Laser additive manufacturing forming area temperature gradient controllable device and implementation method thereof

A laser additive and temperature gradient technology, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

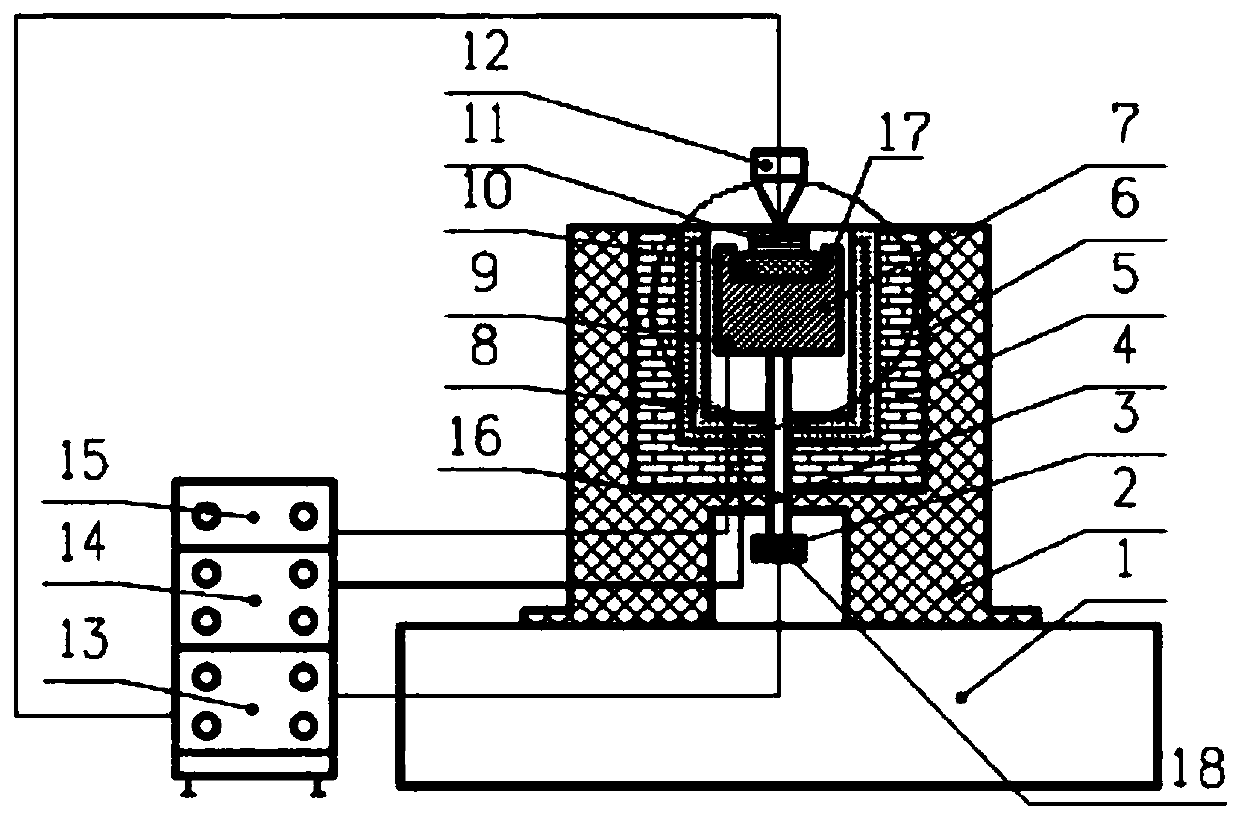

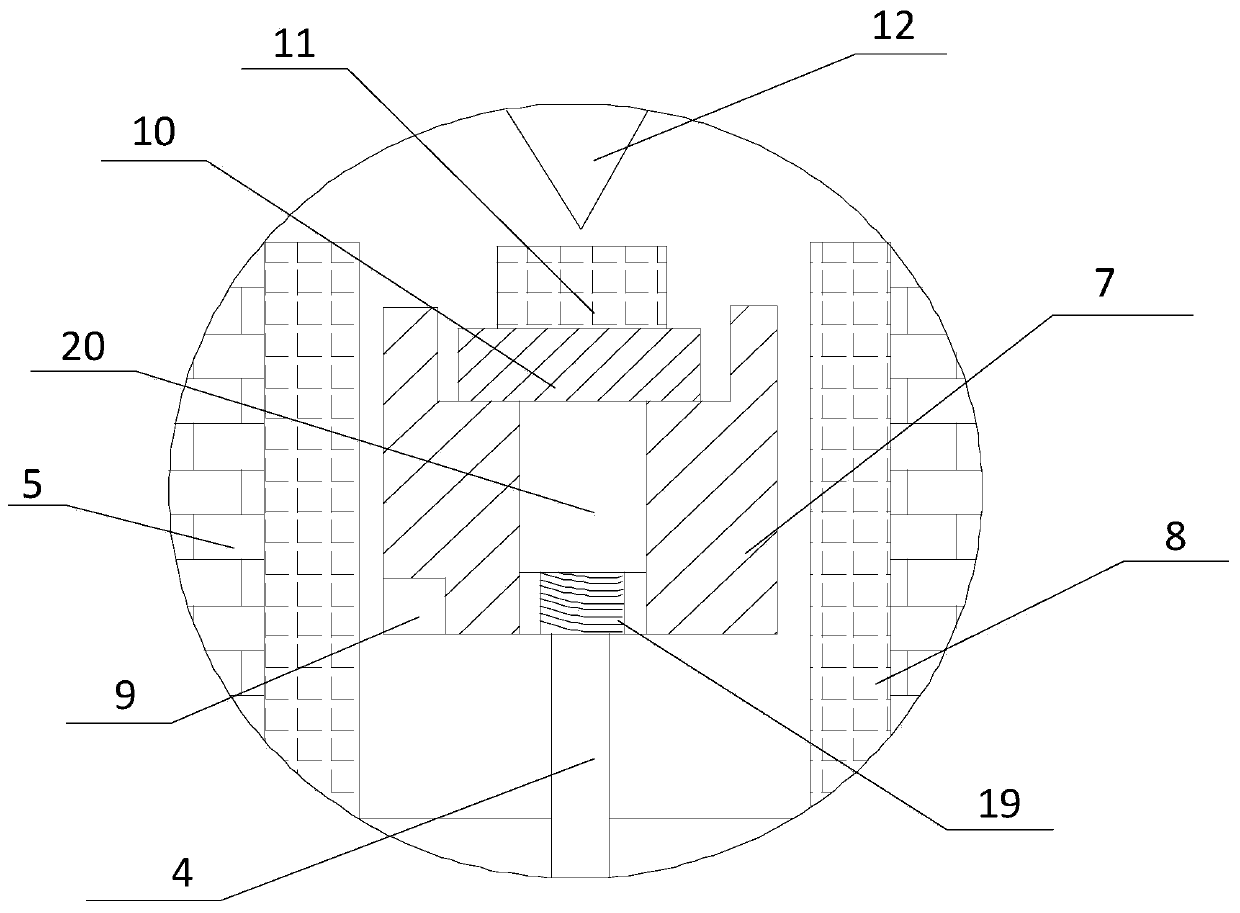

[0031] Such as Figure 1 to Figure 2As shown, the temperature gradient controllable device in the laser additive manufacturing forming area includes a platform 1, a support and fastening base 2, a stepping motor 3, a rotating rod 4, a well-type resistance heating mechanism 6, a superalloy mold 7, and a thermocouple Temperature measuring mechanism 9, substrate 10, forming area 11, laser cladding head 12, motion control system 13, heating control system 14, temperature control feedback system 15, first groove 16, second groove 17, action controller 18 , Nut 19 and rotating space 20 etc. Wherein, the platform 1 is used for processing; the supporting and fastening base 2 is fixed on the platform 1, and is used for installing and fixing the stepping motor 3; the stepping motor 3 is fixed on the bottom of the supporting and fastening base 2 and is supported by the platform 1, and its It is coaxially connected with the rotating rod 4; the action controller 18 is arranged on the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com