No-follow curren metal ceramic gas discharge tube

A gas discharge tube and metal ceramic technology, which is applied in the field of discharge tubes, can solve the problems of inability to increase the current capacity, fire, and breakage, and achieve the effect of solving the explosion of metallized ceramic tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

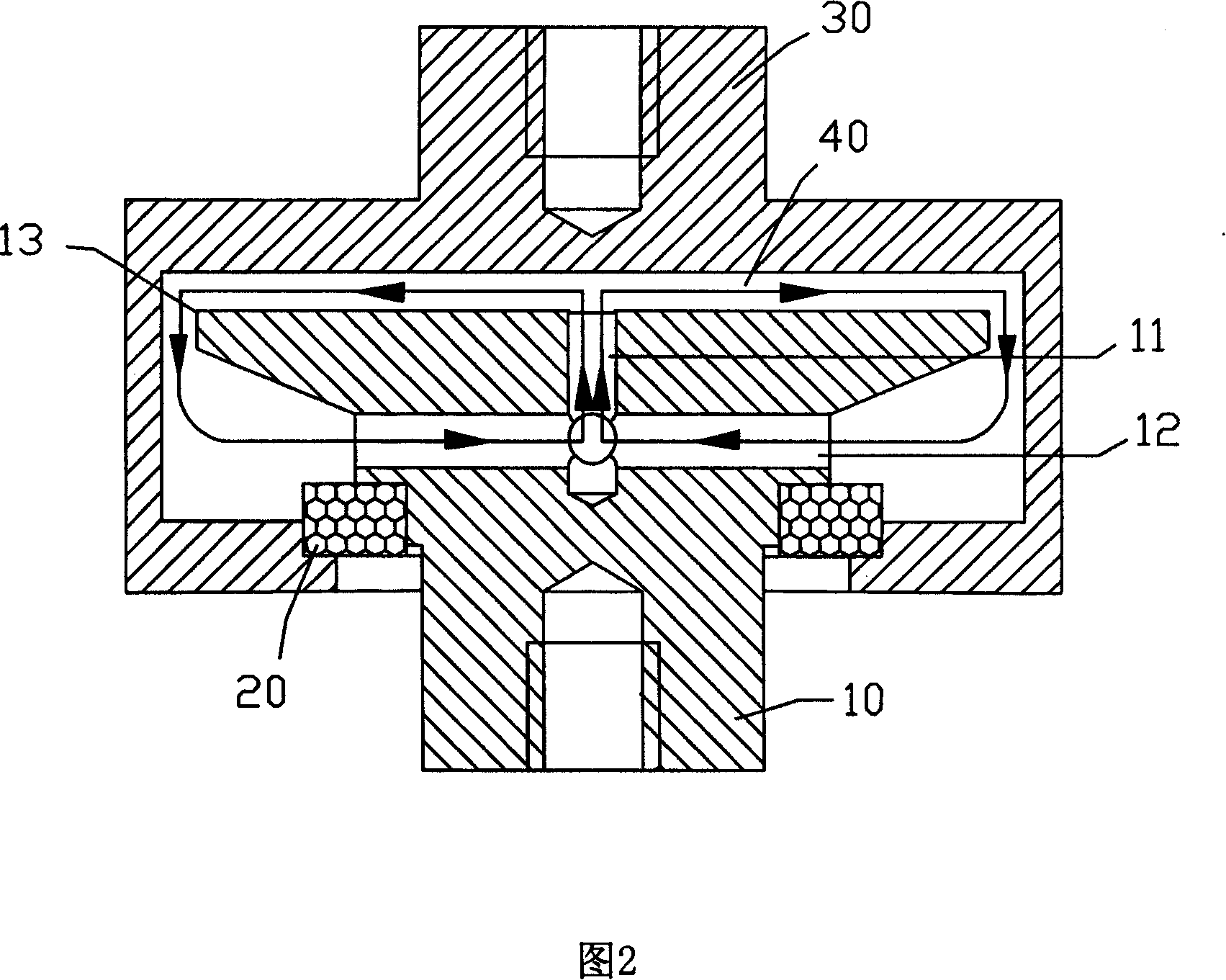

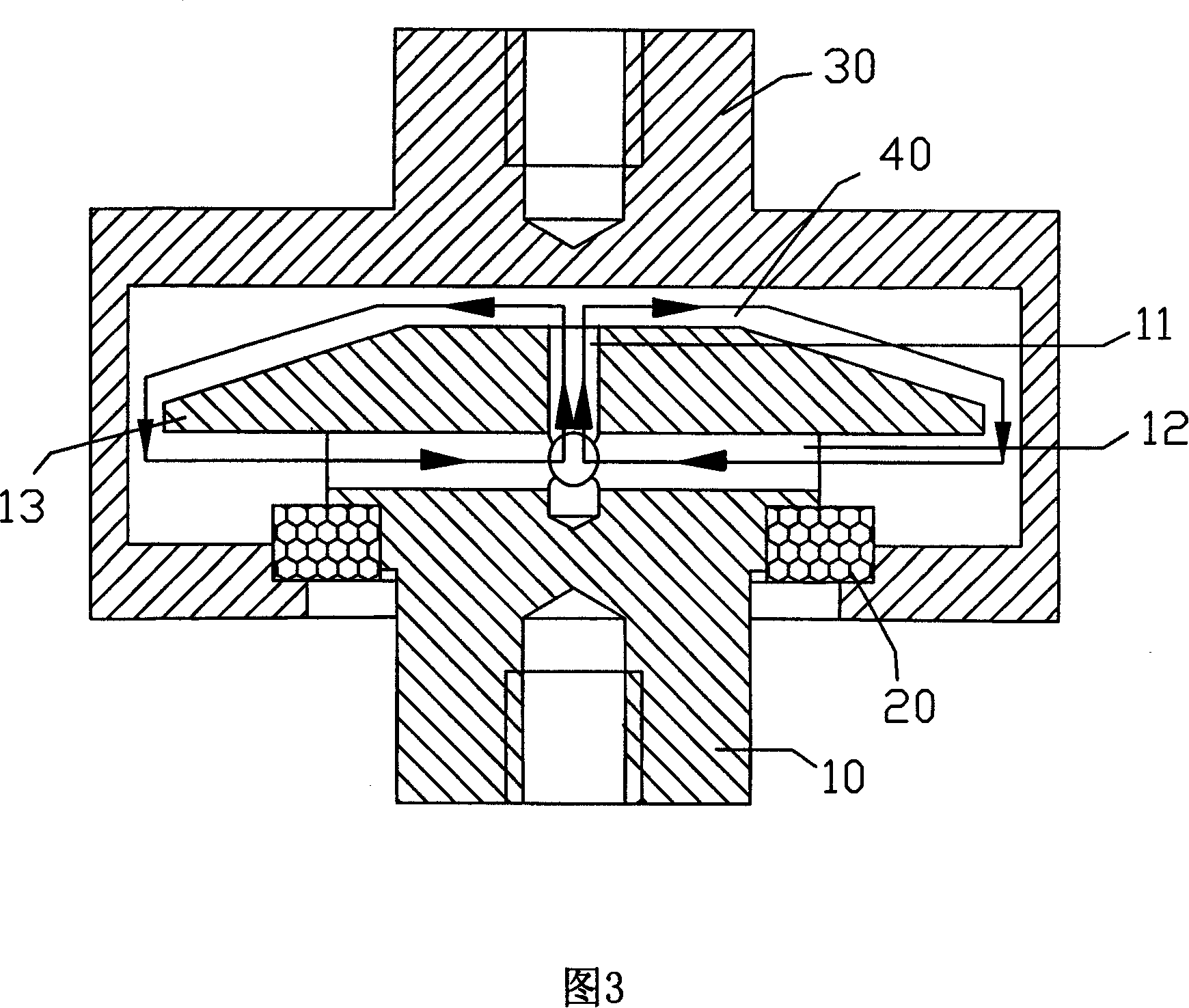

[0030] See accompanying drawing 2, the present invention comprises inner electrode 10, outer electrode 30 and metallized ceramic insulator 20, and the three are combined to form a closed space filled with inert gas, and a discharge gap 40 is arranged in this space, and inner electrode 10 One end is embedded in a closed gas space, and a central hole 11 and several air inlet holes 12 communicating with the central hole 11 are provided at the embedded end, among which the air inlet hole 12, the central hole 11 and the discharge gap 40 are formed Gas circulation path.

[0031] The central hole 11 is designed axially along the centerline, while the air inlet hole 12 is designed radially and communicates with the central hole 11 vertically.

[0032] The gas discharge device consisting of the above-mentioned components is provided with a closed gas circulation path inside, that is, a non-following cermet gas discharge tube.

[0033] When the above-mentioned no-following cermet gas d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com