Single crystal growth device and method

A technology of crystal growth and single crystal, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of reducing the growth rate of single crystal, long solid-liquid interface distance, cracking, etc., to reduce the temperature gradient change, improve Single crystal growth rate, effect of preventing cracks or cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Here, embodiments of the present invention will be described in detail with reference to the drawings.

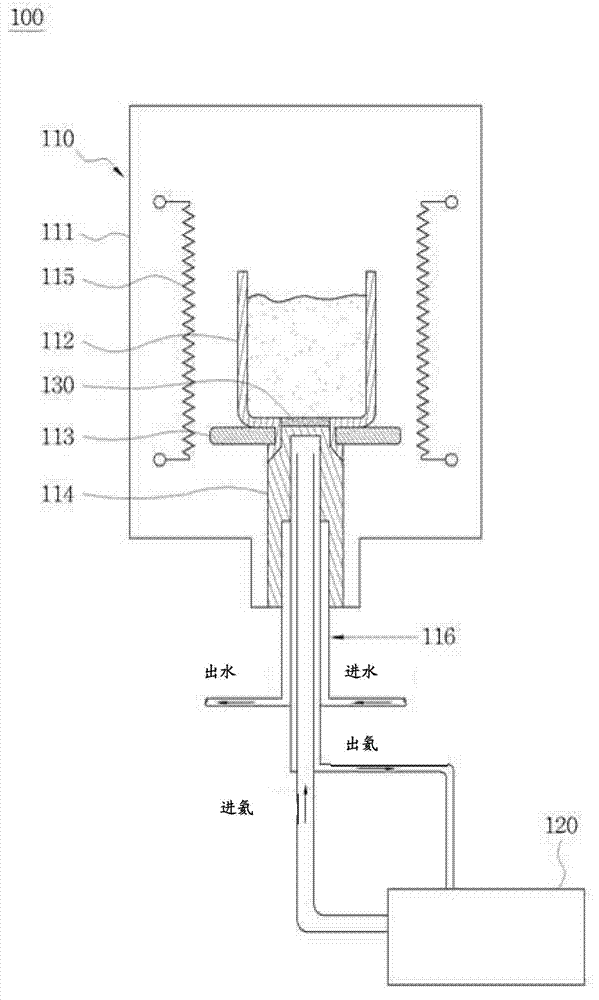

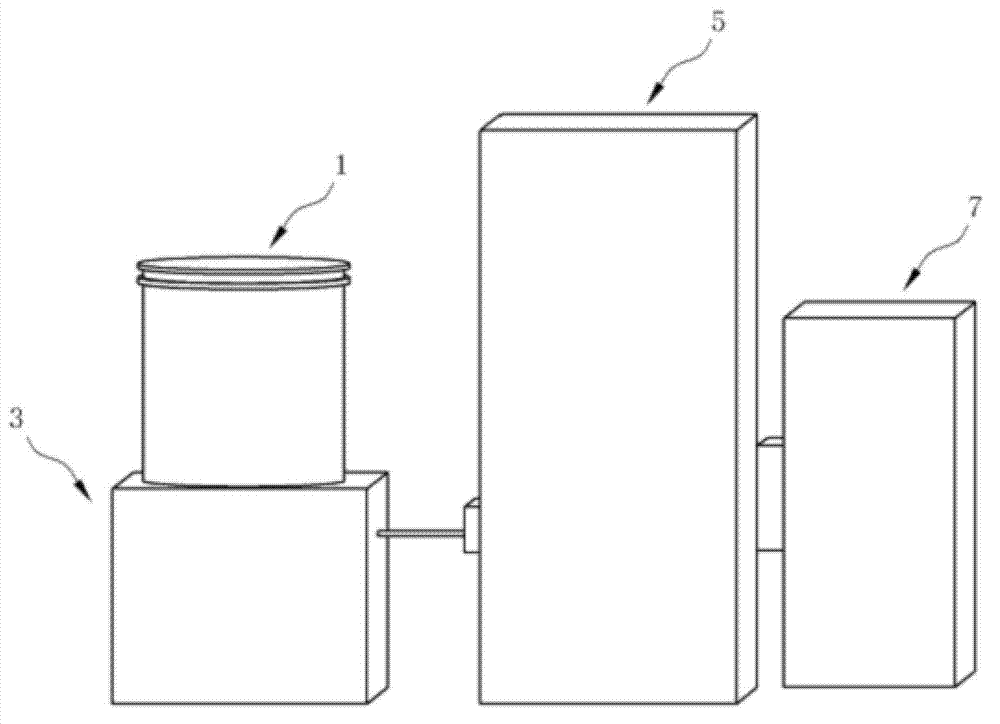

[0054] Such as image 3 As shown, the single crystal growth device of the embodiment of the present invention includes a single crystal growth furnace 1 for cultivating sapphire single crystal growth; the single crystal growth furnace 1 is installed, and has a heat exchanger that provides the necessary heat exchange function for the growth of a single crystal The main frame 3 is the main frame 3; the power supply equipment 5 that provides power for the single crystal growth circuit 1 to form a suitable high-temperature atmosphere for the growth of the single crystal; the power distribution equipment 7 with a control panel and a display. The above-mentioned control panel properly controls the actions of the above-mentioned main frame 3 and power supply equipment 5 respectively, so that the internal temperature gradient of the single crystal growth circuit 1 is in a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com