Cooling water tank

A heat dissipation water tank and water tank cover technology, which is applied to the cooling of engine components, machines/engines, and engines, can solve problems such as bursting, and achieve the effect of improving safety and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings. It should be noted that the following embodiments may be combined or partially replaced in any possible manner.

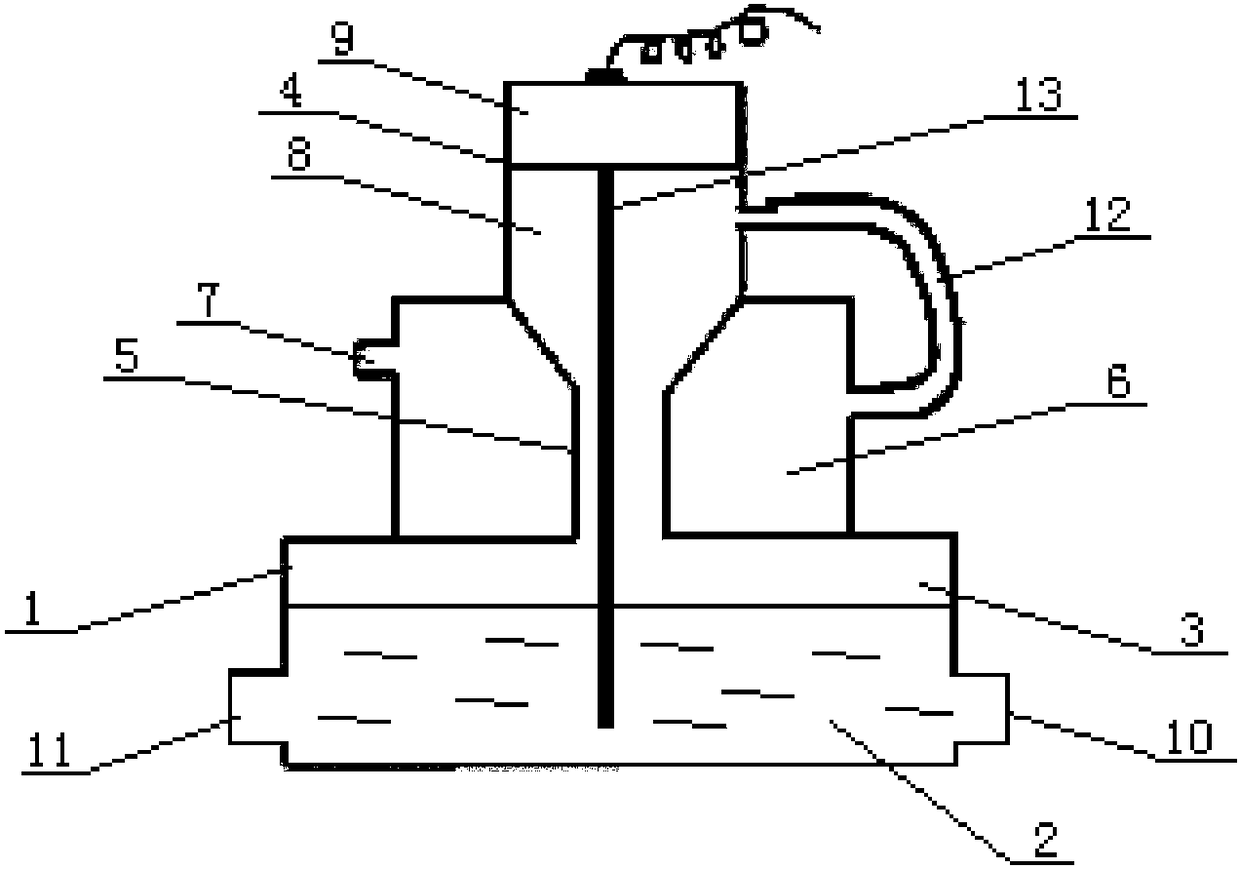

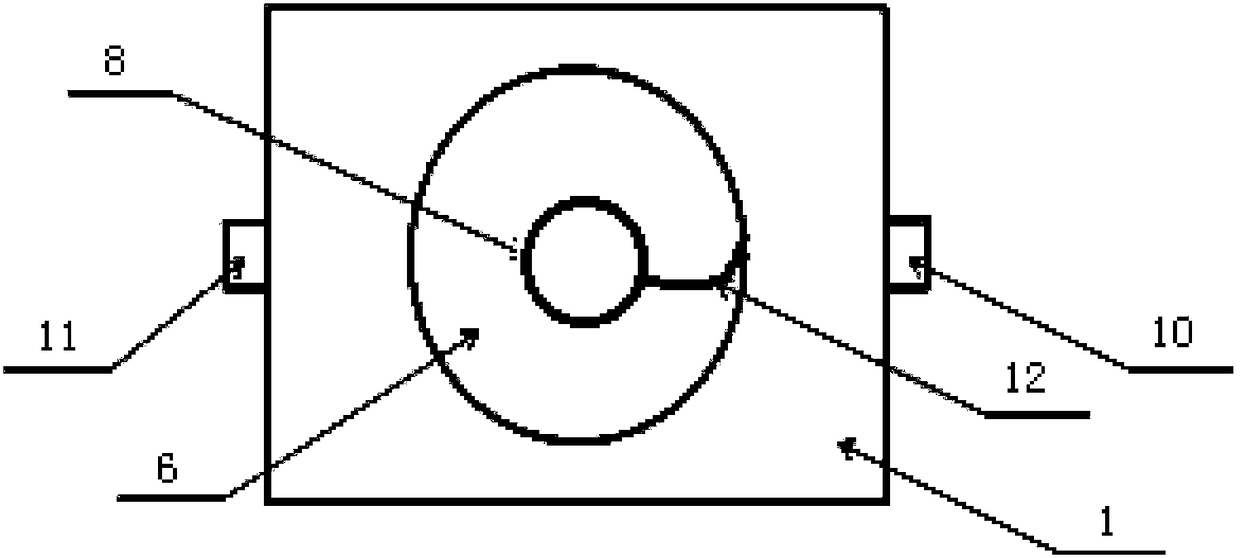

[0023] now refer to figure 1 , which shows a radiator tank according to an embodiment of the present invention. Such as figure 1 As shown, the cooling water tank is used for the cooling system of the engine, and includes a coolant chamber 1, the coolant chamber 1 includes a coolant chamber 3 for containing the coolant 2, and a cooling chamber 3 at the top of the coolant chamber 1 for filling the coolant 2 The coolant filling port 4, and the perfusion chamber 8 located below the cooling liquid filling port 4, wherein, as figure 1 As shown, the perfusion chamber 8 is located between the cooling liquid filling port 4 and the cooling liquid receiving chamber 3, thus the cooling liquid filling port 4 is in fluid communication with the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com