Method for drawing six-inch zone-melting silicon single crystal and used heat shield

A technology for zone melting of silicon and silicon single crystal, applied in the field of semiconductor silicon single crystal growth, can solve the problems of single crystal transformation, single crystal burst or crystal transformation, dislocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

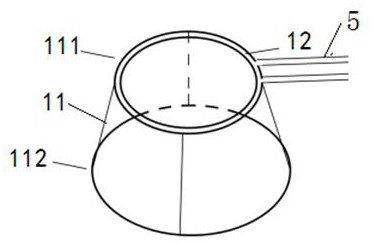

[0013] like figure 2 As shown in the figure, a heat shield for drawing a fused silicon single crystal in a six-inch area includes a heat shield cover 11 and a condensation pipeline 12. The heat shield cover 11 is a copper plate conical cover transparent from top to bottom, and the condensation pipeline 12 is selected from The copper pipes are arranged spirally along the upper edge 111 of the entire heat shield 11, and the copper pipes 5 at both ends of the condensation pipe 12 are drawn out to form the outlet end and the inlet end of the cooling water.

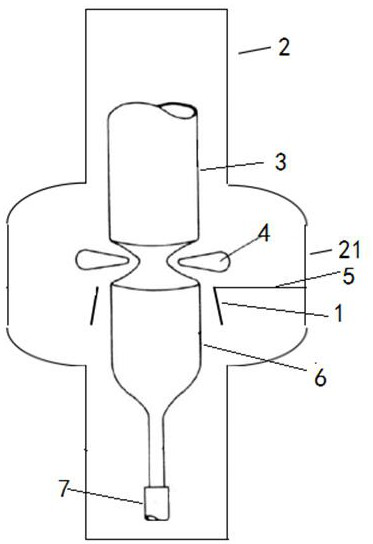

[0014] like figure 1 , figure 2 As shown, a method for pulling a six-inch zone molten silicon single crystal includes the processes of evacuation, preheating, compounding, neck narrowing, shoulder expansion, shoulder turning, equal diameter, finishing, furnace shutdown, and furnace disassembly and assembly; Before evacuation, first enclose the copper tube of the condensation pipeline 12 into a ring with a diameter of 190mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com