Apparatus and method for directional solidification of silicon

A technology of directional solidification and molten silicon, which is applied in the fields of heaters, directional solidification molds, and purified silicon, can solve the problems of high cost, expensive production of large crucibles, and limited economic efficiency of silicon purification devices and methods, and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In the preparative methods described herein, unless a chronological or operational sequence is explicitly indicated, the steps may be performed in any order without departing from the principles of the invention. When it is described in a claim that a step is performed first followed by several other steps, it is understood to mean that the first step is performed before all other steps, but that the other steps may be performed in any suitable order unless the other steps are performed The sequence is described further in . For example, a claim element that describes "step A, step B, step C, step D, and step E" should be understood to mean that step A is performed first, and step E is performed last, and that steps B, C, and D can be performed between steps A and E can be performed in any order that still falls within the literal scope of the claimed method. A given step or subset of steps may also be repeated.

[0025]Furthermore, certain steps may be performed conc...

Embodiment approach 1

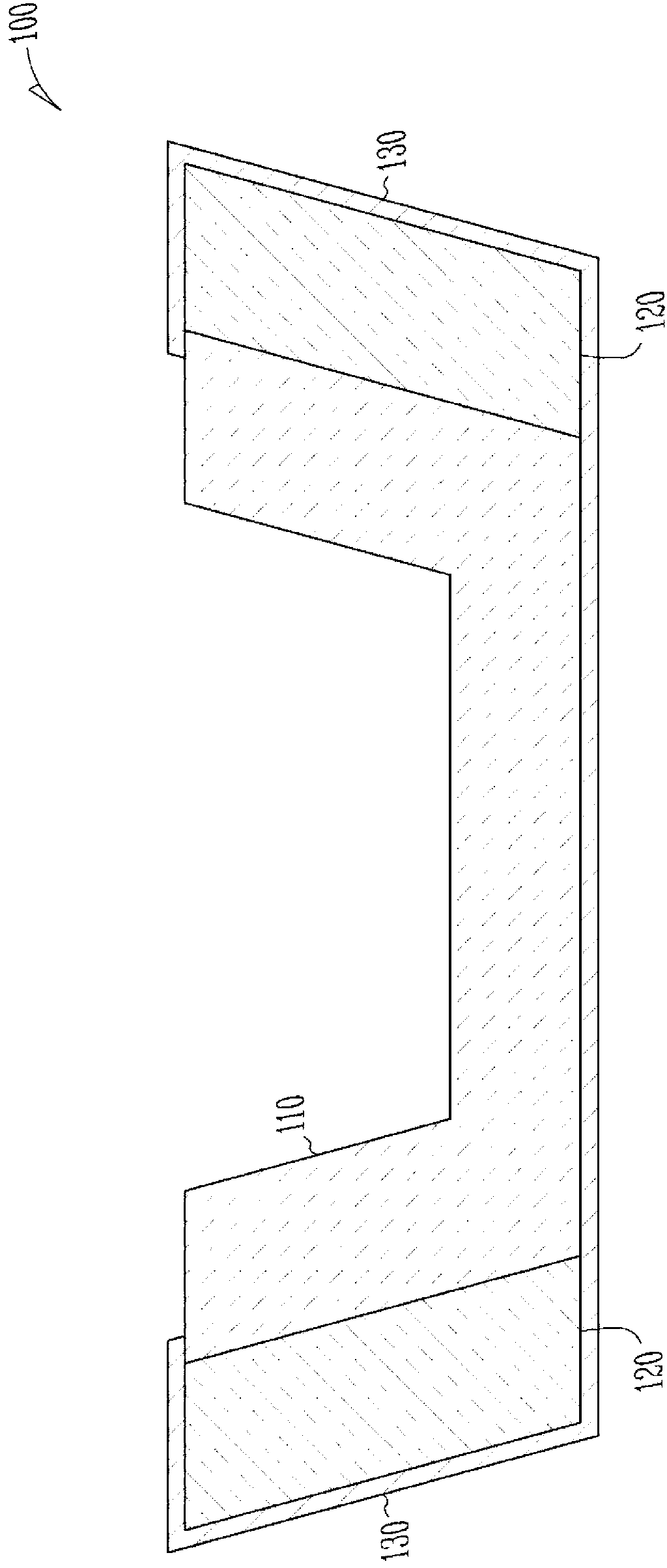

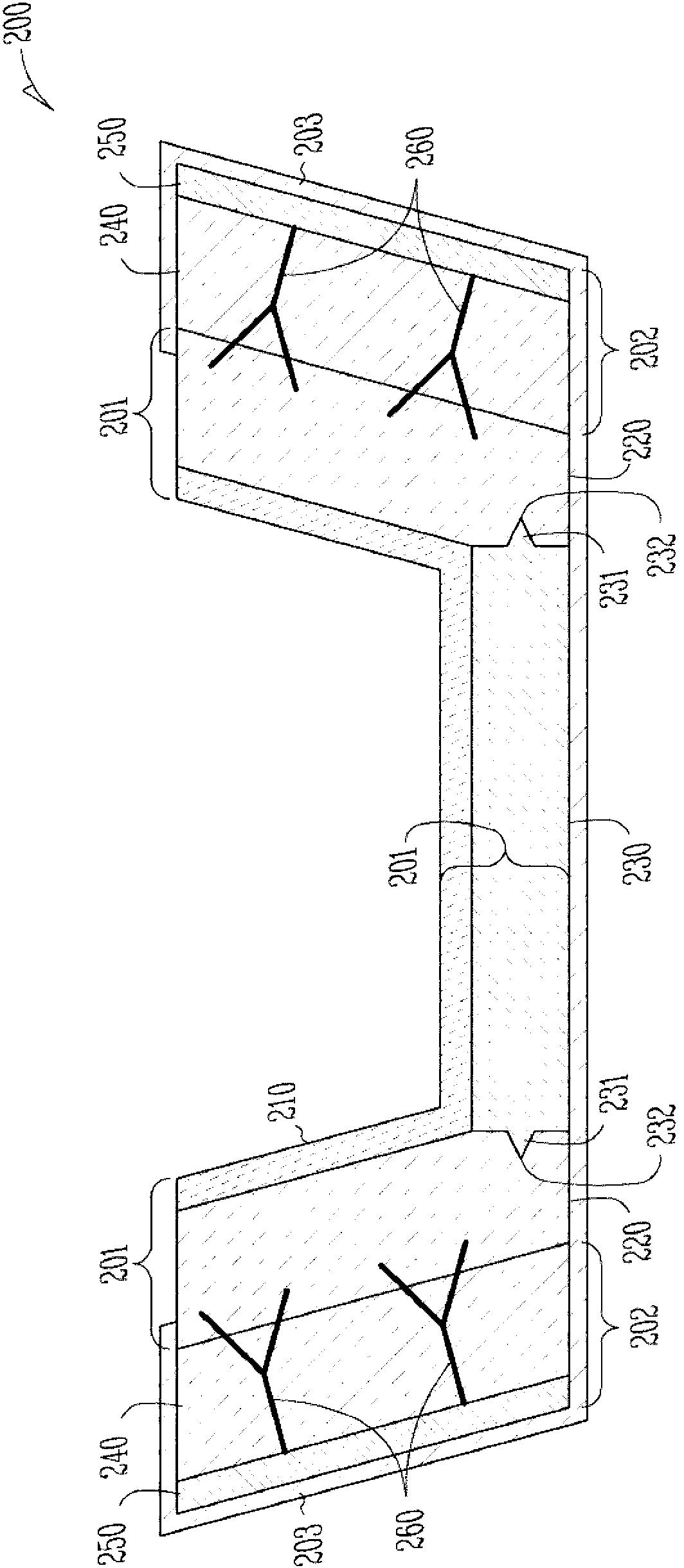

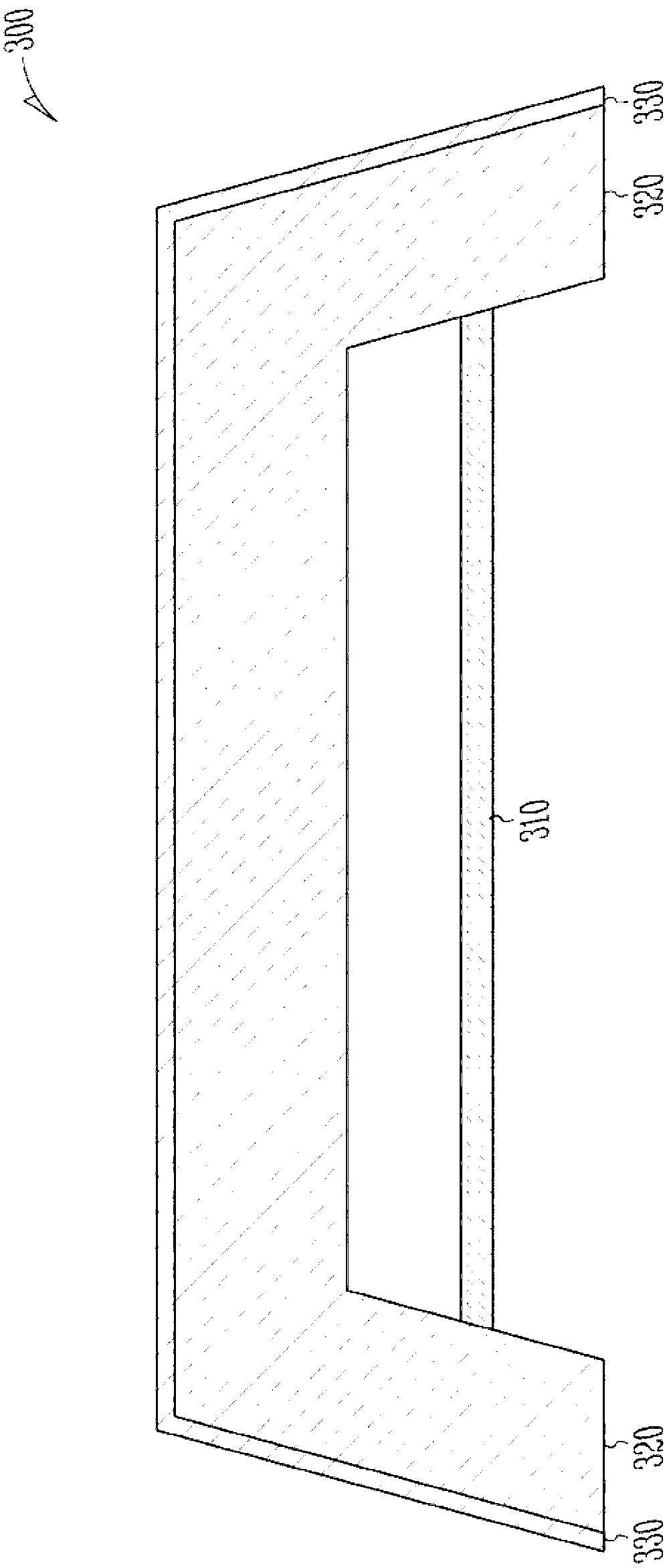

[0106] Embodiment 1. Apparatus for directional solidification of silicon comprising:

[0107] a directionally solidified mold comprising at least one refractory material;

[0108] casing; and

[0109] An insulating layer at least partially disposed between the directional curing mold and the shell.

Embodiment approach 2

[0110] Embodiment 2. The device of embodiment 1, wherein the directional curing mold, housing, and thermal barrier are configured for more than two directional curing of silicon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com