

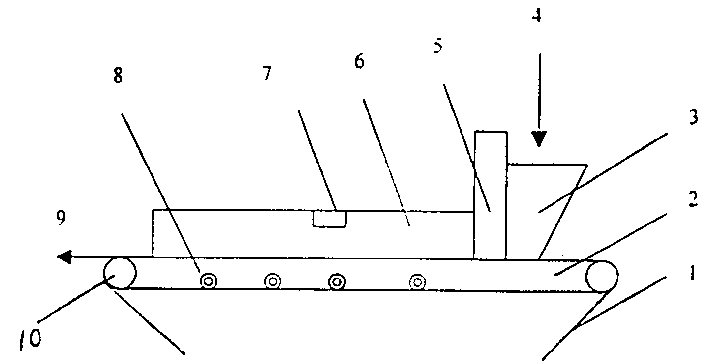

Image

Examples

Embodiment 1

[0018] Embodiment 1: 95 alumina ceramic substrate water-based gel casting molding

[0019] Add 10 grams of acrylamide monomer and 0.01 gram of methylenebisacrylamide to 100 milliliters of water to make a pre-preparation solution, add 400 grams of 95 alumina powder, and add 1 gram of ammonium citrate as a dispersant; the prepared slurry Ball milling and mixing for 40 hours; adding 0.5 ml of ammonium persulfate solution and 0.3 ml of tetramethylethylenediamine solution; using nitrogen protection on a continuous water-based gel casting machine at 60 ° C to complete casting molding to obtain a solidified green sheet, dry The back thickness is 0.2mm.

Embodiment 2

[0020] Example 2: Silicon carbide sheet water-based gel tape casting

[0021] Add 11 grams of methacrylamide monomer and 0.01 gram of methylene bisacrylamide to 100 milliliters of water to make a pre-preparation solution, add 340 grams of silicon carbide powder to the pre-preparation solution, add 0.3 milliliters of tetramethylammonium hydroxide as Dispersant; mix the prepared slurry by ball milling for 20 hours; add 0.6 ml of potassium persulfate solution; use argon protection to complete the polymerization reaction on a continuous water-based gel casting machine at 80 ° C to obtain a solidified green sheet and dry The back thickness is 0.5mm.

Embodiment 3

[0022] Embodiment 3: Water-based gel tape casting of lead zirconate titanate (PZT) ceramic capacitor thin film device

[0023] Lead zirconate titanate powder synthesized by chemical reaction, with a particle size of 0.5-2 microns and a density of 7.6g / cm 3 . A certain amount of lead zirconate titanate powder was added to the pre-mixture of Example (2), and 1% polyacrylic acid was added as a dispersant to make a 55vol% suspension slurry; ball milled for 60 hours; by 100:1 Add ammonium persulfate solution; cast on a continuous water-based gel casting machine, use nitrogen protection to complete the polymerization reaction at 60° C., and obtain a green sheet with a thickness of 0.8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com