Patents

Literature

63results about How to "Solve burst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

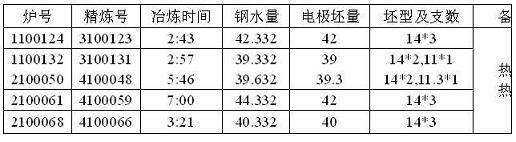

MC5 Steel and large-sized flattening roll prepared by using the same, and manufacturing process of MC5 steel

ActiveCN102433515ASolve burstSkip the preheating processElectric furnaceProcess efficiency improvementChemical compositionMetal

The invention relates to an MC5 steel and a large-sized flattening roll prepared by using the same, and a manufacturing process of the MC5 steel, wherein the MC5 steel comprises the following chemical components in weight percentages: 0.75%-0.90% C, 0.40%-0.80% Si, 0.20%-0.50% Mn, 4.80%-5.20% Cr, 0.30%-0.60% Ni, 0.20%-0.60% Mo, 0.10%-0.20% V, less than or equal to 0.015% P, less than or equal to 0.015% S, less than or equal to 0.20% Cu, less than or equal to 0.01% Al, less than or equal to 0.02% Pb, less than or equal to 0.02% As, less than or equal to 0.02% Sn, less than or equal to 0.02% Sb, less than or equal to 0.02% Bi, less than or equal to 2 ppm of H, less than or equal to 30 ppm of O, less than or equal to 120 ppm of N, and rest being Fe and inevitable impurities; and the MC5 steel is capable of meeting the utilization requirements of high-end metal plate rolling and long service life of the flattening roll.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

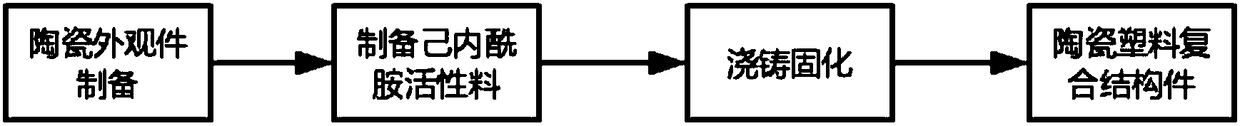

Preparation method for ceramic plastic composite structure part and shell of electronic equipment

The invention provides a preparation method for a ceramic plastic composite structure part and a shell of electronic equipment. The preparation method for the ceramic plastic composite structure partcomprises the steps that a ceramic exterior part is first prepared, and then the ceramic plastic composite structure part is obtained by casting nylon monomer in the ceramic exterior part after heating and heat preservation and curing. The preparation method uses the nylon monomer normal pressure casting process, the problem of ceramic crack due to over-high injection pressure in the in-mold injection molding process is solved, the bonding strength of nylon and ceramics is high, and due to long time of heat preservation and curing, the polymerized nylon molecular weight is large and the mechanical comprehensive performance is good. In order to improve the bonding strength of the ceramics and cast nylon, a nanometer roughened surface is obtained by using acid liquid to corrode the ceramic surface before casting, and then a layer of polyisocyanate glue layer is spin-coated on the roughened surface as the transition layer to improve the bonding strength of the ceramics and the cast nylon.Shells of ceramic plastic composite electronic equipment such as mobile telephone shells, watch back covers, car key shells can be prepared by the preparation method for the ceramic plastic compositestructure part.

Owner:南通通州湾新材料科技有限公司 +1

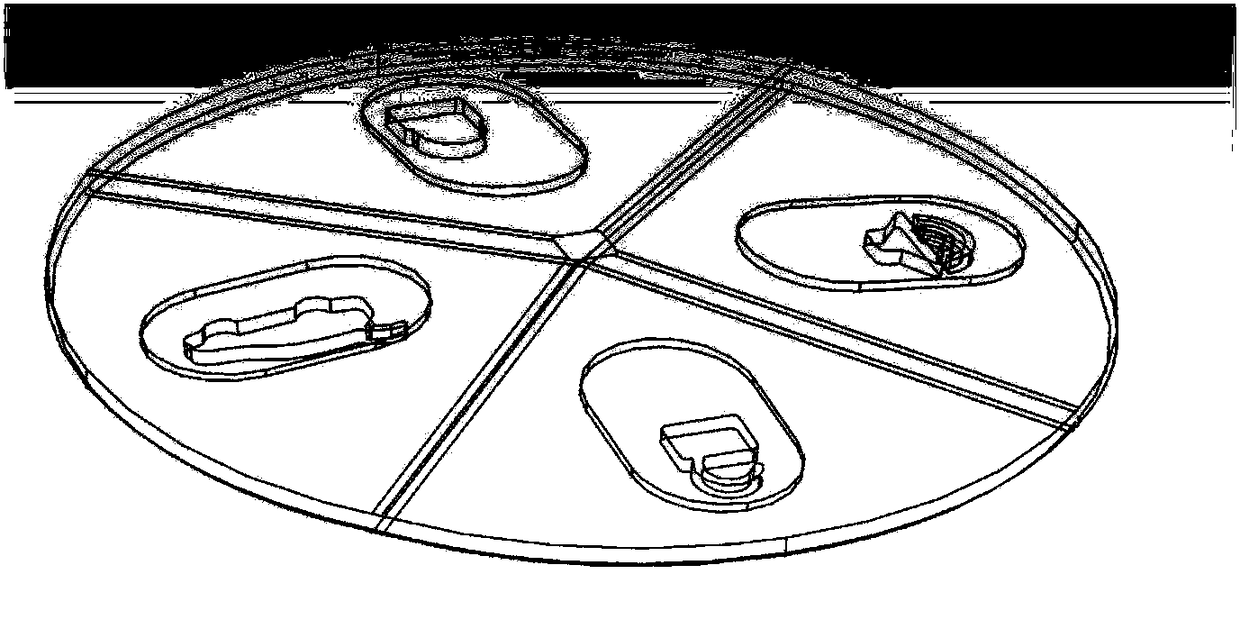

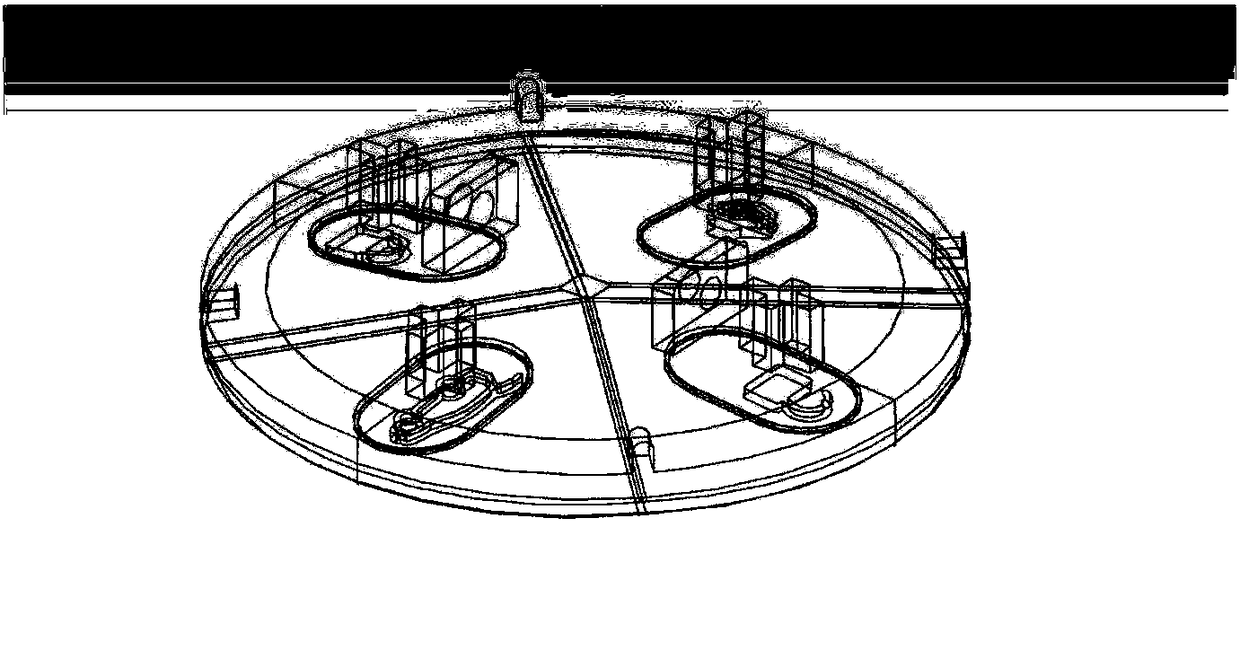

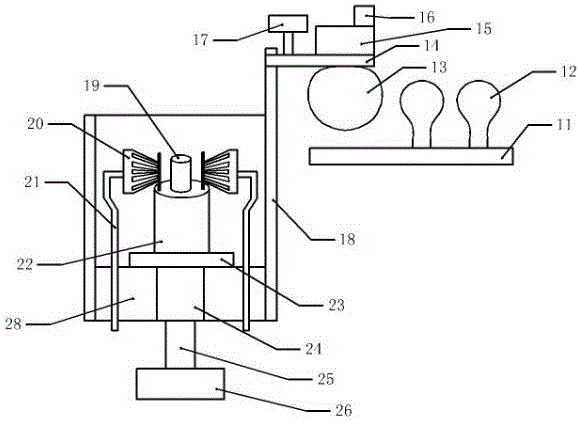

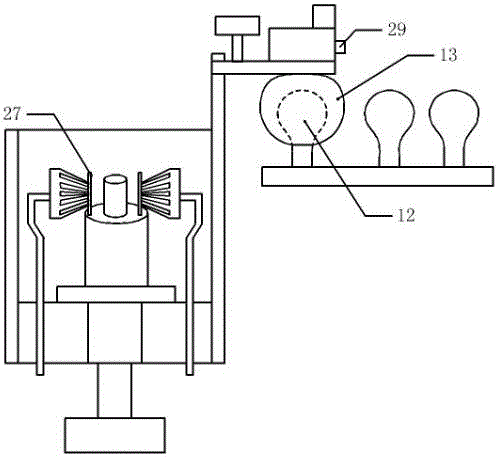

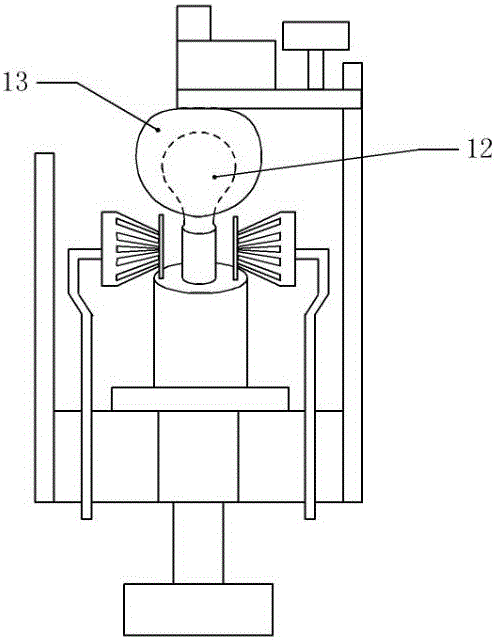

Processing device used for LED lamp bulb

ActiveCN106402700ASolve burstPrevent burstSemiconductor devices for light sourcesProcess engineeringNozzle

The invention belongs to the field of lamp socket sealing equipment, and particularly relates to a processing device used for an LED lamp bulb. The processing device comprises racks and an operation table, wherein the operation table is mounted between the racks; a rotary disk is rotatably mounted on the operation table; a core column supporting ring is fixedly mounted on the rotary disk; a core column is mounted on the core column supporting ring; a spline sleeve is fixedly mounted under the operation table; the spline sleeve is fixedly connected with the rotary disk; a spline shaft matched with the spline sleeve is arranged below the spline sleeve; one end, away from the spline sleeve, of the spline shaft is connected with a motor; a plurality of fuel gas tubes which are fixedly mounted on the operation table are arranged at the outer side of the rotary disk; sintering nozzles are mounted at the upper ends of the fuel gas tubes; a jetting direction of the sintering nozzles is opposite to the core column; the upper end of the rack is rotatably connected with a rotary plate; a gasbag is connected below the rotary plate; a gas box is mounted on the gasbag; a heater is mounted on the gas box; and a conveyor belt is arranged below the gas bag. The processing device solves the problem that the lamp bulb easily bursts because of lamp bulb temperature rise in a lamp bulb sealing and sintering process.

Owner:厦门鑫昊翔科技有限公司

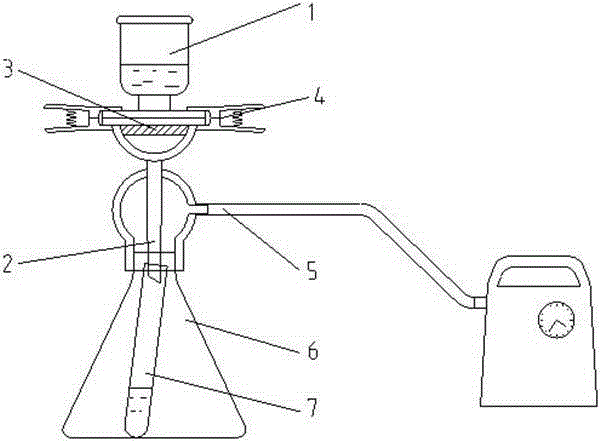

Method for extracting soluble organic carbon in soil

ActiveCN104614223AEfficient extractionAvoid interferencePreparing sample for investigationHigh concentrationSoil science

The invention discloses a method for extracting soluble organic carbon in soil. The method comprises the following steps: weighing 10.00g of a sample, putting the sample into a 100mL bottle, adding 40mL of a 0.5mol / L K2SO4 solution, putting on an oscillator for oscillating for 30min at the speed of 200rpm, carrying out suction filtration by using a special vacuum suction filtration device, collecting filtrate in a 50mL centrifugal tube, putting the filtrate in a low-temperature refrigerator at 4 DEG C to refrigerate for 1h, so that salt in the filtrate is separated out, centrifuging for 5min at the high speed of 2500rpm, so that the salt precipitates and is layered with the filtrate, and measuring supernate in the centrifugal tube by using a TOC instrument so as to obtain the content of the soluble organic carbon in the soil. The soluble organic carbon in the soil is effectively extracted; the problem that a combustion tube of the TOC instrument is exploded due to too-high concentration during extracting by using K2SO4 is solved; simultaneously, interference of saline ions in the soil having the high salt content to measurement is also solved, and therefore, the method has good practicability.

Owner:INST OF SOIL & FERTILIZER XINJIANG ACAD OF AGRI SCI

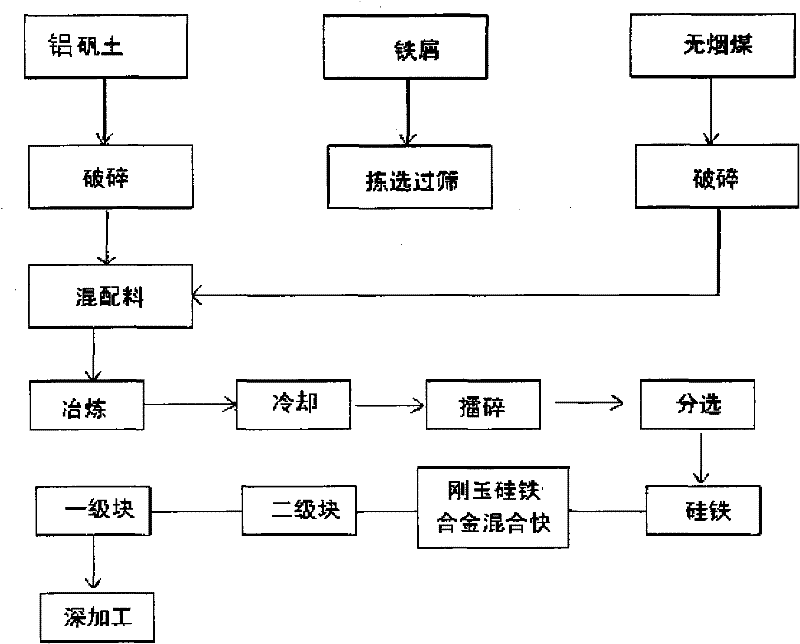

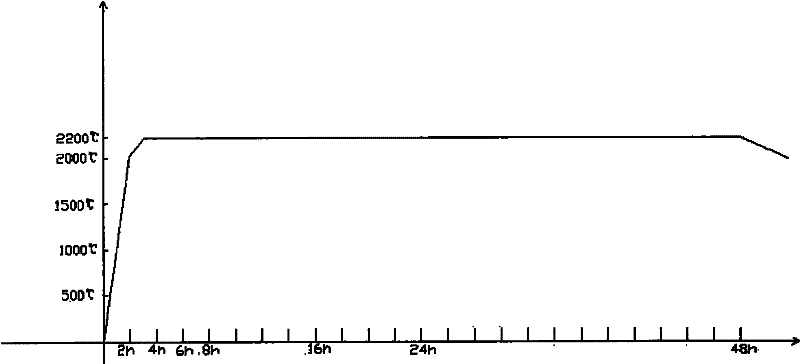

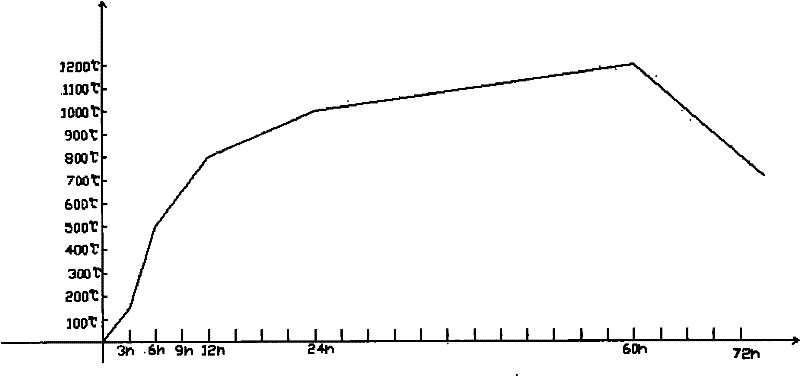

Sub-white corundum and production method thereof

The invention relates to sub-white corundum and a production method thereof. The production method comprises the following steps: separately crushing anthracite and bauxite containing 85wt% of aluminum trioxide, mixing with scrap iron to obtain a mixed material, and smelting the mixed material in an electric arc furnace for 48 hours while increasing the temperature from 0 DEG C to 1100 DEG C at 0-1st hour, increasing the temperature from 1100DEG C to 2000 DEG C at 1st-2nd hour and increasing the temperature from 2000 DEG C to 2200 DEG C at 2nd-3rd hour; naturally cooling for 58 hours after smelting, then adding water, cooling for 36 hours, carrying out cooling crystallization to obtain a frit, and grinding the frit to obtain a sub-white corundum block; and carrying out secondary calciningor pickling to obtain two types of products. The method provided by the invention has the advantages of low cost and high practicality, can be used for completely eliminating the cracking and powdering phenomena of a corundum-based refractory, and achieving obvious economical benefits and social benefits.

Owner:焦作市山阳亚白刚玉厂

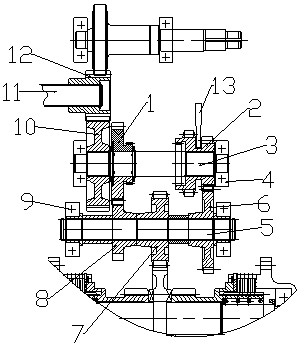

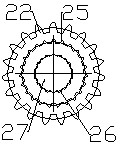

Gear-shift mechanism in gearbox of high-horsepower agricultural machinery equipment

InactiveCN102182796ATroubleshoot gear issuesSolve burstControlled membersToothed gearingsGear wheelAgricultural engineering

The invention discloses a gear-shift mechanism in a gearbox of high-horsepower agricultural machinery equipment. The gear-shift mechanism comprises a duplicate gear, a free gear, a gear change shift fork, a first gear shaft and a second gear shaft, wherein a driven gear is in shaft connection to one end of the first gear shaft; the free gear is freely sleeved on the end part close to the driven gear; the duplicate gear is in spline connection with the first gear shaft; the second gear shaft is sequentially provided with a neutral position gear, a fast gear and a slow gear through a metal spline; and the free gear and the duplicate gear which are arranged on the first gear shaft are controlled by the gear change shift fork to be correspondingly meshed with the neutral position gear, the fast gear and the slow gear which are arranged on the second gear shaft. The gear-shift mechanism has a simple structure and small size; and by using the gear-shift mechanism, the driving performance can be effectively improved and the control to the rotating speed in each gear can be realized; the high-power output can be born; and the high-low frequency change of the load can be born and thus the burst of the gearbox can be prevented.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

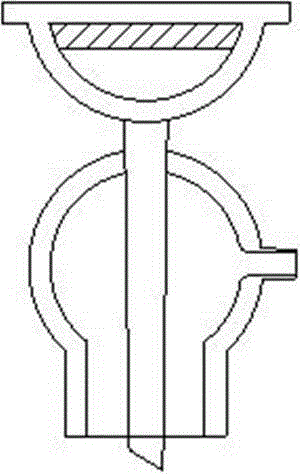

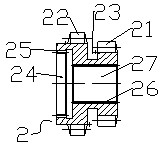

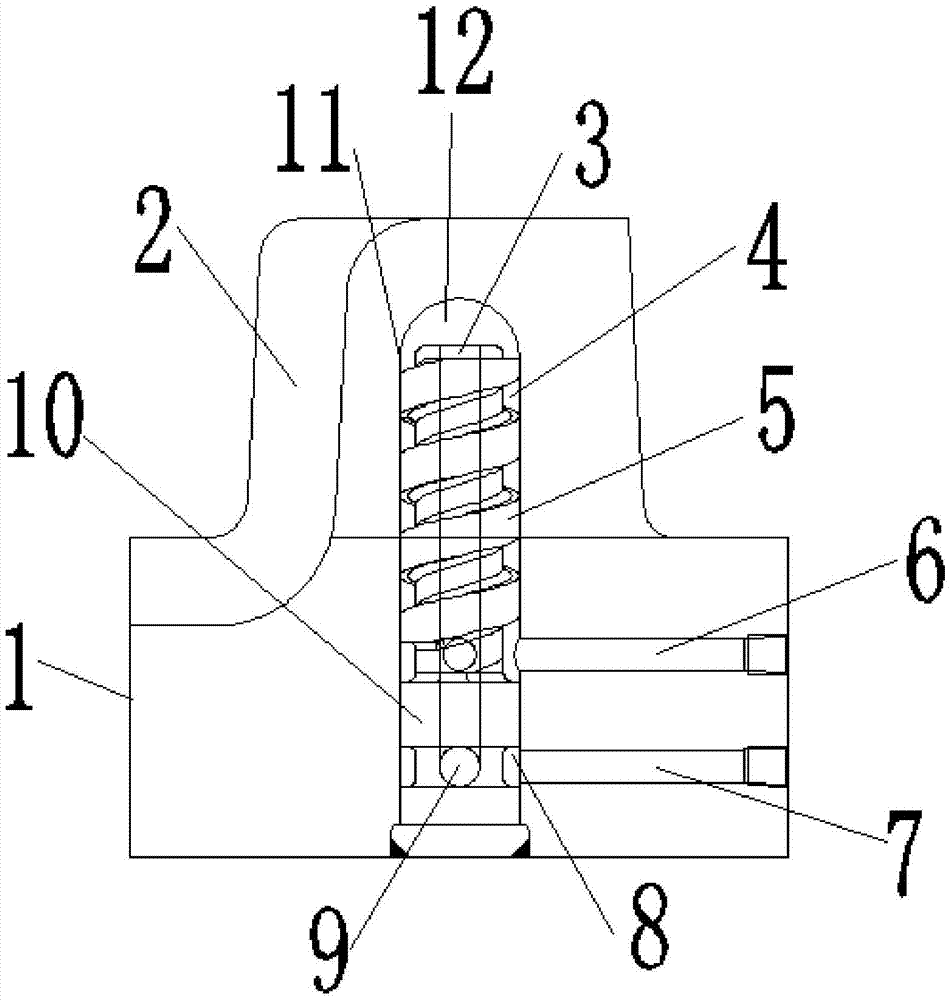

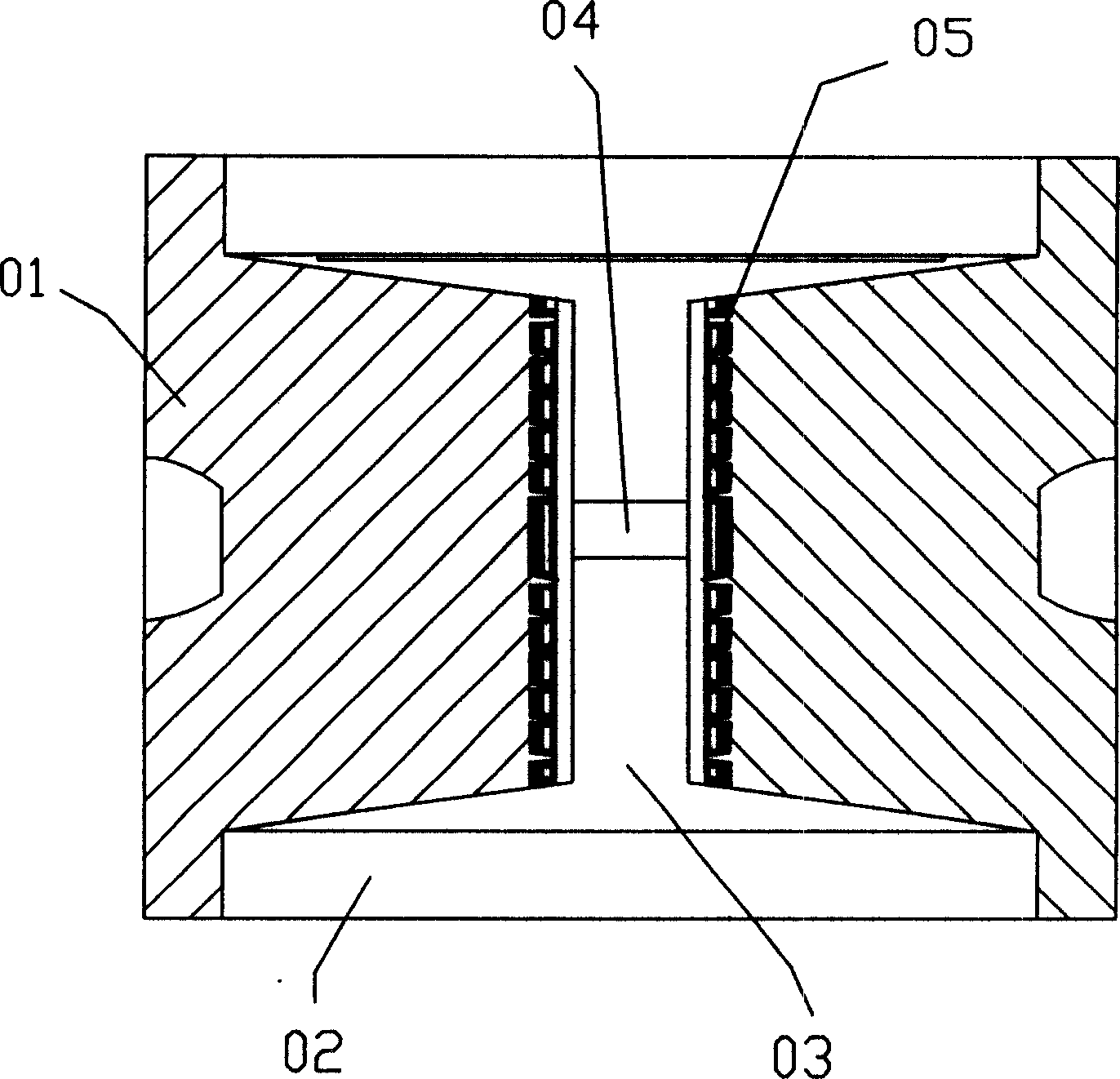

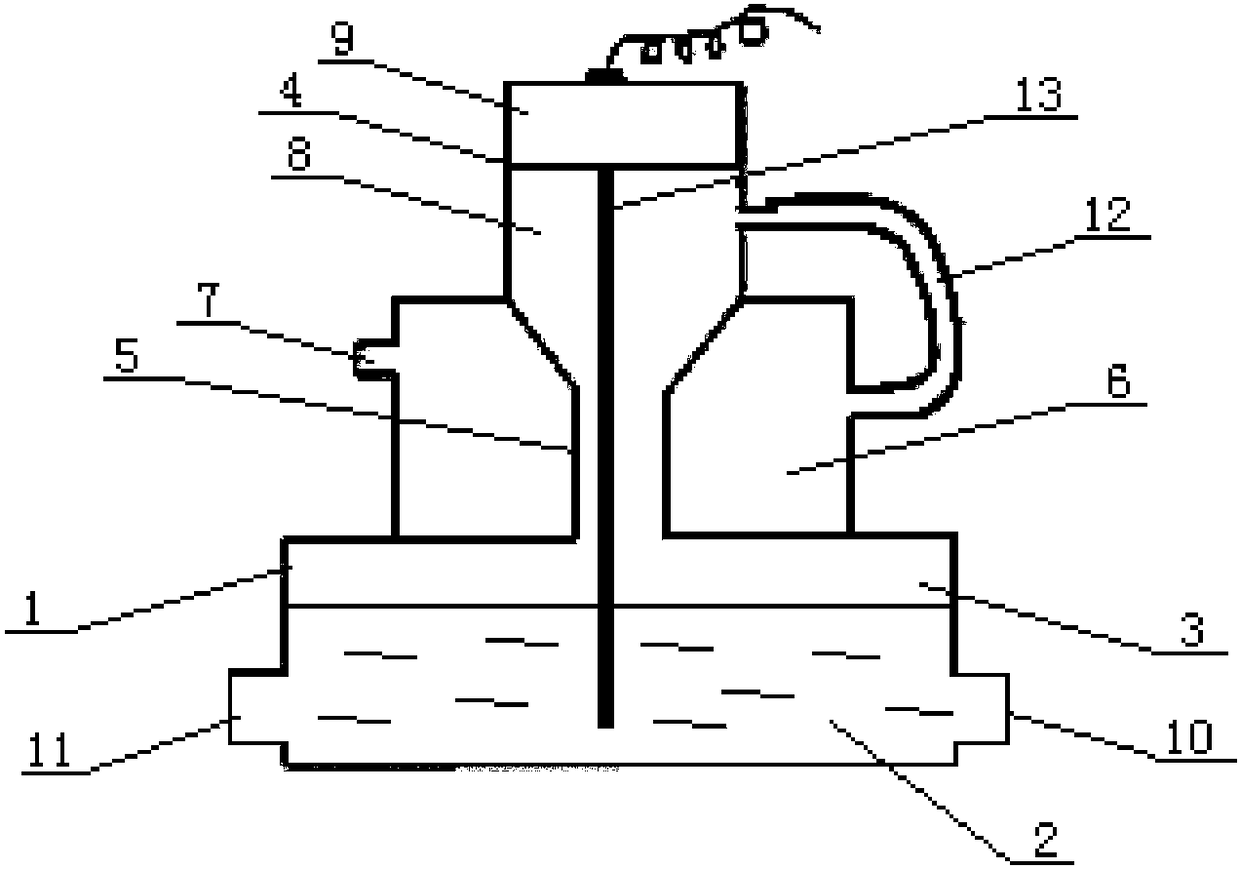

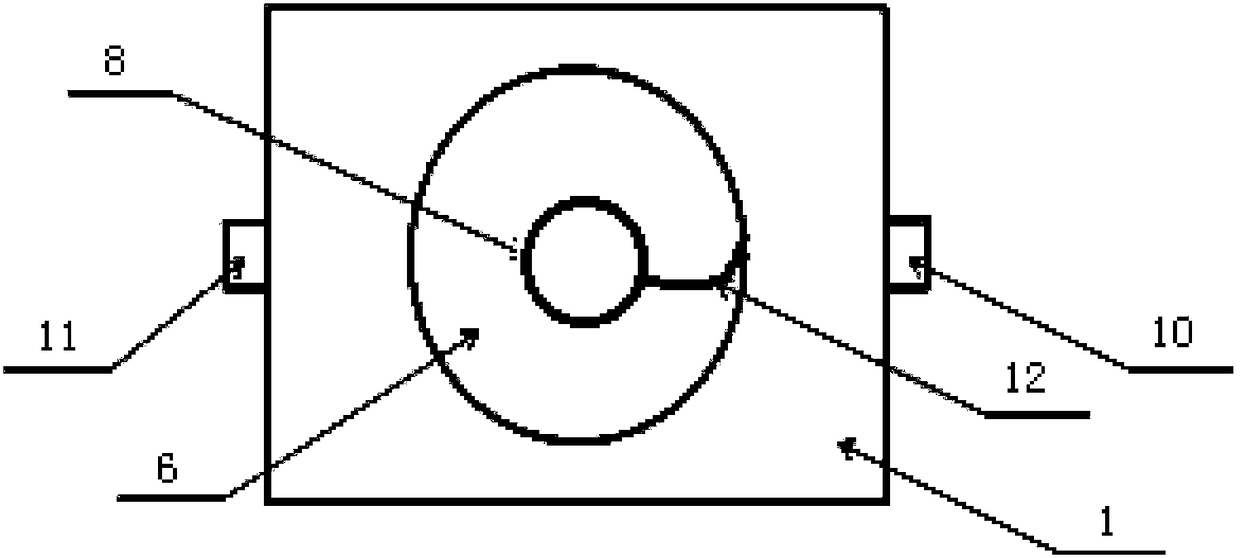

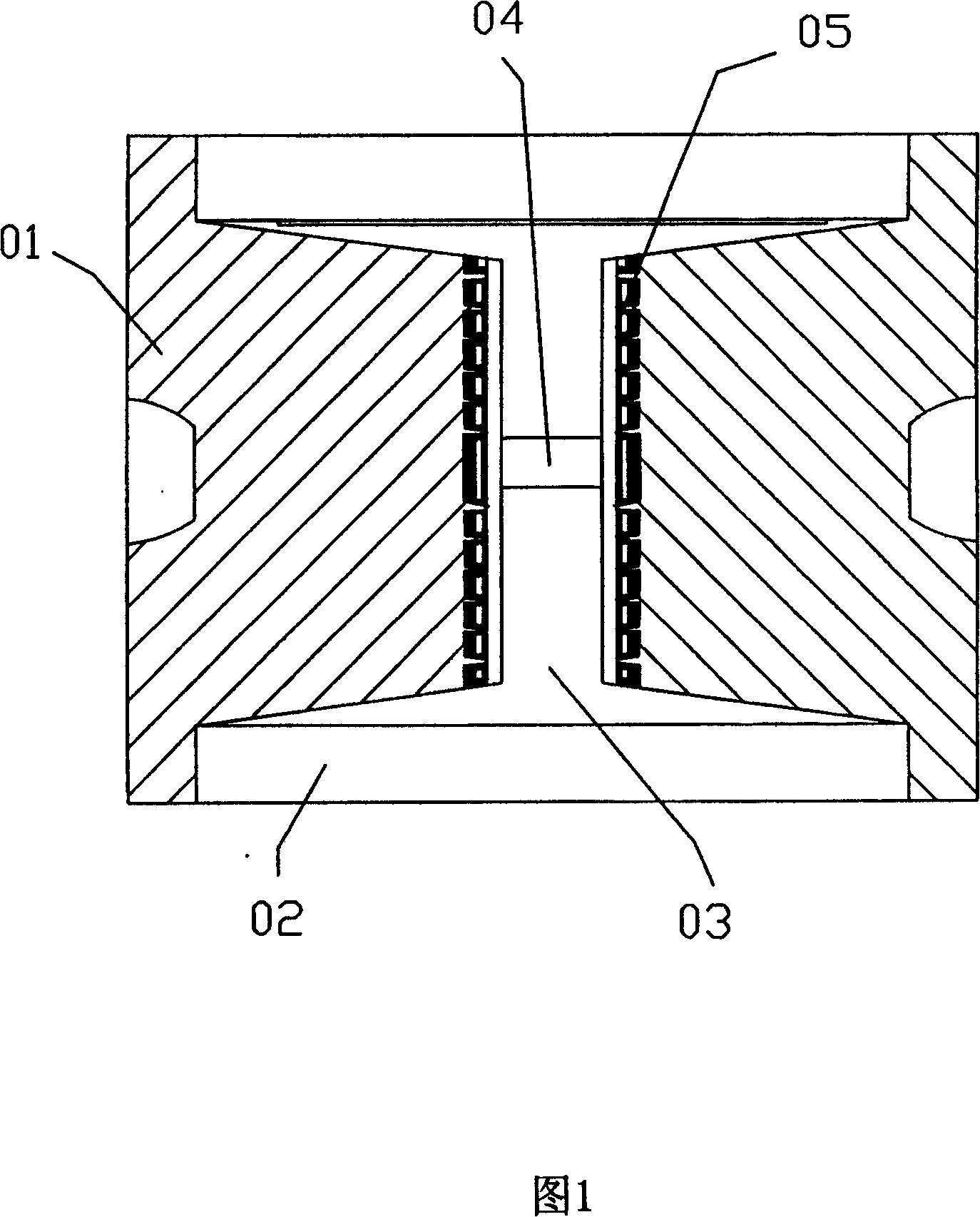

Sprue spreader spiral sufficient cooling structure for die-casting die

The invention relates to a sprue spreader spiral sufficient cooling structure for a die-casting die. The structure comprises a sprue spreader, a water inlet pipe and a water outlet pipe, wherein the water inlet pipe and the water outlet pipe are transversely arranged inside the sprue spreader; a cooling water well is formed at the middle portion of the sprue spreader vertically; a base is installed in the cooling water well; a groove is formed in the middle portion of the base and communicated with the water outlet pipe; a spiral tower is arranged at the upper end of the base; a spiral and upward water tank is formed in the side wall of the spiral tower; a gap is arranged between the upper end of the spiral tower and the cooling water well; the lower end of the water tank is connected with the water inlet pipe; the upper end of the water tank is communicated with the gap; a through hole is vertically formed in the spiral tower and the base; the upper end of the through hole is communicated with the gap; and the lower end of the through hole is communicated with the groove. According to the sprue spreader spiral sufficient cooling structure, the spiral cooling structure is adopted; the superficial area for cooling is increased; and due to the spiral cooling structure, the whole cooling process is full and uniform, and the efficiency of die-casting production is effectively improved.

Owner:NINGBO HUIWANG MACHINERY

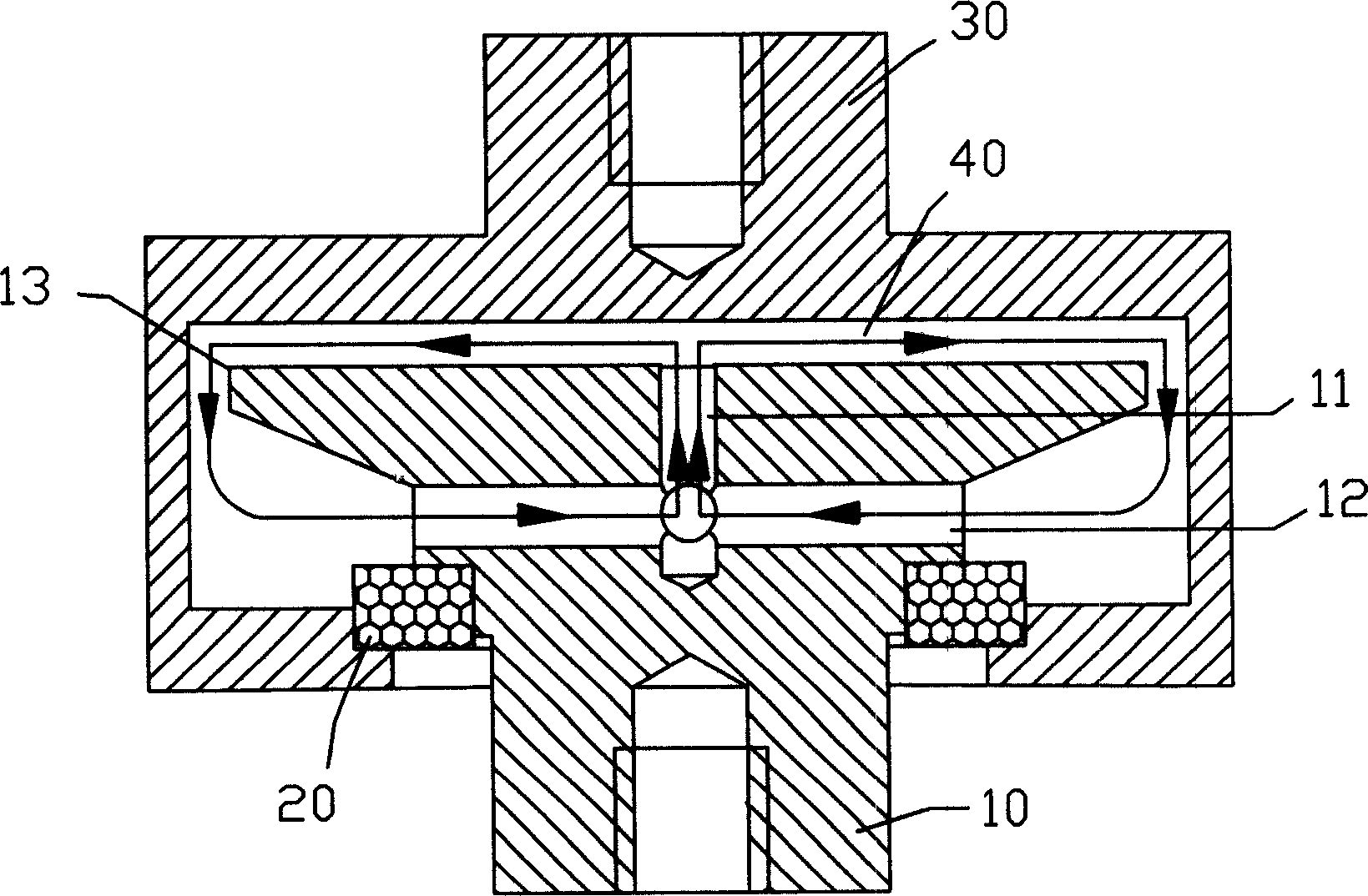

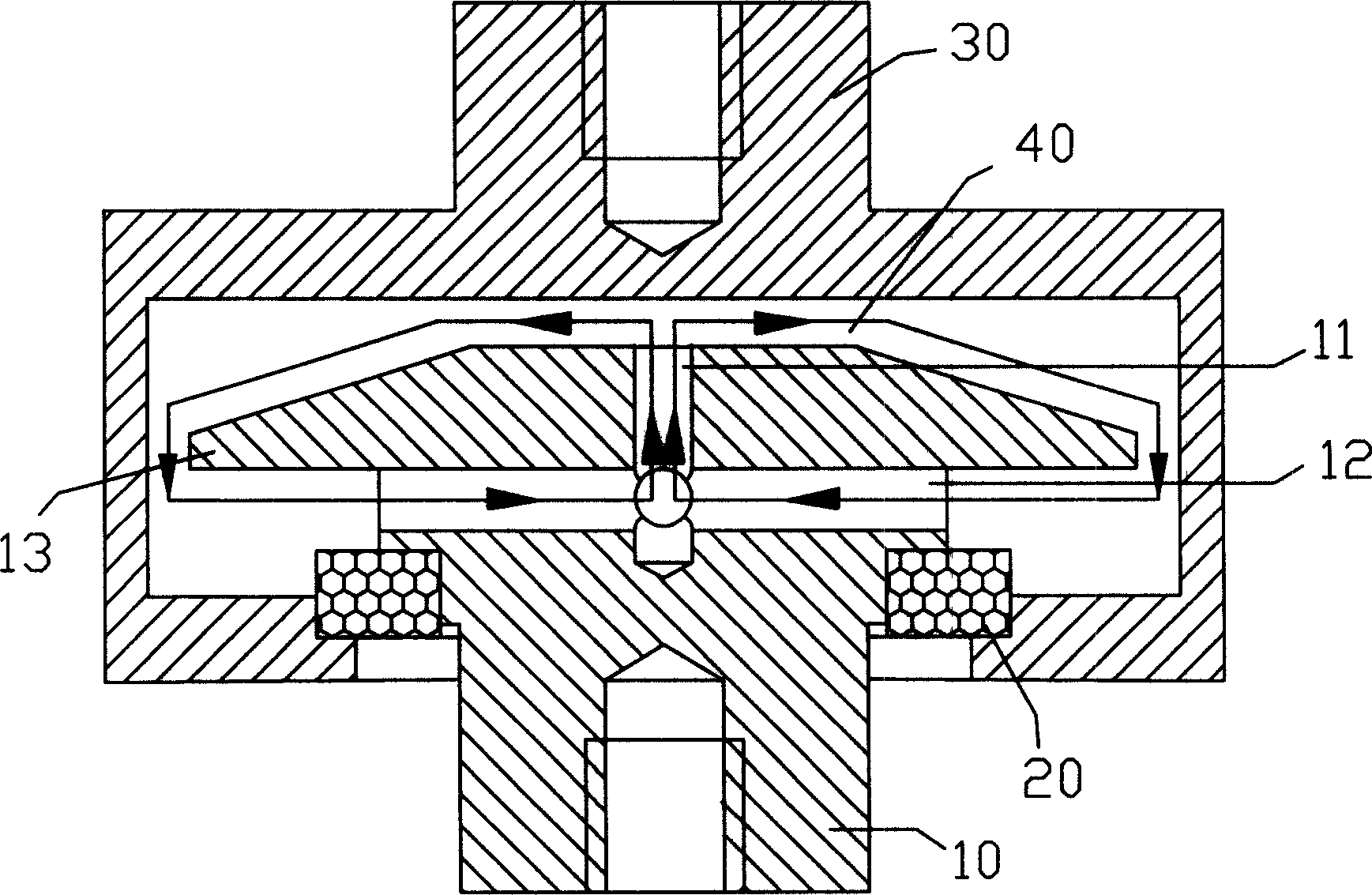

No-follow curren metal ceramic gas discharge tube

InactiveCN1588718ASolve burstAvoid potential hazardsSpark gap detailsOvervoltage arrestors using spark gapsLightning strokesElectron

This metal-ceramic gas discharge tube for unordered current after lightning stroke used for strong current system involves: inner electrode, outer electrode and metallized ceramic insulator. The three are combined to form a space filled with inert gas. In the space there are: discharging gap and one end of inner electrode. It also has central hole coaxial with said inner electrode and several gas-inlet holes connected to siad central hole. The gas inlet hole, central hole and discharging gap are combined to form a circulation loop. This invention solves problems such as: unordered flow in electric source of electronic device, and lightning stroke problem.

Owner:GUANGZHOU HOPEWELL TECH

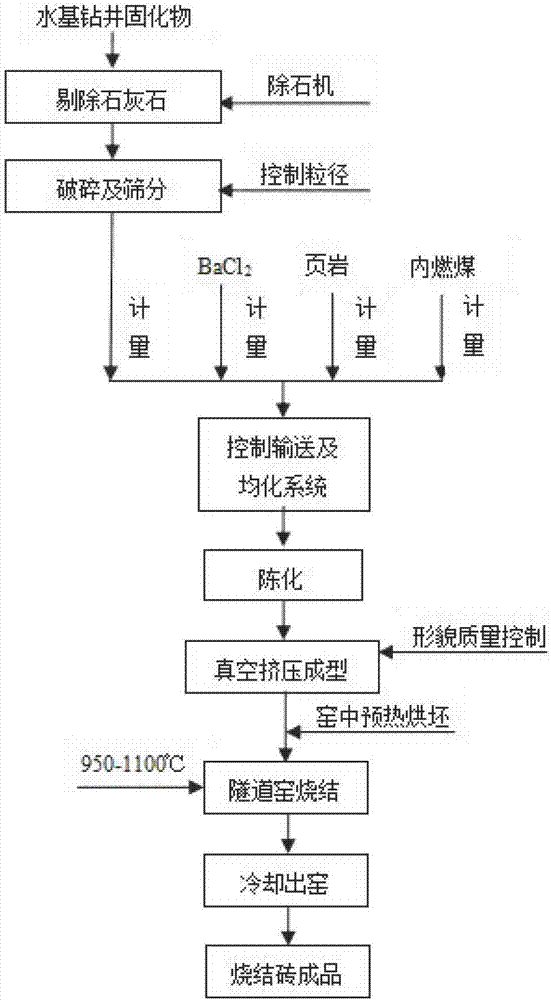

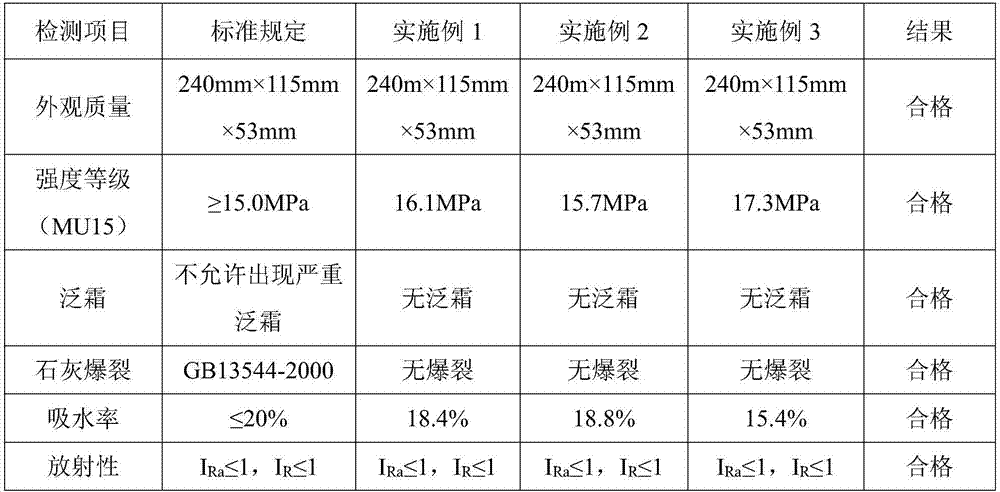

Method for preparing sintered brick by water-based well drilling condensate modification

InactiveCN107459337ASolve the problem of whiteningSolve the problem of bloomingCeramic materials productionClaywaresWater basedCombustion

The invention discloses a method for preparing a sintered brick by water-based well drilling condensate modification. The method comprises a step (1) of causing water-based well drilling condensate to undergo preliminary crushing, adopting a stone removal device to remove most of limestone therein, performing deep crushing on the water-based well drilling condensate from which the limestone has been removed, performing sieving, and obtaining powder with the fineness lower than 1 mm; a step (2) of causing the water-based well drilling condensate powder obtained through the step (1) to be evenly mixed with modifier barium salt, shale soil and internal combustion coal, and obtaining a mixed material; a step (3) of adding water into the mixed material obtained through the step (2), performing stirring, and performing ageing for 2-3 days; a step (4) of making the aged mixed material into a green brick, performing drying and high-temperature sintering, and obtaining the finished sintered brick. According to the method for preparing the sintered brick by water-based well drilling condensate modification, the problems that in the prior art, a brick body of a sintered brick prepared from the water-based well drilling condensate becomes white, bursts and powders are effectively solved.

Owner:四川华恒正合石化科技有限公司

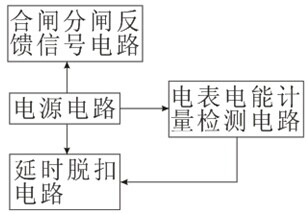

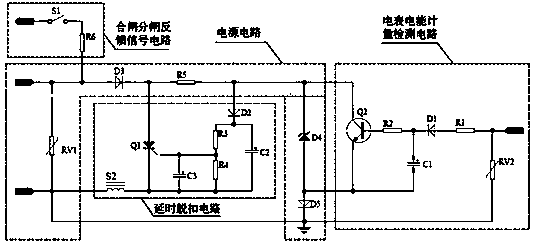

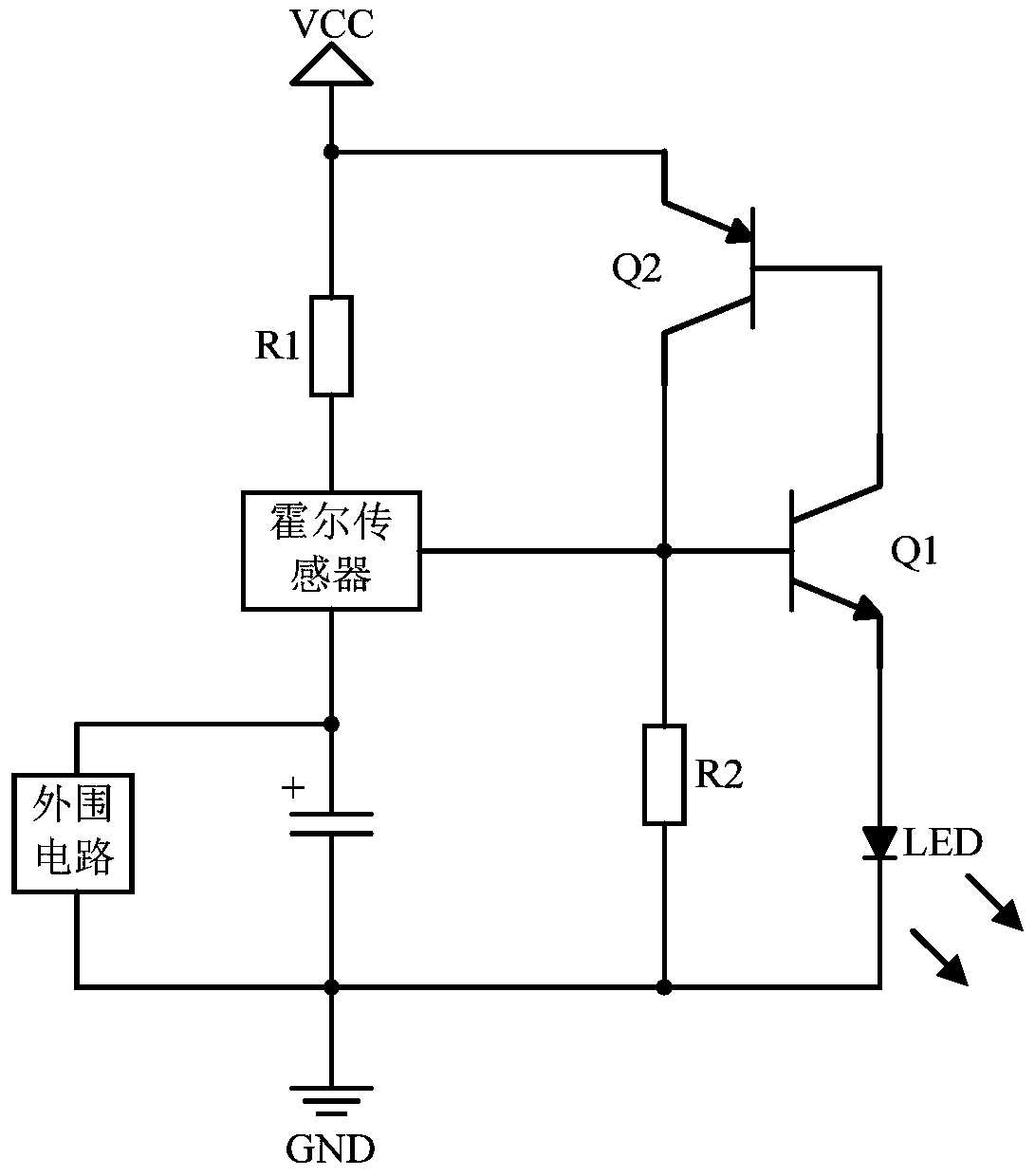

Special breaker circuit for miniature prepaid electricity meter

InactiveCN104268993AImprove accuracyIncreased persistenceApparatus for hiring articlesElectricity meterCurrent limiting

The invention relates to a special breaker circuit for a miniature prepaid electricity meter. The special breaker circuit comprises a power supply input, and is characterized by further comprising a power supply circuit, and a delay trip circuit, a switch-on and switch-off feedback signal circuit, an electricity meter electric energy measurement detecting circuit connected to the power supply circuit, wherein a source circuit comprises a piezoresistor RV1, a rectifier diode D3, a current-limiting resistor R5, a diode D5 and a voltage stabilizing diode D4; the delay trip circuit comprises a diode D2, resistors R3 and R4, capacitors C2 and C3, a silicon controlled rectifier Q1 and a tripper S2; the electricity meter electric energy measurement detecting circuit comprises a piezoresistor RV2, resistors R1 and R2, a diode D1, a capacitor C1 and a transistor Q2; the switch-on and switch-off feedback signal circuit comprises a switch-on and switch-off detecting switch S1 and a current-limiting resistor R6. According to the special breaker circuit for the miniature prepaid electricity meter, measuring accuracy of the electric energy, and continuity, reliability and safety of power supply are greatly improved; delay precision and reliability are improved, design is simple and resistance to electromagnetic compatibility is strong.

Owner:CNC ELECTRIC GRP

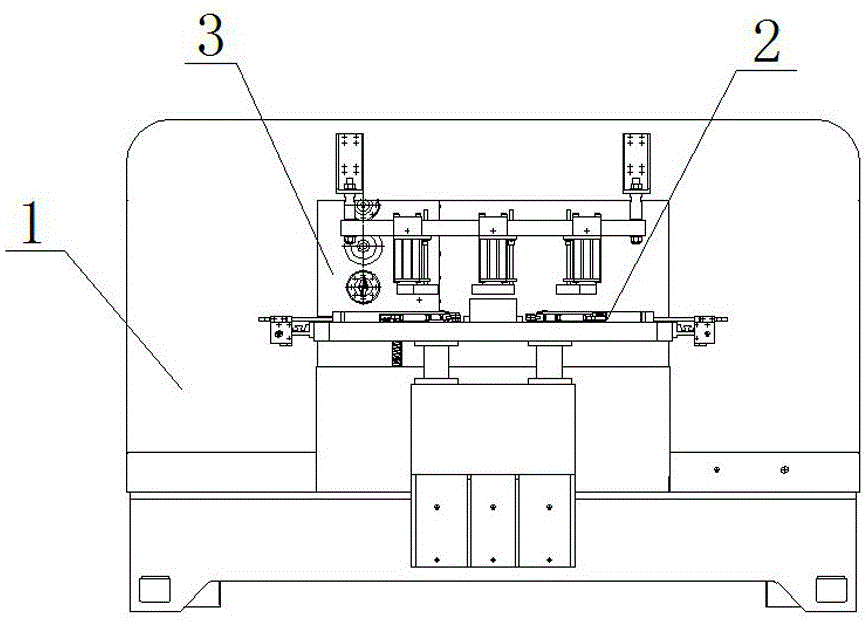

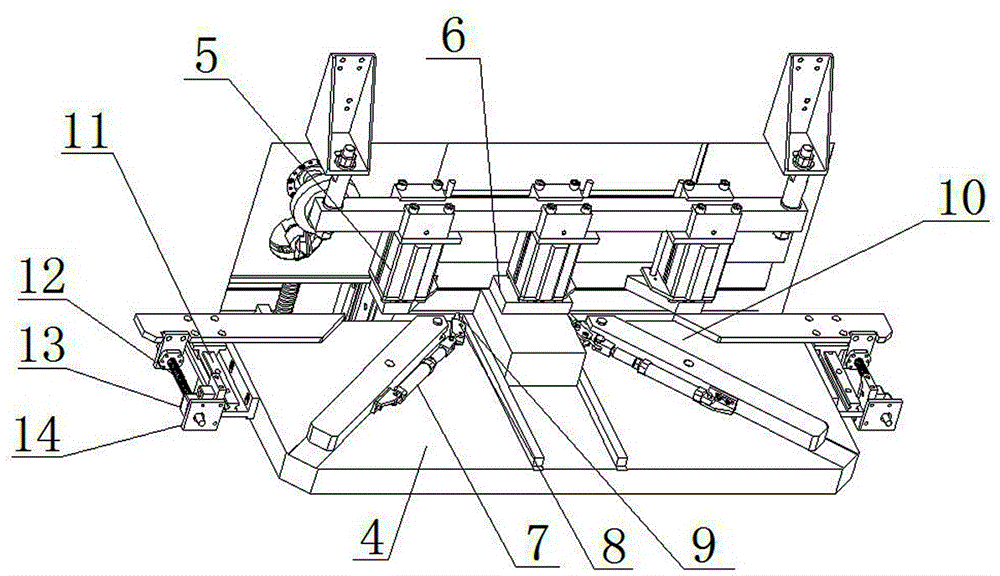

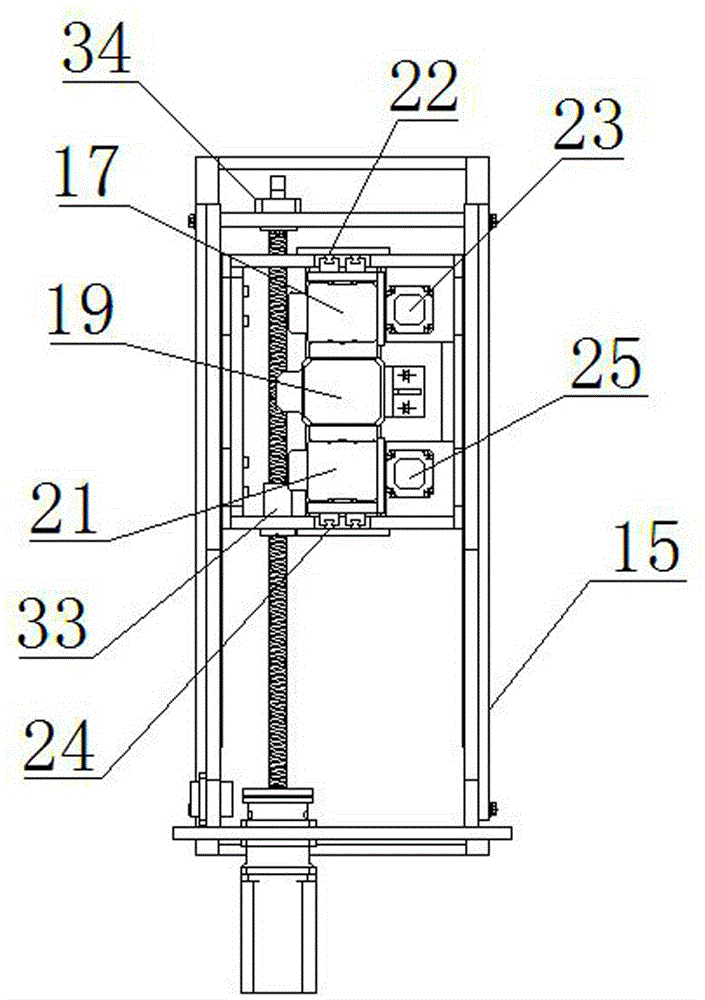

Multi-cutter numerical control scarf jointing machine

ActiveCN106182202ASolve burstEasy to processDrilling machinesDovetailed workNumerical controlMilling cutter

The invention discloses a multi-cutter numerical control scarf jointing machine. The multi-cutter numerical control scarf jointing machine comprises a rack, a workbench, a multi-cutter device, a horizontal moving mechanism and a vertical moving mechanism, wherein the workbench is horizontally arranged on one side of the rack; the multi-cutter device is arranged on the vertical moving mechanism and driven by the vertical moving mechanism to move along the vertical direction; the vertical moving mechanism is arranged on the horizontal moving mechanism and driven by the horizontal moving mechanism to move along the horizontal direction; and the multi-cutter device is positioned on one side of the workbench. According to the multi-cutter numerical control scarf jointing machine disclosed by the invention, a drilling and milling cutter, a large V-shaped cutter and a small V-shaped cutter which are arranged along the vertical direction can be driven by the horizontal moving mechanism and the vertical moving mechanism cooperatively; the lower side surface of a workpiece is machined by utilizing the small V-shaped cutter at first, and then 45-degree or 135-degree tenon-and-mortise machining is completed from top to bottom by utilizing the large V-shaped cutter, thereby solving the problem of conchoidal defects of the workpiece; and meanwhile, the drilling and milling cutter is integrally arranged, and all the working procedure for tongue-and-groove joint are completed through one machine, so that the machining is convenient and fast.

Owner:JIANGSU GUOQUAN AUTOMATION TECH CO LTD

Water-cooled pipe wall spray coating

The invention provides a water-cooled pipe wall spray coating. The water-cooled pipe wall spray coating is prepared from the following raw materials in parts by weight: 40-70 parts of high bauxite aggregate, 10-40 parts of high bauxite fine powder or corundum fine powder, 5-10 parts of aluminum oxide micro powder, 1-3 parts of clay powder, 2-6 parts of silicon dioxide micro powder and 3-10 parts of a composite additive, wherein the composite additive is a mixture of a binding agent A, pure calcium aluminate cement and explosion-proof fibers, a mixture of sodium hexametaphosphate, sodium silicate and explosion-proof fibers or a mixture of sodium hexametaphosphate, calcium nitrate and explosion-proof fibers. The water-cooled pipe wall spray coating has the beneficial effects that the prepared water-cooled pipe wall spray coating is good in caking property and is suitable for semi-dry spraying and wet spraying; dust pollution is small, the spraying thickness is easy to control, and the service life is long. The cost of the high bauxite aggregate is low; by adding the aluminum oxide micro powder and the clay powder, the caking property of the spray coating is improved, the plasticity of the spray coating is improved, the spraying kinetic energy generated by a spraying machine can be partially absorbed by the spray coating, and the spray coating can be firmly adhered on the wall ofa water-cooled pipe.

Owner:北京利尔高温材料股份有限公司

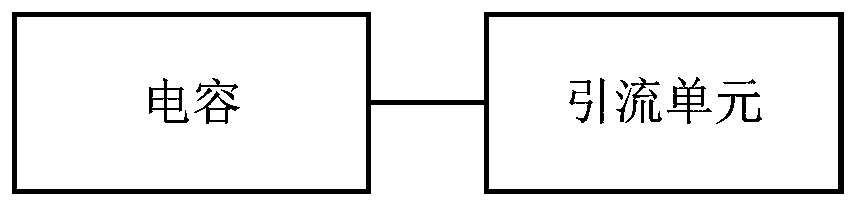

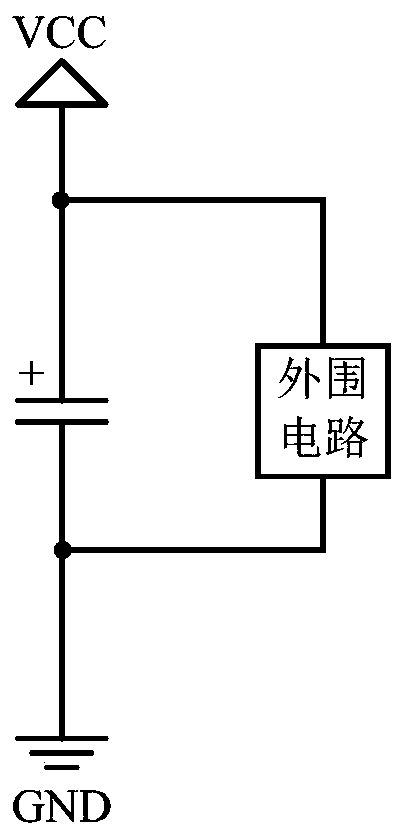

Capacitor reverse connection protection device, capacitor equipment and capacitor reverse connection protection method thereof

InactiveCN111082405APrevent burstImprove securityEmergency protective arrangements for limiting excess voltage/currentCapacitanceElectrical polarity

The invention discloses a capacitor reverse connection protection device, capacitor equipment and a capacitor reverse connection protection method thereof. The device comprises a drainage unit, the drainage unit is used for draining the leakage current generated by reverse connection of the capacitor to a set safety position under the condition that the capacitor generates the leakage current dueto reverse connection of the polarity. According to the scheme provided by the invention, the problem of poor use safety caused by explosion when the polar capacitor is reversely connected can be solved, and the effect of improving the use safety of the polar capacitor is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Slurry spray-drying method

InactiveCN106606887ASolve burstSolve the abnormalityLiquid spraying apparatusEvaporation by sprayingMicrosphereSpray nozzle

The invention relates to the field of spray drying and discloses a slurry spray-drying method. The method is used in a spray-drying machine comprising a spray-drying tower body and a nozzle. The method comprises introducing slurry to be dried into the nozzle, injecting the slurry into tower body containing high temperature hot air through the nozzle, carrying out atomization to obtain a mist cone, and introducing protective wind to positions around the mist cone so that the outer peripheral surface of the mist cone is relatively isolated from the high temperature hot air in the tower body, wherein the temperature of the protective wind is lower than the temperature of the high temperature hot air. When the method is used for spray drying, the method can solve the problems of microsphere burst, special-shaped fine powder production and small powder particle sizes in a drying process and can realize good sphericity of the dried granules.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cooling water tank

PendingCN108252793ASolve burstGuaranteed safe operationMachines/enginesEngine cooling apparatusSystem pressureCooling fluid

The invention provides a cooling water tank. The cooling water tank comprises a cooling liquid chamber (1) and a buffer chamber (6); the cooling liquid chamber (1) comprises a cooling liquid containing cavity (3) for containing cooling liquid (2), a cooling liquid filling opening (4) in the top of the cooling liquid chamber (1) and a filling chamber (8) located below the cooling liquid filling opening (4), and the cooling liquid filling opening (4) and the cooling liquid containing cavity (3) are in liquid communication through the filling chamber (8); and the buffer chamber (6) is in liquid communication with the filling chamber (8) and is provided with a flow via opening (7) communicating to the atmosphere. The cooling water tank provided by the invention is used for an engine cooling system, by additionally arranging the buffer chamber communicating with the cooling liquid chamber in the water tank, when the pressure in the cooling liquid chamber is too high, excess pressure can bedischarged through the buffer chamber, the problem that a water tank explodes during boiling as the system pressure is too high is effectively solved, and thus safety running of the engine cooling system is ensured.

Owner:深圳光启梦想科技有限公司

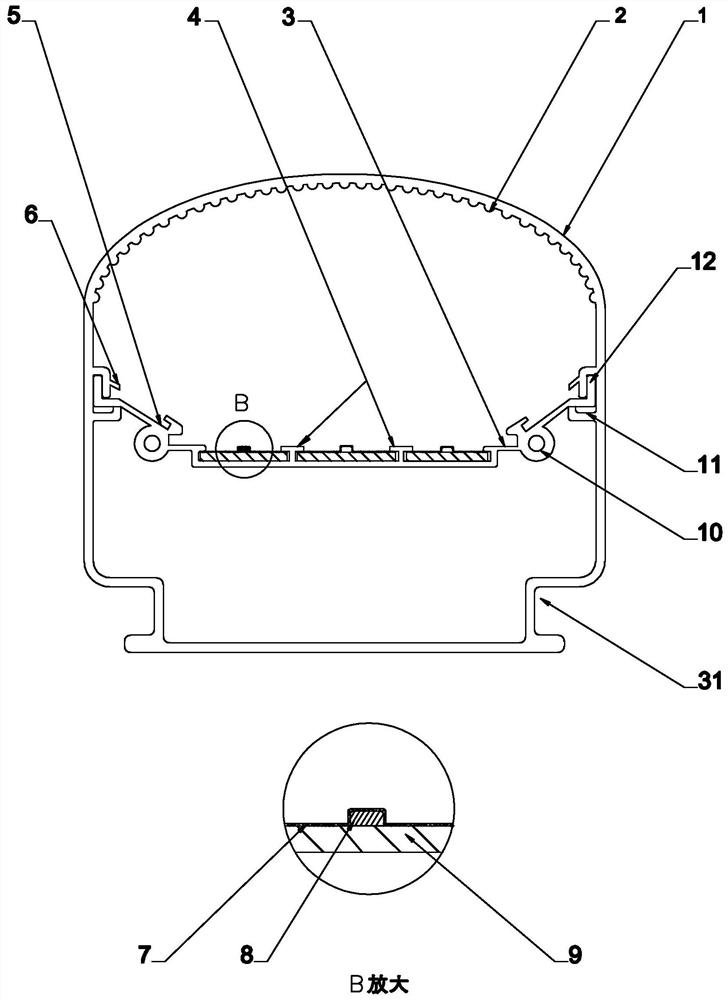

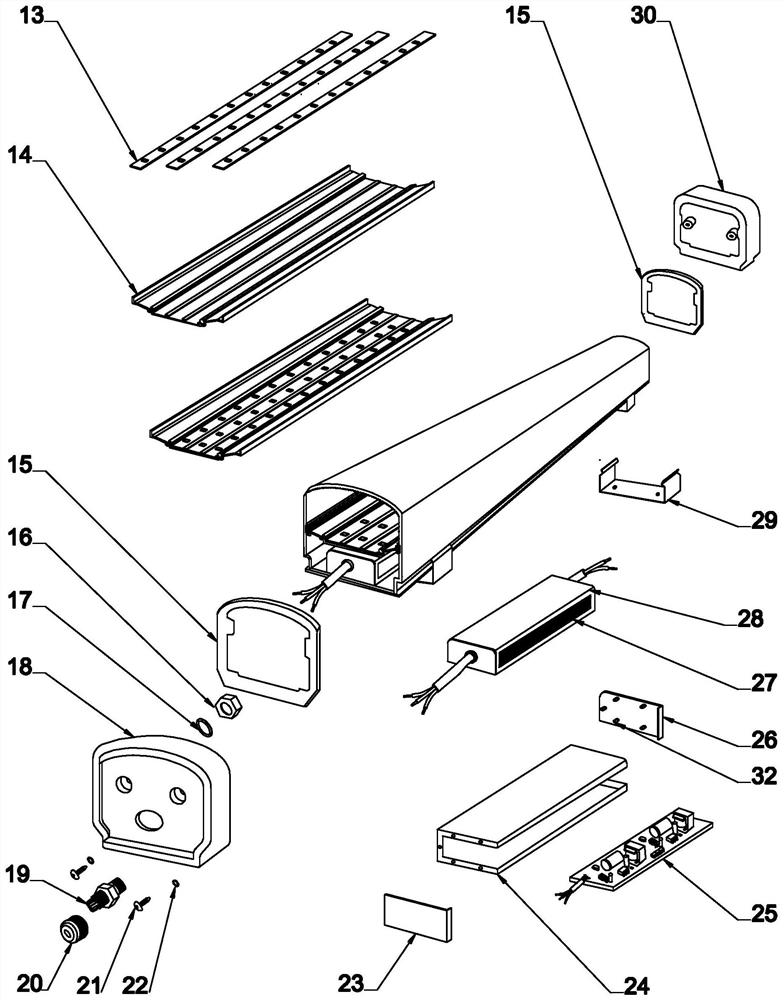

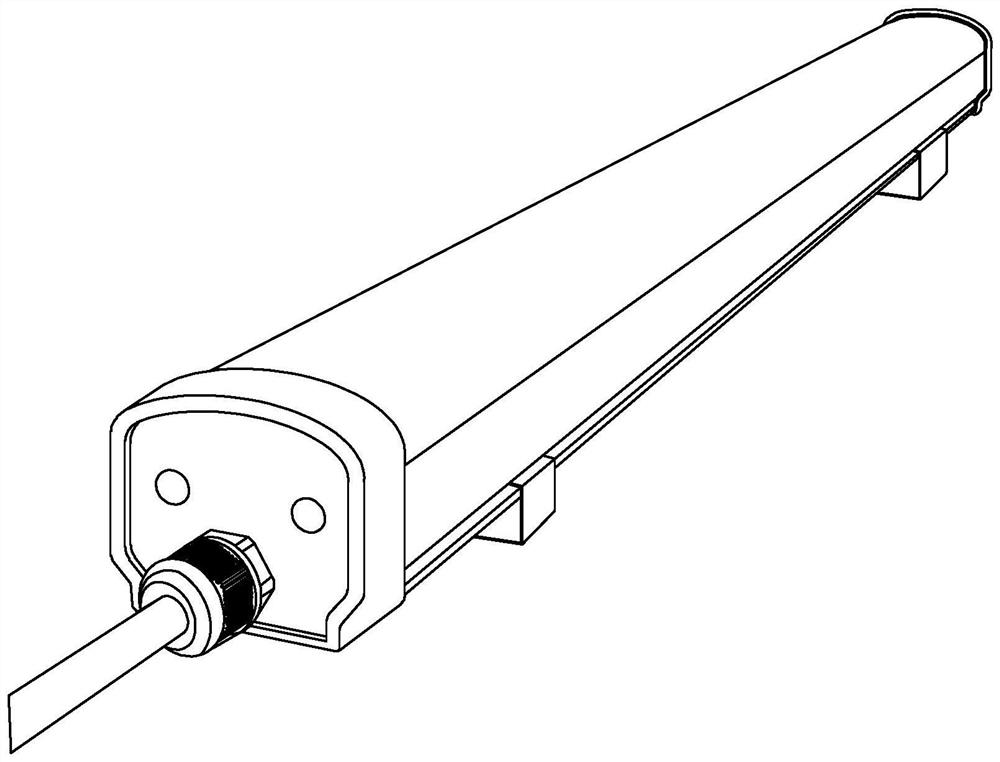

Composite waterproof anti-explosion high-luminous-efficiency LED refrigeration house lighting lamp

PendingCN113108254ASolve burstEasy to configureLighting heating/cooling arrangementsProtective devices for lightingEngineeringSilica gel

The invention discloses a composite waterproof anti-explosion high-luminous-efficiency LED refrigeration house lighting lamp which specifically comprises an integral PC cover assembly, a sealing light source assembly, a heat dissipation plate multi-stage fixing assembly and an end cover sealing assembly, and according to the lamp, integrated shell forming, end cover silica gel sealing, power source integral glue pouring and light source film covering are adopted, so that the high waterproof problem of the lamp is solved; through the design of a semicircular concave-convex inner grain structure on the inner surface of the shell, the problem that the lamp is prone to bursting due to thermal expansion and cold contraction of the lamp is solved, and through the design of different mounting clamping grooves of the multi-stage fixing assembly of the heat dissipation plate, the problem of efficient light source configuration of the lamp is solved. And meanwhile, the illumination effect of the refrigeration houses with different heights is greatly improved, and the lamp can be widely applied to the refrigeration houses and other places with high waterproof, explosion-proof, moisture-proof and illumination requirements.

Owner:珠海金太节能科技有限公司

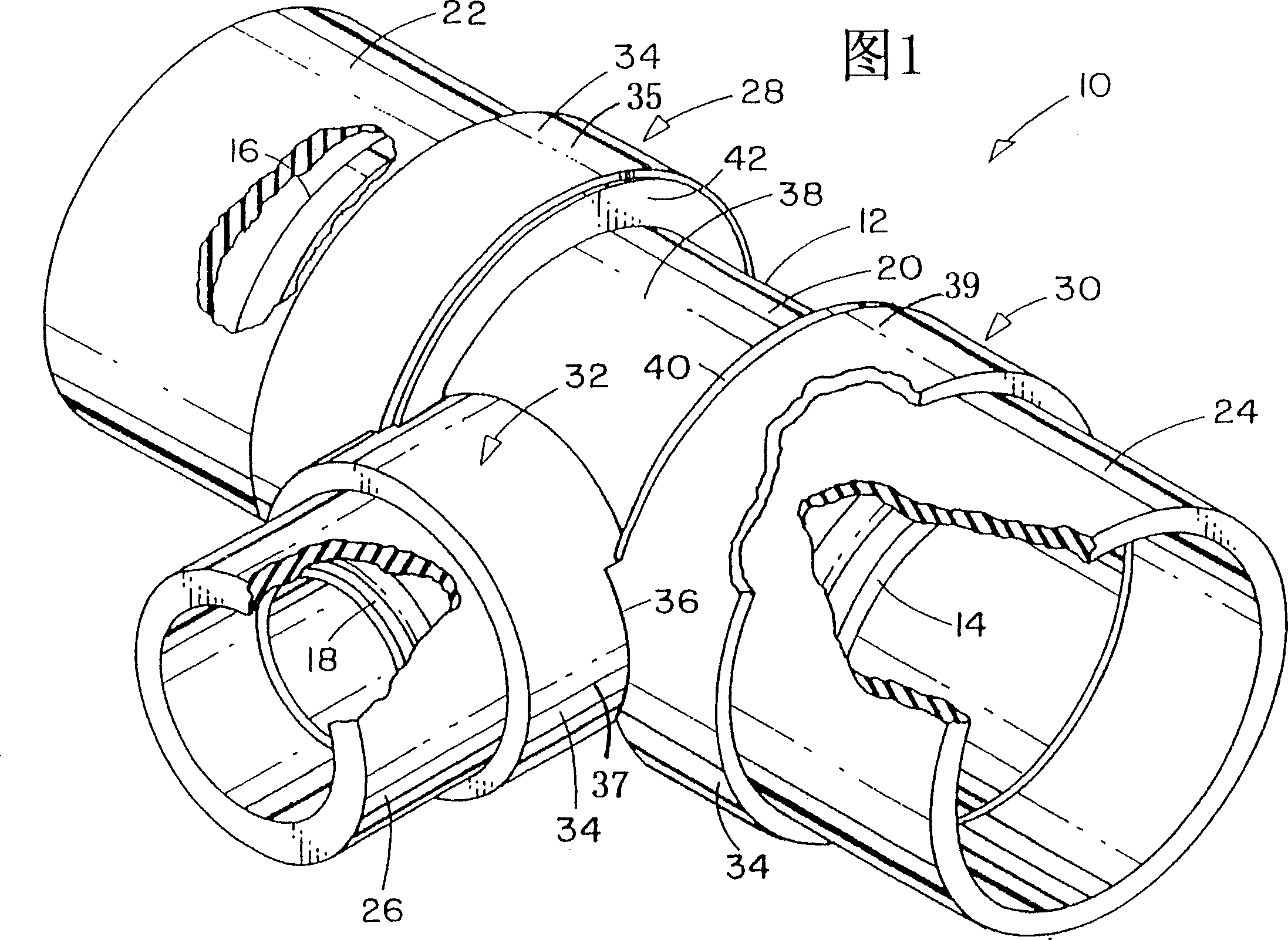

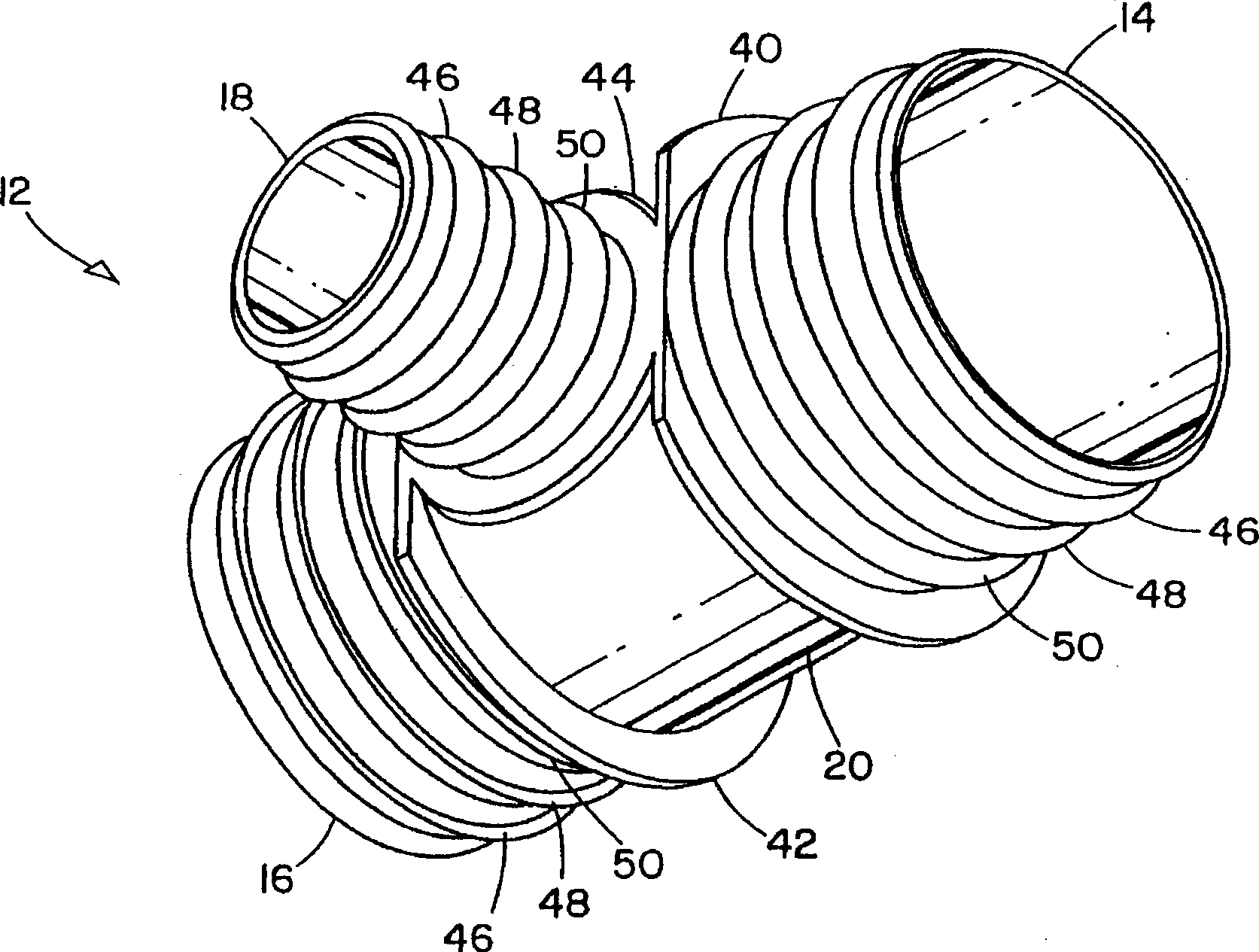

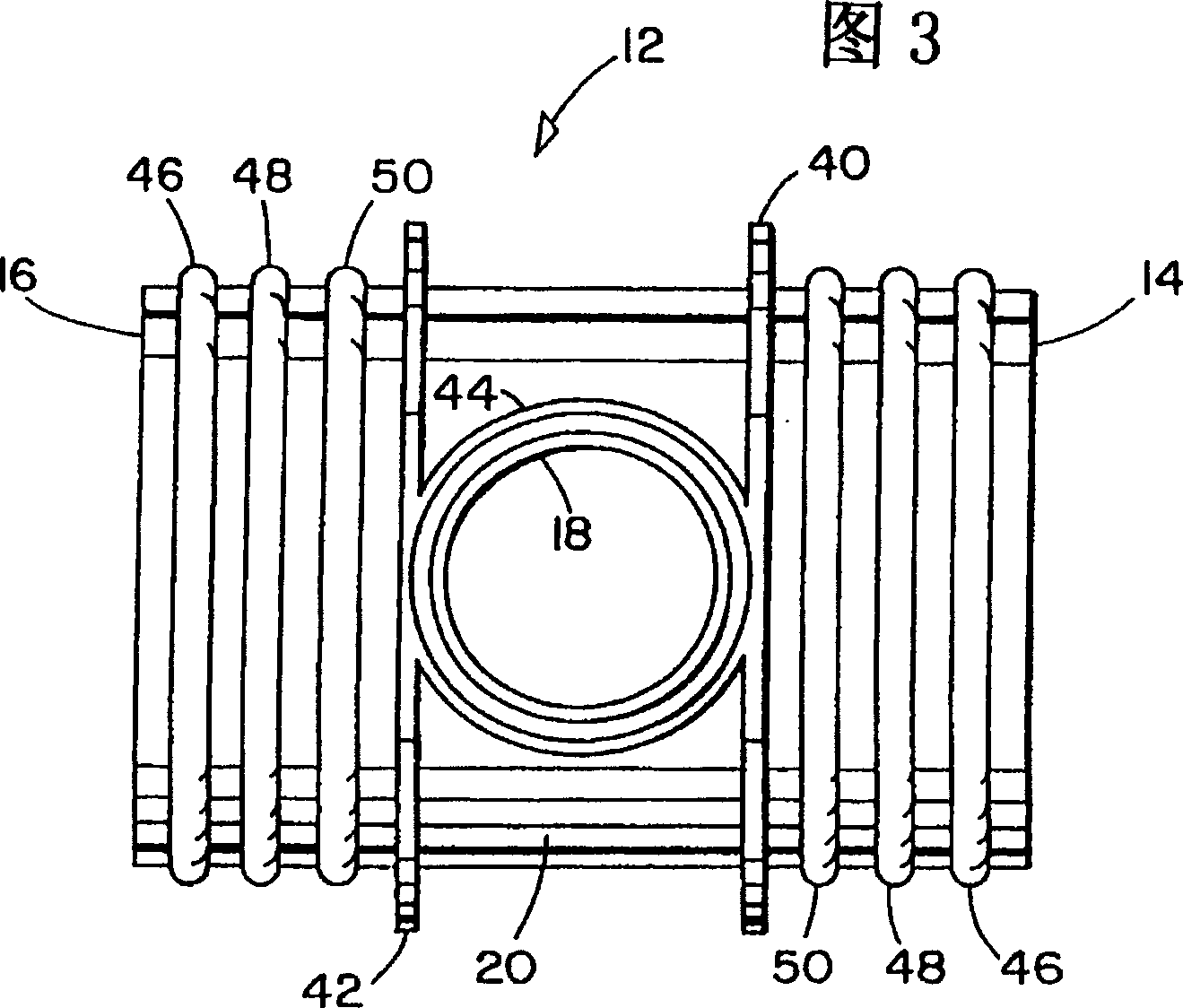

Molded hose joint assembly

InactiveCN1120319CEfficient preparationEasy to manufactureBranching pipesHose connectionsEngineeringHose coupling

Molded hose joint assemblies, e.g., connections, branched hoses and bleeding devices for fluid circuits, and especially such assemblies for use in automotive and industrial coolant circuit assemblies, which assemblies comprise a reduced amount of molded outer covering element over prior art designs, said covering element substantially encapsulating the connection points of generally flexible hose ends to generally rigid inner connection members. The outer covering element forms a unitary mass or interconnecting rings about at least two such hose connection points. Flexible manufacturing techniques for producing such assemblies are provided.

Owner:THE GATES CORP

A kind of leaching method of soluble organic carbon in soil

ActiveCN104614223BEfficient extractionAvoid interferencePreparing sample for investigationHigh concentrationCombustion

Owner:INST OF SOIL & FERTILIZER XINJIANG ACAD OF AGRI SCI

Colored material suitable for SBR thick product and preparation method

PendingCN112521672AGood weather resistanceSolve the problem of differences in the degree of vulcanization inside and outsideRubber materialPolymer science

The invention relates to a colored material suitable for an SBR thick product and a preparation method. The colored material is prepared from the following raw materials in parts by weight: 4-10 partsof ethylene propylene diene monomer, 18-22 parts of butadiene styrene rubber, 9-13 parts of butadiene rubber, 12-16 parts of white carbon black, 4-7 parts of titanium dioxide, 9-15 parts of magnesiumoxide or aluminum oxide, 9-13 parts of light calcium carbonate, 8-12 parts of paraffin oil, 1.0-1.2 parts of silane coupling agent, 3.4-3.8 parts of zinc oxide, 0.6-0.8 part of antioxidant, 0.3-0.5 part of stearic acid, 1-1.2 parts of polyethylene glycol, 1.2-1.4 parts of a vulcanizing agent and 0.56-0.9 part of an accelerant. The weather resistance of the SBR rubber material can be effectively improved, and the problem of difference of internal and external vulcanization degrees of a thick product caused by poor thermal conductivity of the rubber material is effectively solved.

Owner:XIAMEN MAIHUA RUBBER PROD CO LTD

Coffee residue composite material

The invention discloses a coffee residue composite material, and relates to the field of composite materials. The coffee residue composite material is composed of coffee residue, an inorganic adhesive, a natural polymer additive, polyolefin, an ionic polymer, soluble metal salt, polylactic acid, biodegradable copolyester, a compatilizer, a plasticizer, a tackifier and PBS, and the composite material is a fully degradable material. All the added new materials meet the requirements of group degradation, and meanwhile, the degradation efficiency can also be improved; the composite material can solve the problem of bursting during processing, improves the yield, can resist the temperature of more than 100 DEG C, and can better meet daily use; the coffee residue in the composite material belong to wastes after coffee powder production, are recycled and mixed with other materials for secondary production again, so that the wastes are greatly utilized, and the environmental protection property is improved.

Owner:吴卓康

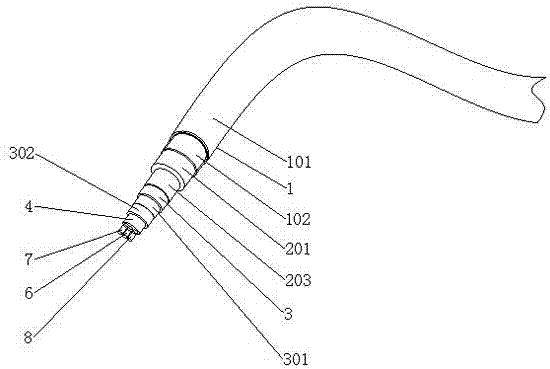

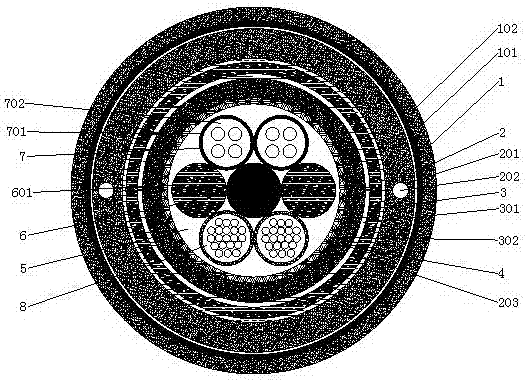

Optical cable with anti-explosion function

InactiveCN107966776AWith explosion-proof functionSolve burstFibre mechanical structuresYarnWire gauze

The invention discloses an optical cable with an anti-explosion function. The optical cable with the anti-explosion function comprises an optical cable body and a protecting sleeve, wherein the protecting sleeve is arranged on the outside of the optical cable body; the optical cable body is inlaid in the inner side of the protecting sleeve; a filling layer is arranged on the inner wall of the protecting sleeve, and is closely attached to the protecting sleeve; an outer sheath is arranged on the inner surface of the filling layer, and is inlaid in the inner surface of the filling layer; an aramid yarn layer is arranged on the inner wall of the outer sheath and is fixedly connected with the outer sheath; a water stopping layer is arranged on the inner side of the aramid yarn layer and is closely attached to the aramid yarn layer; and an inner protecting layer is arranged on the inner wall of the water stopping layer and is closely connected with the water stopping layer. The optical cable with the anti-explosion function is additionally provided with the protecting sleeve on the basis of the original optical cable, a steel wire gauze is added in the optical cable, and under the combined effect of the protecting sleeve and the steel wire gauze, the problem of explosion of the optical cable due to unreasonable design of the original optical cable is solved.

Owner:CHANGSHU BAILIAN PHOTOELECTRIC TECH CO LTD

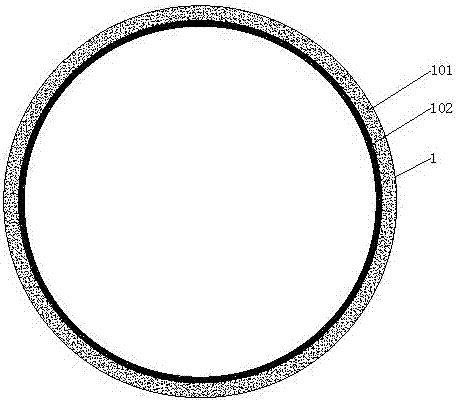

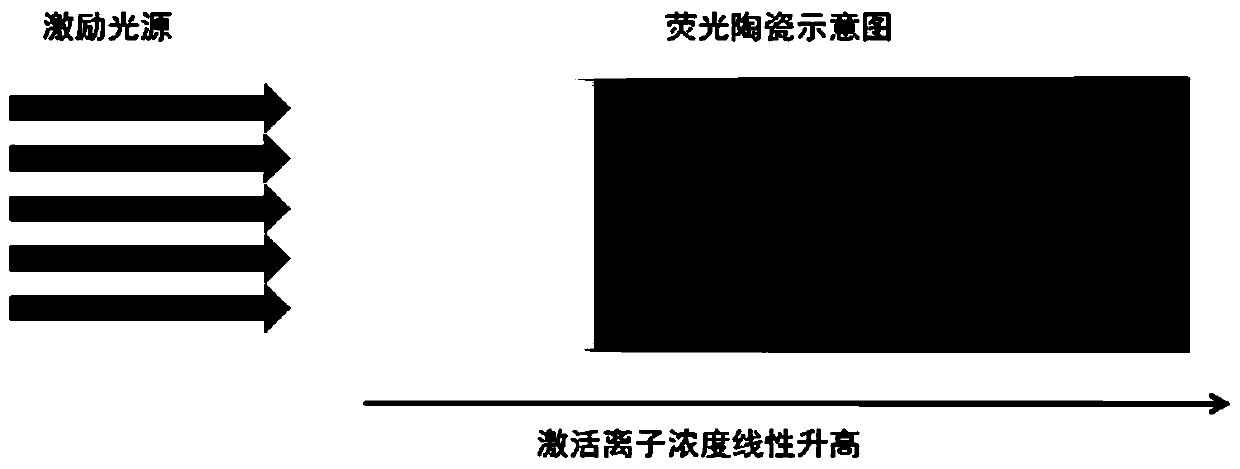

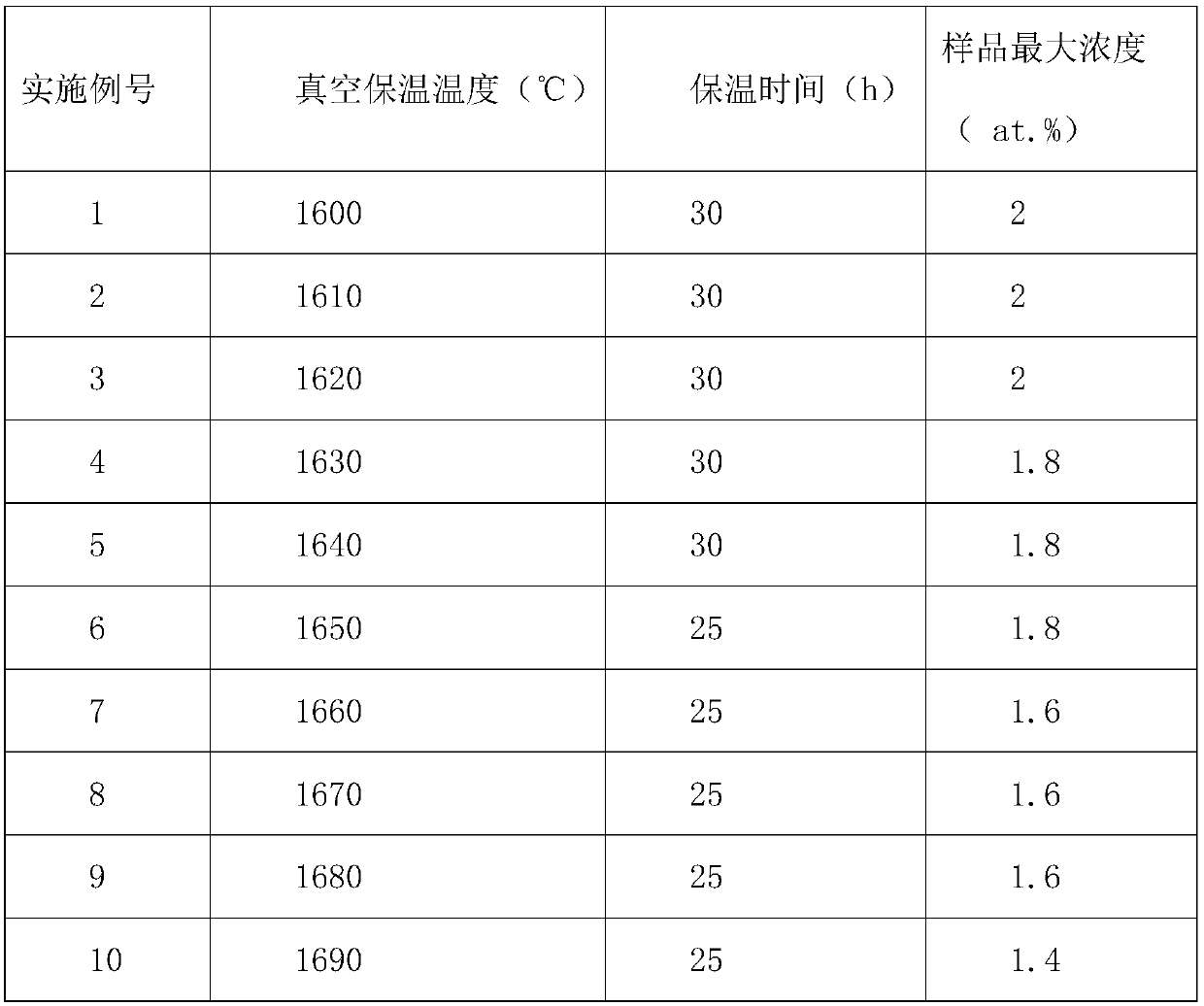

Gradient-concentration-change fluorescent ceramic for laser illumination, and preparation method thereof

InactiveCN111285675ASolve efficiency problemsSolve crackingLuminescent compositionsFluorescence spectraColor rendering index

The invention discloses a gradient-concentration-change fluorescent ceramic for laser illumination, and a preparation method thereof, wherein the fluorescent ceramic uses a YAG ceramic as a matrix material, uses Ce<3+> ions as light-emitting ions, and has a molecular formula of Cex:Y3-xAl5O12, x is larger than or equal to 0 and smaller than or equal to 0.06, and the fluorescent ceramic is distributed in the excitation incident direction of a laser light source in the mode that the concentration is gradually increased. According to the invention, laser energy can be uniformly absorbed and excited, so that the temperature of the material is uniform, the problems of fluorescence conversion efficiency reduction and sample explosion caused by temperature difference of the material are solved, the fluorescence spectrum is widened by utilizing the gradient concentration change, and the color rendering index of the fluorescent ceramic is improved.

Owner:SHANGHAI AVIATION ELECTRIC

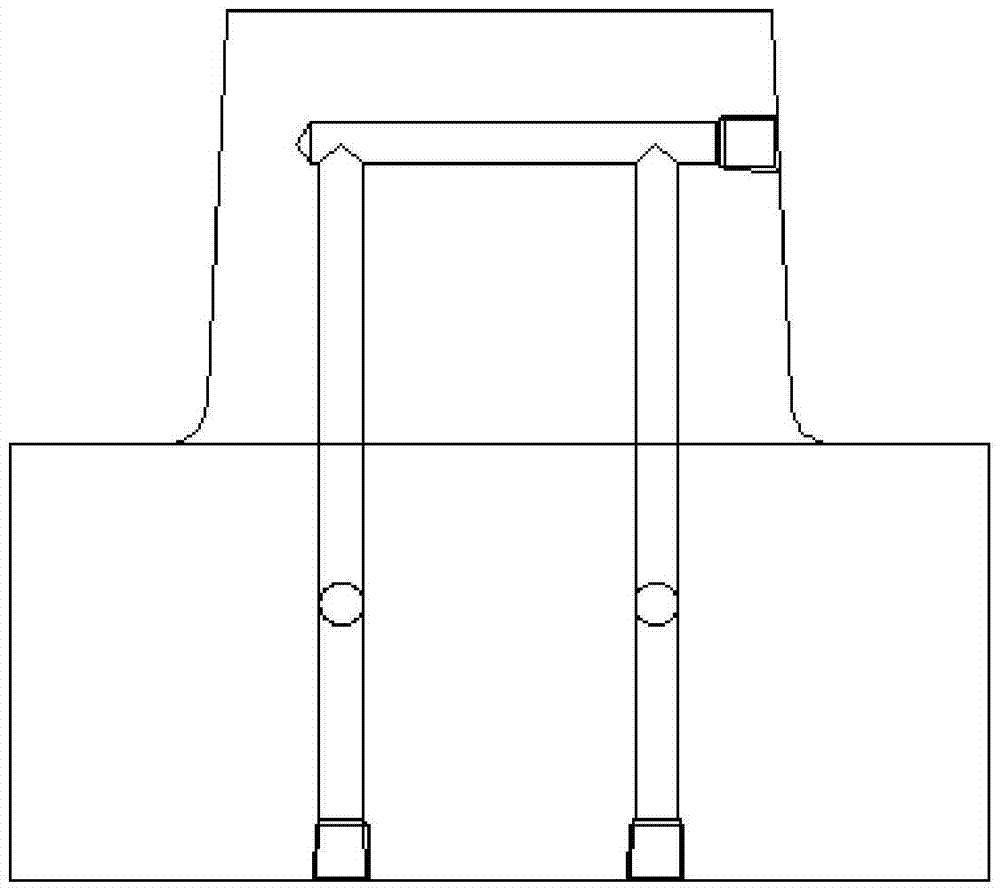

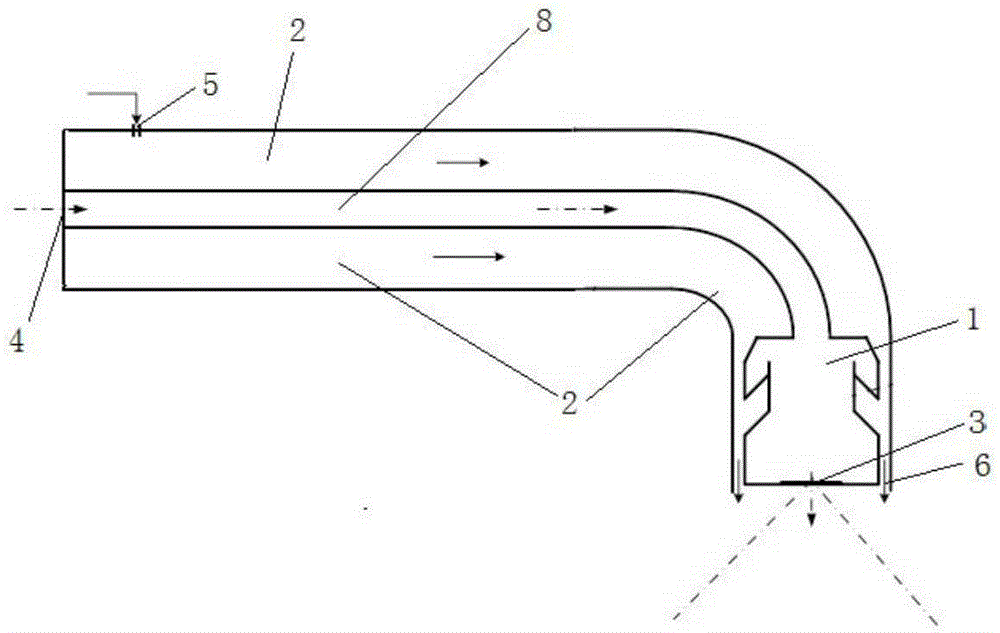

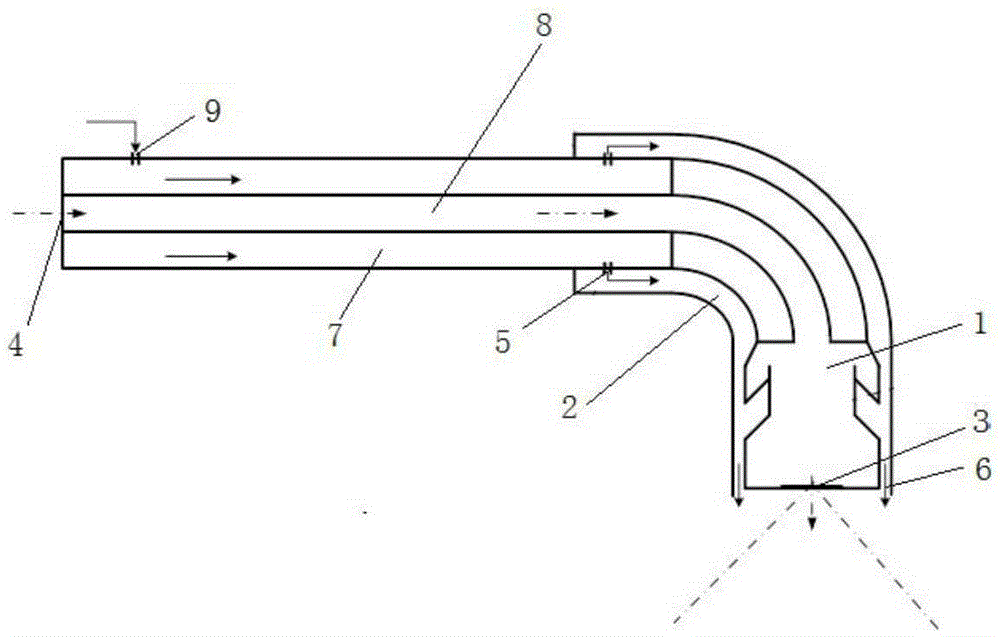

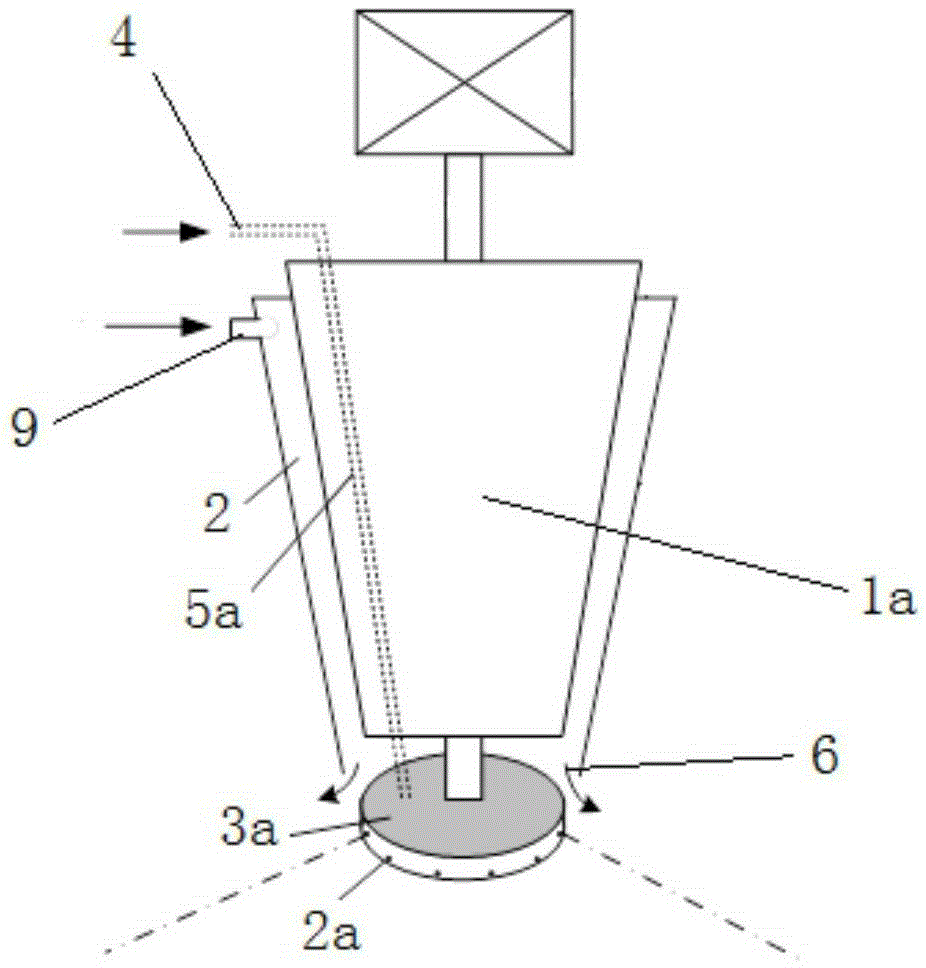

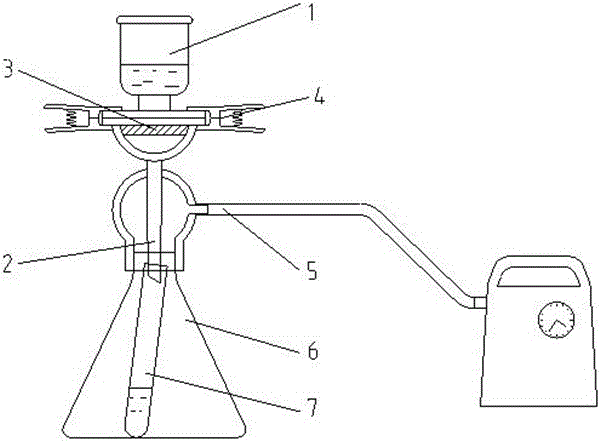

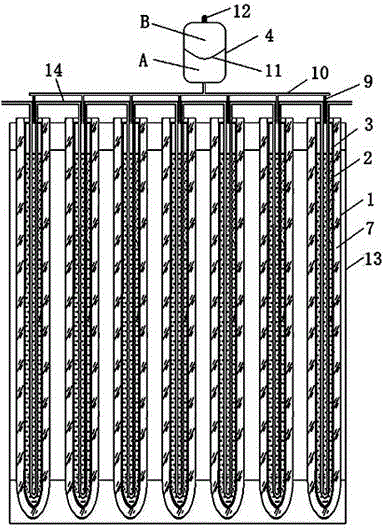

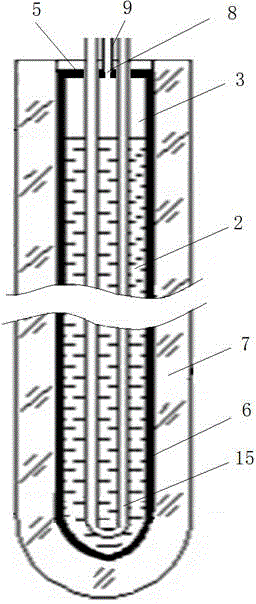

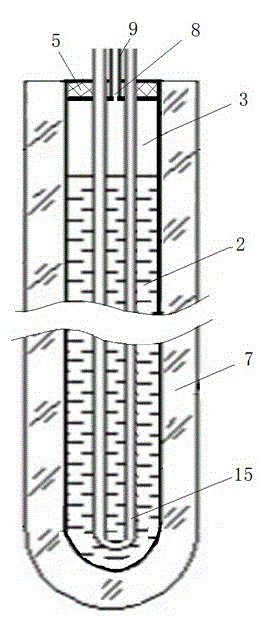

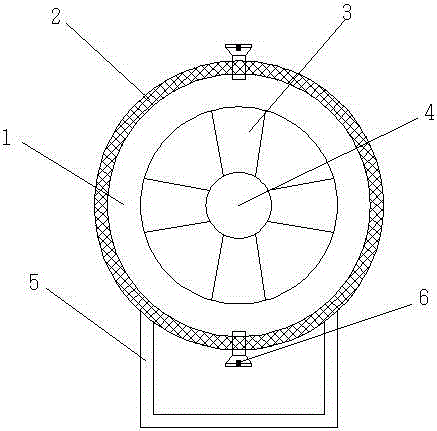

Vacuum pipe phase change heat storage solar water heater

InactiveCN104896775ASolve burstSafe and reliable workSolar heat devicesSolar thermal energy generationThermodynamicsWater storage tank

The invention discloses a vacuum pipe phase change heat storage solar water heater, and belongs to the technical field of solar water heaters. The vacuum pipe phase change heat storage solar water heater comprises a pressure control device (4), a manifold (10) and a plurality of solar heat storage pipes (1). The solar heat storage pipes (1) are filled with phase change materials (2). Openings are sealed through end sockets (5). Reserved spaces (3) are formed between the end sockets (5) and the phase change materials (2). U-shaped water pipes (15) are further arranged in the solar heat storage pipes (1). The pressure control device (4) is communicated with the reserved spaces (3) through connection holes (8) in the manifold (10), connection pipes (9) and the end sockets (5) to control the internal pressure of the solar heat storage pipes (1). The U-shaped water pipes (15) in the solar heat storage pipes (1) are connected with a connection water pipe (14) in series or in parallel to form a water way. Due to the fact that heat storage is achieved through the phase change materials, the water storage tank is omitted; due to the fact that the internal pressure of the solar heat storage pipes (1) is controlled, explosion of vacuum pipes (7) due to internal pressure is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

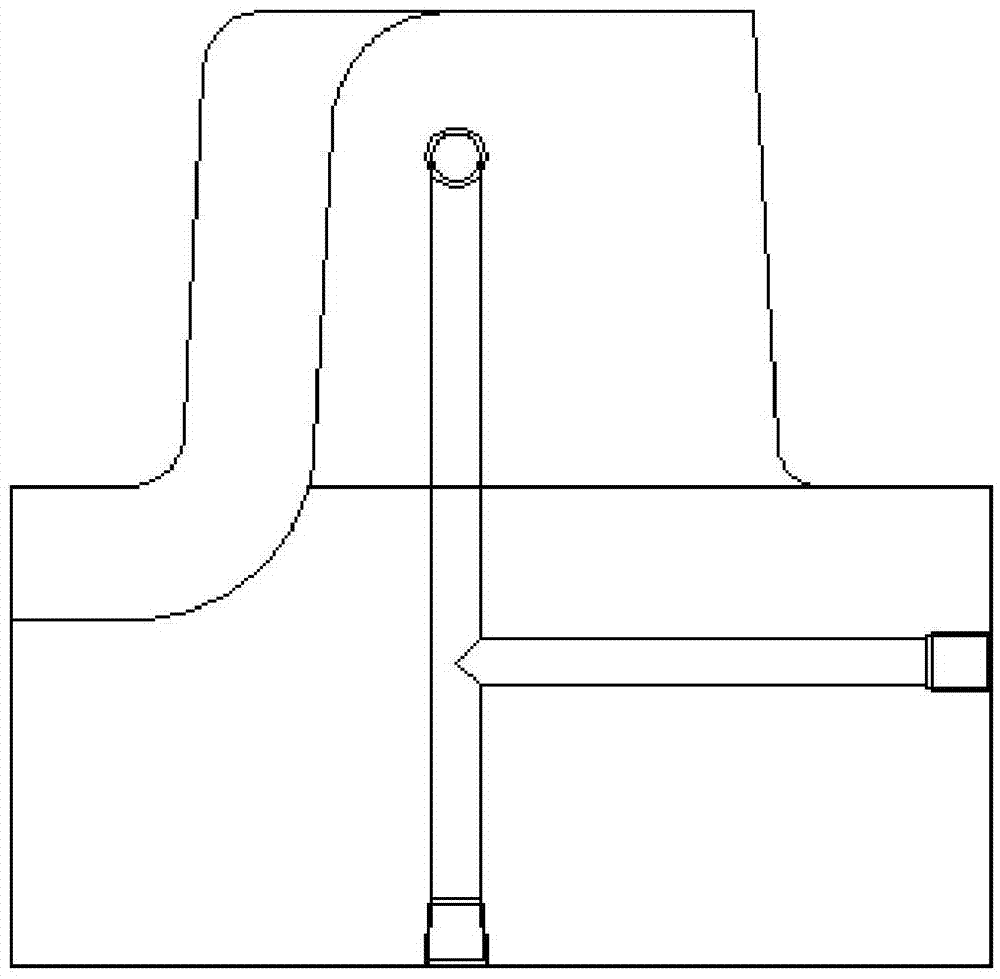

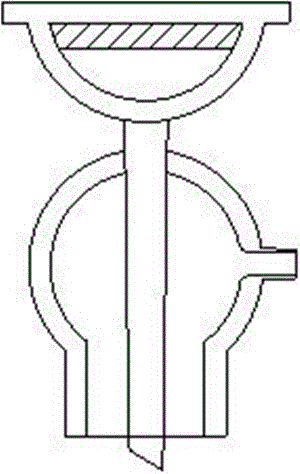

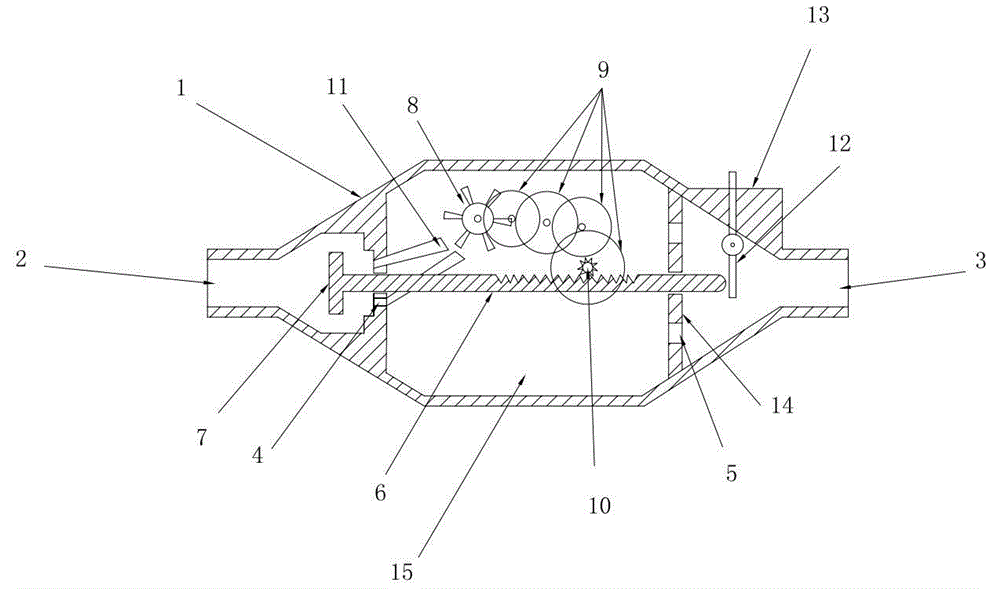

A timing automatic water-saving valve

ActiveCN103292020BSolve burstLoss of protectionOperating means/releasing devices for valvesFluid-delivery valvesImpellerWater saving

The invention discloses a valve automatically saving water through timing. The valve automatically saving water through timing comprises a water saving valve body. A water inlet and a water outlet are arranged at two ends of the water saving valve respectively. A valve accommodating cavity is formed in the water saving body and is provided with a water guiding inlet guiding the water inlet and a water guiding outlet guiding the water outlet. A valve rack penetrating the valve accommodating cavity is arranged in the water saving valve body. A water sealing valve block capable of sealing the water guiding inlet is arranged on the end portion, close to the water inlet, of the valve rod rack. An impeller is arranged in the valve accommodating cavity, a linkage variable gear is connected to the impeller, and a single-direction structure gear is connected to the linkage variable gear and is connected with the valve rack in a matched mode. A water guiding pipe is connected to the water guiding inlet, and the outlet of the water guiding pipe faces the impeller. The water saving valve is further provided with a return timing rod, and the end portion, close to the water outlet, of the valve rod rack is matched with the return timing rod. From the beginning of a natural water using process, the valve automatically saving water through timing starts to conduct timing, when surpassing a prearranged time, the valve automatically saving water through timing automatically closes the water saving valve, and water continues flowing out.

Owner:KAIPING HASSEM SANITARY WARE CO LTD

No-follow curren metal ceramic gas discharge tube

InactiveCN100353625CSolve burstAvoid potential hazardsSpark gap detailsOvervoltage arrestors using spark gapsLightning strokesElectron

This metal-ceramic gas discharge tube for unordered current after lightning stroke used for strong current system involves: inner electrode, outer electrode and metallized ceramic insulator. The three are combined to form a space filled with inert gas. In the space there are: discharging gap and one end of inner electrode. It also has central hole coaxial with said inner electrode and several gas-inlet holes connected to siad central hole. The gas inlet hole, central hole and discharging gap are combined to form a circulation loop. This invention solves problems such as: unordered flow in electric source of electronic device, and lightning stroke problem.

Owner:GUANGZHOU HOPEWELL TECH

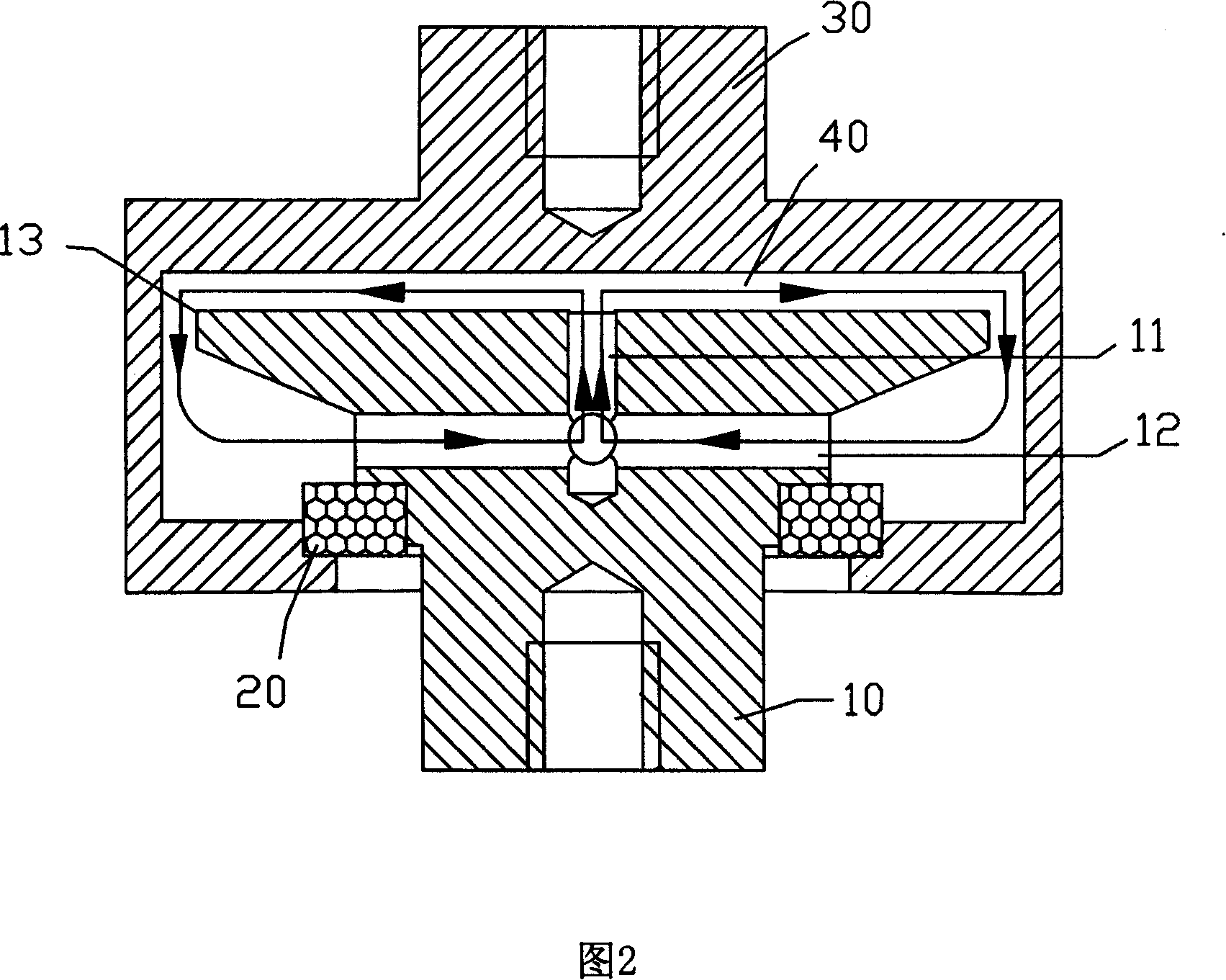

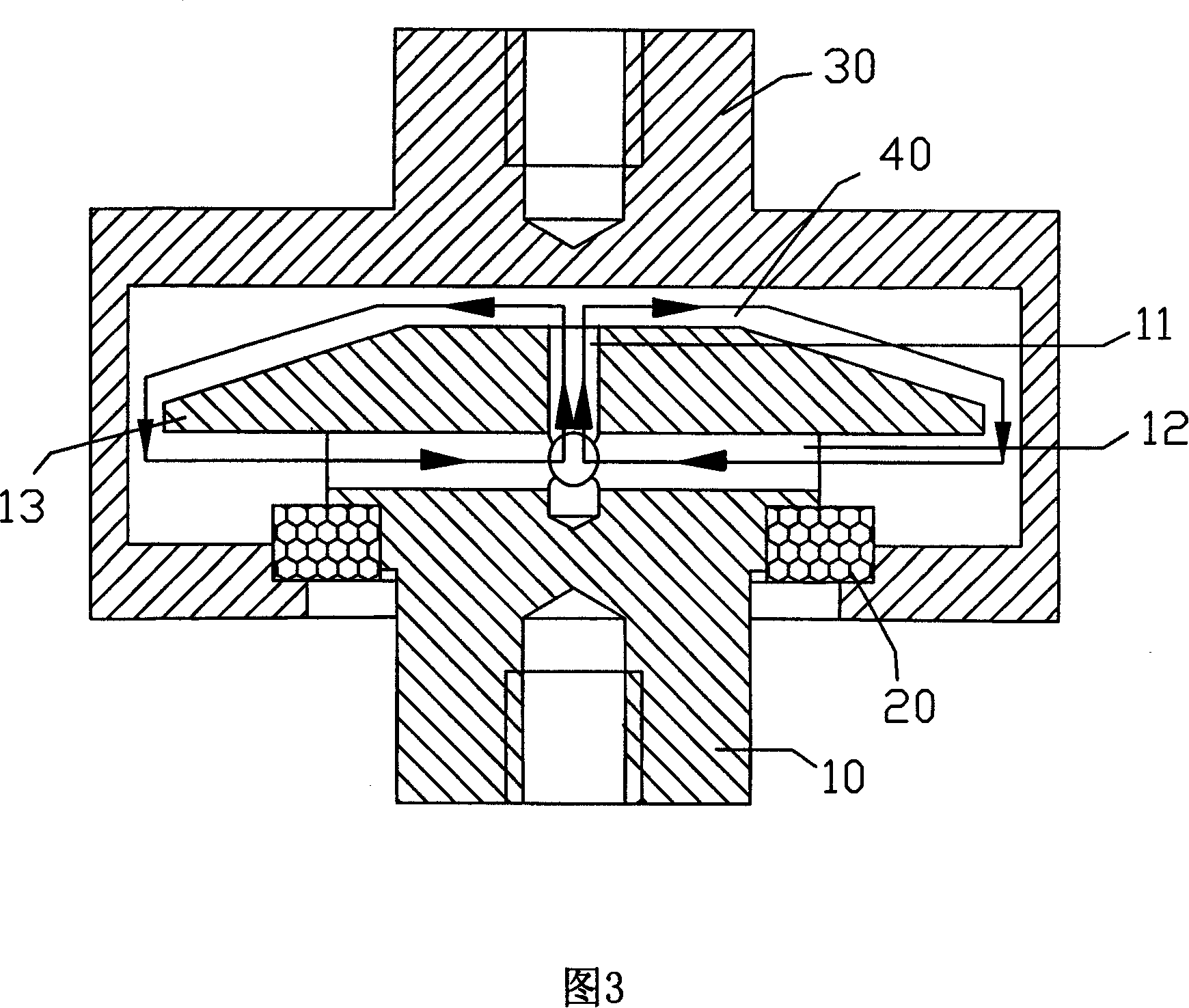

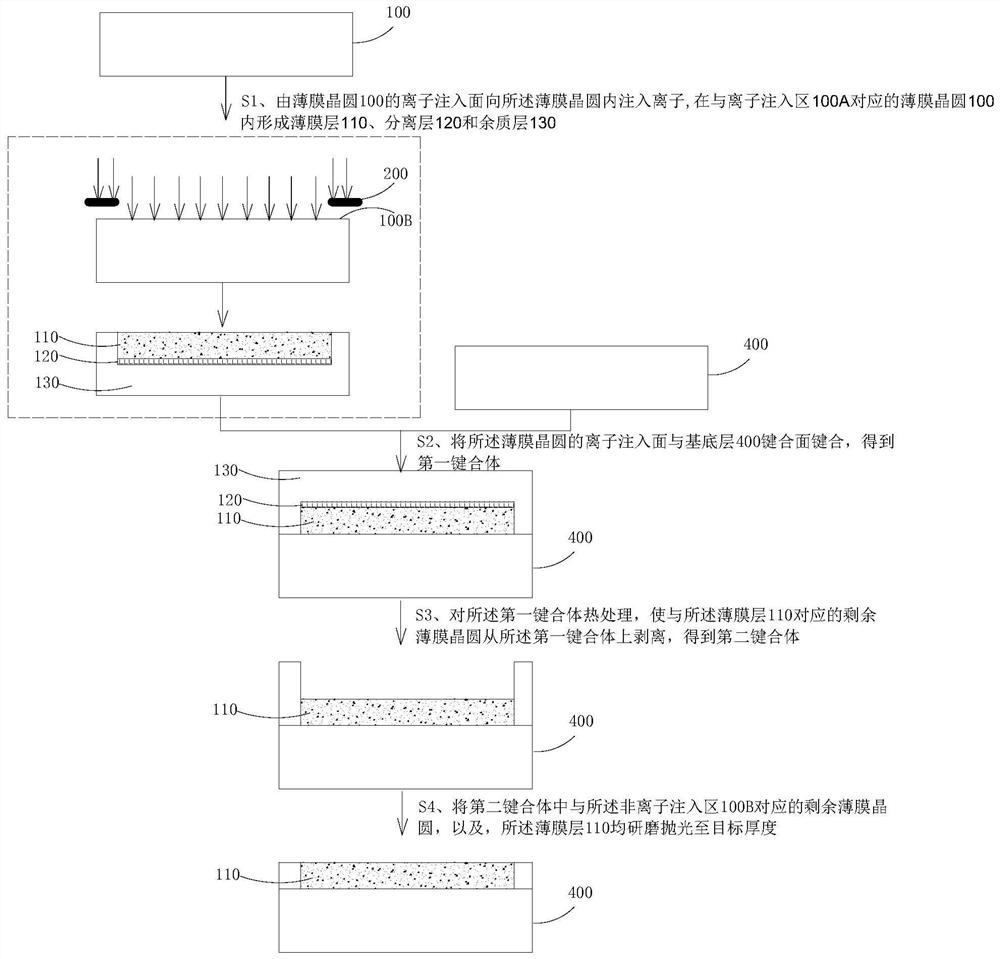

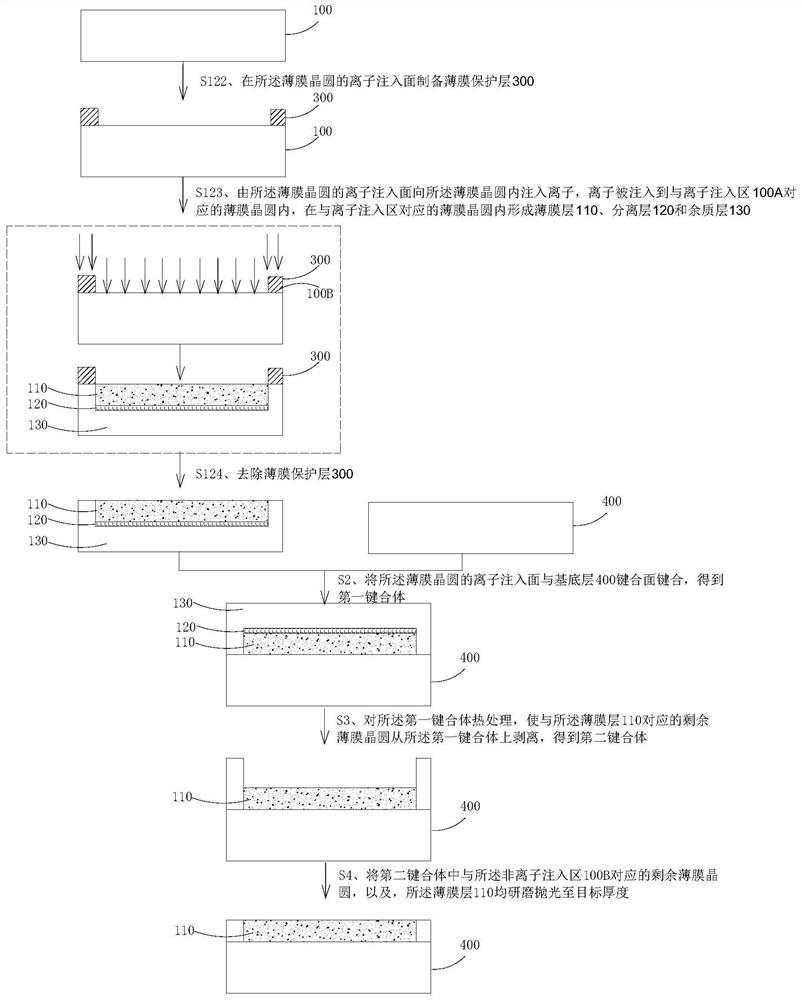

Method for improving bursting of film layer, and film material

ActiveCN112259678AImprove film layer burstingSolve the cracking of the film layerSemiconductor/solid-state device manufacturingPiezoelectric/electrostrictive/magnetostrictive devicesThin membraneFilm material

The invention discloses a method for improving bursting of a film layer, and a film material. The method comprises the following steps: injecting ions into a film wafer from an ion implantation surface of the film wafer, and forming the film layer, a separation layer and a remainder layer in the part, corresponding to an ion injection region, of the film wafer; bonding an ion implantation surfaceof the film wafer with a bonding surface of a substrate layer to obtain a first bonding body; performing heat treatment on the first bonding body to obtain a second bonding body; and grinding and polishing a remaining film wafer part corresponding to a non-ion implantation region in the second bonding body and the film layer to a target thickness. According to the invention, a circle of non-ion implantation region is reserved at the periphery of the ion implantation region, so after ion implantation, the film layer and the separation layer are only formed in the part, corresponding to the ionimplantation region, of the film wafer; and therefore, during bonding separation, due to the existence of the remaining thin film wafer part corresponding to the non-ion implantation region, the filmlayer is prevented from instantaneously recovering to a flat state from a warping state, and the problem of bursting of the film layer is solved.

Owner:JINAN JINGZHENG ELECTRONICS

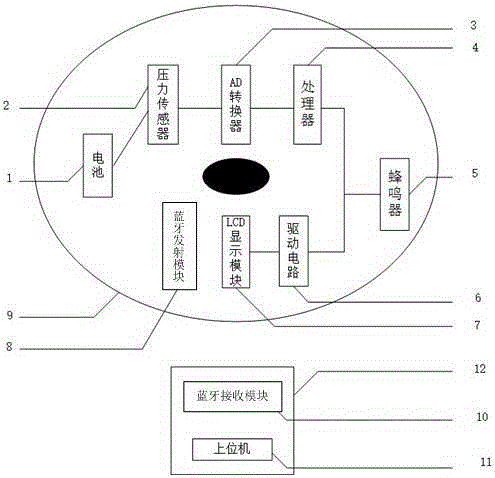

Anti-cracking pot cover capable of monitoring pressure

The invention belongs to the technical field of services for life, discloses an anti-cracking pot cover capable of monitoring pressure, and particularly provides a pot cover with the functions of monitoring a pressure value of itself in real time through a pressure sensor and transmitting information to a user. The pot cover is composed of a battery, a pressure sensor, an AD converter, a processor, a driving circuit, an LCD display module, a buzzer, a Bluetooth emission module, a pot cover shell, a Bluetooth receiving module, an upper computer and a mobile phone. The pot cover solves the problem that when people cook meals in daily life, due to the fact that it is neglected that pressure capable of being borne by the pot cover is limited, glass, ceramic and other fragile pot covers are cracked, and has the advantages of being good in safety, accuracy and real-time performance.

Owner:XIAN ZHISHIXIN ELECTRONICS TECH

Casting technology of vermicular graphite cast iron full-hydraulic redirector body shell cast

InactiveCN109202013AWell formedHigh precisionFoundry mouldsProcess efficiency improvementGraphiteWear resistance

The invention provides a casting technology of a vermicular graphite cast iron full-hydraulic redirector body shell cast and relates to the technical field of cast production. The method includes: manufacturing a mold, smelting components and removing impurities, supplying components, performing vermicularizing inoculation, performing pouring shaping, performing cooling shaping, and cleaning off the sand. The method guarantees that the vermicularizing rates of different parts on the same cast are differed by 5-10%, which satisfies the requirement on vermicularizing rate uniformity of the full-hydraulic redirector body shell cast. The technology can solve the defects of oil leakage, explosion, heavy weight, poor wearing resistance and pressure resistance, short service life, poor manufacturability of the cast and the like of a full-hydraulic redirector body shell.

Owner:ANHUI DATIAN CASTING

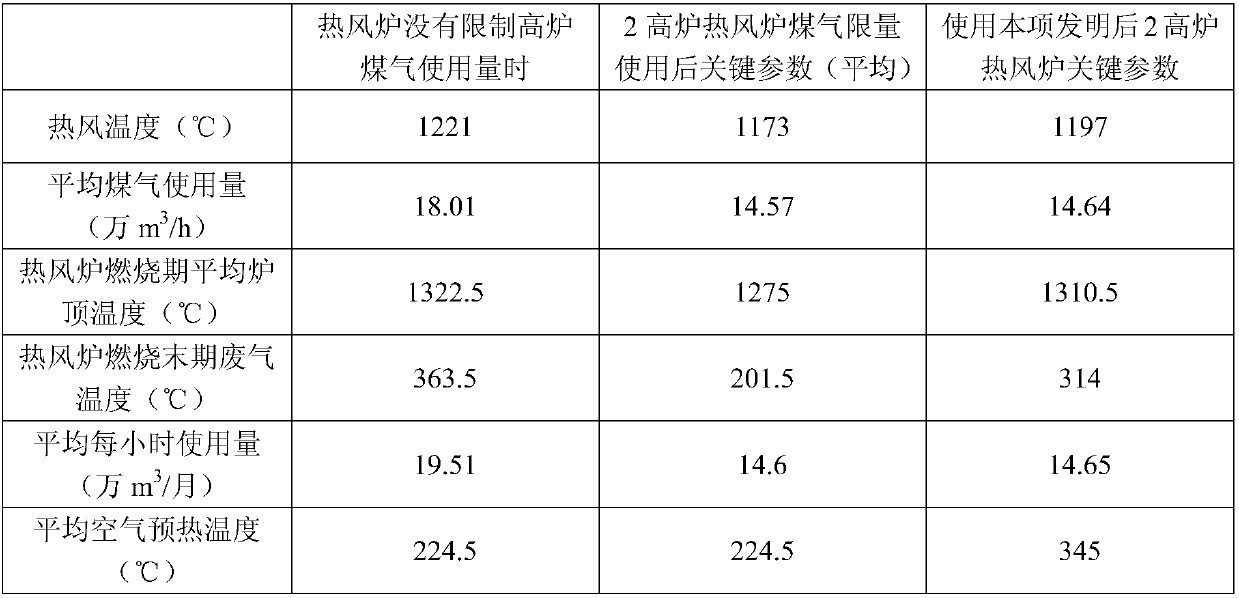

High-efficiency energy-saving hot blast stove combustion method

ActiveCN109252004ARaise the theoretical combustion temperatureIncrease temperatureBlast furnace detailsHeating stovesEngineeringElectric power

The invention especially relates to a high-efficiency energy-saving hot blast stove combustion method, belonging to the technical field of blast furnace iron making in the steel industry. According tothe invention, conventional hot blast stoves and process parameters thereof do not need to be changed; the temperature of combustion air used in the combustion of a hot blast stove and an air-fuel ratio are increased so as to increase the total combustion amount of the hot blast stove; during stove changing of the hot blast stove, the amount of coal gas introduced into the hot blast furnace in the state of single combustion is maximized, and the air-fuel ratio and the amount of the combustion air are increased, so the hot blast stove is allowed to reach a high blast temperature under the condition of limited usage amount of the coal gas. Thus, under the condition of substantial reduction in coal gas consumption, the service life of the hot blast stove is not influenced; the hot blast stove is ensured to reach a high blast temperature; the power outsourcing of enterprises is reduced; and cost per ton of steel is lowered.

Owner:ANGANG STEEL CO LTD

Casing of anti-explosion fan

The invention provides a casing of an anti-explosion fan. The casing comprises a casing body. The outer wall of the casing body is coated with an anti-explosion layer, an impeller is arranged in the casing body and connected through a rotating shaft, the lower end of the casing body is fixedly connected with a base, and a fastening screw is arranged on the outer portion of the casing body. The casing is compact in structure and high in safety performance, and by coating the machine casing with a layer of anti-explosion material, the problem of burst of the fan casing body can be solved effectively.

Owner:WUXI NANFANG EXPLOSION PROOF ELECTRIC MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com