3D hot bending machine large-size multi-station furnace chamber structure

A hot bending machine, large-scale technology, applied in the direction of manufacturing tools, glass forming, glass re-forming, etc., can solve the problems of low production efficiency, small number of stations, poor thermal insulation effect, etc., and reduce the glass forming cycle. , The effect of reducing the operating power consumption of the equipment and reducing the heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

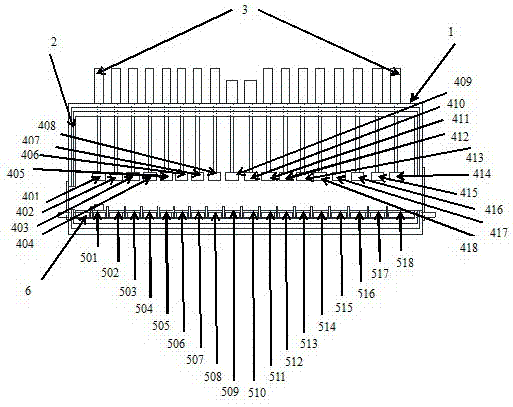

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. combine figure 1 , the outer side of the large-size multi-station furnace cavity structure in this embodiment is a box plate shell 1, the inner side of the box plate shell is overlapped with a multi-layer composite insulation board 2, and the pressing structure 3 is located on the top of the box plate, and the main shaft controlled by the cylinder passes through it. The box board is connected to the upper heating plate 401-418, the lower heating plate 501-518 is below, and the front side of the lower heating plate is the transfer structure 6, wherein the upper heating plate 401-403, 412-418, the lower heating plate 501-503, 512- 518 adopts stainless steel heating plates, and the upper heating plates 416-418 and the lower heating plates 516-518 are not equipped with heating pipes, and there are cooling water circulation channels inside.

[0017] The mold enters the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com