Processing device used for LED lamp bulb

A technology of LED light bulbs and processing devices, which is applied to lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve problems such as bulb bursting, and achieve good sintering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

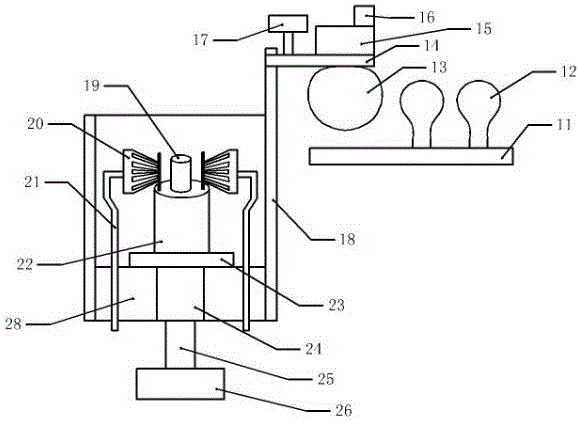

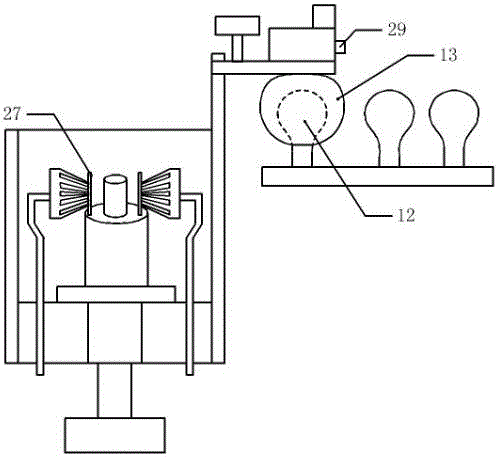

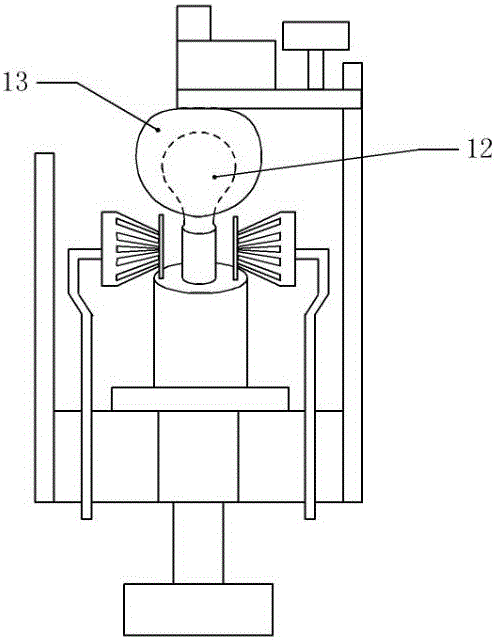

[0018] The reference signs in the accompanying drawings of the specification include:

[0019] Conveyor belt 11, bulb shell 12, air bag 13, rotating disc 14, gas box 15, air pump 16, cylinder 17, frame 18, stem 19, sintering nozzle 20, gas pipe 21, stem support ring 22, rotating plate 23, Spline cover 24, spline shaft 25, motor 26, thin metal rod 27, console 28, heater 29.

[0020] Such as figure 1 , figure 2 and image 3 A processing device for LED light bulbs shown includes a frame 18 and an operating table 28, the operating table 28 is installed between the frame 18, the rotating disk 14 is installed on the operating table 28, and the stem is fixedly installed on the rotating disk 14 Support ring 22, four thin metal rods 27 are evenly fixed around the support ring 22 of the stem, and the thin metal rods 27 divide the support ring 22 into four equal parts, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com