A bottom insulation structure of sapphire single crystal furnace

A technology of sapphire single crystal furnace and insulation layer, which is applied in the direction of single crystal growth, single crystal growth, and seed crystal remaining in the molten liquid during growth, which can solve the problems of difficult control of temperature adjustment, unreasonable temperature field, and easy deformation. , to achieve the effect of avoiding too slow heat conduction, continuous temperature adjustment sensitivity, and high use temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

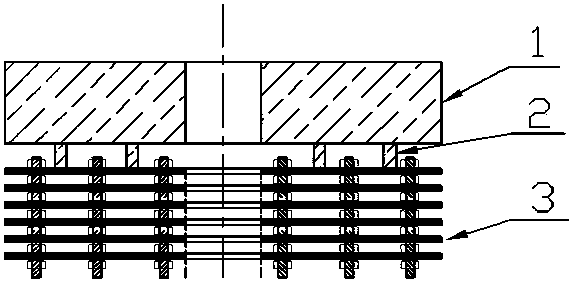

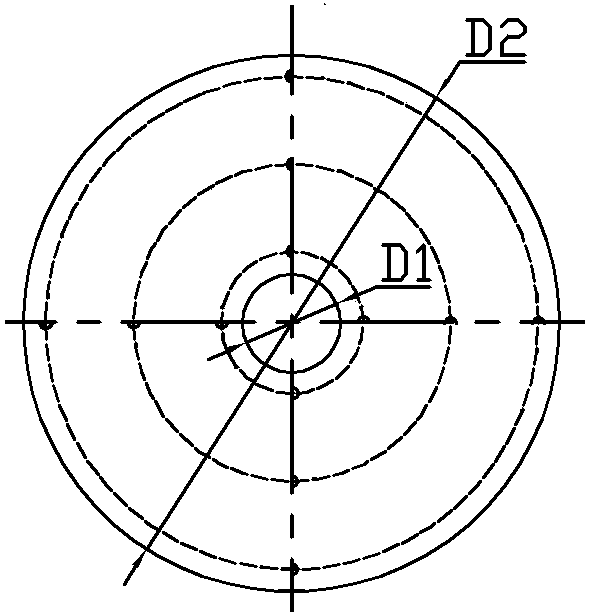

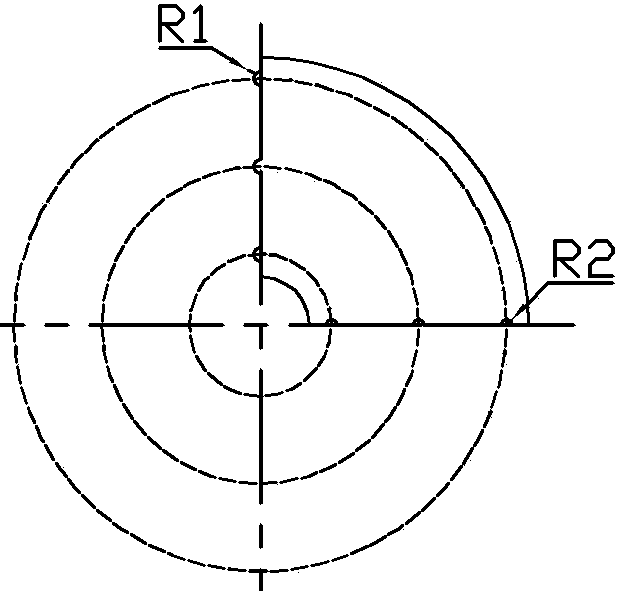

[0028] combine figure 1 , the example of this embodiment is the heat preservation structure at the bottom of the micro-pulling sapphire single crystal furnace with cold heart shouldering method. The structure mainly includes two parts. Composed of molybdenum heat shield. combine Figure 2-Figure 4 , The zirconia insulation layer is a hollow circular block with a height h1 of 10mm spliced by four zirconia fiber bricks with an outer diameter of D2=350mm and an inner diameter of D1=61mm. Between adjacent zirconia fiber bricks, three sets of matching semicircular positioning protrusions and positioning grooves with a radius of R1=5mm and R2=5.2mm are uniformly arranged in the radial direction. There are two zirconia ceramic rings 2 for separation between the zirconia insulation layer and the molybdenum heat shield. The structure of the ceramic rings is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com