A high energy beam additive manufacturing method and equipment with high powder raw material utilization rate

A powder raw material and additive manufacturing technology, applied in the field of high-energy beam additive manufacturing, can solve the problems of low powder utilization rate, excessive redundant powder, hindering the development of SLM technology and EBSM technology, etc., to reduce dust pollution and simplify equipment Effects of mechanical structure, enhancement of humanization and green features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] When using high-energy beam additive manufacturing technology for new product development, it often occurs that the vertical projection size of the formed metal component on the working plane is relatively small relative to the format of the forming cylinder. At this time, the first forming method involved in the present invention is used. The reconfigurable high-energy beam additive manufacturing device of cylinder can significantly improve the powder utilization rate under the premise of ensuring the precision and performance of components.

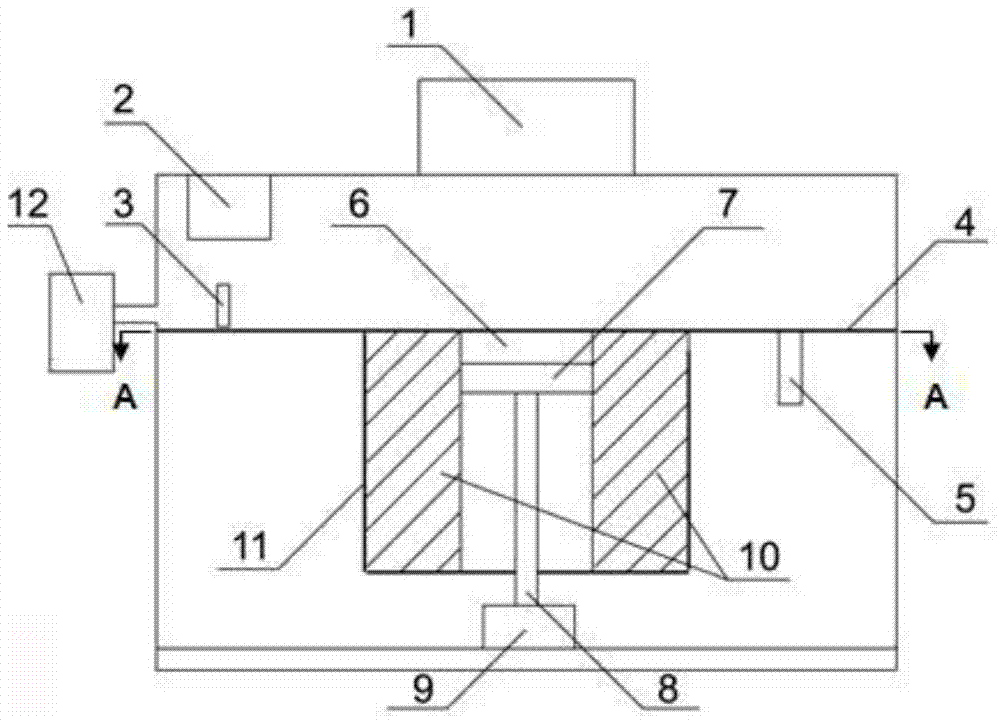

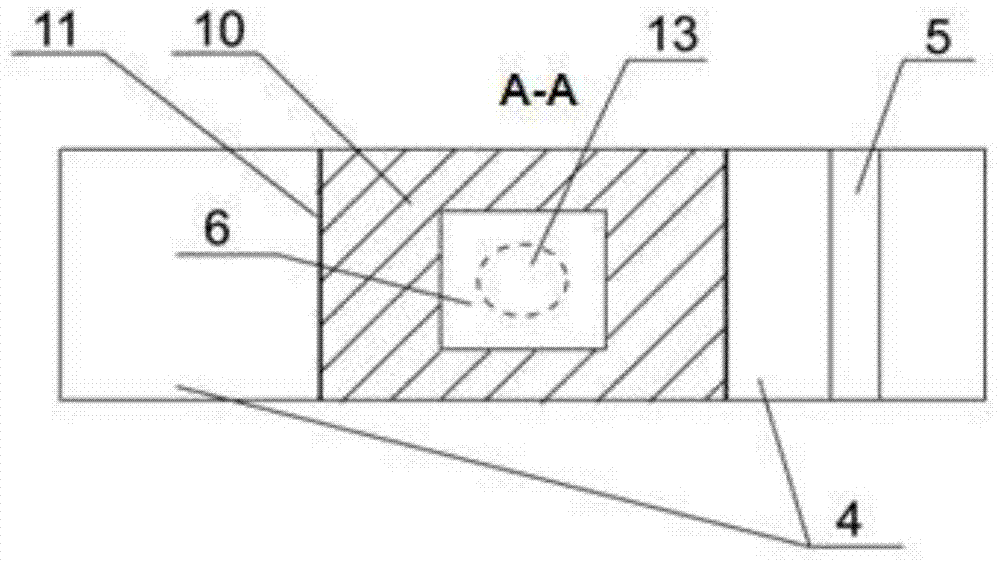

[0049] As shown in Figure 1, the first high-energy beam additive manufacturing device involved in the present invention includes a high-energy beam scanning module 1, a powder storage chamber 2, a powder spreader 3, a working plane 4, a powder recovery cylinder 5, a molding cylinder 11, Control system 9 and gas purification system 12.

[0050] The control system 9 is used to regulate the coordinated work of the high-energy beam s...

Embodiment 2

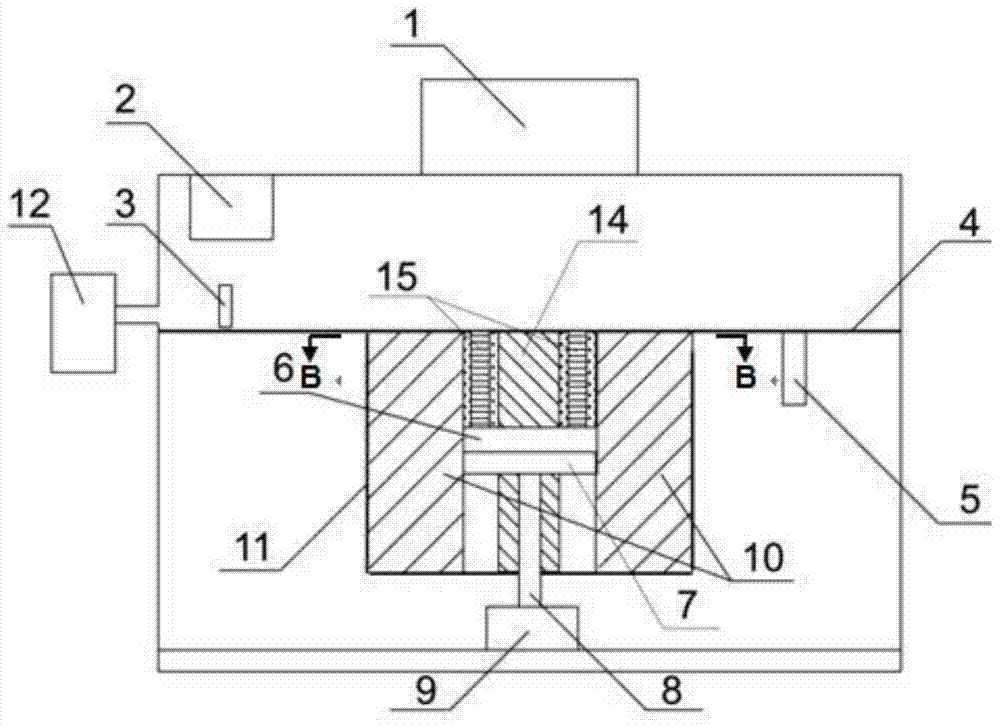

[0068] If the metal part is a hollow frame structure with a larger size and equal cross-section (that is, a large-sized part with a circular through-hole, a square through-hole or other through-holes with a constant cross-sectional area in the height direction), if the traditional SLM or For EBSM forming, a large amount of alloy powder needs to be used to fill the inside of the through hole, which greatly reduces the utilization rate of the powder. At this time, the above-mentioned problems can be better solved by adopting the second reconfigurable high-energy beam additive manufacturing method and device involved in the present invention.

[0069] Without loss of generality, assuming that the metal part to be formed is a large-sized cylindrical ring belonging to one of the above-mentioned equal-section hollow frame structures, the second specific embodiment of the high-energy beam additive manufacturing device involved in the present invention as shown in picture 2. The devi...

Embodiment 3

[0088] If the horizontal cross-sectional area of the through hole contained in the hollow frame member gradually decreases with the increase of the number of processing layers, then when the device involved in Embodiment 2 is used for additive manufacturing, the horizontal cross-sectional area of the inner insert 14 must be smaller than the specified The minimum cross-sectional area of the through hole of the corresponding component can avoid interference between the internal insert 14 and the laser scanning path, thereby ensuring smooth processing. In this case, the inner insert 14 can only occupy a small part of the space inside the through hole of the component, and the remaining space still needs to be filled with redundant powder. In order to realize the forming of such components under the condition of ensuring high powder utilization rate, the structure of the internal insert 14 and its installation method involved in Embodiment 2 can be improved, thereby forming t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com