MC5 Steel and large-sized flattening roll prepared by using the same, and manufacturing process of MC5 steel

A leveling roll and process technology, applied in the field of large leveling roll, large leveling roll and MC5 steel manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

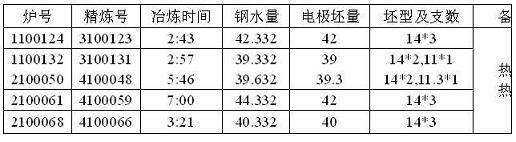

[0049] Electric furnace ingredients: 35% to 50% of high-quality steel scrap, 15% to 25% of returned steel, 15% to 30% of high-quality refining

[0050] Steel pig iron or 35% hot-charged molten iron and 10%-20% sponge iron are charged and melted by electricity.

[0051] Melt analysis of harmful elements As, Sn, Pb are all ≤0.02%.

[0052] Oxidation temperature ≥ 1550 ℃, decarburization ≥ 0.40%.

[0053] Electric furnace tapping conditions: C ≥ 0.50%, P ≤ 0.007%, temperature ≥ 1640 ℃.

[0054] When the steel is tapped, 1Kg to 1.5Kg per ton of steel is added to the ladle for pre-deoxidation, and at the same time, lime or pre-melted slag accounting for about 2% of the molten steel is added, and 70% of Cr, Ni, Mo alloy.

[0055] After tapping, transfer to LF / VD refining station, then add lime and fluorite accounting for about 2% of the molten steel weight, heat with electricity and use 3Kg~5Kg carbon powder per ton of steel and 2Kg~5Kg ferrosilicon powder per ton of steel for de...

specific Embodiment approach

[0130] A kind of technique of manufacturing described MC5 steel is characterized in that: comprise the following steps:

[0131] ①Select steelmaking raw materials and add sponge iron accounting for 10 wt%-20 wt% of the raw materials, and control the content of harmful elements such as Cu, Pb, As, Sn, Sb, and Bi to the range of the above-mentioned MC5 steel;

[0132] ②Control the smelting temperature of the electric arc furnace, and the amount of oxidation and decarburization is ≥0.40wt%. And according to the composition calculation, add the required amount of 60wt% ~ 80wt% Cr, Ni, Mo alloy;

[0133] ③The ladle furnace adopts bottom-blown argon stirring and vacuum degassing compound refining, adding slag material at 2wt%~4wt% of the total weight of molten steel, adding deoxidizer at 6Kg~10Kg per ton of steel, adding the remaining alloy after sampling and analyzing the slag white , adjust the composition to the specified range, transfer the molten steel to the vacuum tank after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com