Patents

Literature

31results about How to "Guaranteed temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

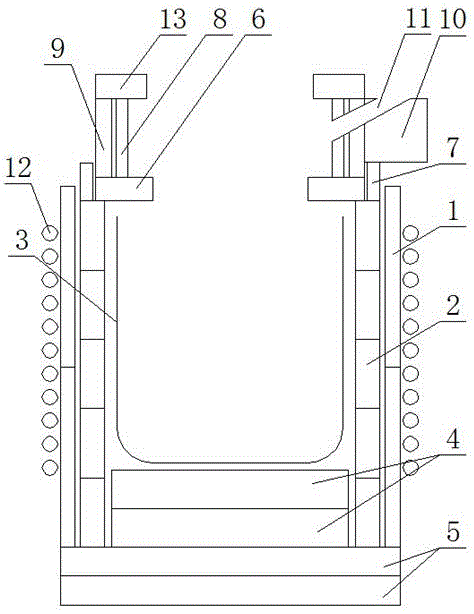

Unidirectional freezing freeze-thaw cycle triaxial apparatus and test method thereof

InactiveCN103196753ASimple structureReduce volumeMaterial strength using tensile/compressive forcesTemperature controlInternal pressure

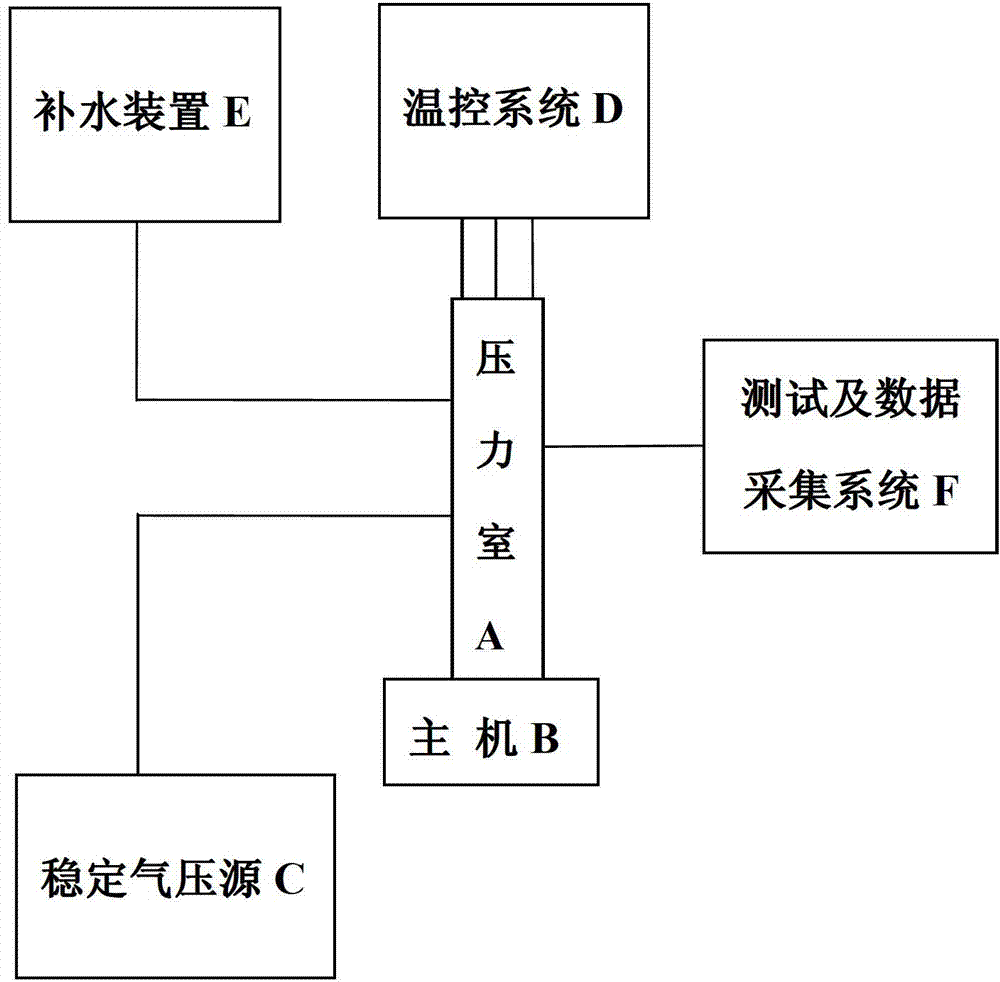

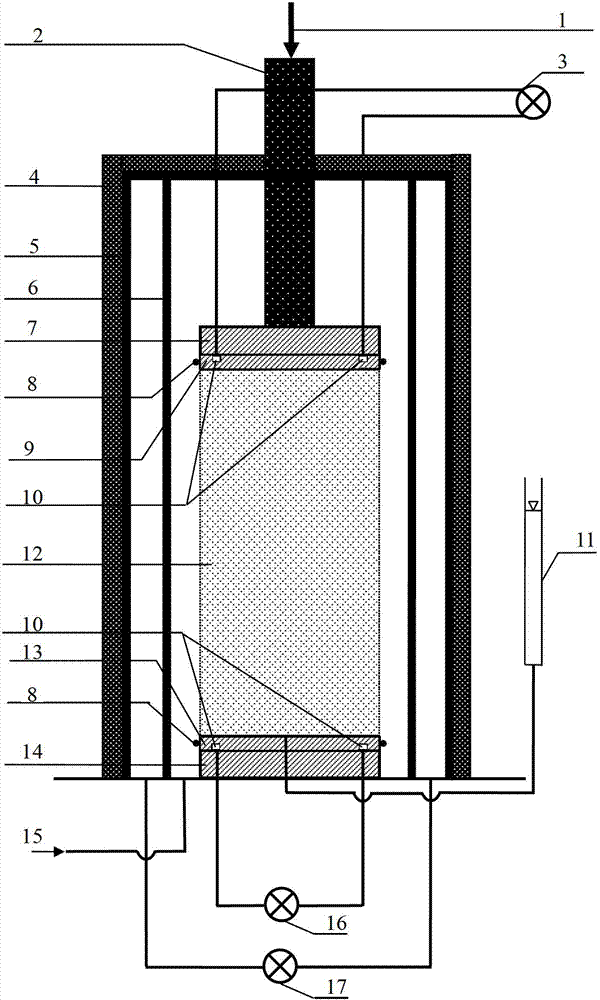

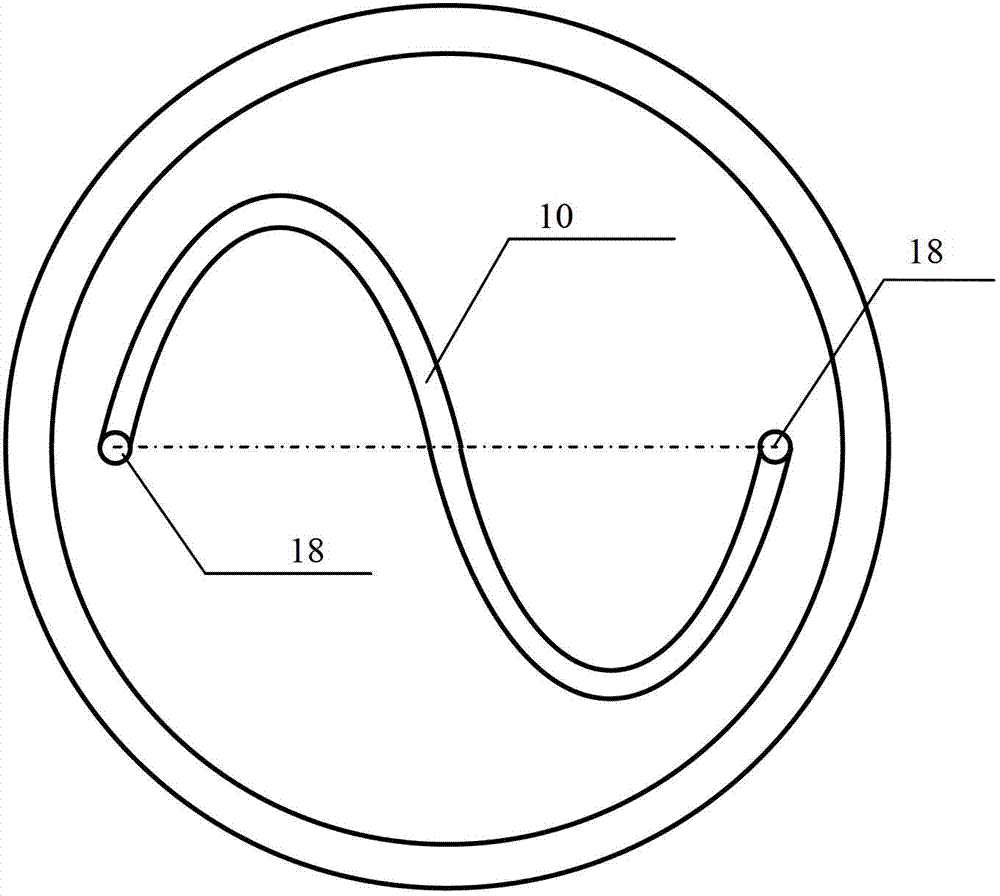

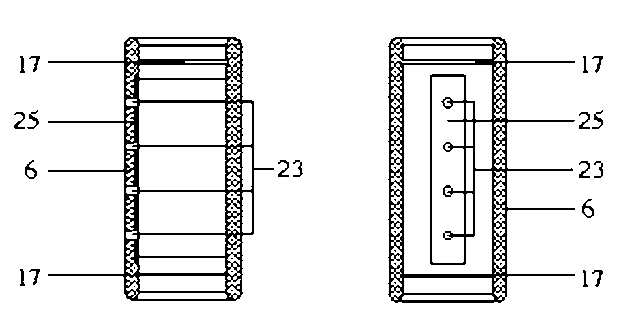

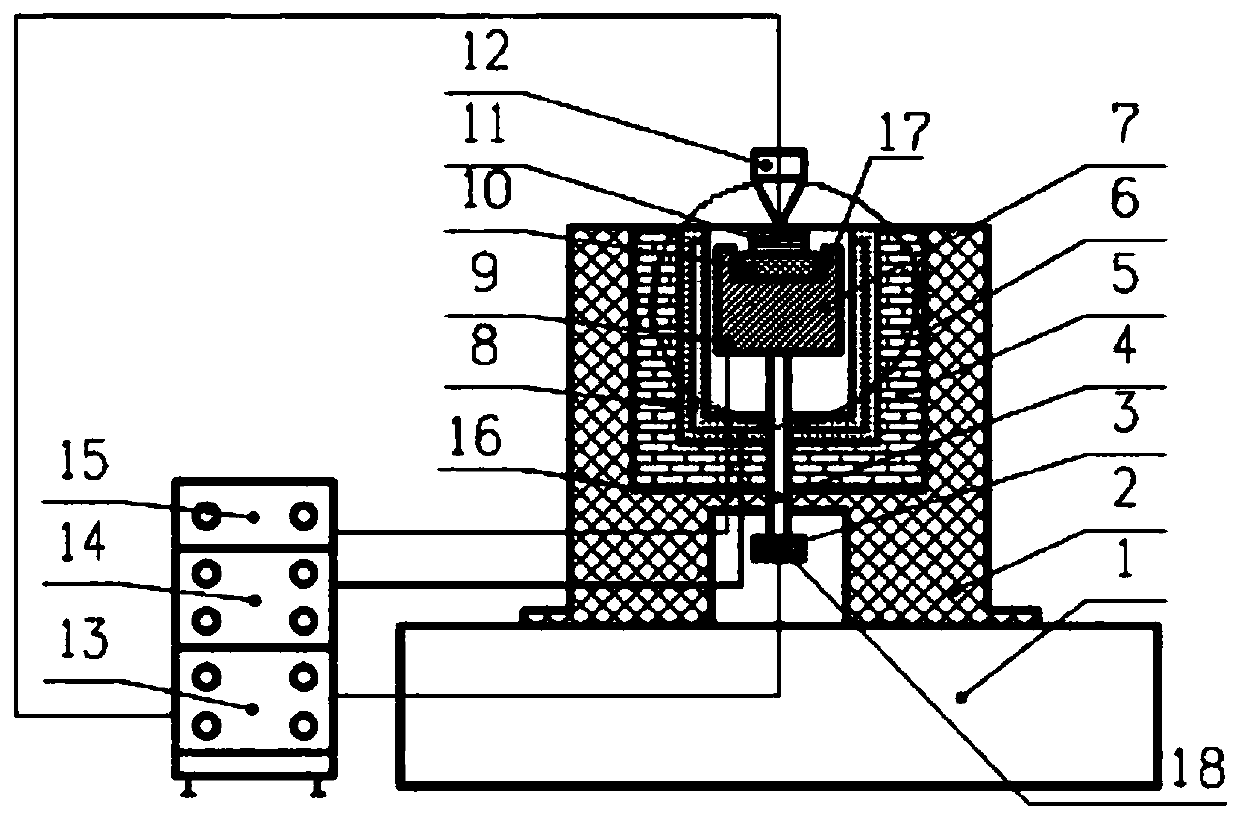

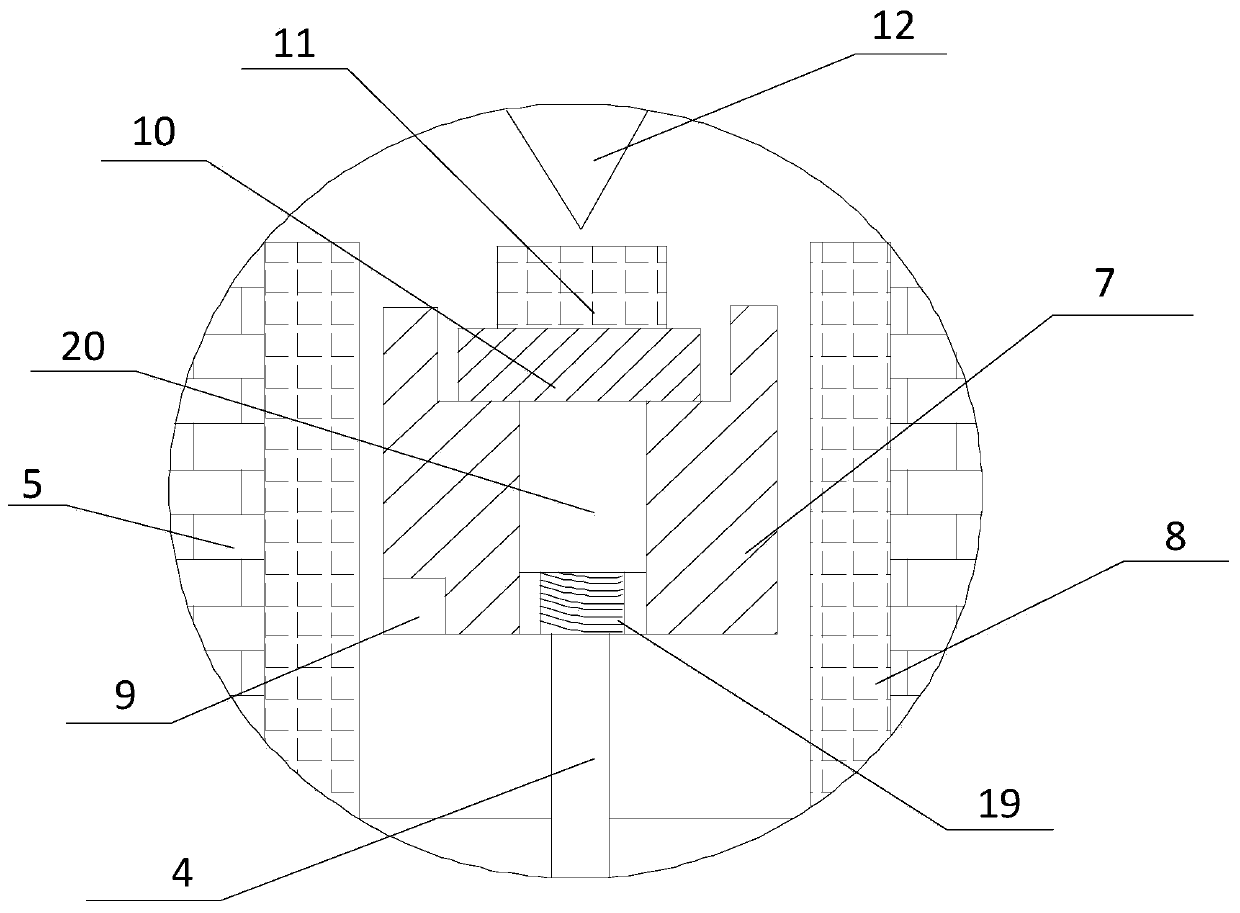

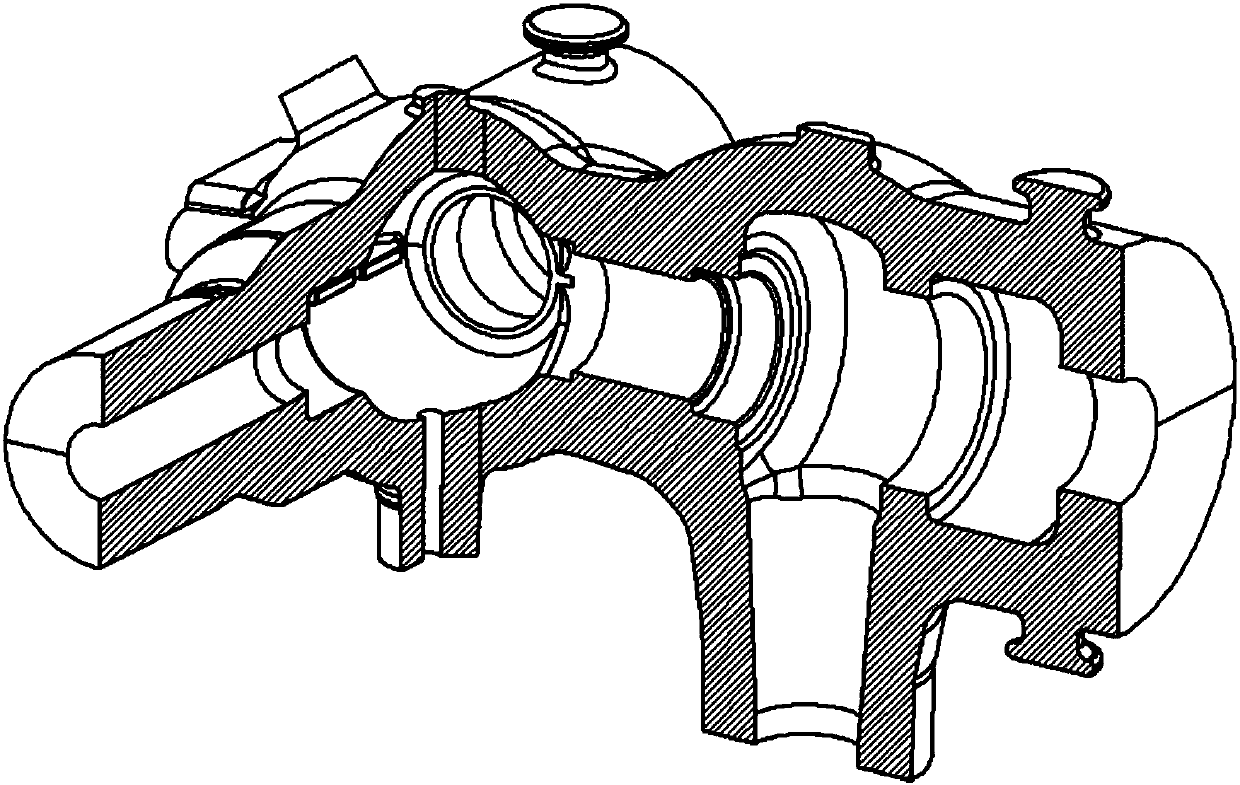

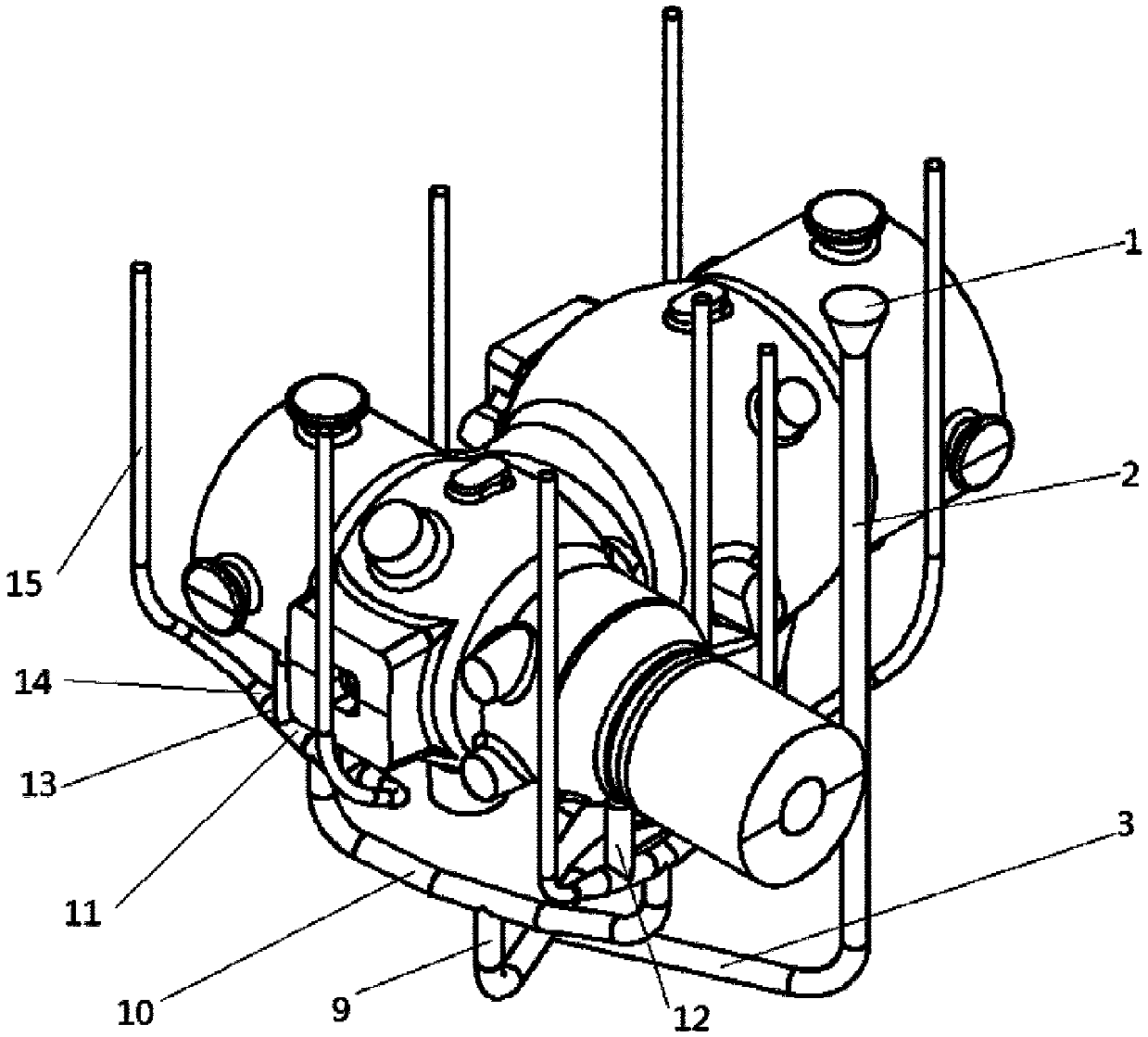

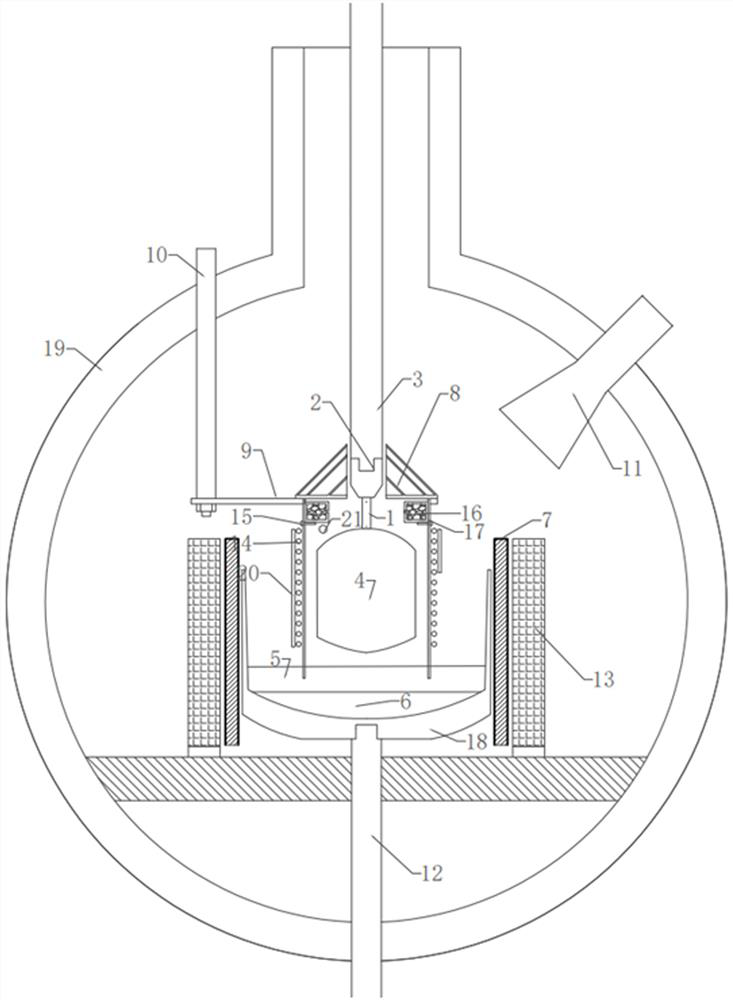

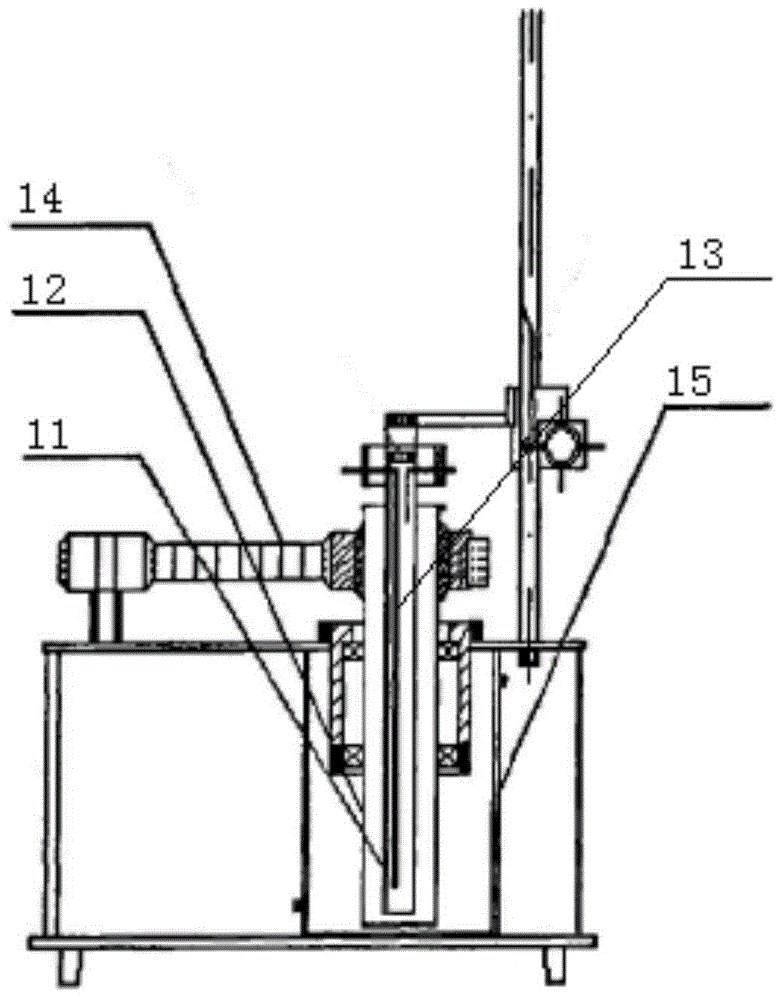

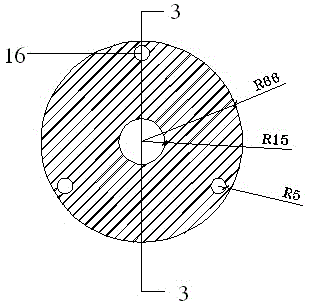

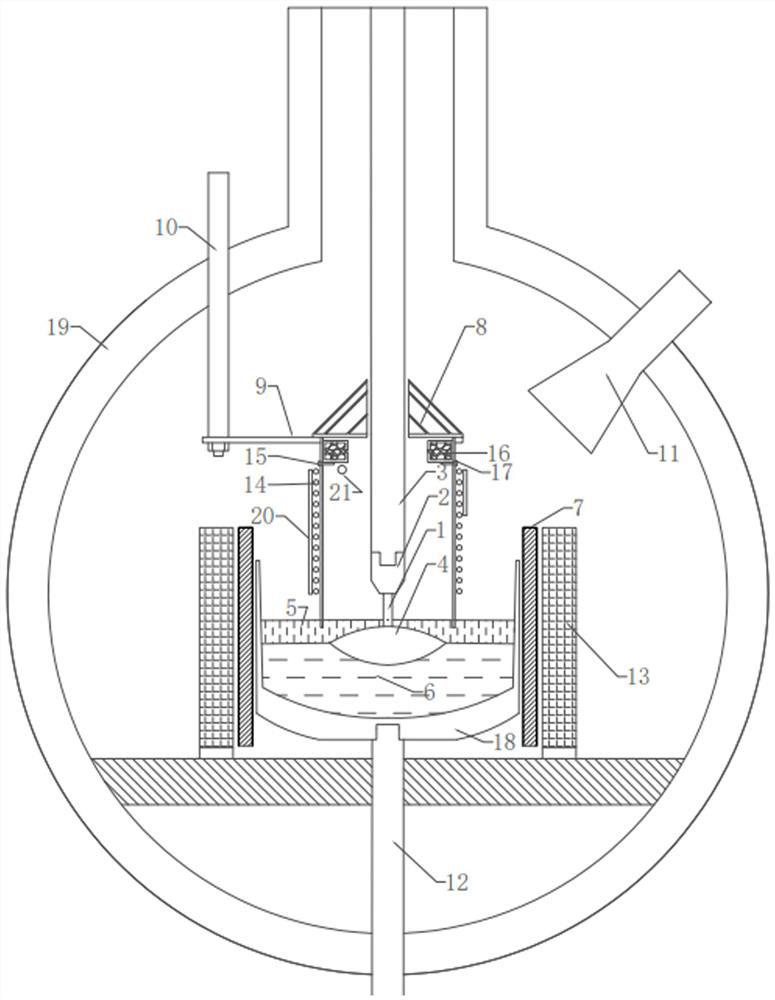

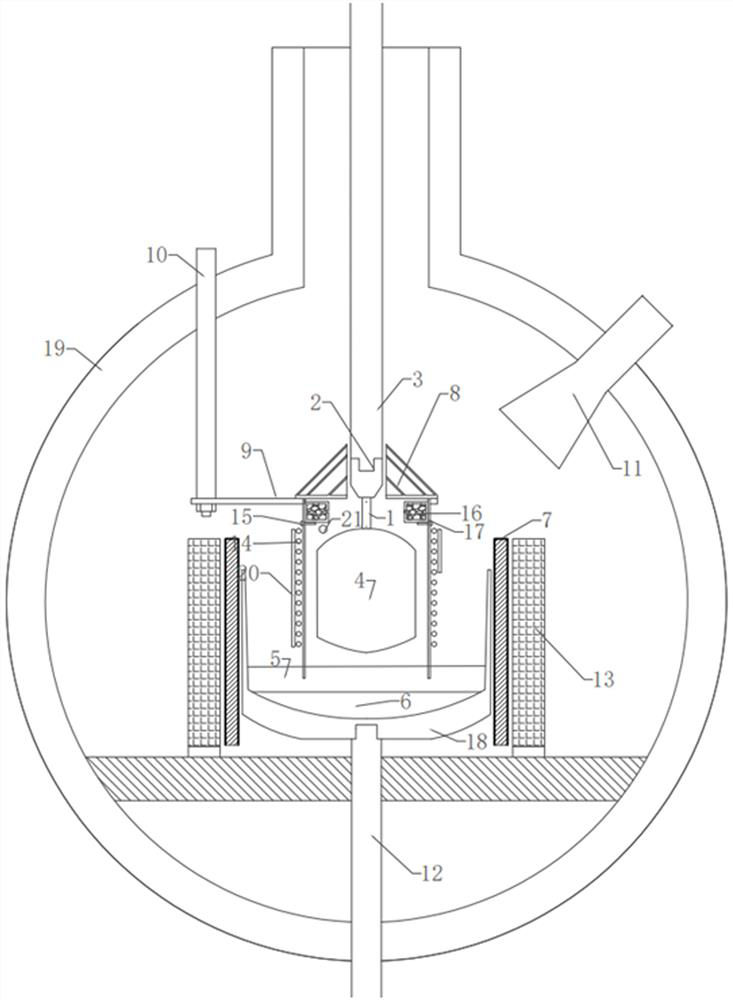

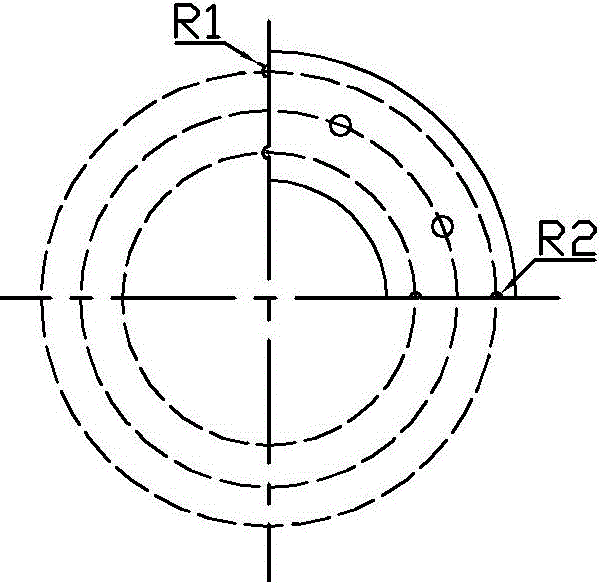

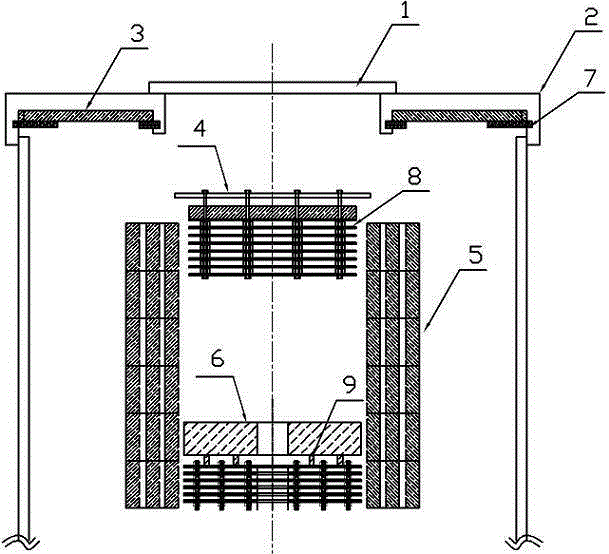

The invention discloses a unidirectional freezing freeze-thaw cycle triaxial apparatus which comprises a pressure chamber, a mainframe, a stable air pressure source, a temperature control system, a water replenishing device and a test and data acquisition system, wherein the pressure chamber comprises an external pressure chamber and an internal pressure chamber; the upper part of the internal pressure chamber is provided with a sample cap formed by an upper box of the sample cap and a lower box of the sample cap; the bottom of the pressure chamber is provided with a base formed by an upper box of the base and a lower box of the base; the sample cap, the base and the external pressure chamber are respectively connected with a refrigerating machine by a heat insulation pipeline; the upper part of the pressure chamber is provided with a load power transmission shaft which passes through an upper cover of the pressure chamber and acts on the upper box of the sample cap; the base of the pressure chamber is connected with the water replenishing device by a pipeline; the mainframe is used for providing power for cutting a sample; and a temperature sensor arranged on the refrigerating machine and a displacement sensor and a load sensor which are arranged on the mainframe are connected with the test and data acquisition system. The unidirectional freezing freeze-thaw cycle triaxial apparatus can realize the unidirectional freezing freeze-thaw cycle test under the conditions of low temperature and water supplement, and meanwhile can be used for testing the triaxial strength under the freeze-thaw cycle condition.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

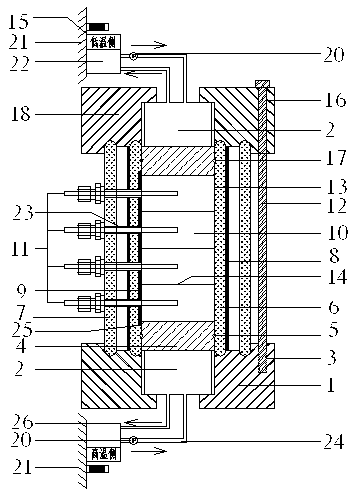

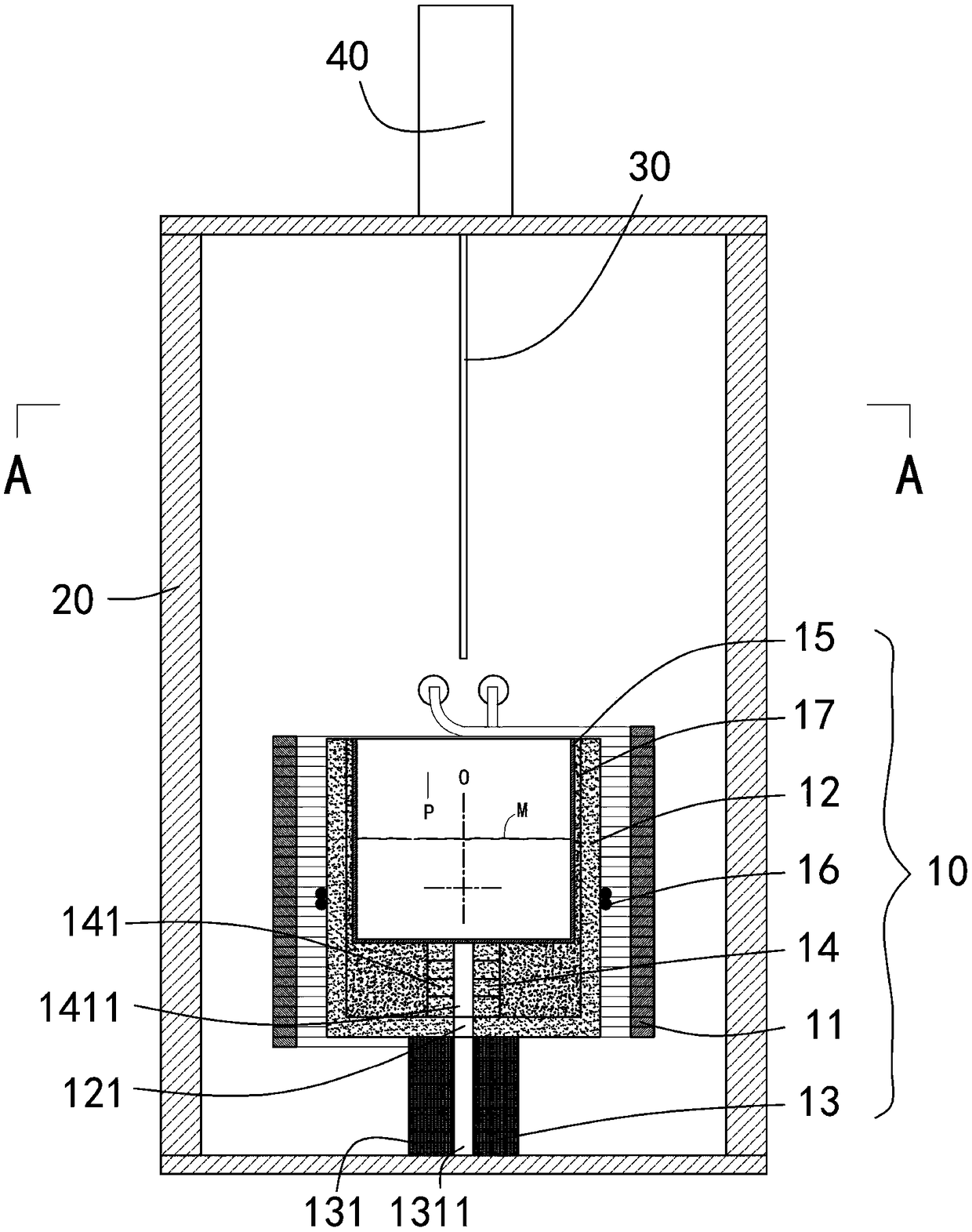

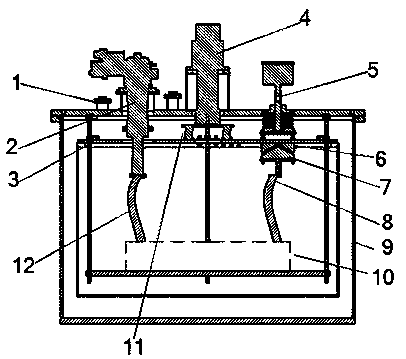

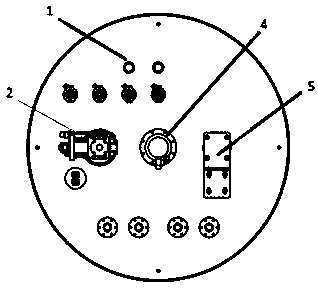

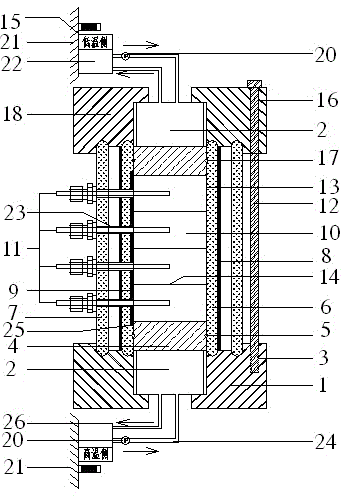

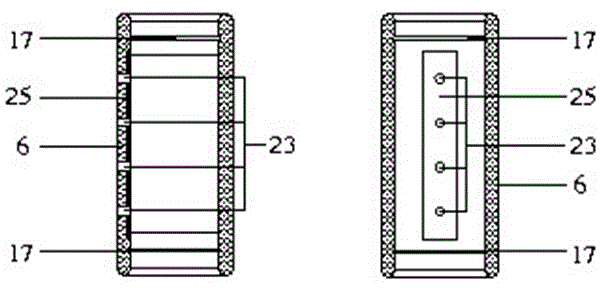

Device and method for testing deformation and water transfer characteristics of soil body under temperature gradient effect

ActiveCN103344748AHighlight substantiveAvoid disturbanceEarth material testingWater bathsTemperature control

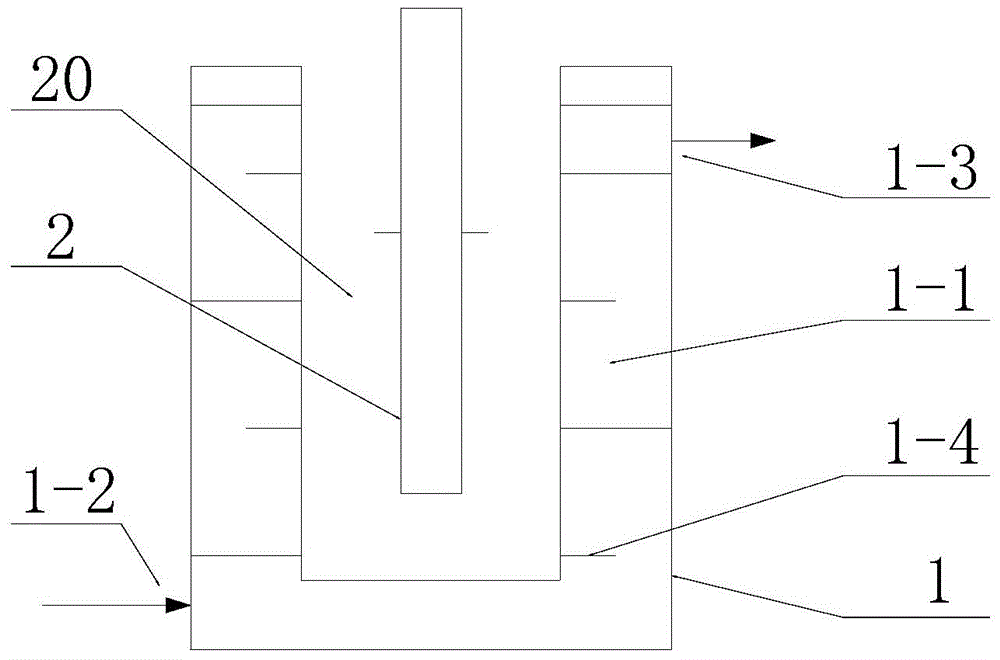

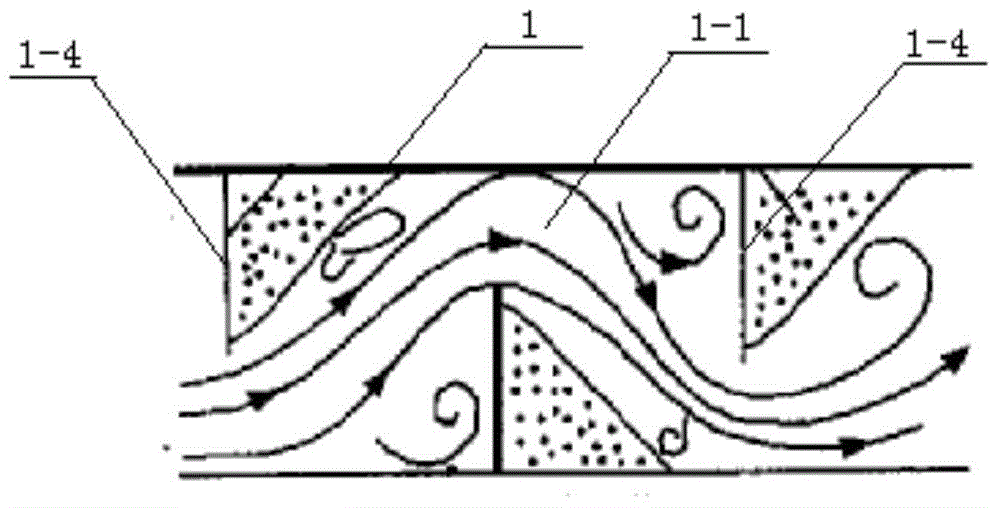

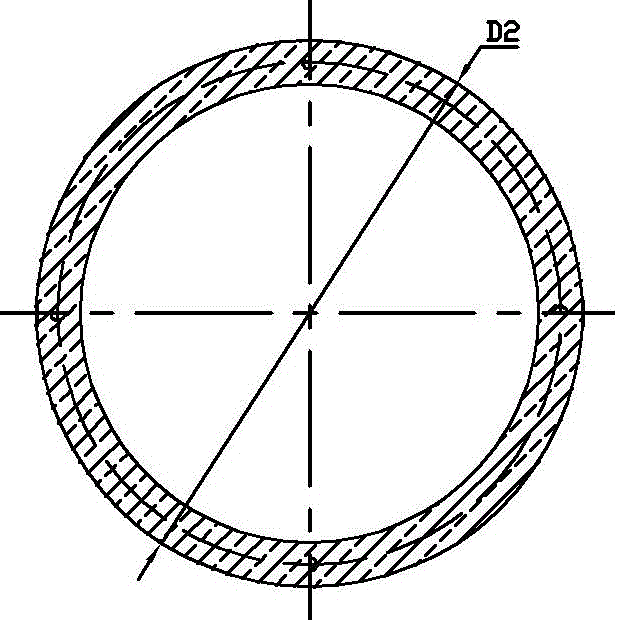

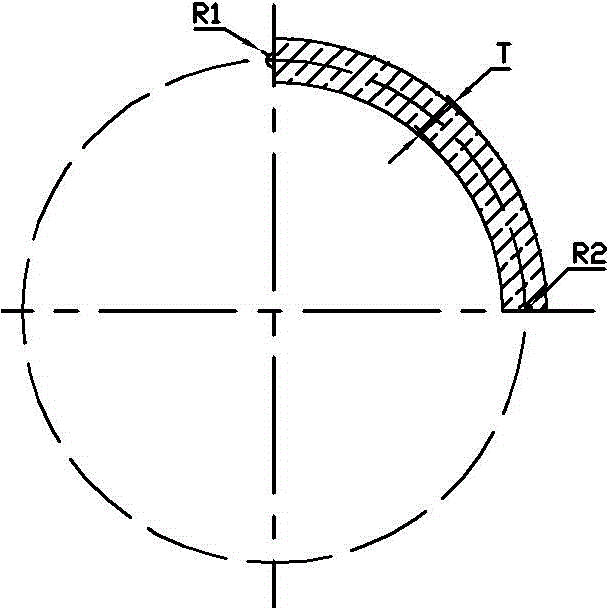

The invention discloses a device and method for testing deformation and water transfer characteristics of a soil body under a temperature gradient effect. The device comprises a sample chamber, a temperature gradient control device and a temperature and water content collecting device, wherein the sample chamber comprises an dual-layer hollow organic glass interlayer sleeve and a cover plate; a high-temperature control device and a low-temperature control device are arranged at the upper end and the lower end of the temperature gradient control device respectively, and the temperature gradient control device comprises a constant-temperature water bath, a heating chamber inside the sample chamber, heat transfer plates at two ends of a sample, and a full-closed circulating pipeline. The device for testing the water and temperature of the soil body can be used for testing the water content and the temperature of the soil body synchronously in real time. The device provided by the invention is convenient, simple and light in design, convenient to operate, good in integration performance, and high in testing precision.

Owner:SHANGHAI UNIV

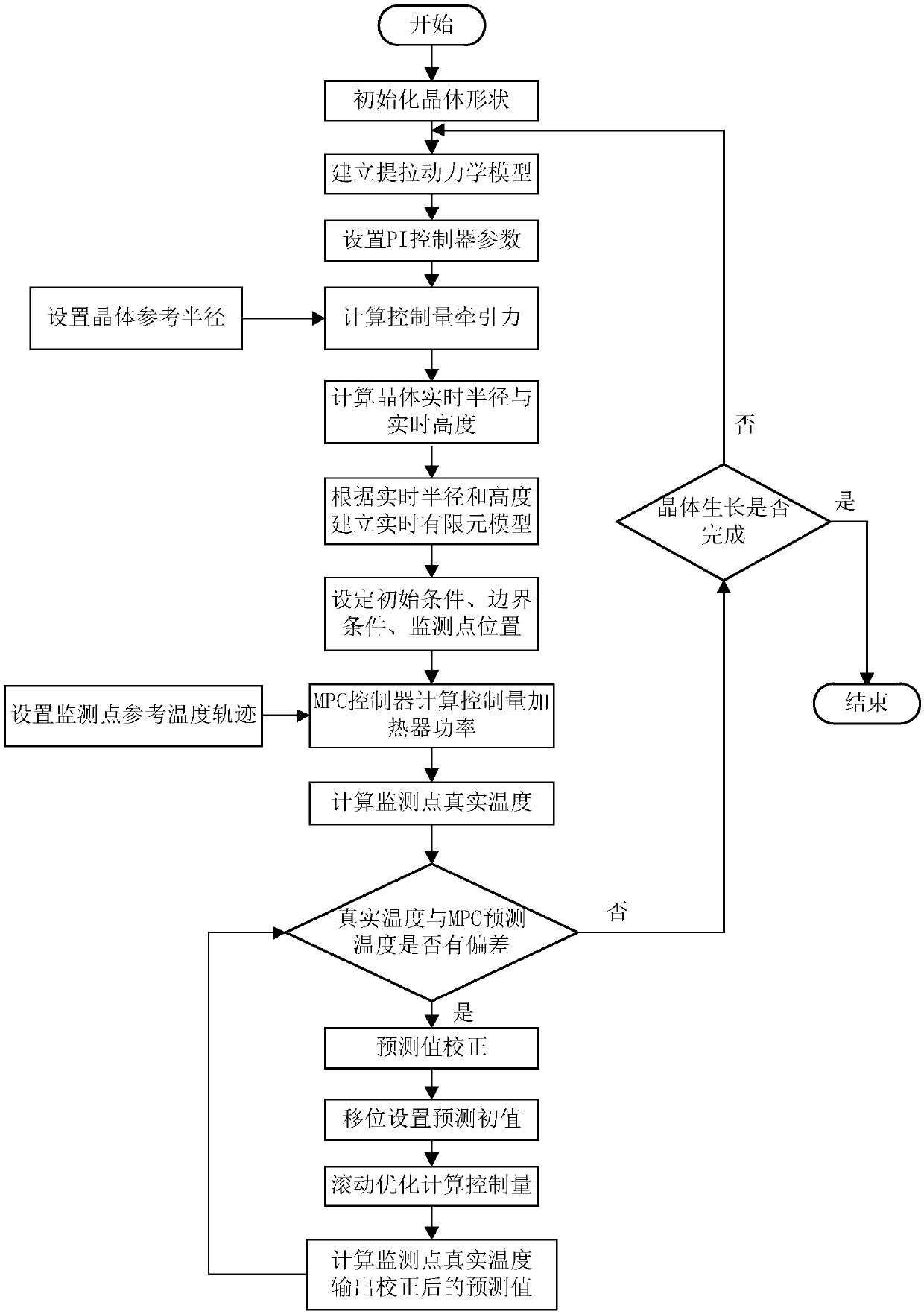

Low-stress crystal growth method

ActiveCN112746312AReduce stressStable growthPolycrystalline material growthBy pulling from meltCzochralski methodCondensed matter physics

The invention discloses a low-stress crystal growth method, and relates to the field of crystal preparation, in particular to a method for preparing low-stress and low-defect crystals by using a Czochralski method, the method is realized by using a Czochralski method crystal growth device with a movable crystal heating cover, and the crystal growth device comprises a furnace body, a crucible at the bottom of the furnace body, a heating and heat preservation system, a crystal lifting mechanism, and a quartz observation window. The device further comprises a movable crystal heating cover which comprises a heating cover body, heating wires arranged on the periphery of the heating cover body and a heating cover lifting mechanism. In the crystal growth process and after the crystal is pulled out of the melt, the movable crystal heating cover is used for covering. By adopting the method, the temperature gradient in the crystal in the crystal growth process and the cooling process after the crystal is lifted can be reduced, so that the crystal stress is reduced, the defects are reduced, the crystal cracking is avoided, the temperature gradient in the melt is kept, the stability of the crystal growth process is ensured, and the crystal yield is ensured.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

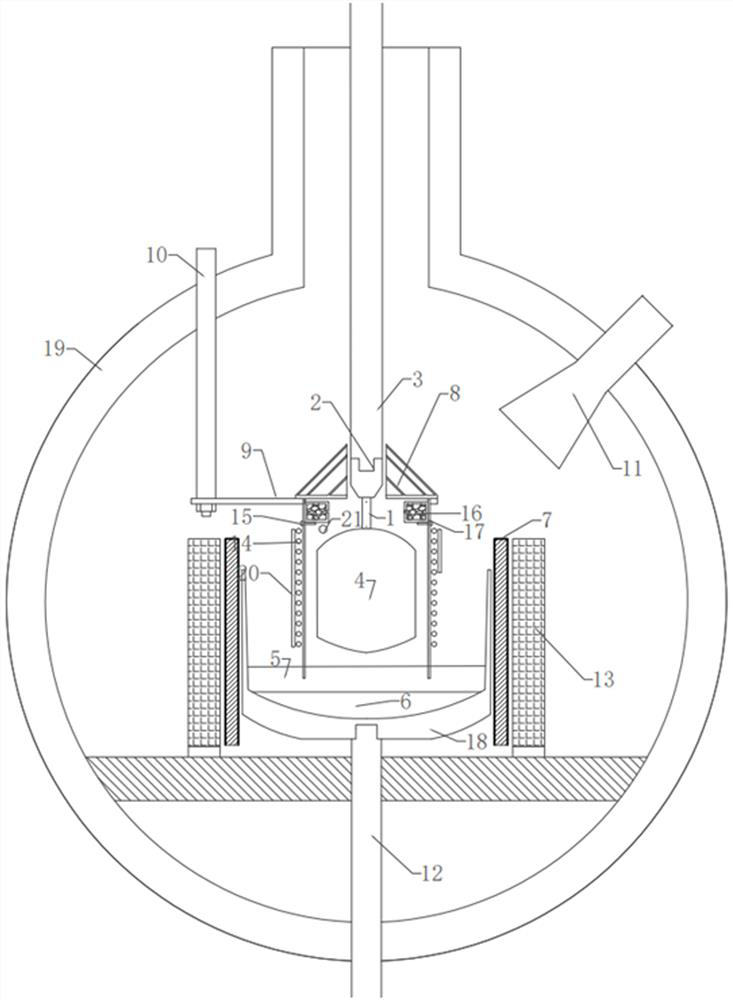

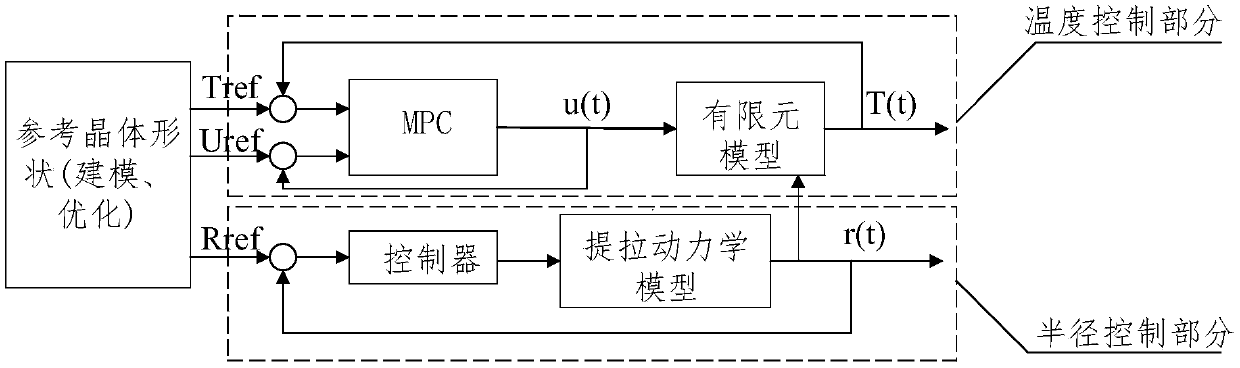

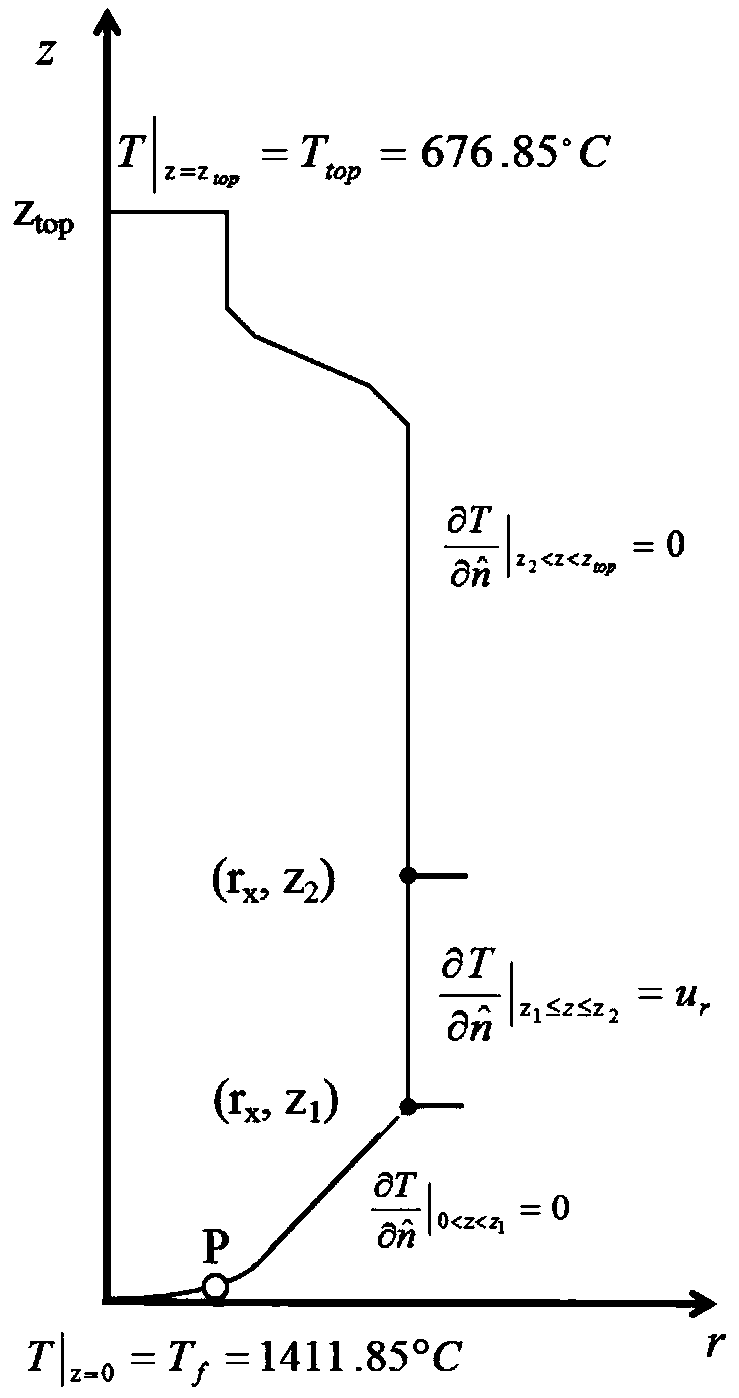

Method for controlling silicon single crystal growth temperature on basis of finite element numerical simulation

InactiveCN108754599AAvoid dislocation defectsBreak through the limitations of quality requirementsPolycrystalline material growthBy pulling from meltSingle crystalElement modeling

The invention discloses a method for controlling silicon single crystal growth temperature on the basis of finite element numerical simulation. The method comprises the following steps: firstly, finite element modeling is performed by referring to crystal shape, and reference shape and boundary conditions of crystals in the whole process are set; the optimal trajectories, meeting constraints, of crystal temperature and heater power are calculated in an offline optimized manner with an optimization method by adopting the highest crystal cooling speed as the target and adopting adjustable rangeof the heater power and the maximum temperature gradient in the crystals as constraint conditions, and the optimal trajectories are used as reference input of a control system; then, crystal radius iscontrolled; finally, tracking control is performed on temperature trajectory in the crystals. The problem of crystal dislocation defect caused by the fact that crystal temperature control cannot be realized with the silicon single crystal growth control method in the prior art is solved.

Owner:XIAN UNIV OF TECH

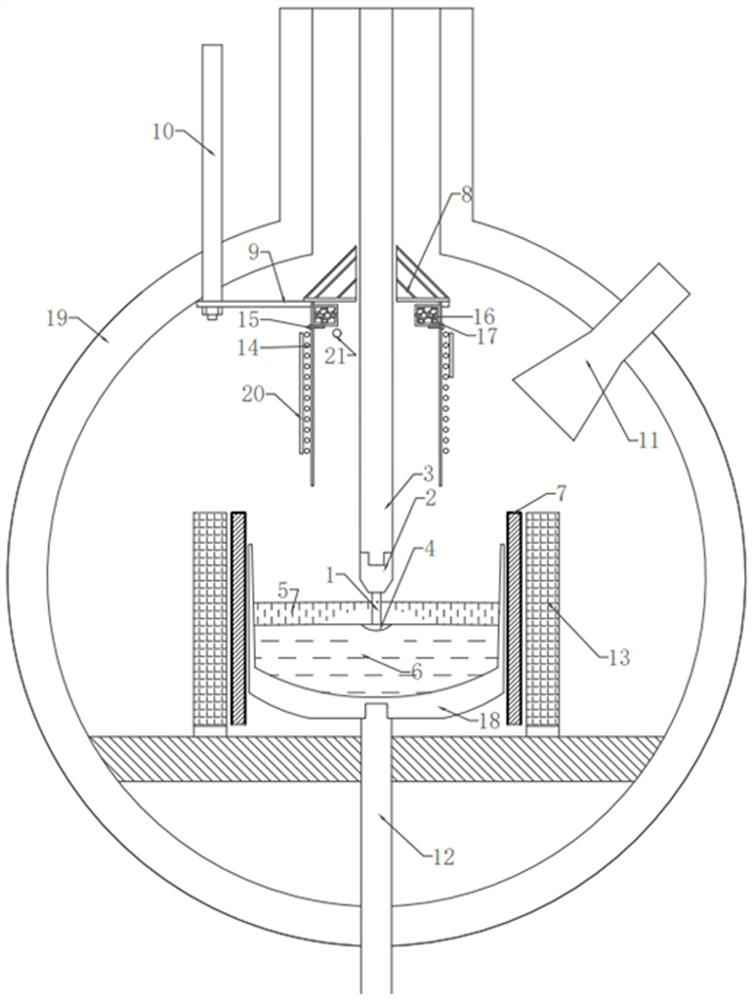

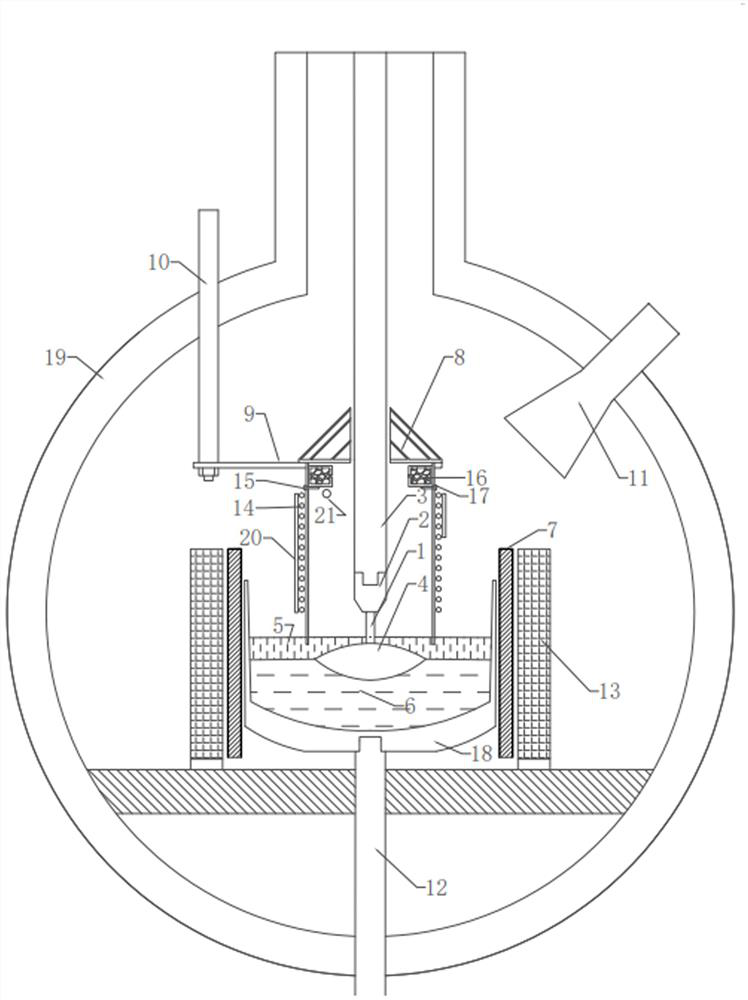

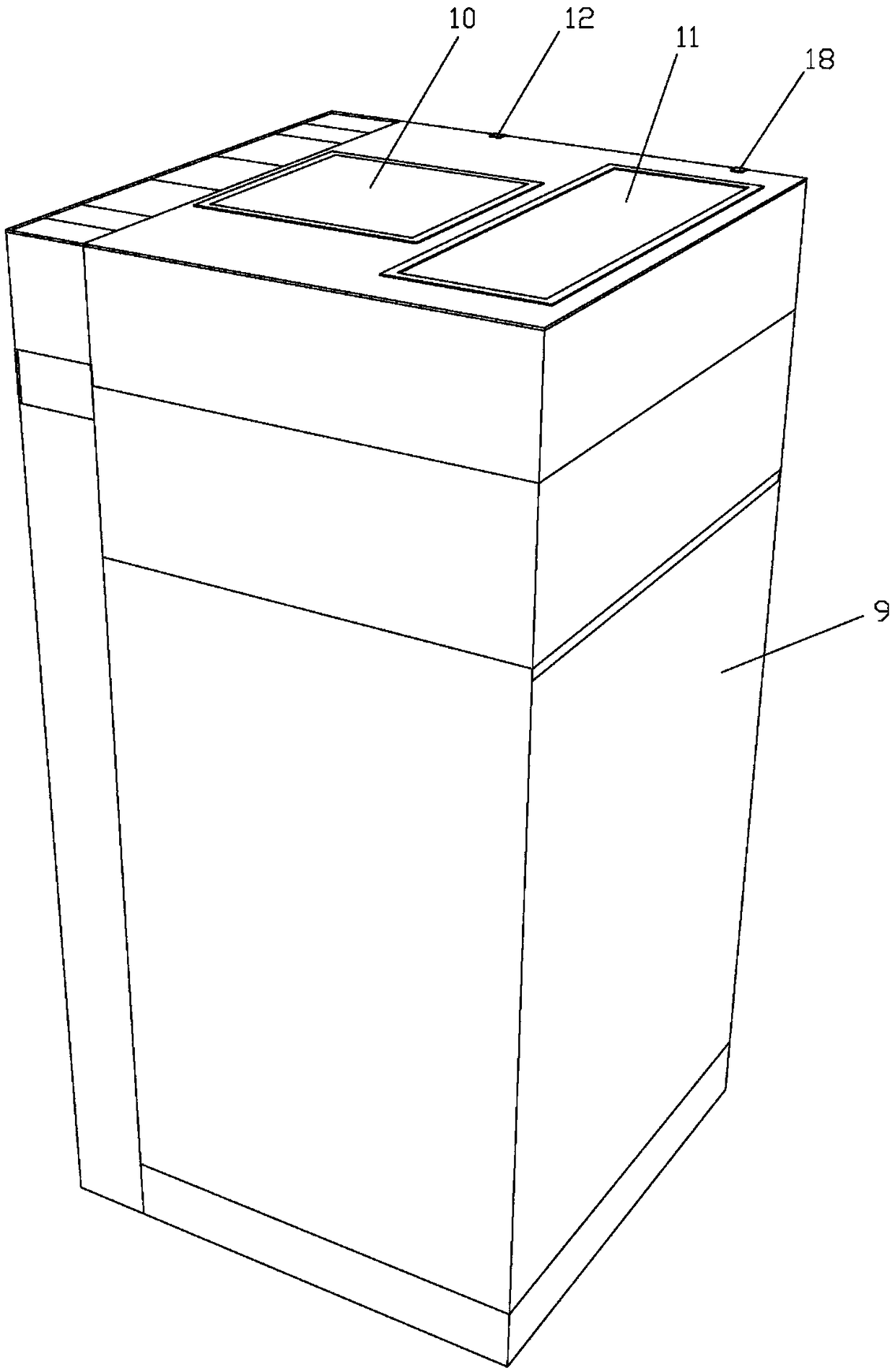

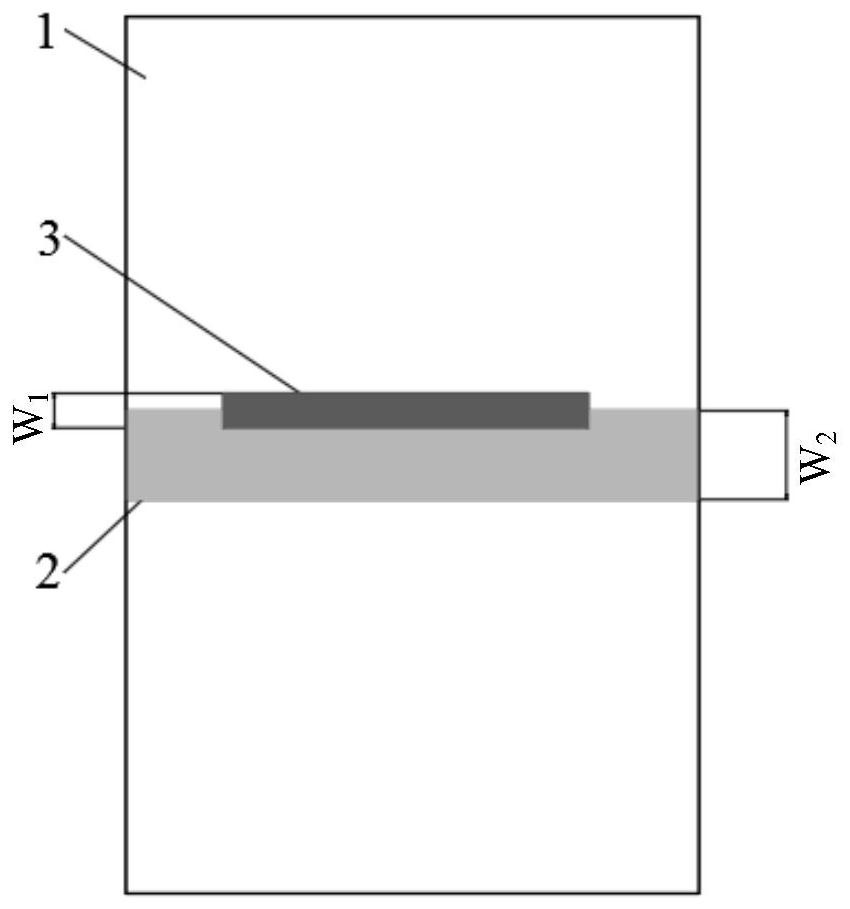

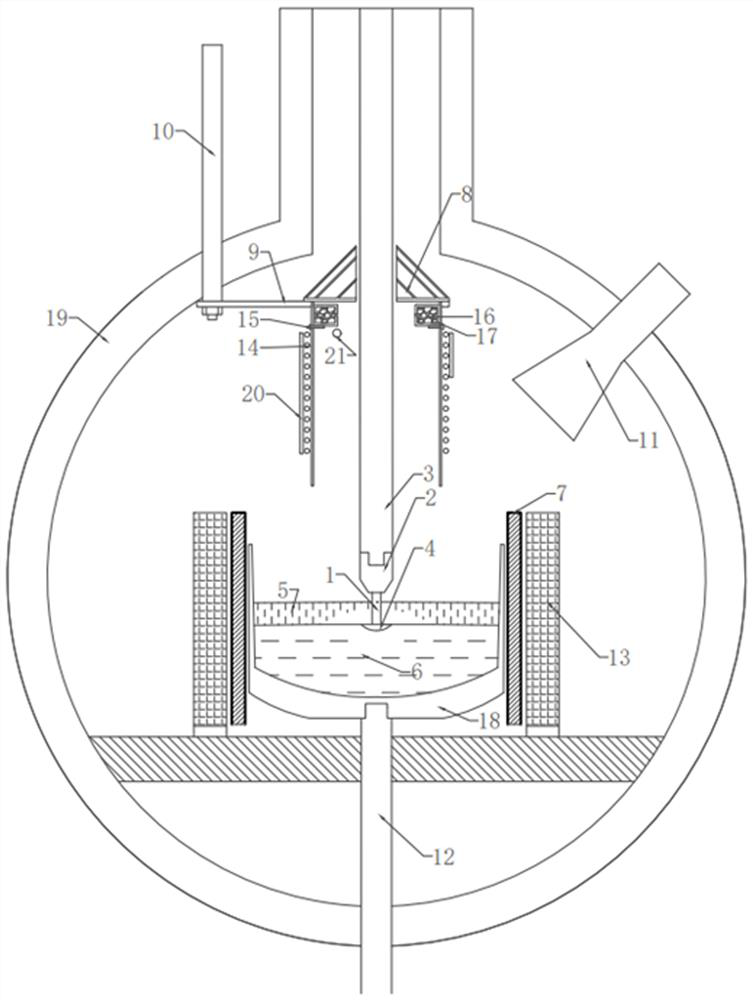

Laser additive manufacturing forming area temperature gradient controllable device and implementation method thereof

ActiveCN111375766AReduce residual stressGuaranteed temperatureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringSuperalloy

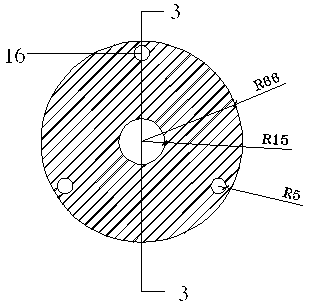

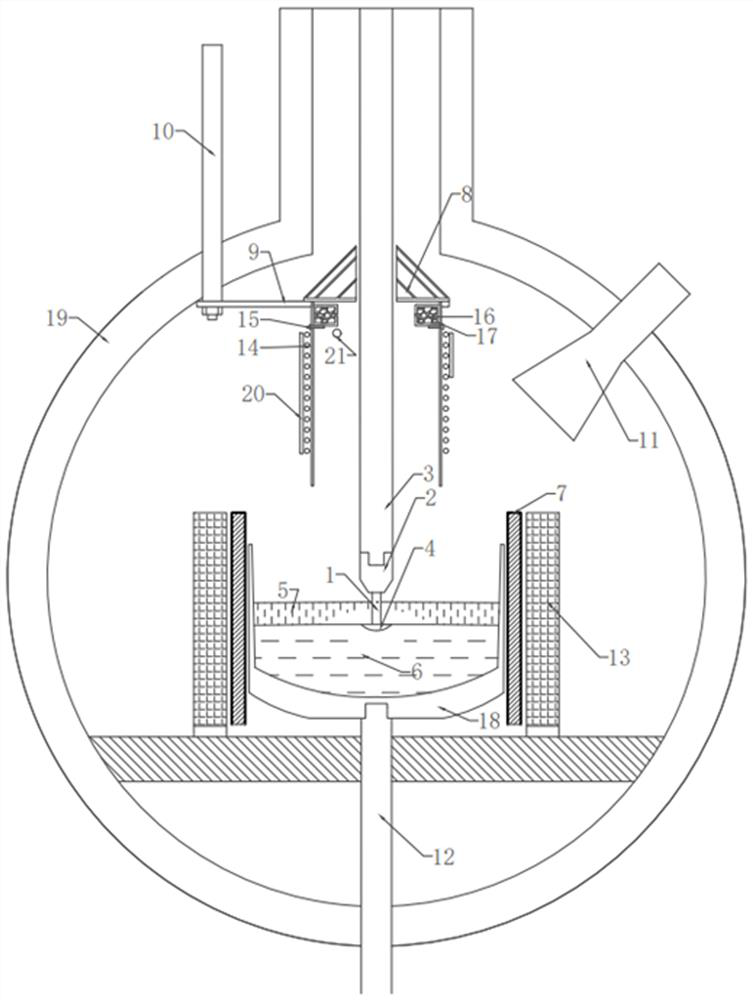

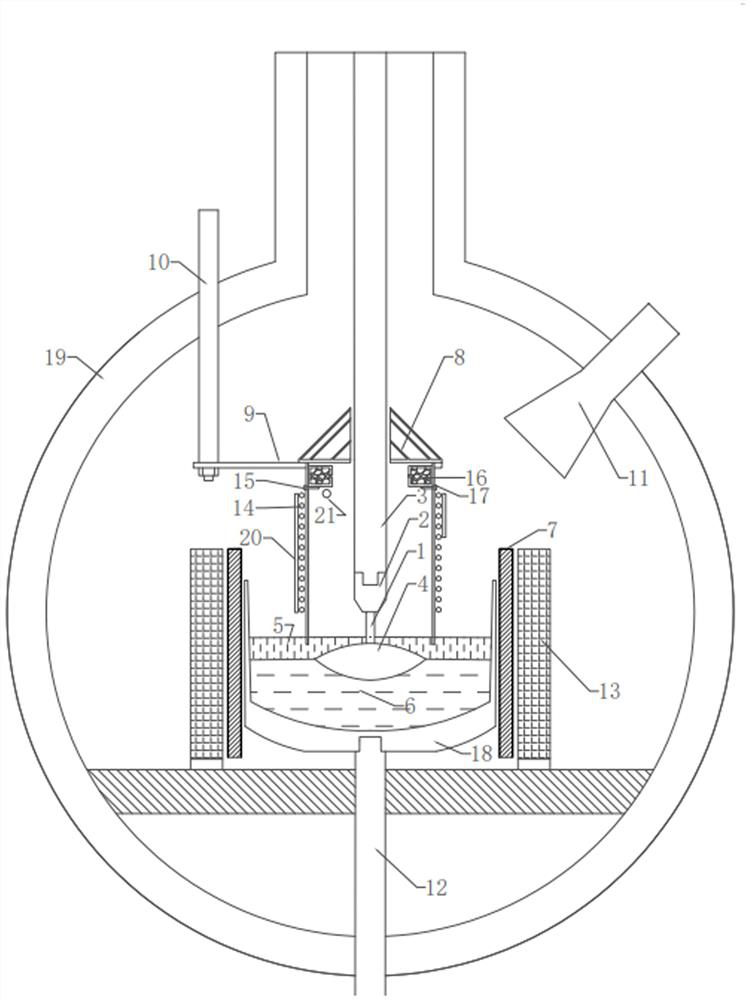

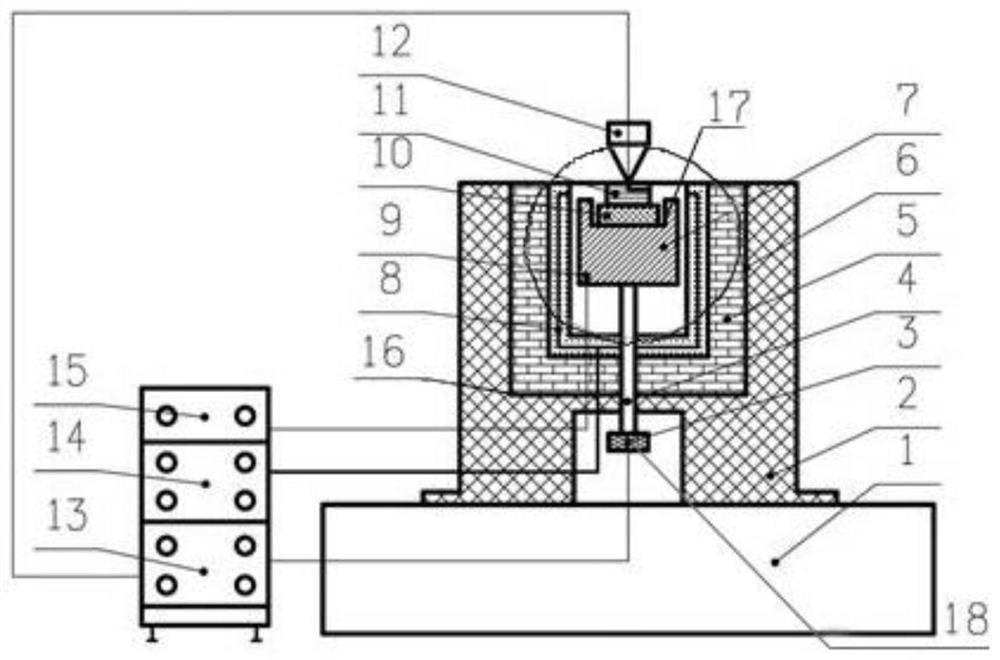

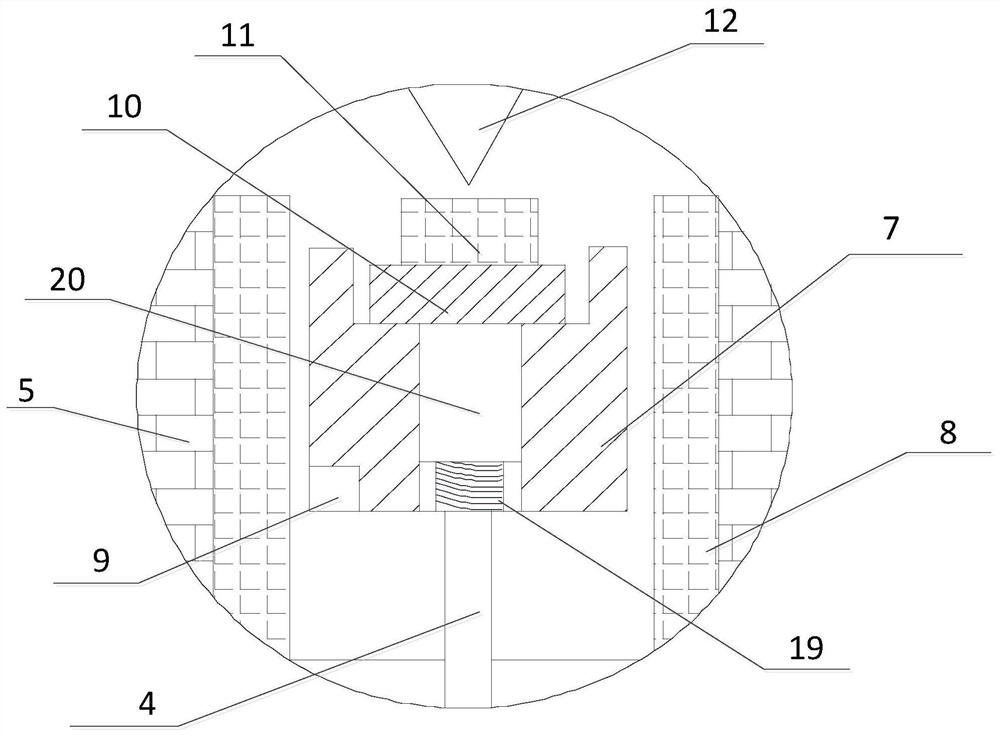

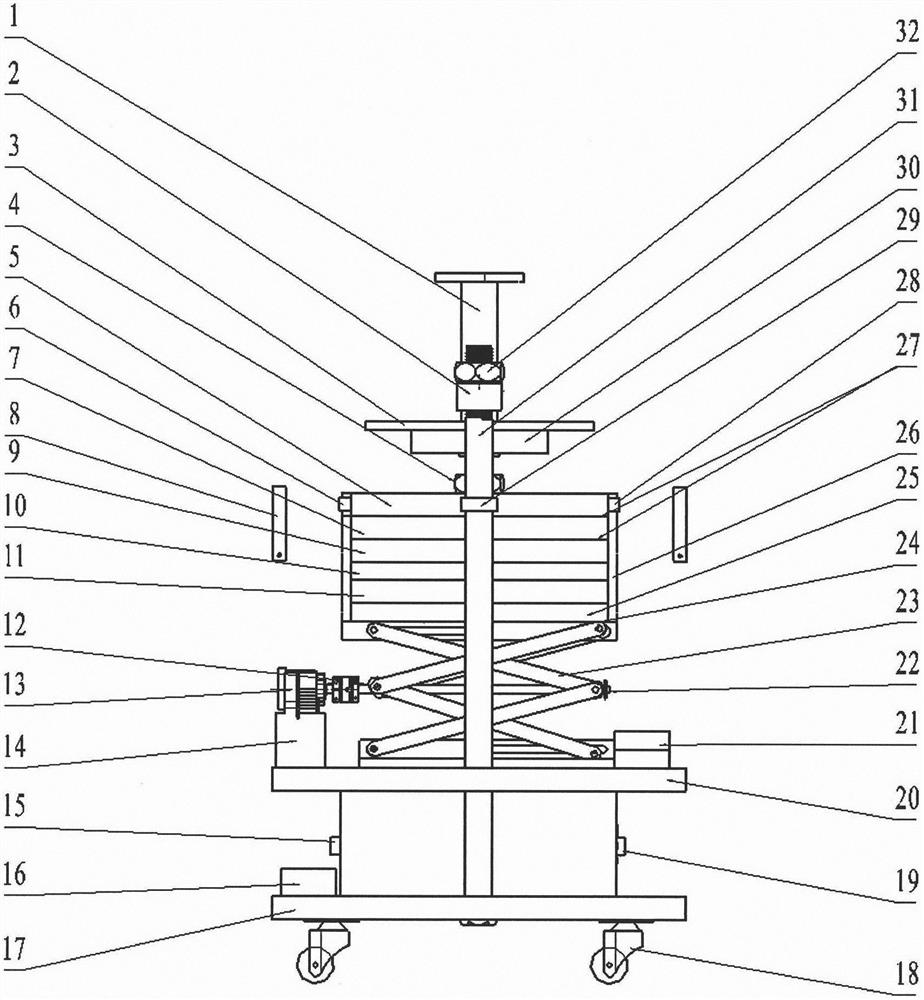

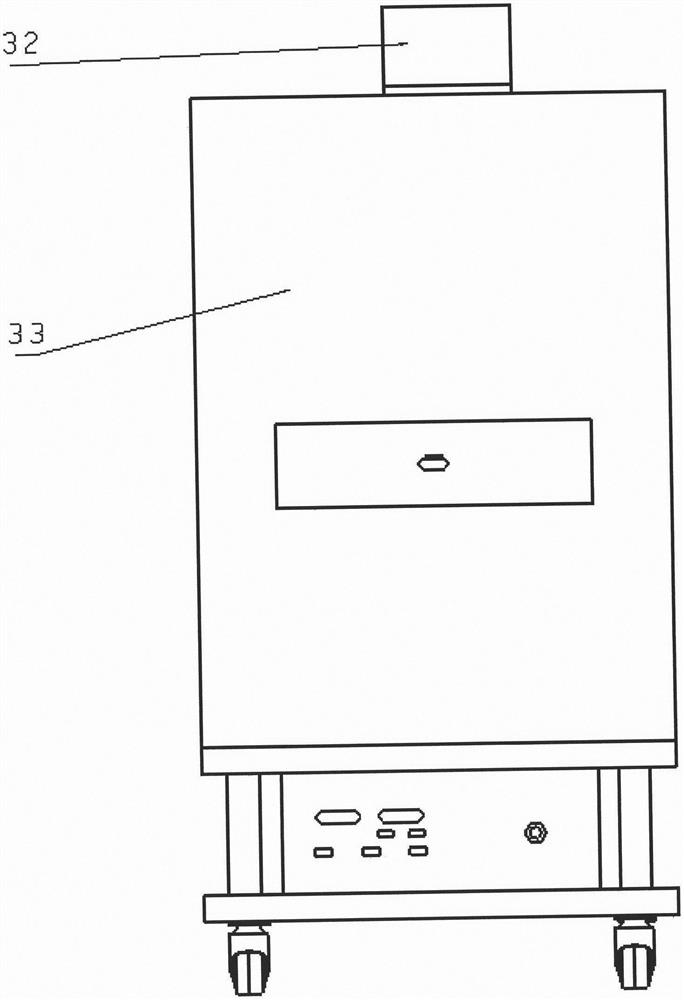

The invention discloses a laser additive manufacturing forming area temperature gradient controllable device. The device comprises a platform, a supporting and fastening base, a stepping motor fixed to the bottom end of the supporting and fastening base, a first groove formed in one side of the supporting and fastening base, a rotating rod with one end coaxially connected with the stepping motor,a well-type resistance heating mechanism installed in the first groove, a high-temperature alloy mold arranged in the well-type resistance heating mechanism and driven by the rotating rod to move up and down, a thermocouple temperature measuring mechanism, a substrate, a laser cladding head located above the substrate, a forming area, a motion control system, a heating control system and a temperature control feedback system, wherein the high-temperature alloy mold is matched with the first groove in shape. The invention further provides an implementation method of the laser additive manufacturing forming area temperature gradient controllable device. According to the device and the implementation method, the substrate can be heated and subjected to temperature control, the temperature gradient of the forming area is guaranteed, and the thermal stress cracking risk and the overall residual stress of a formed part in the forming and repairing process are reduced.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

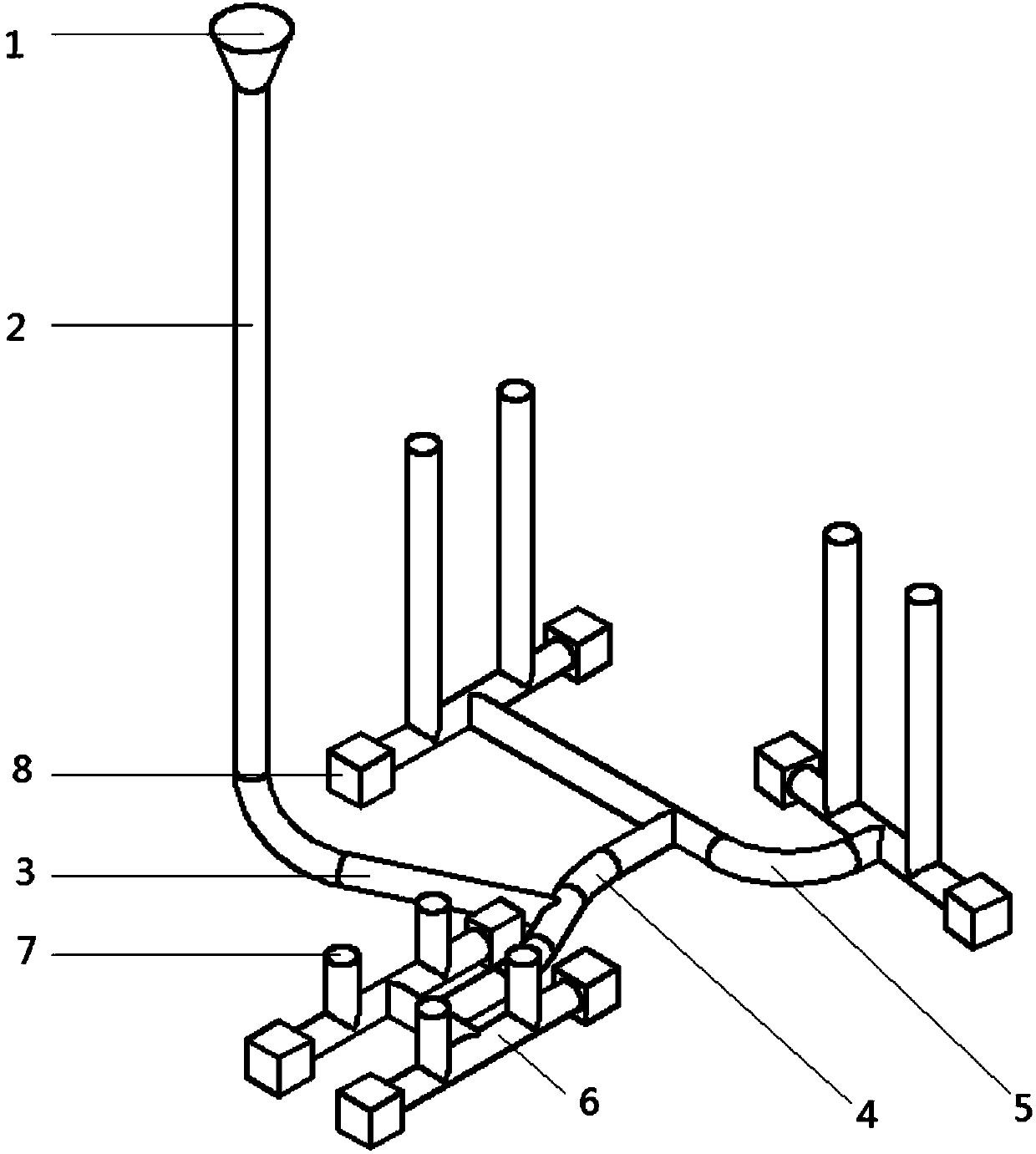

Pouring system for large valve casing type steel castings

The invention provides a pouring system for large valve casing type steel castings. The pouring system structurally comprises a sprue cup, a sprue, a slow-flow cross gate, a cross gate and an inner gate which are connected sequentially; the slow-flow cross gate is a first-class cross gate and is connected with a second-stage cross gate above the slow-flow cross gate through a vertical drainage gate; the second-stage cross gate has the V-shaped longitudinal section; the tail end of the second-stage cross gate is connected with a third-stage cross gate at the upper end of the second-stage crossgate through the vertical drainage gate; the third-stage cross gate has the V-shaped longitudinal section; the inner gate is perpendicularly connected with the third-stage cross gate and faces vertically upwards; and the tail end of the third-stage cross gate is sequentially connected with a slag guiding gate, a reducing gate and a slag collecting gate which is perpendicularly connected with the reducing gate and faces vertically upwards. By the aid of the pouring system, the mold filling process of molten steel is stable, the slag collecting effect is remarkable, and slag inclusion and impurity inclusion defects on the surfaces of the castings are reduced.

Owner:KOCEL STEEL

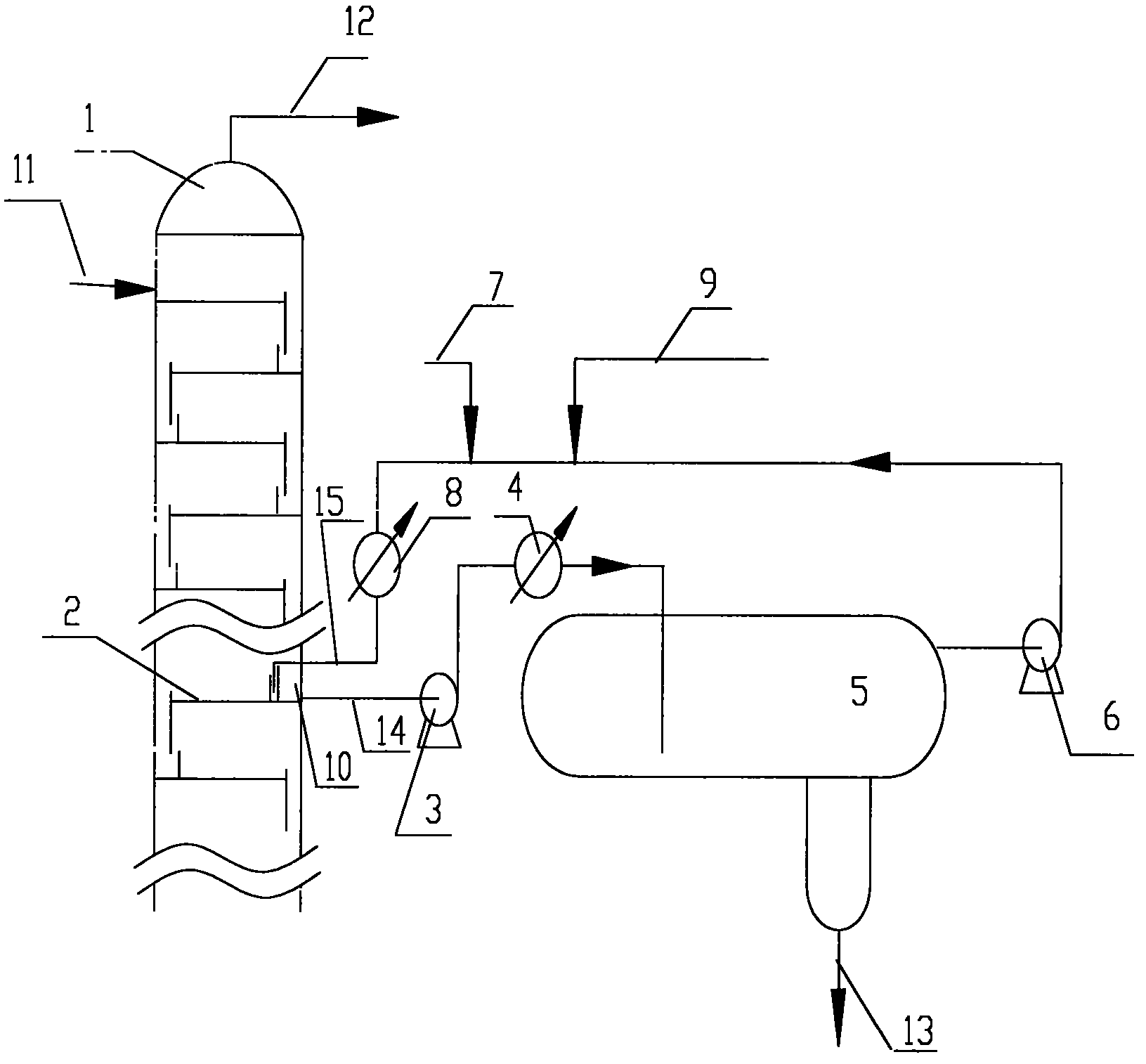

Method and device for preventing fractionation tower salt coagulation

InactiveCN104342191AIncrease profitGuaranteed temperature gradientDistillation corrosion inhibitionFractionationLiquid tank

The invention discloses a method and a device used for preventing fractionation tower salt coagulation. According to the invention, a mixed liquid of distillate oil and NH4Cl water solution in a tray liquid tank of a fractionation tower with a temperature of 110-130 DEG C is pumped out; the mixed liquid is cooled, and is subjected to oil-water separation in an oil-water separation tank; the oil phase is heated to a temperature same as that when pumped out, and is returned to the fractionation tower; and a water phase comprising NH4Cl is discharged. According to the invention, the utilization rate of space in the tower is high, and salt-removing effect is good.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Auxiliary heating method and device and single crystal furnace for growing single crystals with induction heating czochralski method

The invention discloses an auxiliary heating method for growing single crystals with an induction heating czochralski method. At a crystal growth stage, an auxiliary temperature field is arranged on the outer side of a crucible, the crucible can emit heat, the auxiliary temperature field is placed on the outer side of the crucible side wall extending in the radial direction, melt in the crucible is heated by the auxiliary temperature field, and the longitudinal temperature gradient of the melt in the crucible is improved. In the technical scheme, the auxiliary temperature field is added to theouter side of the crucible to heat the melt in the crucible, so that heat produced by the crucible side wall exposed above the liquid level of the melt on the melt can be offset, and the required temperature gradient for crystal growth is guaranteed. The invention also provides an auxiliary heating device and a single crystal furnace for growing single crystals with the induction heating czochralski method.

Owner:BEIFANG UNIV OF NATITIES

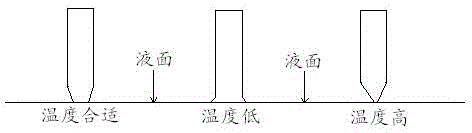

Crystal pulling growth furnace temperature field structure and pulling growth technology thereof

The invention discloses a crystal pulling growth furnace temperature field structure and a pulling growth technology thereof. The temperature field structure comprises an aluminum oxide heat preservation cylinder (1), a zirconium oxide brick heat preservation cylinder (2), an iridium crucible (3), a zirconium oxide crucible holder (4), an aluminum oxide bottom holder (5), a first zirconium oxide cover plate (6), a second zirconium oxide cover plate (13), an aluminum oxide positioning ring (7), an aluminum oxide upper heat preservation inner cylinder (8) and an zirconium oxide upper heat preservation outer cylinder (8). The technology comprises: preparation before charging, iridium crucible treatment, charging, feeding, first material melting, seed crystal preparation and adjustment, second material melting, air inflation, seed crystal preheating, crystal growth, and ending. According to the invention, the reasonable temperature field structure and the pulling growth technology thereof are designed, and the energy consumption is reduced on the premise of ensuring high temperature and temperature gradient required by growth. Necking is performed before shouldering, that is, the temperature is slightly high when pulling is started, so as to enable the diameter of a seed crystal to be reduced by about 1mm; then the temperature is reduced for shouldering, so as to prevent a seed crystal defect from extending into the crystal as far as possible.

Owner:成都晶九科技有限公司

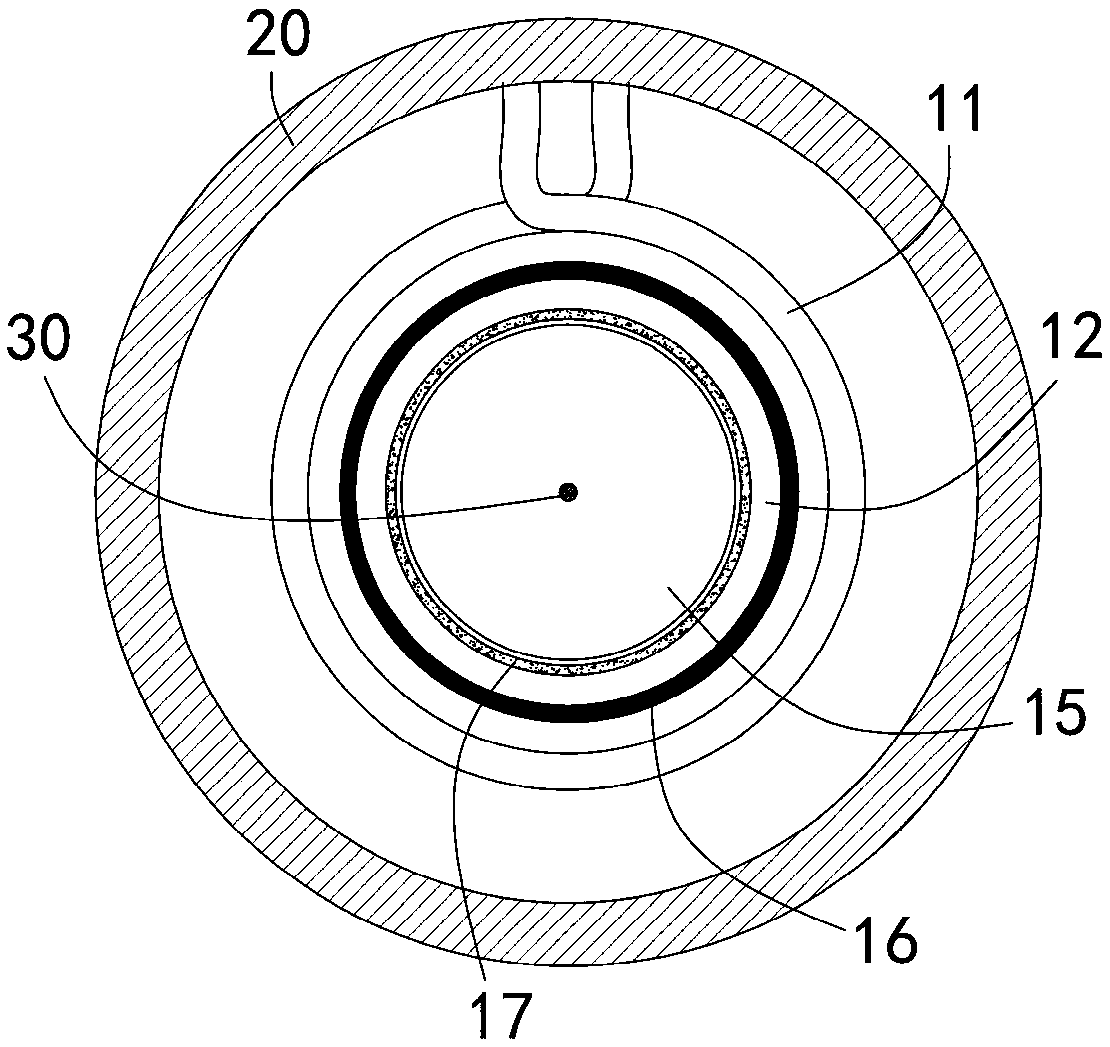

Crystal growth device

PendingCN112695376AReduce temperature gradientReduce stressBy pulling from meltCzochralski methodCrucible

The invention discloses a crystal growth device, and relates to the field of crystal preparation, in particular to a device for preparing low-stress and low-defect crystals by using a pulling method. The device comprises a furnace body, a crucible arranged at the bottom of the furnace body, a heating and heat preservation system, a crystal lifting mechanism and a quartz observation window, and further comprises a lifting type heating cover mechanism which comprises a heating cover body, a heating cover supporting part, heating wires arranged on the periphery of the heating cover body and a heating cover lifting mechanism. By adopting the device, the stress in the crystal in the growth process of the crystal and the cooling process after the crystal is lifted can be reduced, the defects are reduced, the crystal cracking is avoided, the temperature gradient in the melt is maintained, the stability of the crystal growth process is ensured, and the crystal yield is ensured.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

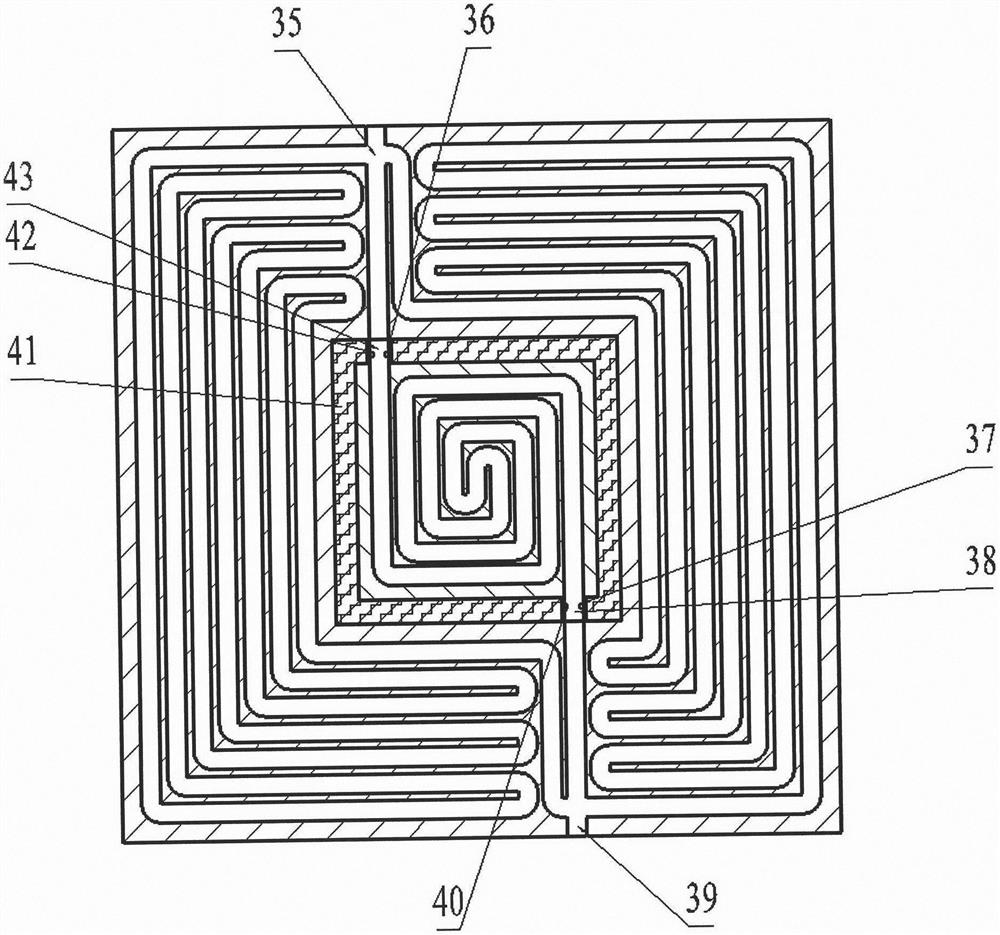

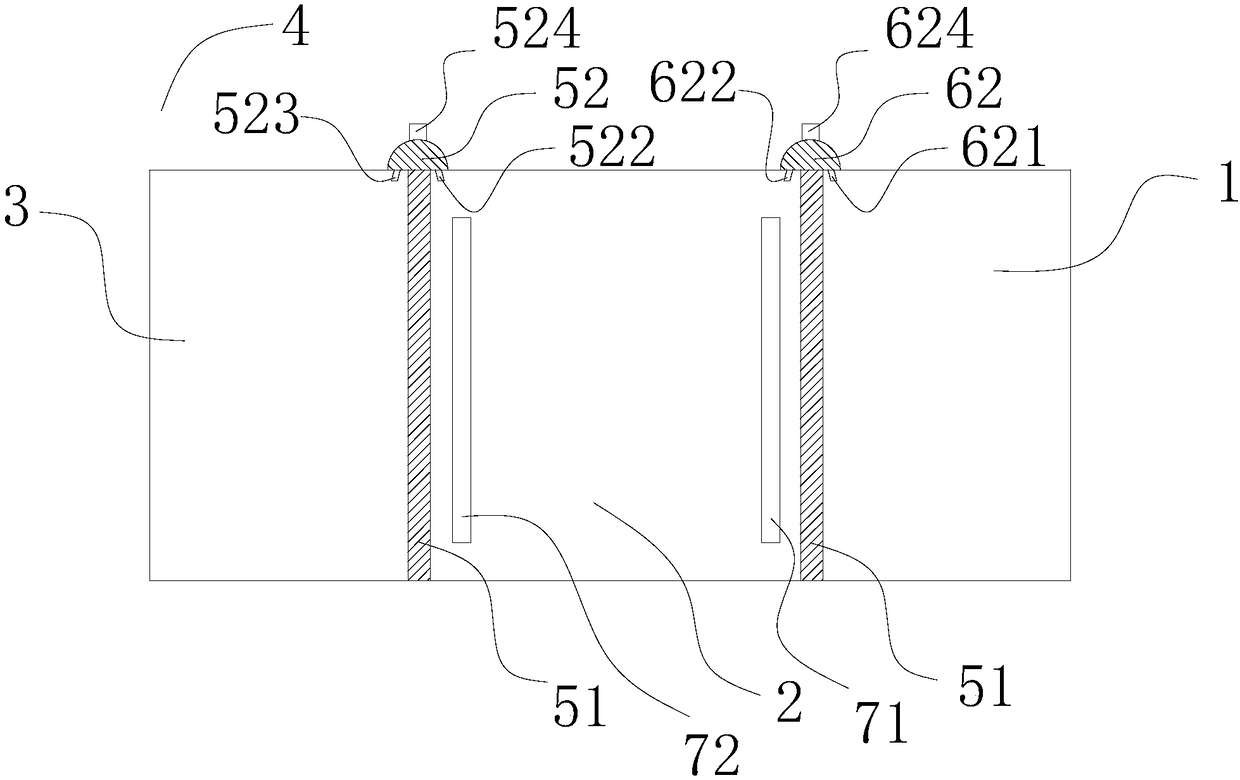

Tester of crude oil wax content

InactiveCN106546713AHigh control precisionImprove heat transfer coefficientMaterial testing goodsHeat flowEngineering

The invention relates to a tester of crude oil wax content. The tester comprises an external barrel and an internal barrel, the internal barrel is filled with a cooling medium, a ring groove gap formed between the internal barrel and the external barrel is used for storing a crude oil sample, an internal wall and an external wall of the external barrel are mutually separated for forming a channel, and an external barrel is also provided with a liquid inlet and a liquid outlet; wherein, the channel comprises several tortuous segments, a hot-fluid medium continuously enters from the liquid inlet into the channel and is discharged from the liquid outlet, and the crude oil sample in the ring groove gap is heated in the mode. Compared with the prior art, multiple tortuous segments change the flow direction of the hot-fluid medium in the channel, so that the hot-fluid medium accompanies with generation of small whirlpools, a heat transfer coefficient of the external barrel wall surface is improved, and control precision of the temperature of the crude oil sample is guaranteed. In addition, rotation speed of the internal barrel is continuously increased, different flow fields are produced in the ring groove gap, so that turbulent flow state of the crude oil sample is realized, staffs can carry out research of wax sedimentation in the state, and key parameters corresponding to the practical situation are obtained.

Owner:YASHENTECH CORP

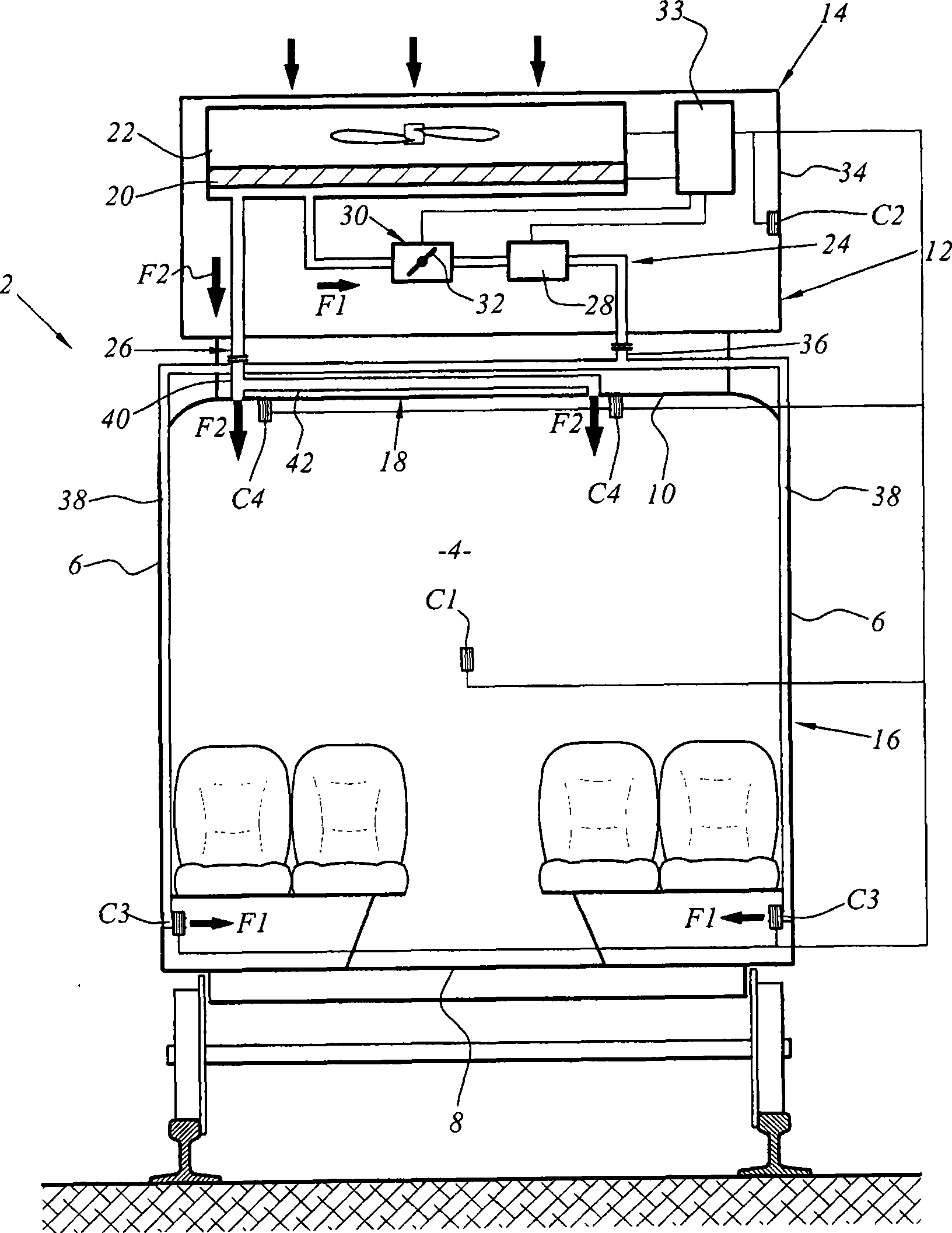

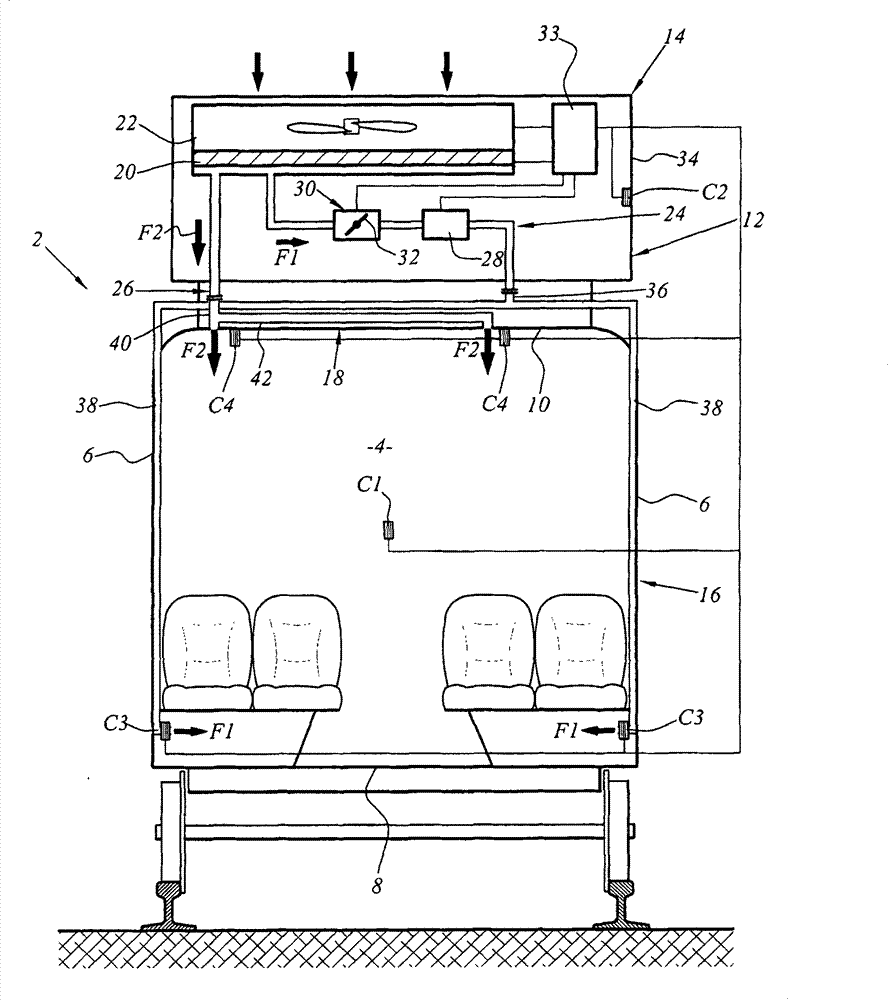

Air conditioning system for a compartment of a rail vehicle, corresponding rail vehicle and air conditioning method thereof

InactiveCN101428624ASatisfactory temperature gradientGuaranteed temperature gradientAir-treating devicesRailway heating/coolingAir treatmentAir conditioning

The invention discloses an air conditioning system of a rail vehicle carriage, a corresponding rail vehicle carriage and an air conditioning method. The air conditioning system comprises air processing devices (20, 28) for heating and / or cooling air; a first net (16) for delivering air to the carriage bottom, and a second net (18) for delivering air to the carriage bottom. According to one aspectof the invention, the air processing devices (20, 28) are arranged to deliver a first air flow (F1) and a second flow (F2) with different temperatures through the first net (16) and the second net (18).

Owner:ALSTOM TRANSPORT TECH SAS

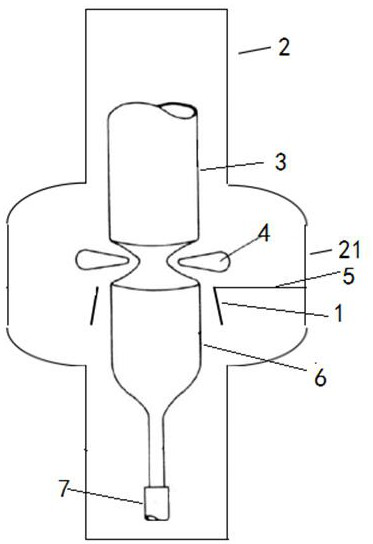

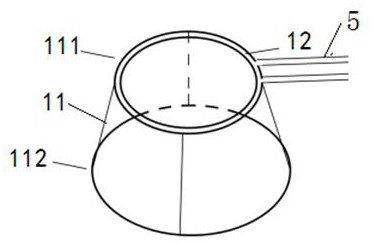

Movable self-positioning rapid cooling mechanical switch for direct-cooling magnet and cooling method

PendingCN111564275AImprove cooling speedImprove cooling efficiencySuperconducting magnets/coilsPhysicsCooling speed

The invention relates to a movable self-positioning rapid cooling mechanical switch for a direct-cooling magnet and a cooling method. The movable self-positioning rapid cooling mechanical switch comprises a Dewar, a mechanical switch and a magnet, a top plate is arranged in the upper portion of the Dewar, the top plate is provided with a hoisting structure, an evacuation connector and an air cylinder. The air cylinder is connected with and disconnected from a movably connected cold conduction device arranged in the Dewar through a corrugated pipe; the movably connected cold conduction device is composed of a conical head and a conical bowl which are of a self-positioning structure, the conical bowl is kept still, the conical head is connected with the air cylinder, the air cylinder ascendsand descends, connection and disconnection of the conical head and the conical bowl are achieved, and therefore the cooling control requirement is met flexibly. The cooling method comprises mountinga magnet; loading a magnet, and evacuating the Dewar; performing vacuum leak detection, turning on a refrigerator, turning on the self-positioning mechanical switch, and turning off the self-positioning mechanical switch after an expected temperature is reached. The movable self-positioning mechanical switch solves the problem that the cooling speed of the magnet is low in the early cooling process; the magnet cooling device is simple in structure, practical, reliable and convenient to operate.

Owner:西部超导材料科技股份有限公司

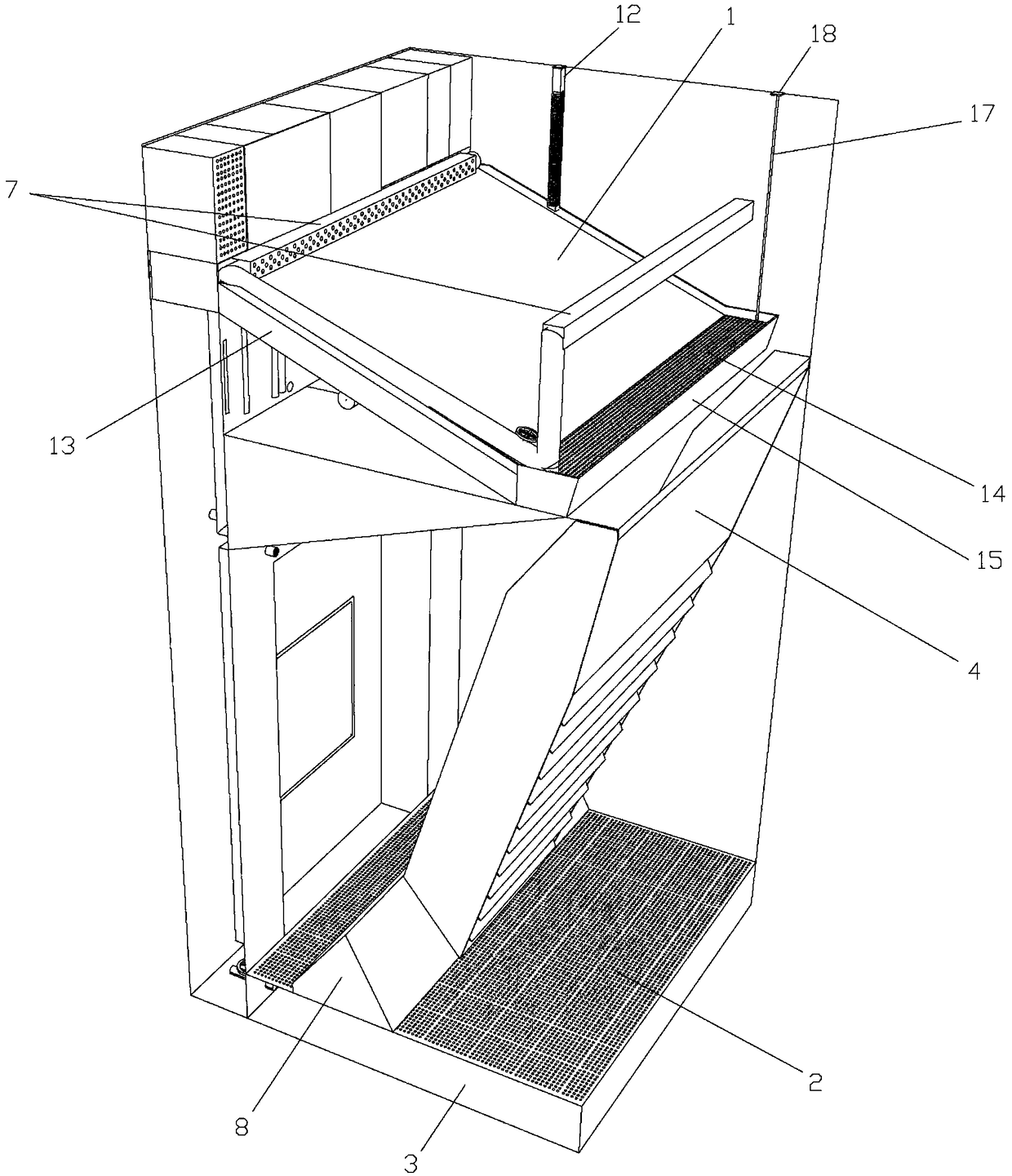

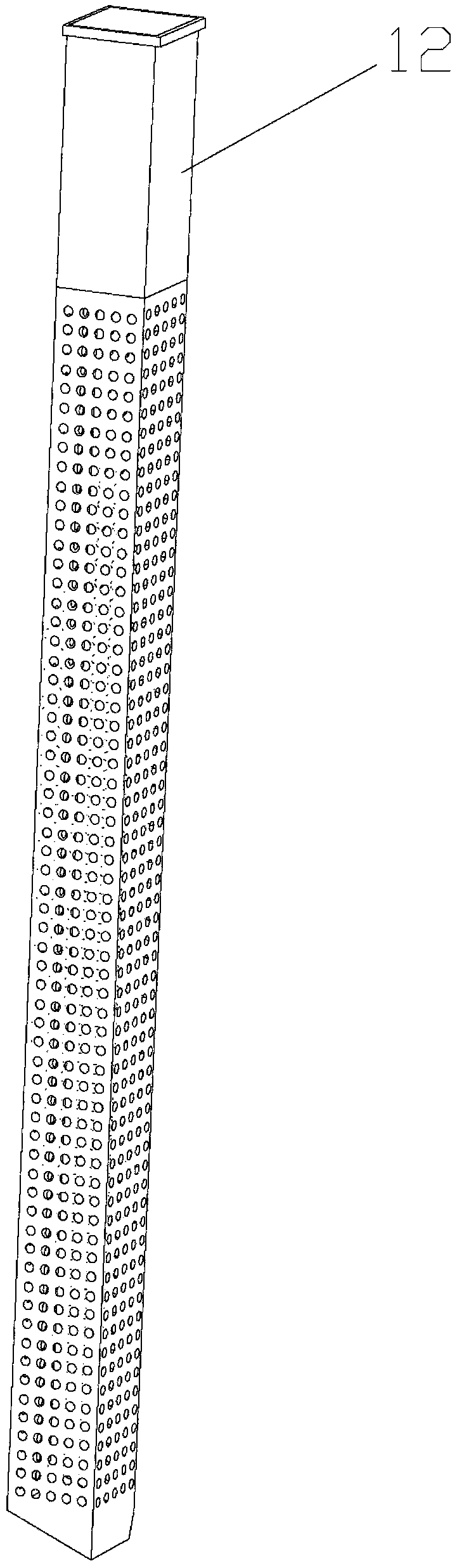

Biological combined treatment device for kitchen food wastes

PendingCN108947150AReduce oil and saltReduce the content of irritating substancesFatty/oily/floating substances removal devicesWater aerationSaline waterEngineering

The invention discloses a biological combined treatment device for kitchen food wastes. The biological combined treatment device comprises an airtight box, a first guide platform, a filtering platform, a second guide platform, a bottom platform, a residual liquid box, a worm egg feeding channel, a filtering cabin, a gas recovery cabin and a saline water cabin, wherein the first guide platform is arranged as a height gradient type platform; a feeding port and the worm egg feeding channel are arranged on the box; the filtering platform is jointed with the lower end of the first guide platform and the higher end of the second guide platform; the bottom platform is located under the box; the residual liquid box is located under the bottom platform; a through hole on the bottom platform is connected with the residual liquid box; the filtering cabin, the gas recovery cabin and the saline water cabin are placed on the rear side of the first guide platform; gases generated by all the cabins are pumped into the gas recovery cabin for recycling; the saline water cabin is used for concentrating and storing saline water. In the biological combined treatment device for kitchen food wastes, a stereoscopic coexistence space is formed in the airtight box, black soldier flies live on the upper layer and earthworms live on the lower layer, wherein black soldier flies, earthworms and bacteria cooperate with each other for ecologically efficient treatment of the kitchen food wastes.

Owner:胡小军

Device and method for testing soil deformation and moisture migration characteristics under temperature gradient

ActiveCN103344748BAvoid disturbanceAvoid hysteresisEarth material testingWater bathsTemperature control

The invention discloses a device and method for testing deformation and water transfer characteristics of a soil body under a temperature gradient effect. The device comprises a sample chamber, a temperature gradient control device and a temperature and water content collecting device, wherein the sample chamber comprises an dual-layer hollow organic glass interlayer sleeve and a cover plate; a high-temperature control device and a low-temperature control device are arranged at the upper end and the lower end of the temperature gradient control device respectively, and the temperature gradient control device comprises a constant-temperature water bath, a heating chamber inside the sample chamber, heat transfer plates at two ends of a sample, and a full-closed circulating pipeline. The device for testing the water and temperature of the soil body can be used for testing the water content and the temperature of the soil body synchronously in real time. The device provided by the invention is convenient, simple and light in design, convenient to operate, good in integration performance, and high in testing precision.

Owner:SHANGHAI UNIV

A device with controllable temperature gradient in forming area of laser additive manufacturing and its realization method

ActiveCN111375766BReduce residual stressGuaranteed temperatureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringSuperalloy

The invention discloses a device with controllable temperature gradient in the forming area of laser additive manufacturing, which includes a platform, a support and fastening base, a stepping motor fixed to the bottom of the support and fastening base, and arranged on one side of the supporting and fastening base The first groove of the first groove, the rotating rod coaxially connected with the stepper motor at one end, the well-type resistance heating mechanism installed in the first groove, the superalloy that is set in the well-type resistance heating mechanism and driven up and down by the rotating rod A mold, a thermocouple temperature measuring mechanism, a substrate, a laser cladding head located above the substrate, a forming area, a motion control system, a heating control system, and a temperature control feedback system, wherein the superalloy mold matches the shape of the first groove. The invention also provides a realization method of the device with controllable temperature gradient in the laser additive manufacturing forming area. The invention can heat and control the temperature of the substrate, ensure the temperature gradient of the forming area, reduce the risk of thermal stress cracking and the overall residual stress of the formed part in the process of forming and repairing.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Aluminum alloy material, aluminum alloy hollow pipe and preparation method of aluminum alloy hollow pipe

PendingCN114277290AReduce traditional extrusionReduce stabilityFoundry mouldsFoundry coresMachiningHeating system

The invention belongs to the technical field of aluminum alloy pipe machining, and discloses an aluminum alloy material, an aluminum alloy hollow pipe and a preparation method of the aluminum alloy hollow pipe. The aluminum alloy material comprises the following components: 2.0 to 2.5 percent of Mg, 0.1 to 0.5 percent of Mn, 0.01 to 0.05 percent of Ti, 0.15 to 0.25 percent of Si, less than or equal to 0.2 percent of Fe and the balance of Al. The aluminum alloy hollow pipe is prepared in a continuous casting mode, traditional extrusion and stabilizing annealing steps are reduced, the mechanical property of the prepared pipe meets the use requirement, and the productivity is improved; and the heating system and the casting system adopt forced heating and forced cooling systems, so that the temperature gradient of a solid-liquid surface is ensured, the degree of supercooling is ensured, alloy grains are refined, and compared with an aluminum alloy pipe prepared by a semi-continuous casting method, the mechanical property is improved by 10%-15%.

Owner:YANTAI NANSHAN UNIV

A bottom insulation structure of sapphire single crystal furnace

ActiveCN103205804BIncrease temperatureLow thermal conductivityPolycrystalline material growthUsing seed in meltFiberBrick

Owner:HARBIN AURORA OPTOELECTRONICS TECH

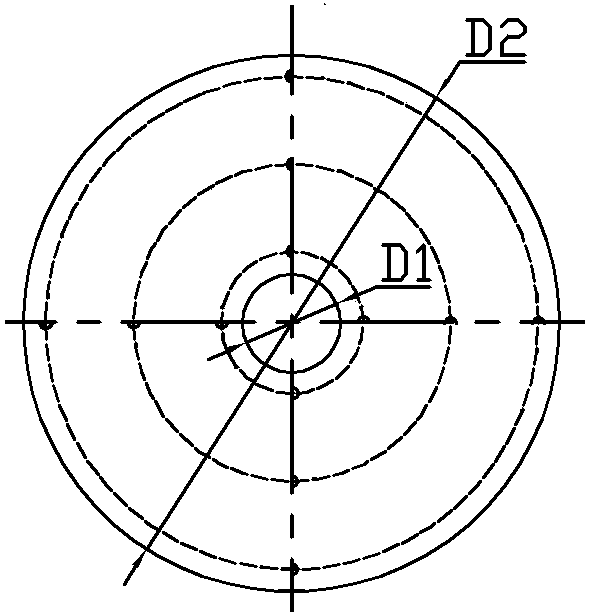

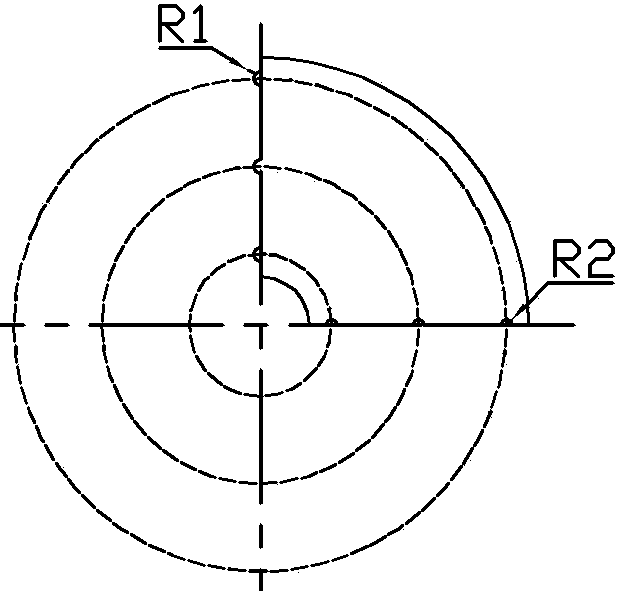

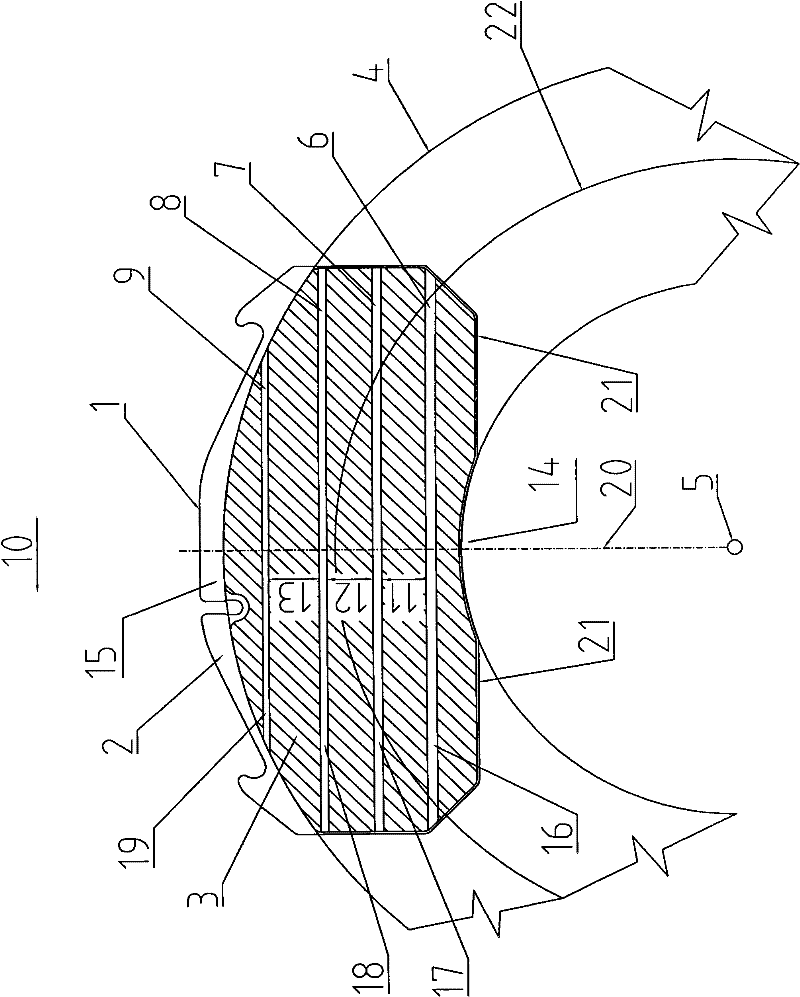

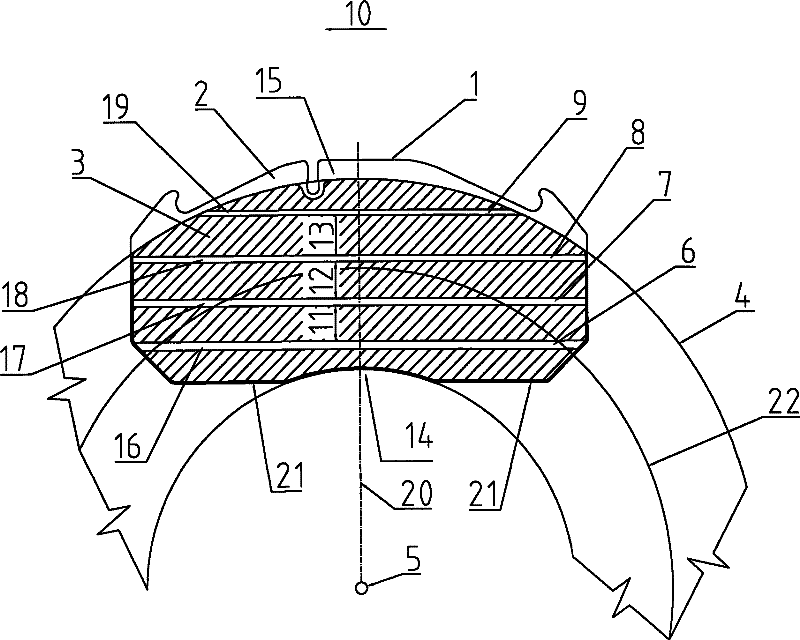

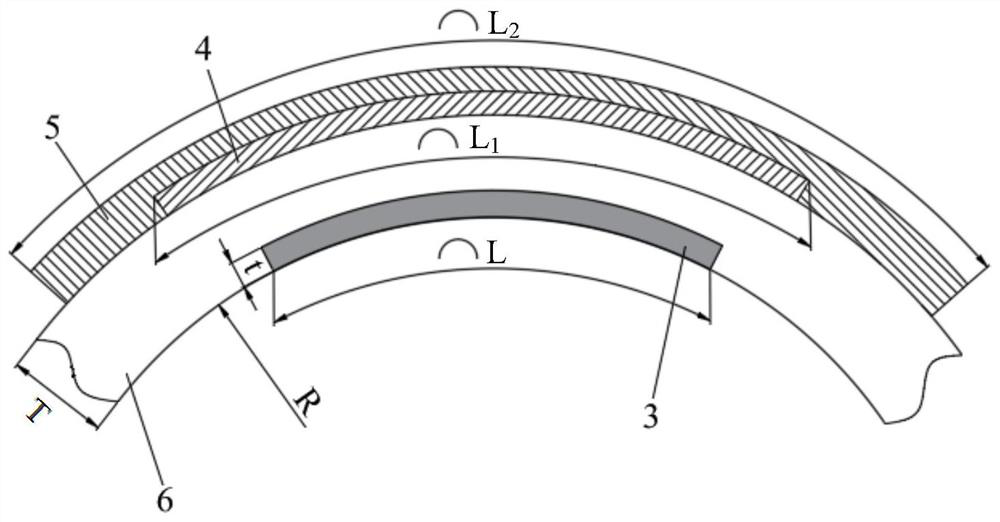

Brake lining for disc brakes

ActiveCN101825147BReduce the probability of crackingReduce wear rateBraking elementsFriction liningEngineeringBrake lining

The lining (1) has a brake lining carrier (2) and friction lining (3) arranged on the brake lining carrier. The friction lining has four recesses (6, 7, 8, 9) that run in a longitudinal extension of the friction lining and parallel to each other. Spaces (11-13) formed between the adjacent recesses reduce from a radially inner lying side (14) of the friction lining to a radially outer lying side (15) of the friction lining in relation to a brake disk (4).

Owner:TMD FRICTION SERVICES

Method for drawing six-inch zone-melting silicon single crystal and used heat shield

PendingCN114574940ADissipate quicklyGuaranteed temperature gradientPolycrystalline material growthBy zone-melting liquidsPhysical chemistrySingle crystal

The invention relates to a method for drawing a six-inch zone-melting silicon single crystal and a heat shield used in the method. A heat shield is arranged at a position 40mm below a heating coil in a middle furnace chamber of the zone-melting single crystal furnace, the diameter of the upper edge of the heat shield is 90mm, the diameter of the lower edge of the heat shield is 215mm, the height of the heat shield is 40mm, and the pressure of cooling water in a condensation pipeline is 3.2 bar; when the procedures of shoulder expansion, shoulder rotation, equal diameter and ending are carried out, the silicon single crystal moves downwards along with the lower shaft and enters the heat shield area, heat reflected by the heat shield acts on the lower portion of the silicon single crystal, and the phenomenon that due to the fact that the temperature gradient is too large or too small, the silicon single crystal explodes or melts back, and crystal forming fails is avoided.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

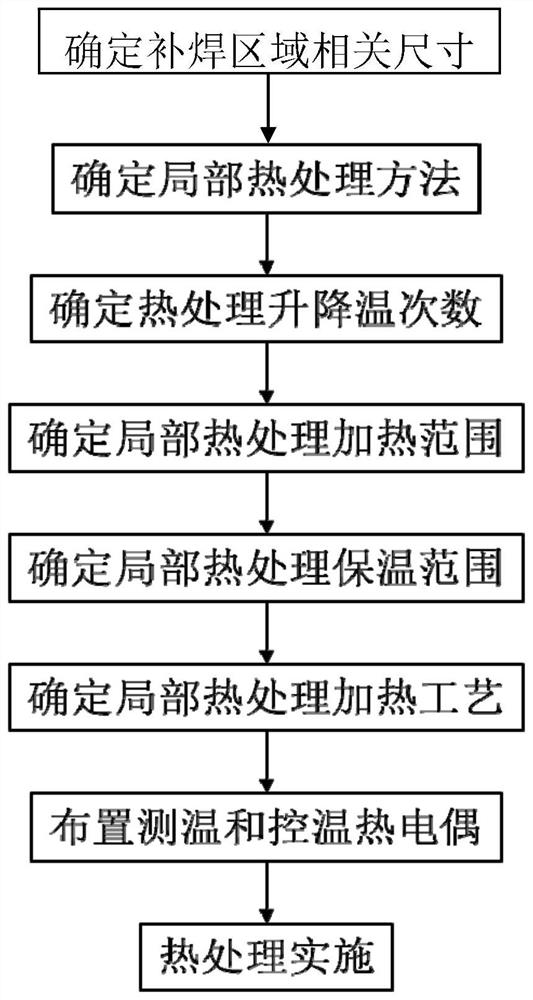

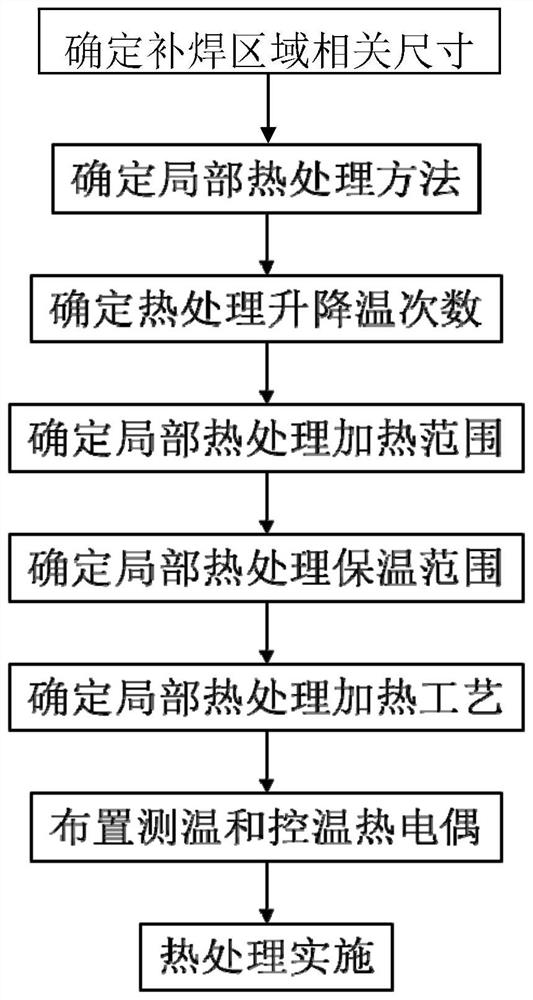

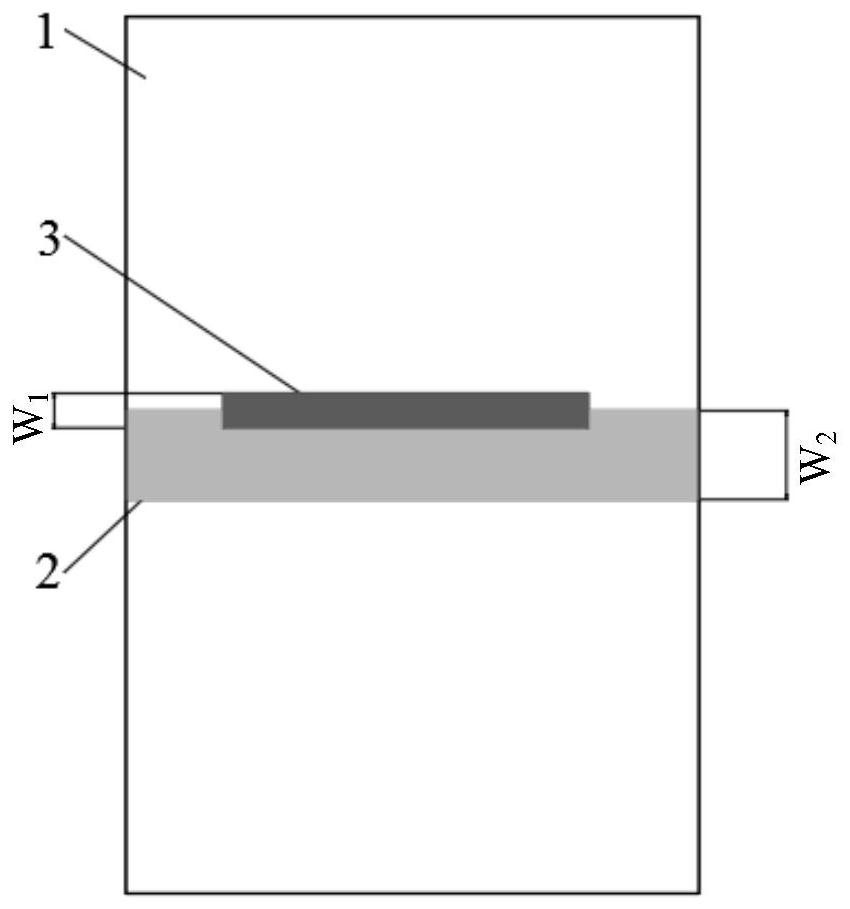

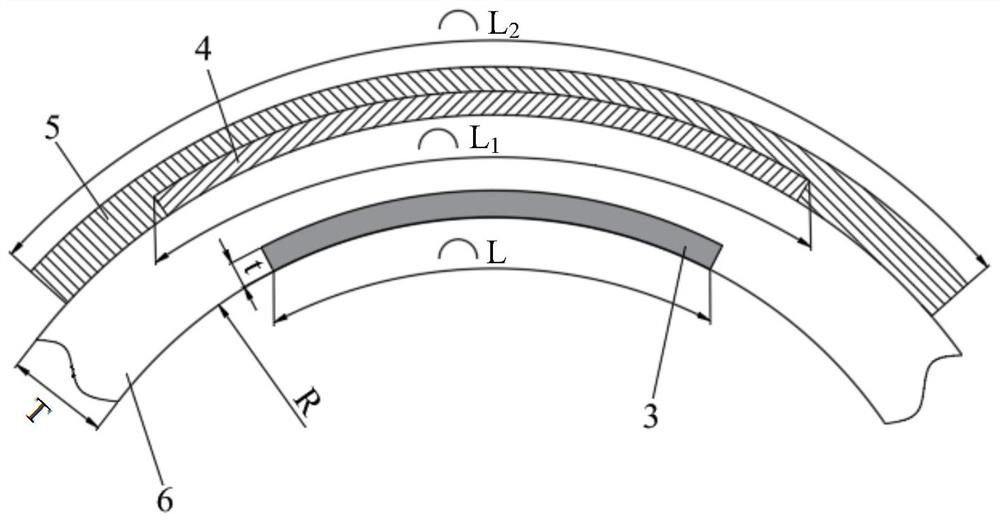

Local heat treatment method for inner wall of large quenched and tempered steel pressure vessel after repair welding

ActiveCN113201627AReduce residual stressEnsure consistencyIncreasing energy efficiencyFurnace typesTemperature controlEngineering

The invention discloses a local heat treatment method for the inner wall of a large quenched and tempered steel pressure vessel after repair welding. The local heat treatment method comprises the following steps: (1) determining relevant size parameters of a repair welding area of the quenched and tempered steel pressure vessel; (2) determining a local heat treatment heating mode; (3) determining local heat treatment heating and cooling times; (4) determining a local heat treatment heating range; (5) determining a local heat treatment heat preservation range; (6) determining a local heat treatment heating process including heat treatment heat preservation temperature and heat preservation time; (7) arranging a temperature measurement thermocouple and a temperature control thermocouple; and (8) performing heat treatment, and recording a heat treatment temperature curve. According to the local heat treatment method for the inner wall of the large quenched and tempered steel pressure vessel after repair welding, strict standard operation is provided for postweld heat treatment, and the residual stress of the repair welding area can be effectively reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

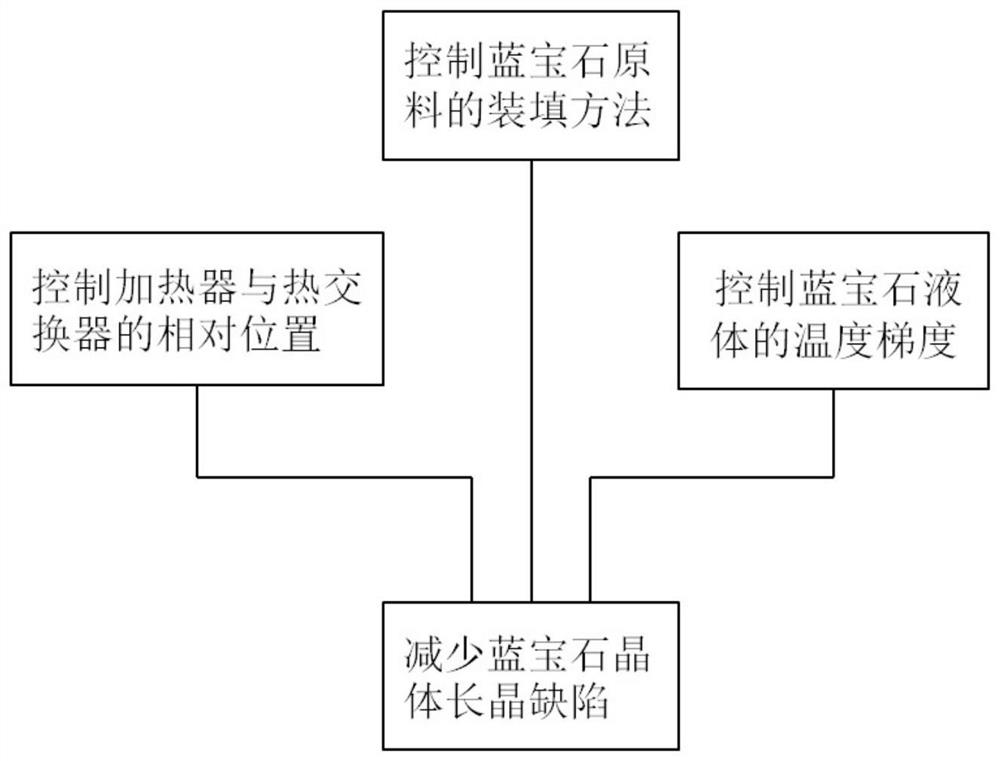

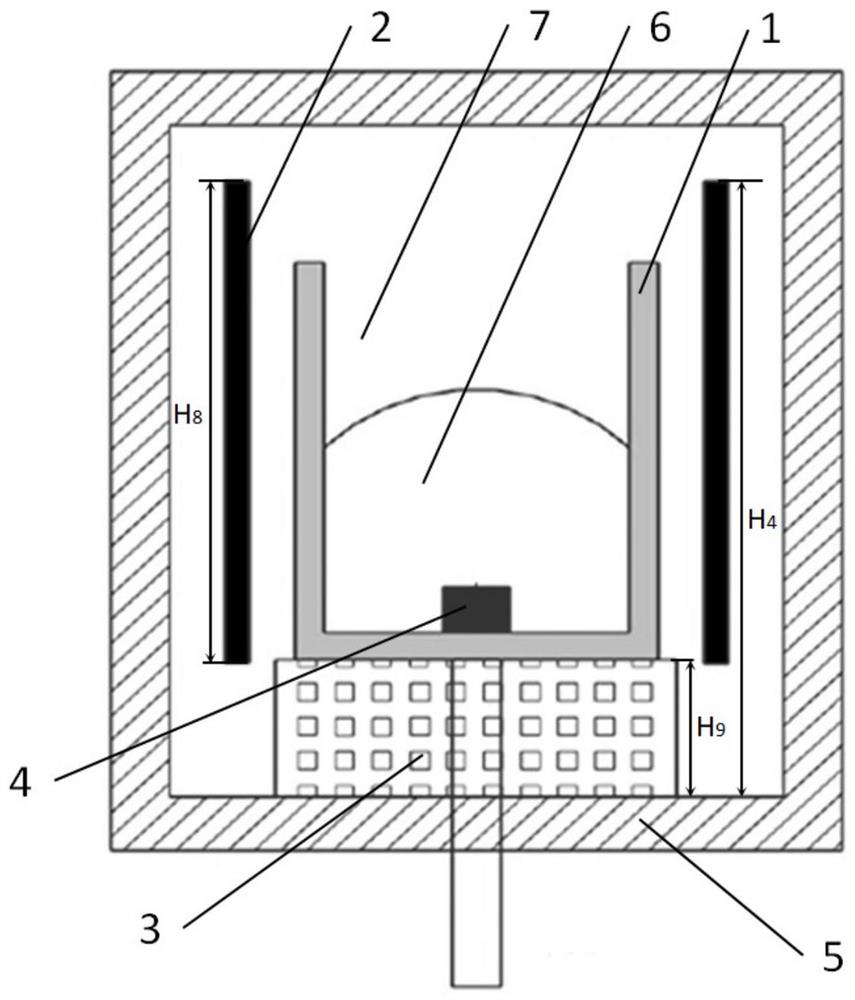

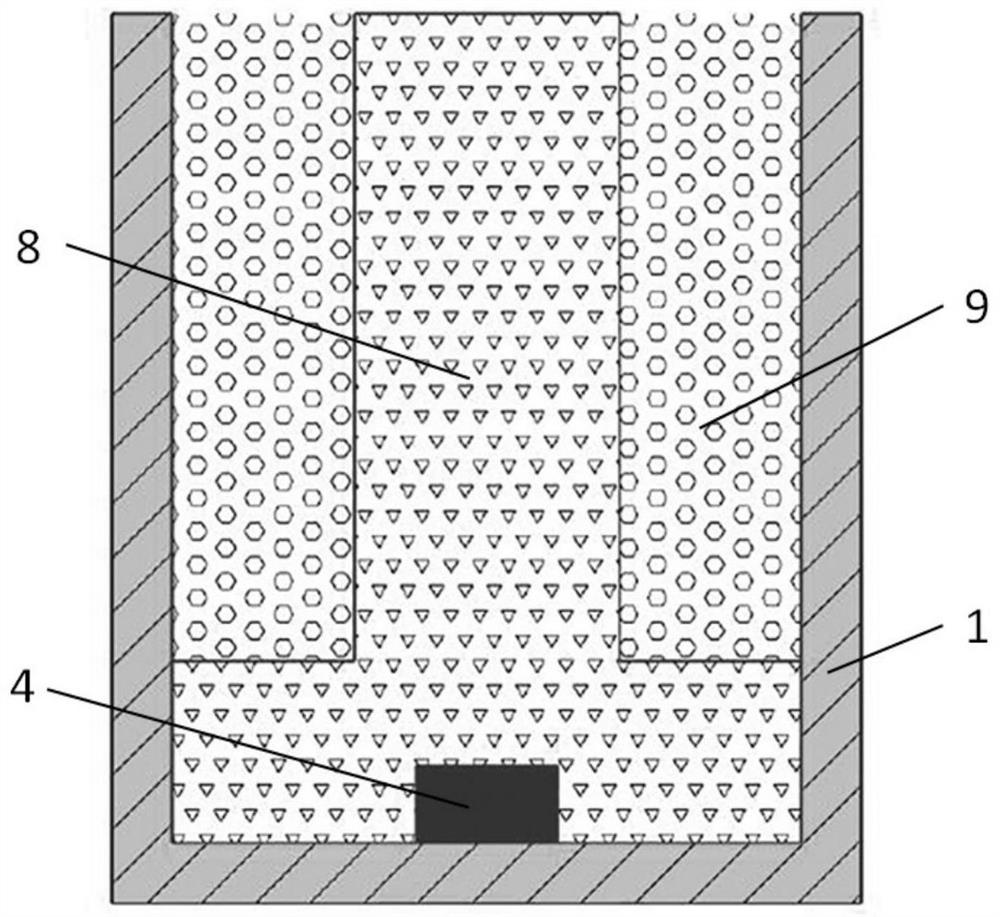

Method for reducing sapphire crystal growth defects and sapphire crystal growth furnace

ActiveCN114318494AReduce crystal growth defectsReduce floatingPolycrystalline material growthFrom frozen solutionsCruciblePhysical chemistry

The invention relates to sapphire crystal manufacturing, and discloses a method for reducing crystal growth defects of sapphire crystals, which comprises the following steps of: 1) controlling the relative positions of a heat exchanger arranged at the bottom of a crucible and a heater arranged at the periphery of the crucible, so that the height of the bottom end of the heater is lower than the height of the top of the heat exchanger; (2) controlling the filling method of the sapphire raw material in the crucible, filling the recycled raw material at the bottom of the crucible, filling the initial raw material at the periphery of other parts, and filling the recycled raw material in the middle; and (3) controlling the temperature of the sapphire liquid at different parts in the crucible in the heating process, and increasing the temperature gradient of the sapphire liquid at the bottom of the crucible and around the crucible. And the probability of bubble and hole defects in the produced sapphire crystal is lower. The invention also discloses a sapphire growth furnace.

Owner:江苏吉星新材料有限公司 +1

Local heat treatment method after repair welding of inner wall of large quenched and tempered steel pressure vessel

ActiveCN113201627BReduce residual stressEnsure consistencyIncreasing energy efficiencyFurnace typesTemperature curveEngineering

The invention discloses a local heat treatment method after repair welding of the inner wall of a large-scale quenched and tempered steel pressure vessel, which comprises the following steps: (1) determining the relevant size parameters of the repair welding area of the quenched and tempered steel vessel; (2) determining the heating mode of the local heat treatment; (3) ) Determine the heating and cooling times of local heat treatment; (4) Determine the heating range of local heat treatment; (5) Determine the heat preservation range of local heat treatment; (6) Determine the heating process of local heat treatment: including heat treatment temperature and heat preservation time; (7) Arrange temperature measurement and temperature control thermocouple; (8) heat treatment is implemented, and the heat treatment temperature curve is recorded. The invention provides a local heat treatment method after repair welding of the inner wall of a large-scale quenched and tempered steel pressure vessel, which provides strict standard operation for the post-weld heat treatment and can effectively reduce the residual stress in the repair welding area.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of growth method of low stress crystal

ActiveCN112746312BReduce stressStable growthPolycrystalline material growthBy pulling from meltCzochralski methodCondensed matter physics

A method for growing low-stress crystals, relating to the field of crystal preparation, in particular to a method for preparing low-stress, low-defect crystals using the pulling method, which is realized by means of a pulling method crystal growth device with a movable crystal heating mantle, and the crystal growth device The realization includes a furnace body, a crucible at the bottom of the furnace body and a heating and heat preservation system, a crystal pulling mechanism, a quartz observation window, and the device also has a movable crystal heating cover, including a heating cover body and heating wires arranged around the heating cover body , Heating cover lifting mechanism. During crystal growth and after crystals are pulled out of the melt, they are covered with a removable crystal heating mantle. This method can reduce the temperature gradient inside the crystal during the crystal growth process and during the cooling process after the crystal is lifted, thereby reducing crystal stress, reducing defects, avoiding crystal cracking, and maintaining the temperature gradient in the melt to ensure the stability of the crystal growth process. , so as to ensure the crystal yield.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

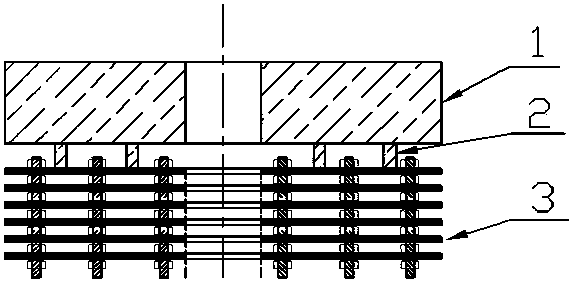

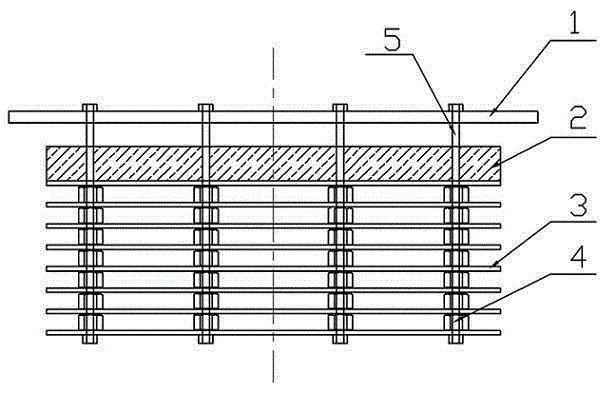

Lifting type heat conductivity coefficient testing instrument of constant-temperature water tank

The invention discloses a lifting type heat conductivity coefficient testing instrument of a constant-temperature water tank, and aims to adopt an automatic lifting device to facilitate taking and placing during a test, adopt a constant-temperature water tank to more conveniently control the temperature difference between a cold plate and a hot plate in the test process, and further ensure that heat flow is uniformly transferred in a test piece; the flow and the temperature of a water inlet and a water outlet of a core part of the cold plate are measured, so that the heat taken away by water is obtained, the one-dimensional steady-state power of the test piece is more accurate when the heat conductivity coefficient is calculated, the test result is more accurate, and the automation of an instrument is improved. For further making the measurement result better, an attractive visual interface is set by using LABVIEW. The testing instrument can accurately measure the heat conductivity coefficient of the test piece, and is simple and convenient to operate.

Owner:CHANGAN UNIV

Air conditioning system for a compartment of a rail vehicle, corresponding rail vehicle and air conditioning method thereof

InactiveCN101428624BSatisfactory temperature gradientGuaranteed temperature gradientAir-treating devicesRailway heating/coolingAir treatmentEngineering

Owner:ALSTOM TRANSPORT TECH SAS

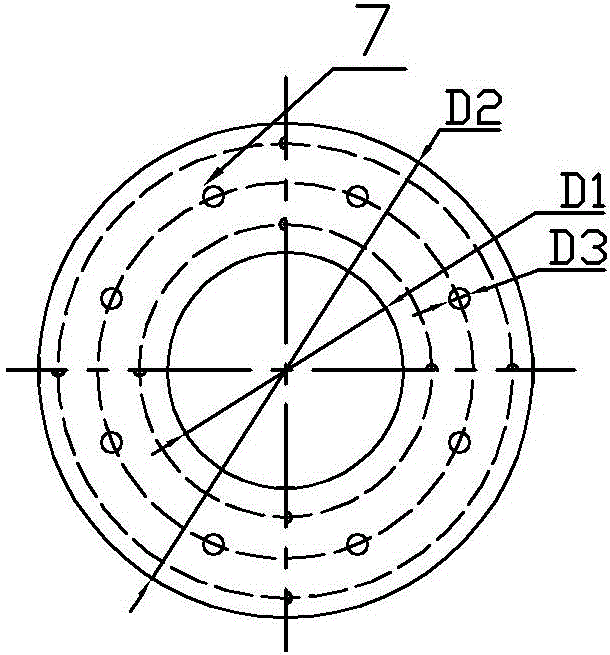

A thermal insulation structure for the upper part of a sapphire single crystal furnace

ActiveCN103233270BLow thermal conductivityGuaranteed temperaturePolycrystalline material growthBy pulling from meltFiberInsulation layer

The invention provides a thermal insulation structure for the upper part of a sapphire single crystal furnace. The structure consists of circular support structure, zirconia insulation layer and molybdenum heat shield from top to bottom. The fixed support structure is a single-layer circular stainless steel plate. The molybdenum heat shield is composed of multi-layer molybdenum sheets. The zirconia bricks made by sintering zirconia fibers are assembled. There are circular center holes and rectangular observation holes on the molybdenum sheet. Molybdenum bolts and molybdenum nuts are used between the circular support structure, zirconia insulation layer and molybdenum heat shield. The connection is fixed. The invention can reduce the heat loss of the upper part, enhance the heat preservation effect, establish a reasonable temperature gradient, and make the temperature field easier to adjust, thereby solving the problem of the molybdenum upper heat shield structure used in the traditional Kyropoulos single crystal furnace in the high temperature environment. The inner and upper parts dissipate heat quickly, the temperature field is not reasonable enough, and the temperature adjustment is difficult to control.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

A sapphire single crystal furnace insulation structure

ActiveCN103215635BHigh temperature resistantAntioxidantPolycrystalline material growthBy pulling from meltFiberThermal energy

The invention provides a heat insulation structure of a sapphire single crystal furnace. The heat insulation structure comprises a furnace cover lower zirconium oxide fiber brick heat insulation structure, an upper heat shield zirconium oxide fiber brick structure, a side heat shield zirconium oxide fiber brick structure and a lower heat shield zirconium oxide fiber brick structure. According to the heat insulation structure of the sapphire single crystal furnace, which is disclosed by the invention, the heat can be effectively utilized, the heat loss is reduced, the heat insulation effect is enforced, and the reasonable temperature gradient is established so that a temperature field is easier to be regulated, and the problems that the heat utilization rate is low, a utilized molybdenum heat shield structure is evaporated and deformed and is short in service life under the high temperature environment and the like in the traditional kyropoulos method single crystal furnace are solved.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

A concrete air curtain steam curing temperature control system

ActiveCN105906373BIsolated flowNot affected by temperatureCeramic shaping apparatusTemperature controlControl system

The invention relates to the technical field of building, and in particular, relates to a concrete air curtain steam-curing temperature-control system including a fan A and a fan B which produce air curtains; the fan A is arranged between a concrete heating steam-curing area and a constant-temperature steam-curing area; the temperature of the air curtain produced by the fan A is the same as that of the heating steam-curing area. The system also comprises a heating device A arranged in a constant-temperature area; a part of gas in the air curtain produced by the fan A enters the constant-temperature steam-curing area, and the heating device A is used for heating the part of gas; the fan B is arranged between a concrete cooling steam-curing area and the constant-temperature steam-curing area; the temperature of the air curtain produced by the fan B is the same as that of the cooling steam-curing area. The system further includes a heating device B arranged in the constant-temperature area; a part of gas in the air curtain produced by the fan B enters the constant-temperature steam-curing area, and the heating device B is used for heating the part of gas. The system also includes a humidity control device for ensuring the air curtain humidity; therefore, the temperature gradient and the humidity between the regions can be ensured, and the steam-curing quality is ensured.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD +1

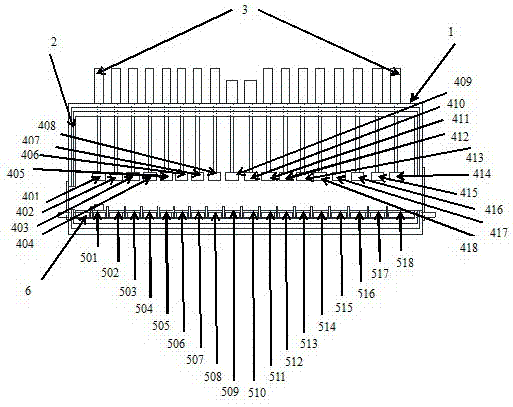

3D hot bending machine large-size multi-station furnace chamber structure

PendingCN107382039AReduce lossSave the beatGlass reforming apparatusGlass productionEngineeringSlow cooling

The invention discloses a 3D hot bending machine large-size multi-station furnace chamber structure. The large-size multi-station furnace chamber structure comprises a board housing, a heating structure, a press-down structure, and a transmission structure and the like, and contains 18 mold work stations which are preheating stations, moulding stations, slow cooling stations and cooling stations in order from left to right. Through different selection and design of heating plate materials and structures of each heating zone and each cooling zone, the rapid heating and cooling of the molds can be realized, and temperature gradient uniformity is guaranteed. The structure can effectively increase the production efficiency, glass sheet moulding quality, and yield rate.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com