A method of 3D printing metal materials with controllable temperature gradient in the solidification process

A metal material and temperature gradient technology, applied in the field of temperature, can solve problems such as thermal stress, and achieve the effect of low cost, reasonable price and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

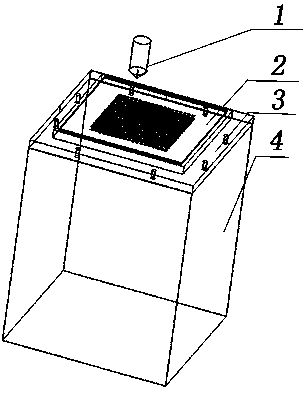

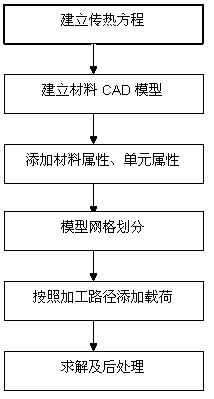

Method used

Image

Examples

Embodiment 1

[0036] Preparation scheme of Ni718 alloy material parts:

[0037] 1) modeling

[0038] Establish Ni718 alloy material part model, cuboid model, length × width × height: 100mm × 20mm × 10mm.

[0039] 2) Selected processing technology

[0040] Select processing technology, laser power P=300W~500W, laser spot diameter d=1mm, spot moving speed v=0.005m / s~0.05m / s, powder feeding speed δ=0.1mm 3 / s~2mm 3 / s.

[0041] 3) Single pass cladding experiment

[0042] Select the appropriate processing substrate according to the specific material. Here, 304 stainless steel sheet is selected, and the processing parameters selected in 2) are used to conduct a single-pass cladding experiment. The single-pass cladding width is 1.0mm-1.5mm and the single-pass height is 0.2mm. ~0.5mm.

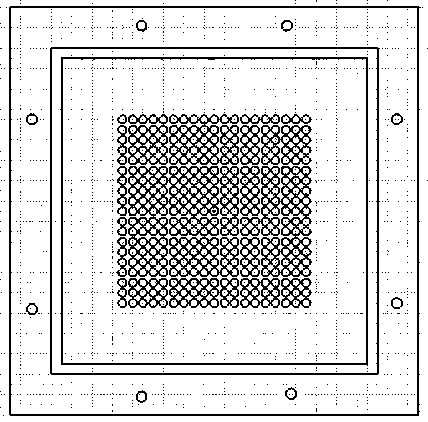

[0043] 4) Model slicing and processing trajectory design

[0044] The model is sliced and layered, with a layer thickness of 0.2mm to 0.5mm; according to the set overlap rate of 20% to 30% and the width of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com