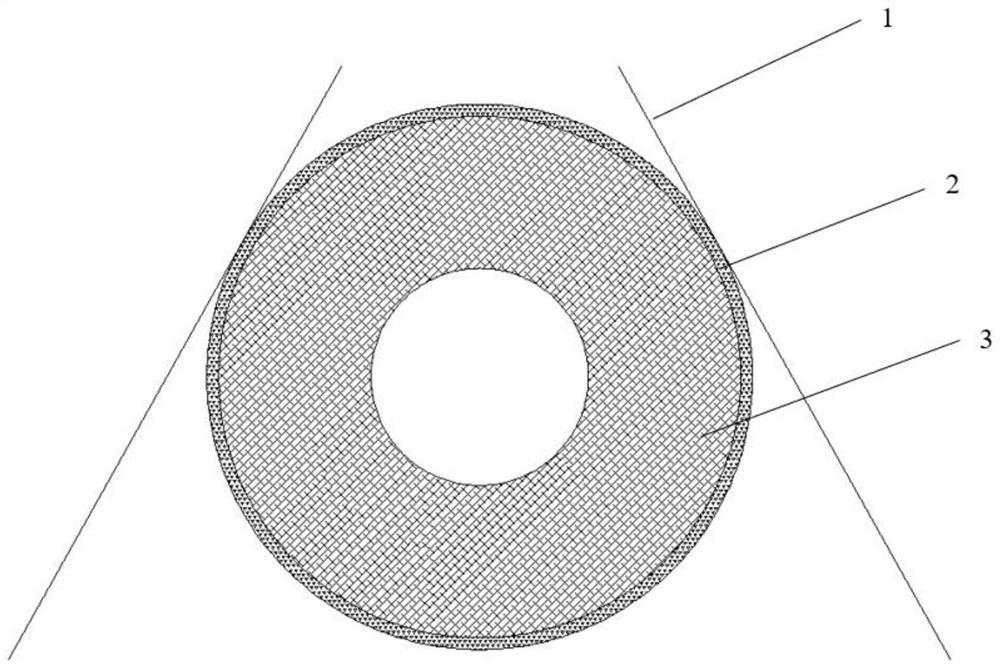

Light high-conductivity slip ring and preparation method thereof

A high-conductivity, light-weight technology, which is applied in the manufacture of slip rings, circuits, and current collectors, can solve problems such as excessive temperature in local areas of the substrate, decreased stability of slip rings, and poor friction performance, and achieve current-carrying efficiency and load-carrying efficiency. Improved flow stability, improved arc corrosion resistance, and better surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

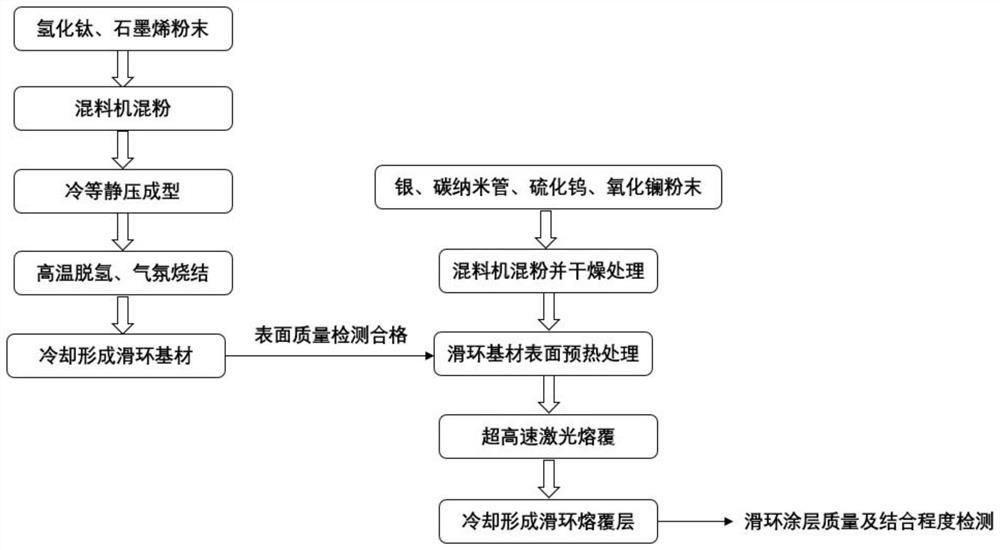

[0028] (1) Gas a graphene powder and mass fraction of a mass fraction of 5% are mixed with powder, and the particle size of the graphene is selected from 10 um, and the particle size of titanium hydride is selected from 40 um. Pumping the ball milling powder to the vacuum, then charged into argon as a protective gas, the rotation speed is 300r / min, the mixture is 4 h;

[0029] (2) Weigh 250 g of a mixed powder, press into the rubber sleeve in the rubber sleeve, and press the pressure, the pressure is 350 MPa, and the press is completed for 10 min;

[0030](3) Put the pressed blank into the tubular sintering furnace, first taking the sintering furnace to vacuum, then tonify at a rate of 5 ° C / min for dehydrogenation treatment, and heat insulation 1.5 h. The high-purity argon is charged as a protective gas, and the gas flow rate is 100 mL / min, and the rate of sintering at a rate of 5 ° C / min is raised to 1100 ° C for sintering, the sintering time is 3 h, and the temperature ...

Embodiment 2

[0034] (1) Pretrating the graphene powder and mass fraction of mass fraction of 92.5% is 5 um, the granularity of the grainhene is selected from 5 um, and the particle size of the titanium hydride is selected from 20 um. The ball milling powder was taken to vacuum, and then argon was charged as a protective gas, the rotation speed was 350 r / min, and the mixture time was 4.5 h.

[0035] (2) Weigh 300 g of a mixed powder, press into the rubber sleeve to press the static pressing machine, press the pressure of 400 MPa, and press the pressure for 15 min.

[0036] (3) Put the suppressed blank into the tubular sintering furnace, first taking the sintering furnace to vacuum, then tonify at a rate of 5 ° C / min for dehydrogenation treatment, and heat insulation 1.8 h. The high-purity argon was filled with high purity argon as a protective gas, and the gas flow rate was 110 mL / min, and then the rate of sintering was raised to 1200 ° C at a rate of 10 ° C / min, the sintering time was ...

Embodiment 3

[0040] (1) Pretty graphene powder and mass fraction of a mass fraction of 90% are mixed with a mixed powder in a ball mill, and the granularity of the graphene is selected from 10 um, and the particle size of titanium hydride is preferably 30 um. The ball milling powder was taken to vacuum, and then argon as a protective gas, the rotational speed was 400 r / min, and the mixture time was 5 h.

[0041] (2) Weigh 350g mixed powder, loaded into the rubber sleeve in the rubber sleeve for pressing, pressing the pressure of 450 MPa, and press 20 min after pressing.

[0042] (3) Put the suppressed blank into the tubular sintering furnace, first take the sintering furnace to the vacuum, then temperature rise to 730 ° C at a rate of 10 ° C / min for dehydrogenation treatment, and heat insulation for 2 h, then charge it into high purity Argon gas was protected from 125 ml / min, and then the rate of sintering at a rate of 5 ° C / min was tapered to 1250 ° C, the sintering time was 4 h, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com