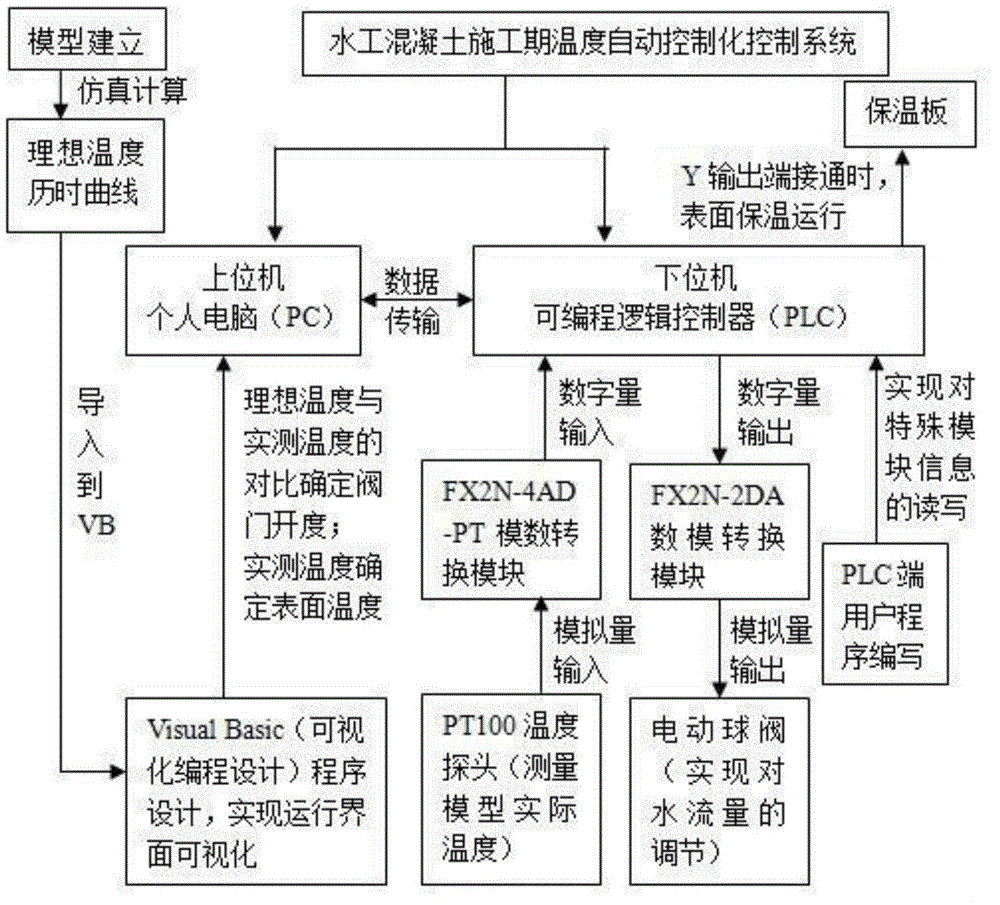

System for automatically controlling temperatures in concrete construction periods

A technology of automatic control and control system, which is applied in the direction of control/regulation system, humidity control, non-electric variable control, etc. It can solve the problem that construction management personnel and construction personnel do not have a deep understanding and cannot carry out temperature control work in strict accordance with the requirements. The quality of construction operators is uneven, so as to reduce adverse interference, improve construction conditions, and save workers' time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

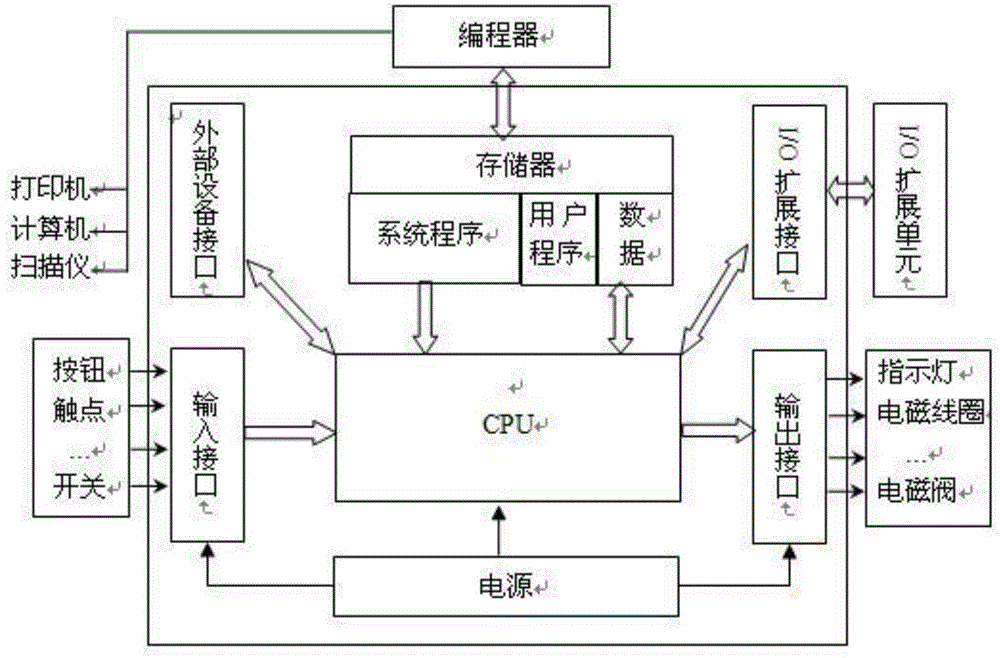

Method used

Image

Examples

Embodiment

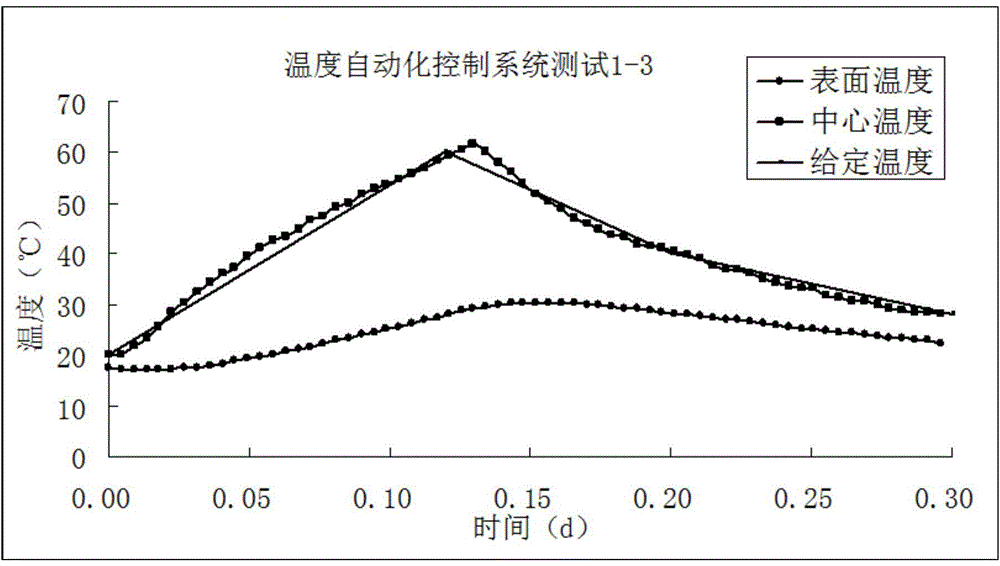

[0030] In this embodiment, a concrete construction box is built indoors, with a length of 1.70 m, a width of 1.20 m, and a height of 0.83 m. The inside of the box is sand. Cooling water pipes are buried inside the sand, and the water pipes are arranged in five layers, with a total length of about 60m. The heating rod is used to simulate the temperature rise process of the material. The heating rod is arranged in four layers and evenly arranged between the water pipes. The PLC is properly connected with the electric control valve, the actuator temperature probe, and the host computer (such as a personal computer). The self-heating steel plate (that is, the insulation board) is placed on the upper surface of the box body.

[0031] In this embodiment, the central temperature refers to the measured temperature at the geometric center of the box, and the surface temperature refers to the measured temperature at the center of the upper surface of the box. The whole simulation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com