Sub-white corundum and production method thereof

A sub-white corundum and production method technology, which is applied in the field of sub-white corundum and its production, can solve the problems of unfavorable popularization and application of corundum refractory materials, shortage of white corundum raw materials, low alumina content, etc., and achieve obvious economic and social benefits , low cost, high content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

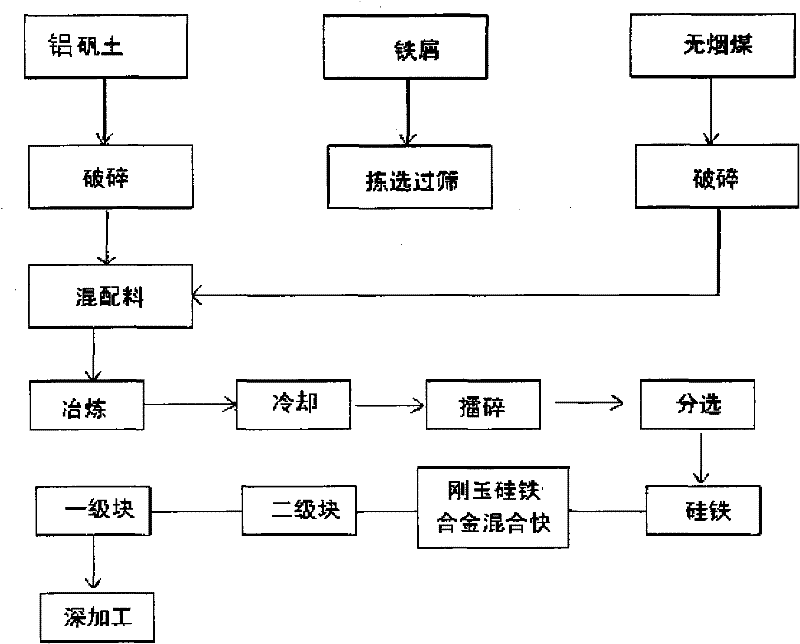

[0051] Embodiment 1: as figure 1 As shown, a kind of sub-white corundum is made through the following formula and steps:

[0052] 1) Anthracite and bauxite containing 85% by weight of aluminum oxide are respectively crushed, iron filings are sorted and sieved, and then the crushed anthracite and bauxite are mixed with iron filings to form a mixed batch, wherein The weights of anthracite, bauxite and iron filings are respectively: 9500 kg of bauxite, 200 kg of iron filings, and 300 kg of anthracite;

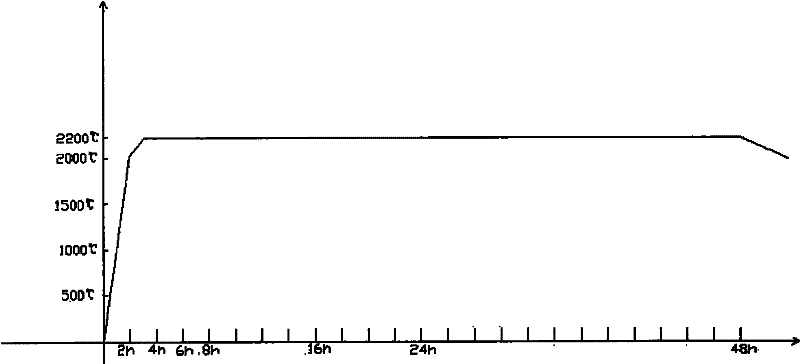

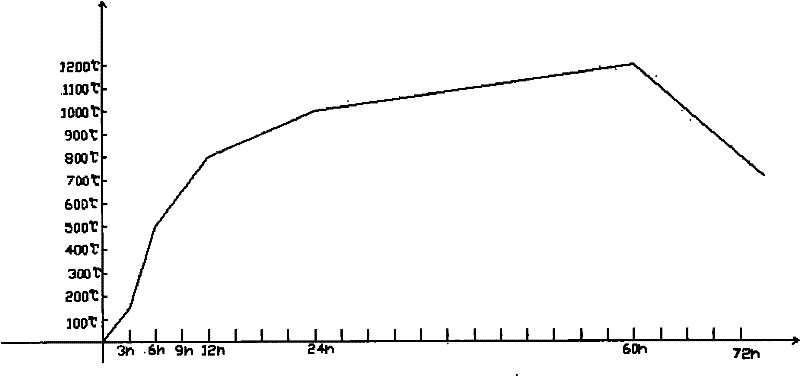

[0053] 2) Put the mixed ingredients in 1) into an electric arc furnace for smelting. The smelting time is 48 hours. The temperature is controlled as follows: from the 0th to the 1st hour, the temperature is increased from 0 degrees Celsius to 1100 degrees Celsius, and from the first to the second hour The temperature is increased from 1100 degrees Celsius to 1100 degrees Celsius. The temperature is increased to 2000 degrees Celsius, the temperature is increased from 2000 degrees ...

Embodiment 2

[0057] Embodiment 2: as figure 1 As shown, a kind of sub-white corundum is made through the following formula and steps:

[0058] 1) Anthracite and bauxite containing 85% by weight of aluminum oxide are respectively crushed, iron filings are sorted and sieved, and then the crushed anthracite and bauxite are mixed with iron filings to form a mixed batch, wherein The weights of anthracite, bauxite and iron filings are respectively: 9500 kg of bauxite, 200 kg of iron filings, and 300 kg of anthracite;

[0059] 2) Put the mixed ingredients in 1) into an electric arc furnace for smelting. The smelting time is 48 hours, and the temperature is controlled as follows: the temperature increases from 0 degrees Celsius to 1100 degrees Celsius in the 0th to the 1st hour, and the temperature in the 1st to the 2nd hour is changed from Increase from 1100 degrees Celsius to 2000 degrees Celsius, and increase the temperature from 2000 degrees Celsius to 2200 degrees Celsius in the second to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com