Welding deformation and joint quality control method

A quality control method and welding deformation technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficulty in meeting manufacturing requirements, large welding deformation of components, and increasing manufacturing costs, so as to improve welding quality and control welding. Deformation, controlling the effect of temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for welding deformation and joint quality control, comprising: a welding heat source and a heating heat source, the method comprising the steps of:

[0018] (1) Select the metal material, the thickness of the metal material is ≥ 4mm;

[0019] (2) The heating heat source is located on the back of the weld seam, ahead along the welding direction, and the welding heat source is located on the front of the weld seam. When the distance D between the heating heat source and the heating heat source is within the range of 0-100mm, the effect of controlling welding deformation is the best;

[0020] (3) The type of front welding heat source is determined according to the requirements, and the back heating heat source includes but not limited to high-frequency induction heat source, arc heat source and resistance heat source;

[0021] (4) During the welding process, the front welding heat source is used for welding, and the back heating heat source is used to heat the are...

Embodiment 2

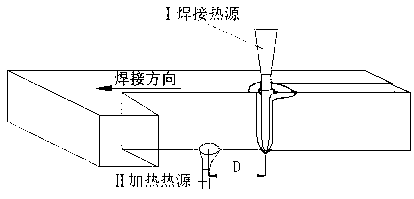

[0024] (1) combine figure 1 The welding deformation and joint quality control method of this embodiment is composed of I welding heat source and II heating heat source. The heating heat source is located on the back of the weld and is in front along the welding direction; the welding heat source is located on the front of the weld, and when the distance D between the welding heat source and the heating heat source is within the range of 0-100mm, the effect of controlling welding deformation is the best.

[0025] (2) combine figure 1 To illustrate this embodiment, during the welding process, the front welding heat source performs welding, and the rear heating heat source heats the area of the weld seam at the front. During welding, the moving speed of the two is the same, and the relative position does not change.

[0026] (3) combine figure 1 To illustrate this embodiment, the welding process parameters of the front welding heat source are determined according to the joint...

Embodiment 3

[0028] Material HQ785 steel, thickness 10mm, plate (weld seam) length 20 meters, plate width 10 meters, butt welding, single-sided single-pass welding. The groove profile adopts Y-shaped butt joint, the blunt edge is 6mm, and the combined groove size is 45°. The welding method adopts laser + MAG composite welding method, and the back heating heat source is in front, which is high-frequency induction heating. Brief welding process parameters are as follows:

[0029] Laser power Kw Current A Welding speed m / min Distance between heating heat source and welding heat source mm Rear heating instant temperature ℃ 8.0 220 1.5 20 400-500

[0030] After welding, the welding deformation is significantly reduced, and the welded joint has no defects such as cracks and pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com