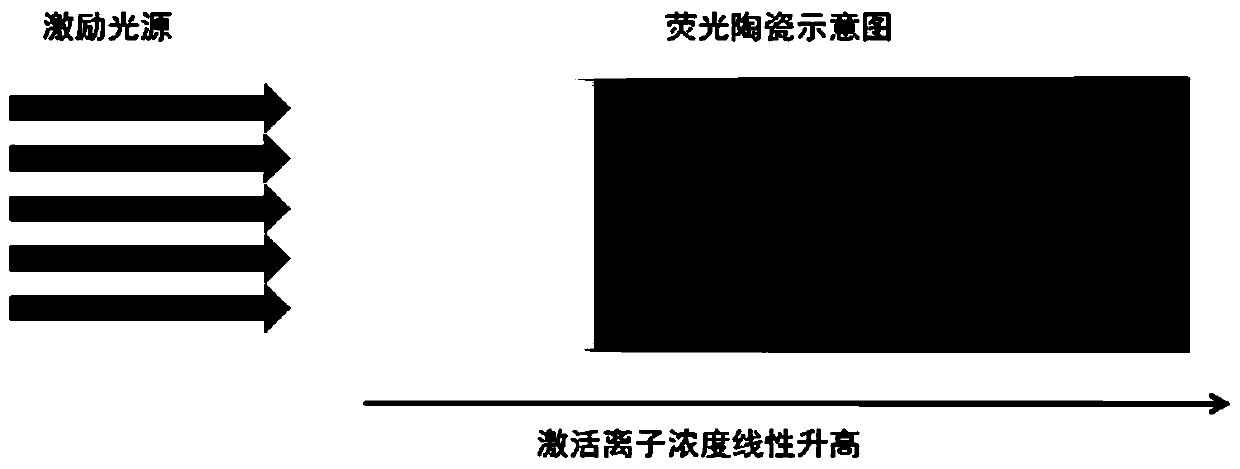

Gradient-concentration-change fluorescent ceramic for laser illumination, and preparation method thereof

A fluorescent ceramic, concentration gradient technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of sample cracking and sample fluorescence efficiency reduction, and achieve high yield, solve the problem of sample explosion, and poor thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

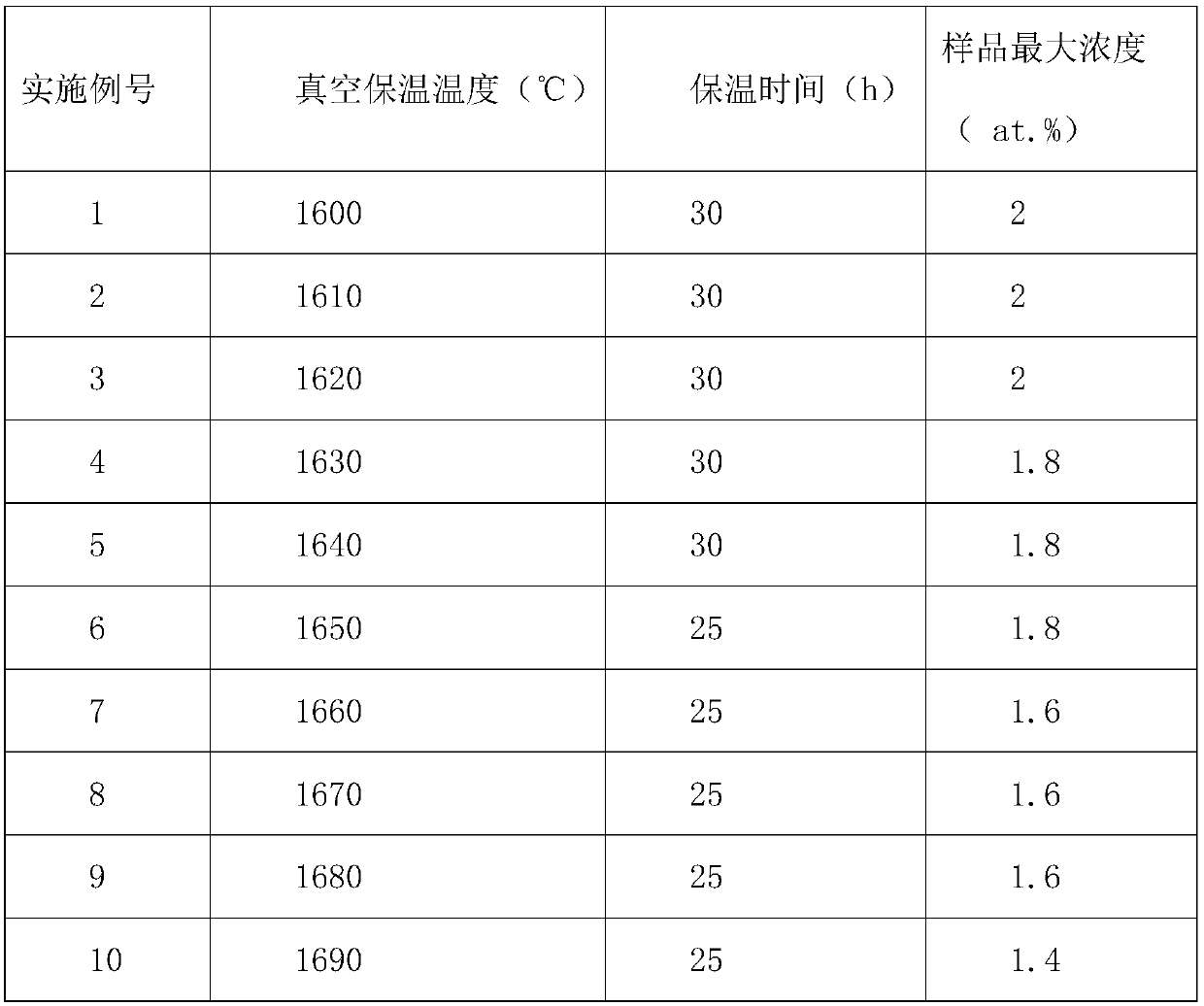

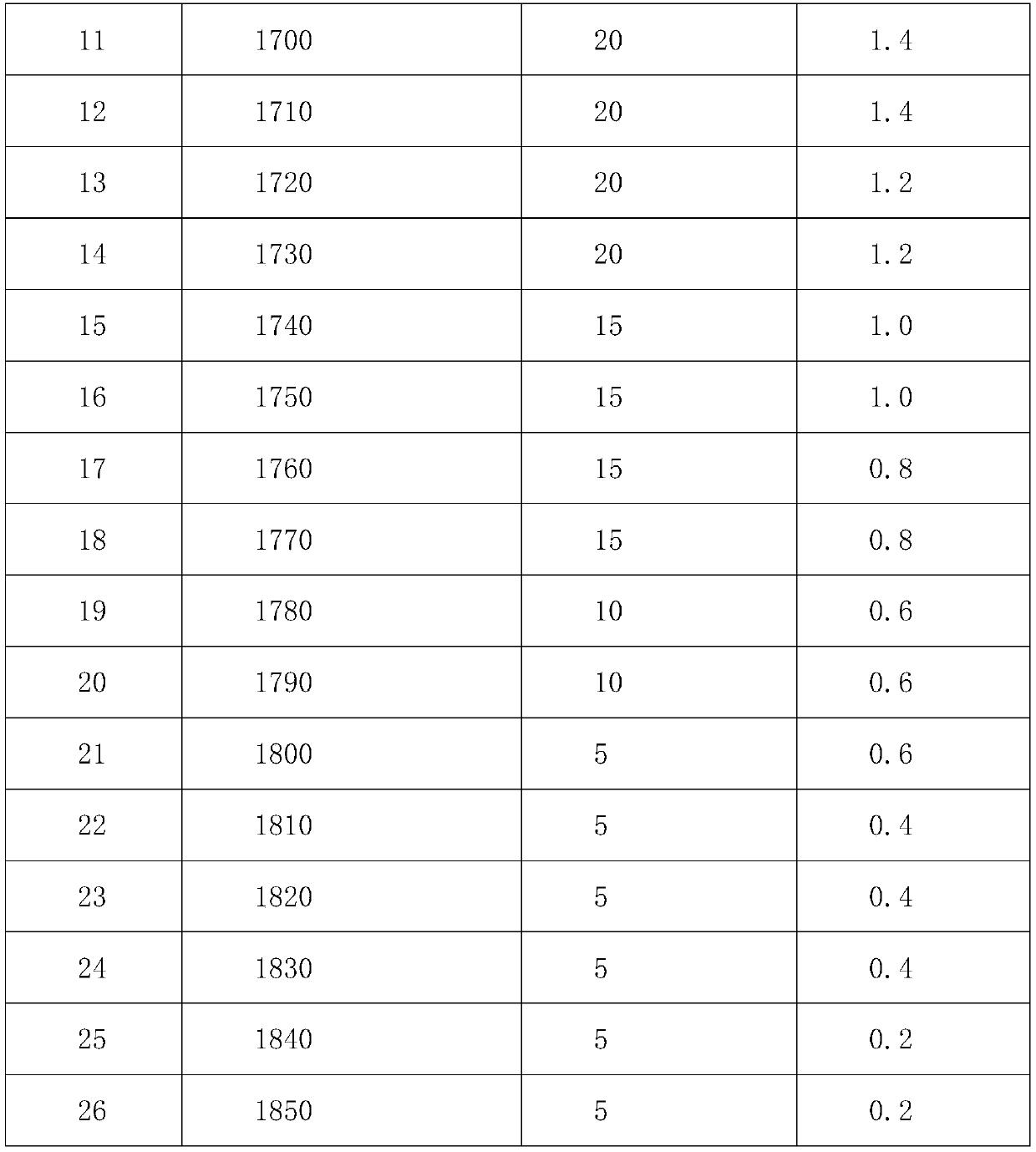

Embodiment 1

[0021] According to the required material properties, design a suitable concentration distribution, select the maximum active ion doping concentration y=2at.%, and the preparation method is as follows:

[0022] 1. Preparation of different Ce 3+ Ion molar concentration Ce: YAG series standard ceramic powder, Ce 3+ The range of ion molar concentration y is: 0≤y≤2at.%. Standard ceramic powder is Ce 3+ 11 types of Ce:YAG powders with ion molar concentration gradient tolerance of 0.2at.%, minimum concentration of 0, and maximum concentration of 2at.%.

[0023] 2. Select a mold with a suitable size according to the size of the fluorescent ceramics to be prepared, select the maximum concentration according to the requirements of the specific lighting system for the material, pour the prepared YAG ceramic powder into the mold, perform 1MPa dry pressing for 30 seconds, and then sequentially Pour the powder into the mold in the order of increasing Ce ion concentration and perform dry...

Embodiment 2

[0027] According to the required material properties, design a suitable concentration distribution, select the maximum active ion doping concentration y=1.8at.%, and the preparation method is as follows:

[0028] 1. Select a mold with a suitable size according to the size of the fluorescent ceramics to be prepared, select the maximum concentration according to the requirements of the specific lighting system for the material, pour the prepared YAG ceramic powder into the mold, perform 1MPa dry pressing for 30 seconds, and then sequentially Pour the powder into the mold in the order of increasing Ce ion concentration and carry out dry pressing for 30 seconds until the dry pressing of the powder with the maximum concentration y=1.8at.% is selected, and the green body is kept at 5MPa for 1 minute and then cooled and isostatic Press 210MPa for two minutes to form the green body;

[0029] 2. Put the green body into the vacuum sintering furnace and vacuumize to 10 -3 Pa for heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com