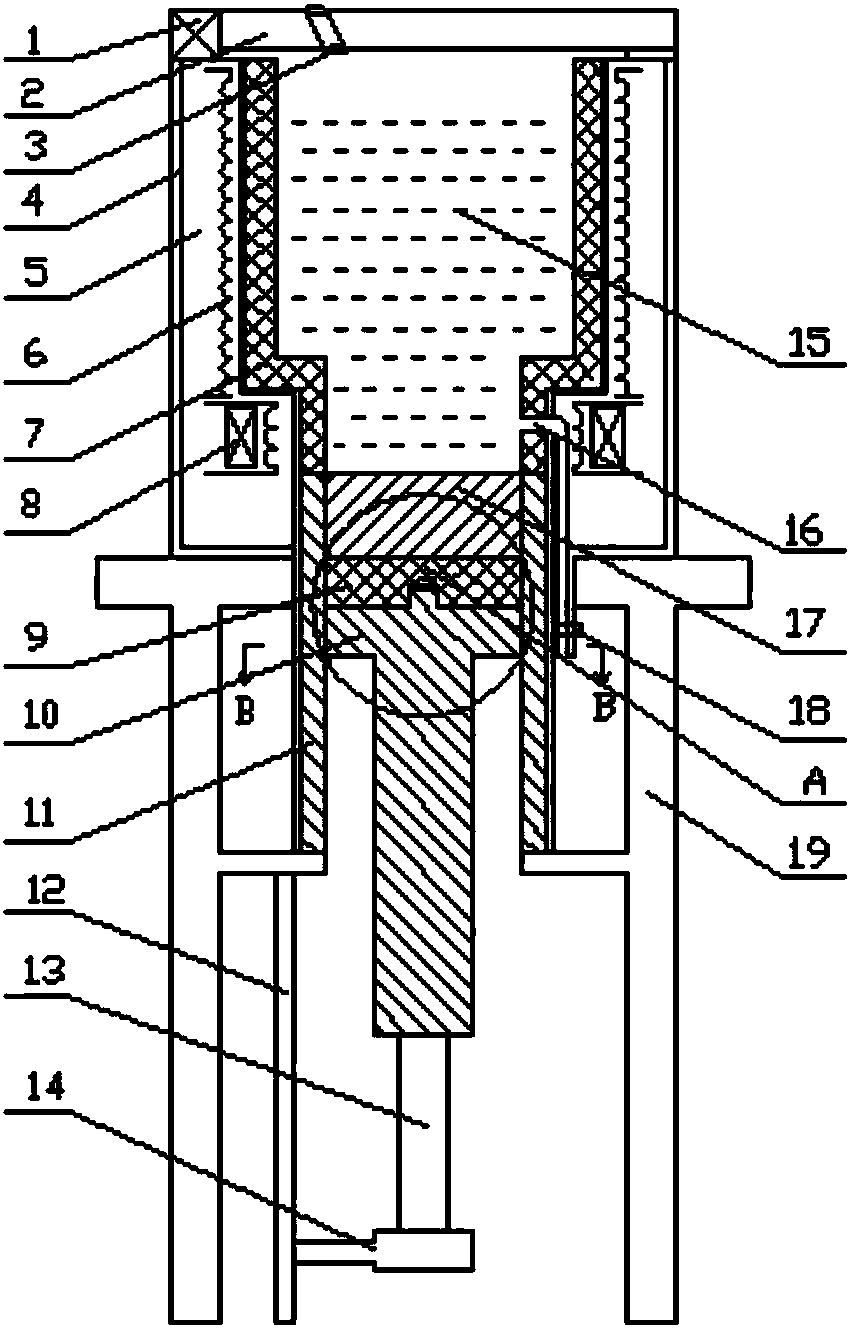

A purification device for high-purity aluminum and its application method

A high-purity, heating device technology, applied in the field of foundry metallurgy, can solve problems such as unfavorable large-scale industrial production, impurity removal effect needs to be improved, difficult liquid-solid interface stirring, etc., to improve product purity and crystal growth rate, and facilitate large-scale scale. Production, the effect of avoiding the interference of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

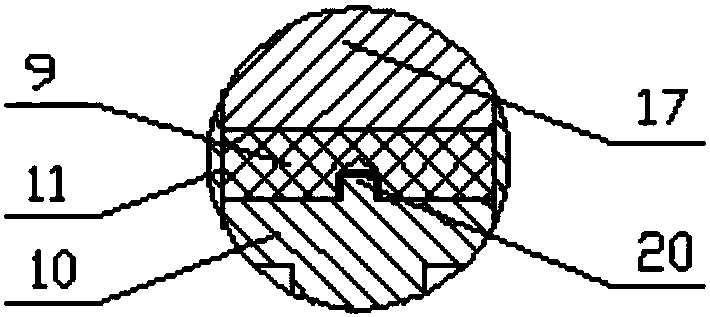

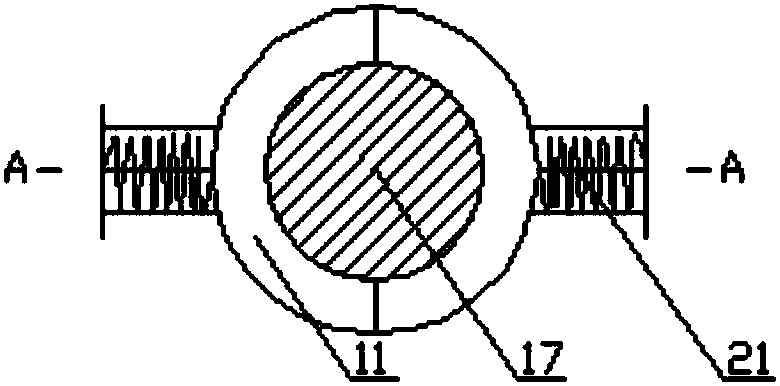

Method used

Image

Examples

Embodiment 1

[0026] 1) Prepare materials, choose 500Kg of high-purity aluminum with a purity of 99.99% as raw material, clean the surface and dry it, put it into the melting furnace, heat it to 740 ° C until it is completely melted, and keep it warm for 1 hour, add the intermediate alloy, and turn on the stirrer. After reacting for 0.5-2 hours, keep it still for heat preservation;

[0027] 2) Prepare the furnace, raise the lower lead mechanism to the highest position, that is, the high-purity aluminum plate is in direct contact with the crucible, turn on the heating device, and heat the empty furnace to 740 °C and then keep it warm;

[0028] 3) Segregation, open the furnace cover of the device, use a vacuum ladle to absorb 49.8Kg of heat-preserved aluminum melt into the device, close the furnace cover, heat to 740°C for 0.5h, turn on the electromagnetic stirrer, start the solidification device and the lower Induction mechanism, the induction rate is 22cm / h. After the crystal grows, open th...

Embodiment 2

[0032] 1) Prepare materials, choose 500Kg of high-purity aluminum with a purity of 99.996% as raw material, clean the surface and dry it, put it into the melting furnace, heat it to 720 ° C until it is completely melted, and keep it for 1 hour, add the intermediate alloy, and turn on the stirrer. After reacting for 0.5-2 hours, keep it still for heat preservation;

[0033] 2) Prepare the furnace, raise the lower lead mechanism to the highest position, that is, the high-purity aluminum plate is in direct contact with the crucible, turn on the heating device, and heat the empty furnace to 720°C and then keep it warm;

[0034] 3) Segregation, open the furnace cover of the device, use a vacuum ladle to absorb 58.6Kg of heat-preserved aluminum melt into the device, close the furnace cover, heat to 720°C for 0.5h, turn on the electromagnetic stirrer, start the solidification device and the lower Induction mechanism with a down-induction rate of 10cm / h. After the crystal grows, open ...

Embodiment 3

[0038] 1) Prepare materials, choose 500Kg of high-purity aluminum with a purity of 99.99% as raw material, clean the surface and dry it, put it into the melting furnace, heat it to 750 ° C until it is completely melted, and keep it warm for 1 hour, add the intermediate alloy, and turn on the stirrer , after reacting for 0.5-2 hours, let it stand for heat preservation;

[0039] 2) Prepare the furnace, raise the lower lead mechanism to the highest position, that is, the high-purity aluminum plate is in direct contact with the crucible, turn on the heating device, and heat the empty furnace to 750 °C and then keep it warm;

[0040] 3) Segregation, open the furnace cover of the device, use a vacuum ladle to absorb 97.9Kg of heat-preserved aluminum melt into the device, close the furnace cover, heat to 750°C for 0.5h, turn on the electromagnetic stirrer, start the solidification device and the lower Induction mechanism, the induction rate is 28cm / h. After the crystal grows, open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com