Preparation method of electrical contact strengthened coating on metal surface

A metal surface and electrical contact technology, which is applied in the coating process and coating of metal materials, can solve the problems of coating powder material performance degradation, inconvenient thermal spraying method, coating powder waste, etc., and achieve high powder utilization rate , Combining the effects of excellent performance and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

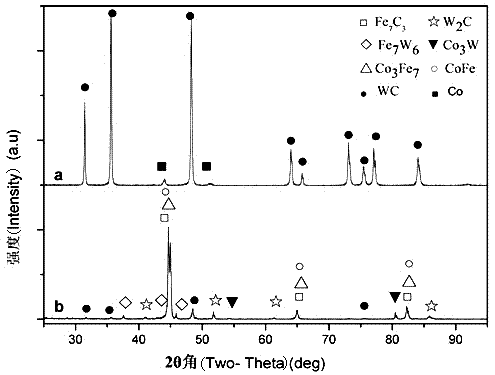

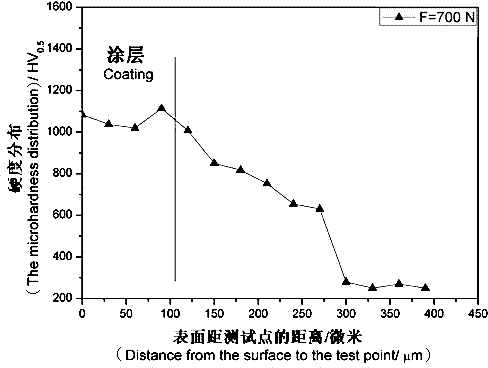

Embodiment 1

[0029] A preparation method for an electrical contact strengthening coating on a metal surface, comprising the steps of:

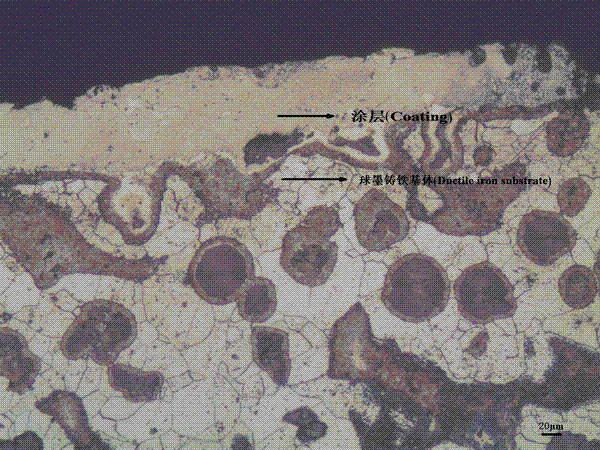

[0030] (1) Pretreatment of roughening, cleaning and descaling of the metal surface, wherein the metal matrix is made of ductile iron QT 600-3, and the matrix structure is ferrite and pearlite;

[0031] (2) Prepare the liquid paint of the coating material and the binder slurry by mechanical stirring: mix 0-30 grams of cellulose acetate (CAS No.: 9004-35-7, Sinopharm Chemical Reagent Co., Ltd.), 0-40 Gram carboxymethylcellulose sodium (CAS No.: 9004-32-4, Sinopharm Chemical Reagent Co., Ltd.), 0-100ml ethylene glycol (CAS No.: 107-21-1, Sinopharm Chemical Reagent Co., Ltd.), 0 -250ml of acetone (CAS No.: 67-64-1, Sinopharm Chemical Reagent Co., Ltd.), 0-100ml of ethanol (CAS No.: 64-17-5, Sinopharm Chemical Reagent Co., Ltd.) and 0-150ml of distilled water are stirred and miscible , to obtain the binder slurry, the viscosity is 300-500mPa s; the powder co...

Embodiment 2

[0040] A preparation method for an electrical contact strengthening coating on a metal surface, comprising the steps of:

[0041] (1) Pretreatment of roughening, cleaning and descaling of the metal surface, wherein the metal substrate is made of white cast iron.

[0042] (2) The mixture of coating material and binder slurry is prepared by mechanical stirring method: 0-30 grams of cellulose acetate, 0-40 grams of sodium carboxymethyl cellulose, 0-100 ml of ethylene glycol, 0-250 ml of Acetone, 0-100ml ethanol and 0-150ml distilled water are stirred and miscible to obtain a binder slurry with a viscosity of 300-800mPa·s; the powder coating material is WC-12% Co powder; the coating powder is mixed with a binder containing The agent slurry is mechanically stirred and mixed for use;

[0043] (3) Presetting the above-mentioned powder slurry on the metal surface: spray the above-mentioned suspension on the surface of the metal substrate with an air spray gun, and the thickness of th...

Embodiment 3

[0046] A preparation method for an electrical contact strengthening coating on a metal surface, comprising the steps of:

[0047] (1) Pretreatment of roughening, cleaning and descaling of the metal surface, wherein the metal substrate is made of 45 steel.

[0048] (2) The mixture of coating material and binder slurry is prepared by mechanical stirring method: 0-30 grams of cellulose acetate, 0-40 grams of sodium carboxymethyl cellulose, 0-100 ml of ethylene glycol, 0-250 ml of Acetone, 0-100ml ethanol and 0-150ml distilled water are stirred and miscible to obtain a binder slurry with a viscosity of 300-500mPa·s; the powder coating material adopts self-made nano WC-1~4%MgO-1%Co( wt%) powder (WC[CAS No.: 12070-12-1], MgO[CAS No.: 1309-48-4], Co[CAS No.: 7440-48-4], all produced by Sinopharm Chemical Reagent Co., Ltd. , the equipment for mechanical activation of the powder is the QM-1SP4 planetary ball mill produced by Nanjing University Instrument Factory, the ball milling time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com