Process for achieving laser cladding of silver layer on surface of high-current aluminum bus hardware terminal

A laser cladding, aluminum busbar technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of low powder utilization rate, large porosity of silver coating, workpiece deformation, etc., to improve the performance of substrate, surface The effect of high flatness and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The laser cladding silver layer process on the surface of the metal fittings terminal of the high-current aluminum busbar includes the following steps:

[0036] 1) Pre-treat the surface of the high-current aluminum busbar fittings terminal, and manually polish to remove surface oxides to ensure that the base aluminum alloy material is exposed on the surface of the workpiece; during the grinding process, an electric angle grinder is used for metallographic operation;

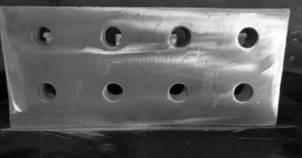

[0037] 2) Install a supporting base plate on the other side of the silver layer of the high-current aluminum busbar fitting terminal to be clad, and then install the entire workpiece on the workbench; the supporting base plate is a steel plate, and use at least two G-shaped pliers to connect the terminal and the supporting base plate fixed;

[0038] 3) Use alcohol to clean the part of the cladding silver layer to remove the residual oil on the surface and ensure that the silver layer preparation surface is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com