Crystal growth device

A crystal growth and crystal technology, which is applied in the field of low-stress, low-defect crystal devices, can solve the problems of low crystal stability, low control precision, and no obvious improvement in stress and dislocation defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

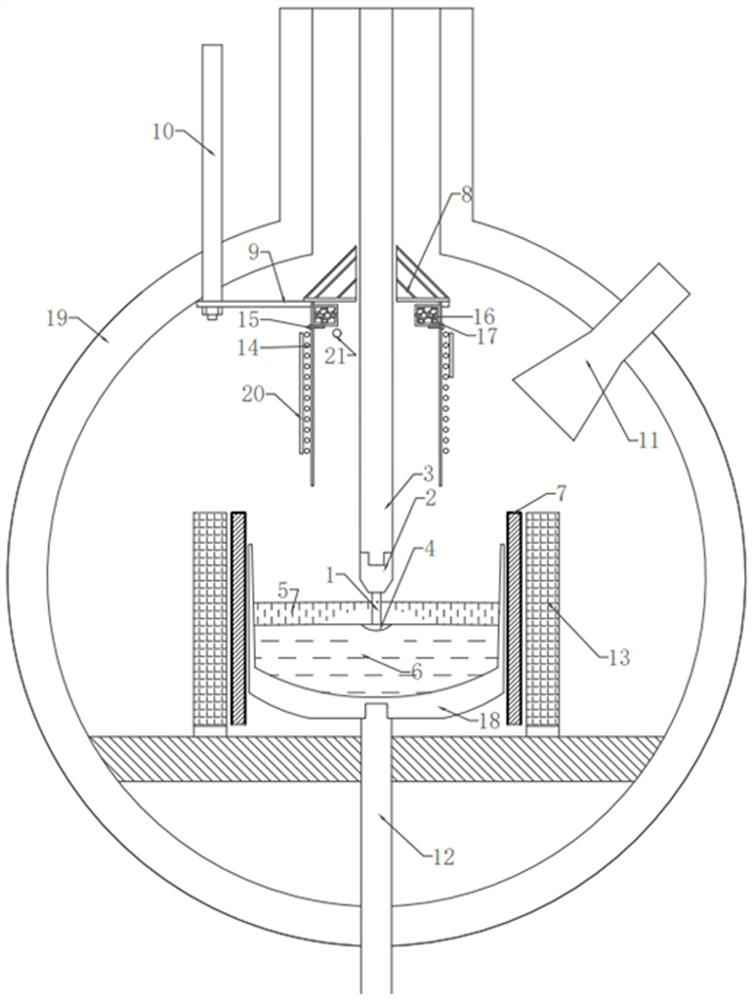

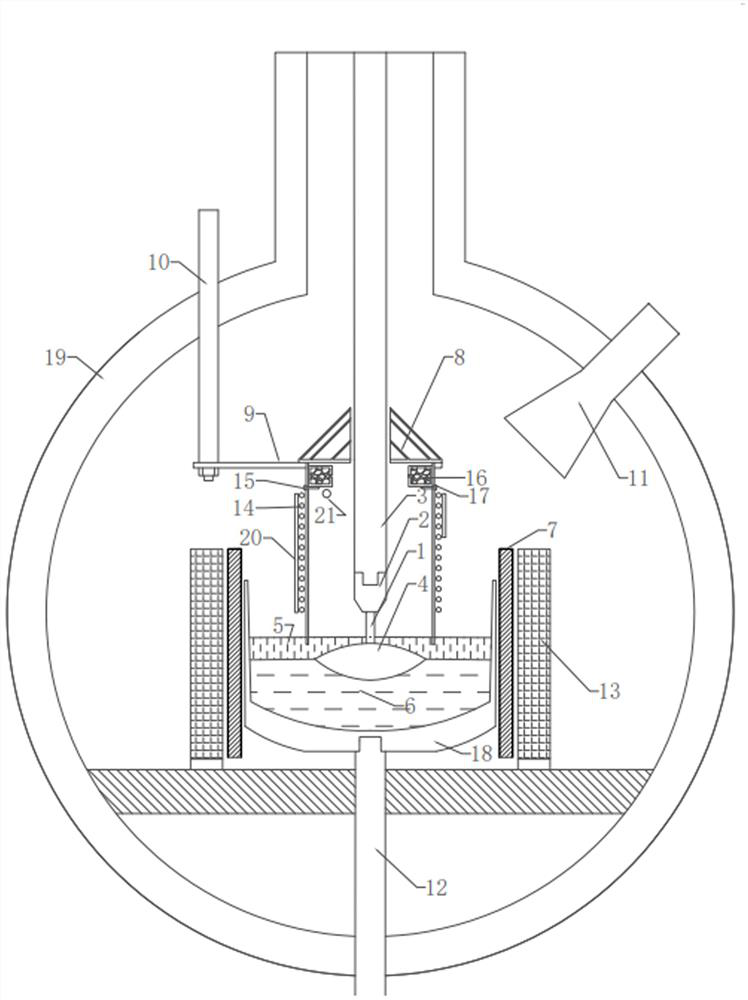

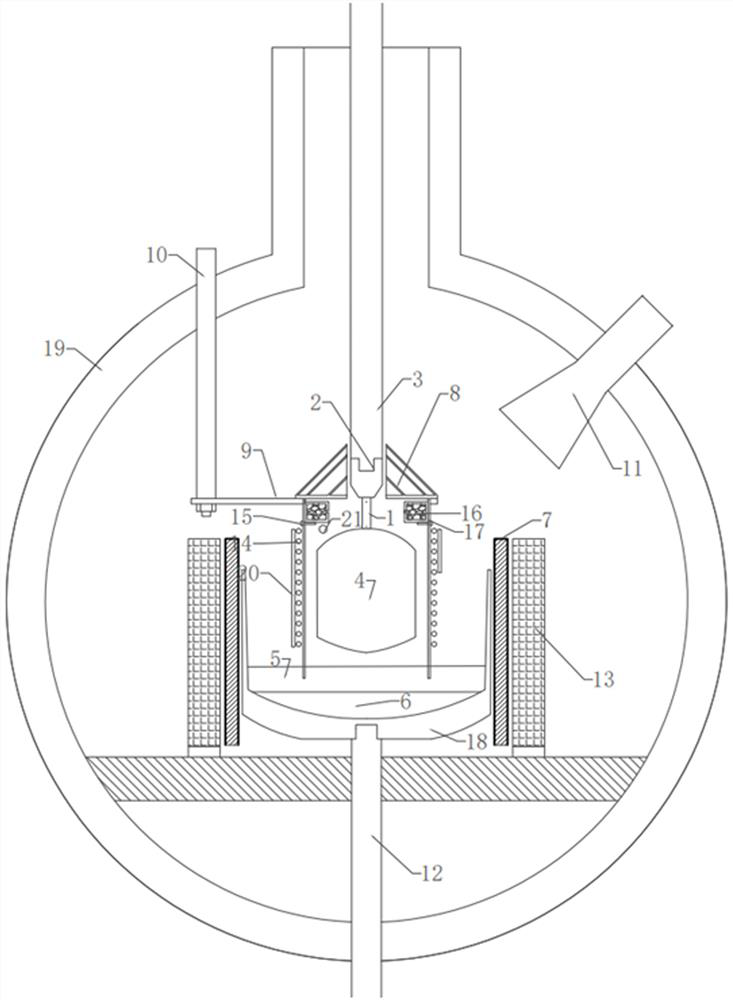

[0025] A crystal growth device, see figure 1 , including a furnace body 19, a crucible 18 placed at the bottom of the furnace body 19 and a heating and heat preservation system, a crystal pulling mechanism facing the center of the crucible, and a quartz observation window 11 placed on the side of the furnace body 19.

[0026] The heating and heat preservation system includes a heater 7 placed around the crucible 18, a crucible rod 12 supporting the crucible 18 below, and an insulation cover 13 outside the heater 7.

[0027] The crystal pulling mechanism includes a seed rod 3 and a seed chuck 2 .

[0028] The device also includes a liftable heating cover mechanism, including a heating cover body 8 , a heating cover support member 9 , heating wires 14 arranged around the heating cover body 8 , and a heating cover lifting mechanism 10 . The heating cover elevating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com