Device and method for growing large-size single crystals through dynamic temperature gradient method

A temperature gradient method, large-scale technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficult to control temperature gradient, poor crystal integrity, serious grain boundaries, etc., to achieve large size, high yield, complete good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Growth of large size MgF by a dynamic temperature gradient method 2 The single crystal method includes the following steps:

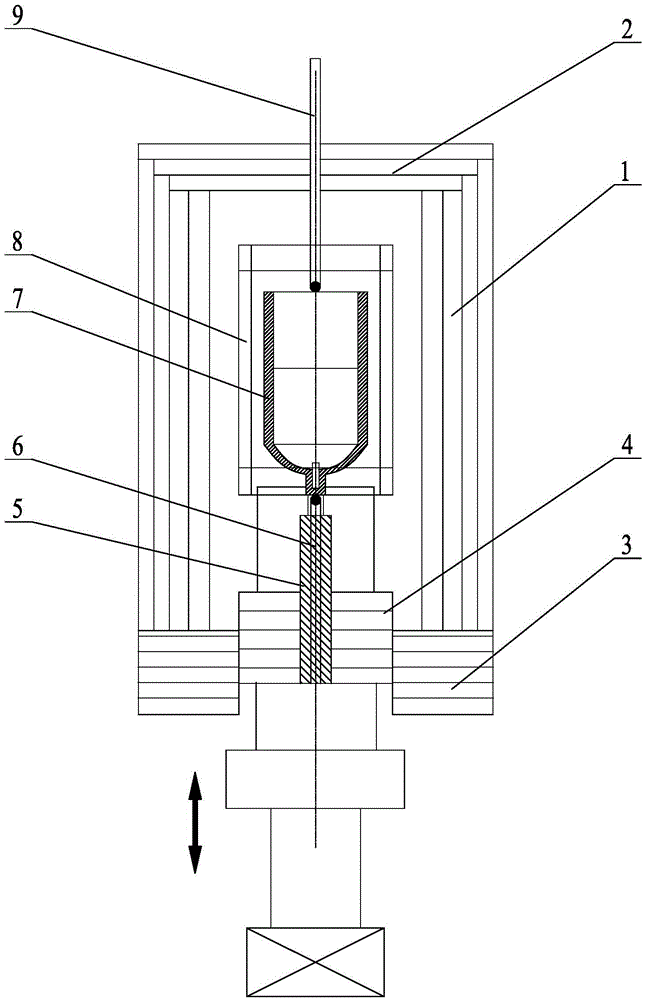

[0024] a. MgF 2 The seed crystal is put into the seed crystal tank at the bottom of the inner cavity of the crucible 7, and the polycrystalline MgF with a purity greater than 99.99% 2 The raw material is put into the crucible 7, and the crucible 7 is put into the complete insulation screen composed of the circumferential insulation screen 1, the top insulation screen 2, the bottom insulation screen 3 and the center insulation screen 4, and the complete insulation screen is put into the single crystal furnace and Vacuum the single crystal furnace;

[0025] b. Start the central control system so that the heating element 8 can heat up the single crystal furnace. The heating rate is set to 10~15°C / h. Protective gas (such as N 2 or Ar), raise the temperature of the growth furnace to 20-50°C above the growth temperature required for the crystal, an...

Embodiment 2

[0033] Growth of large size CaF by a dynamic temperature gradient method 2 The single crystal method includes the following steps:

[0034] a. CaF 2 The seed crystal is put into the seed crystal tank at the bottom of the inner cavity of the crucible 7, and the polycrystalline CaF with a purity greater than 99.99% 2 The raw material is put into the crucible 7, and the crucible 7 is put into the complete insulation screen composed of the circumferential insulation screen 1, the top insulation screen 2, the bottom insulation screen 3 and the center insulation screen 4, and the complete insulation screen is put into the single crystal furnace and Vacuum the single crystal furnace;

[0035] b. Start the central control system so that the heating element 8 can heat up the single crystal furnace. The heating rate is set to 10~15°C / h. Protective gas (such as N 2 or Ar), raise the temperature of the growth furnace to 20-50°C above the growth temperature required for the crystal, an...

Embodiment 3

[0043] A device for growing large-size YAG single crystal by dynamic temperature gradient method comprises the following steps:

[0044] a. Put the YAG seed crystal into the seed tank at the bottom of the inner cavity of the crucible 7, put the polycrystalline YAG raw material with a purity greater than 99.99% into the crucible 7, and put the crucible 7 into the crucible 7 by the circumferential insulation screen 1 and the top insulation screen 2 In the complete heat preservation screen formed by the bottom heat preservation screen 3 and the center heat preservation screen 4, the complete heat preservation screen is put into the single crystal furnace and the single crystal furnace is evacuated;

[0045] b. Start the central control system, so that the heating element 8 heats the single crystal furnace, and the heating rate is set to 10~15℃ / h. During the heating process, the single crystal furnace can be charged according to the requirements of the crystal for the atmosphere. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com