Method for controlling silicon single crystal growth temperature on basis of finite element numerical simulation

A technology of numerical simulation and growth temperature, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of inability to meet crystal temperature control, crystal dislocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

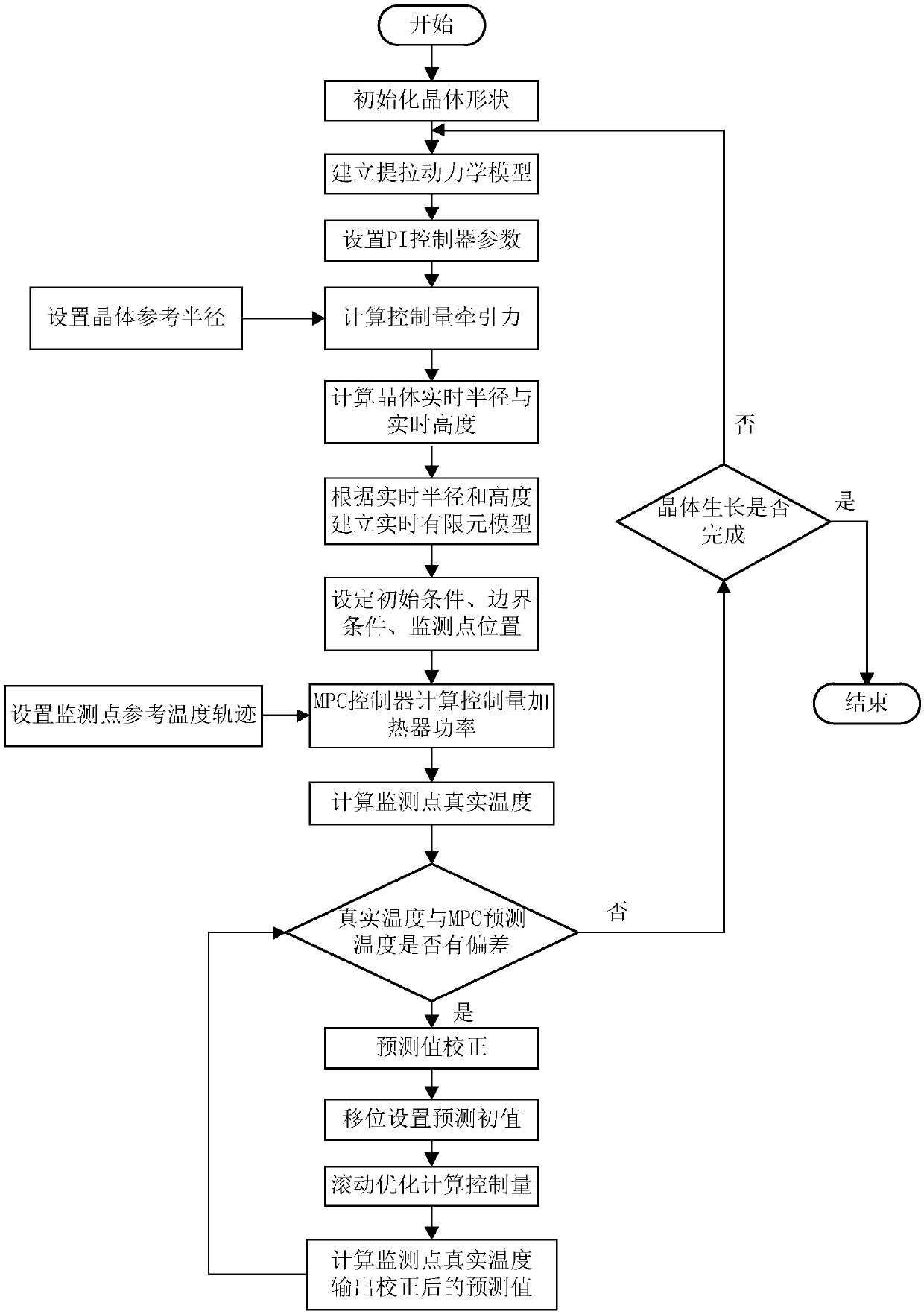

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

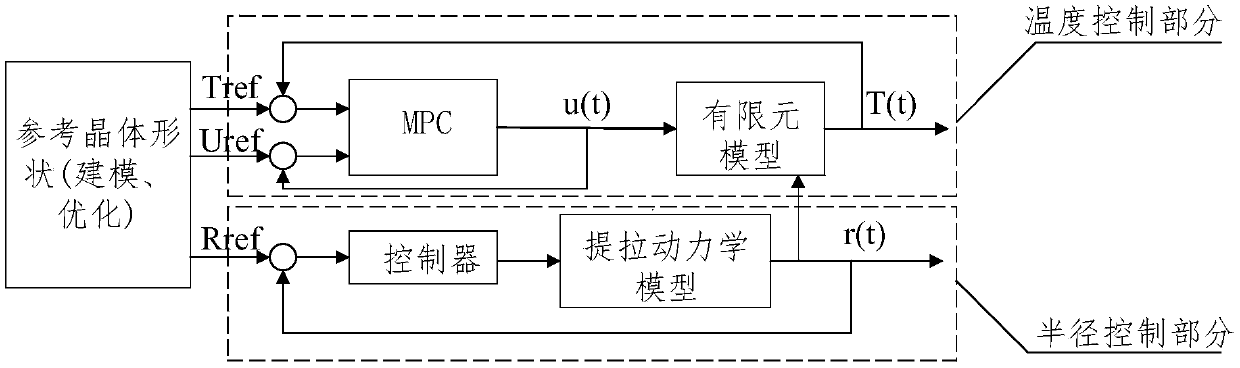

[0069] The present invention is a silicon single crystal growth temperature control method based on finite element numerical simulation. The crystal growth mainly includes four stages of shouldering, turning, equal diameter and finishing. The control block diagram is as follows figure 1 As shown, the specific steps are as follows:

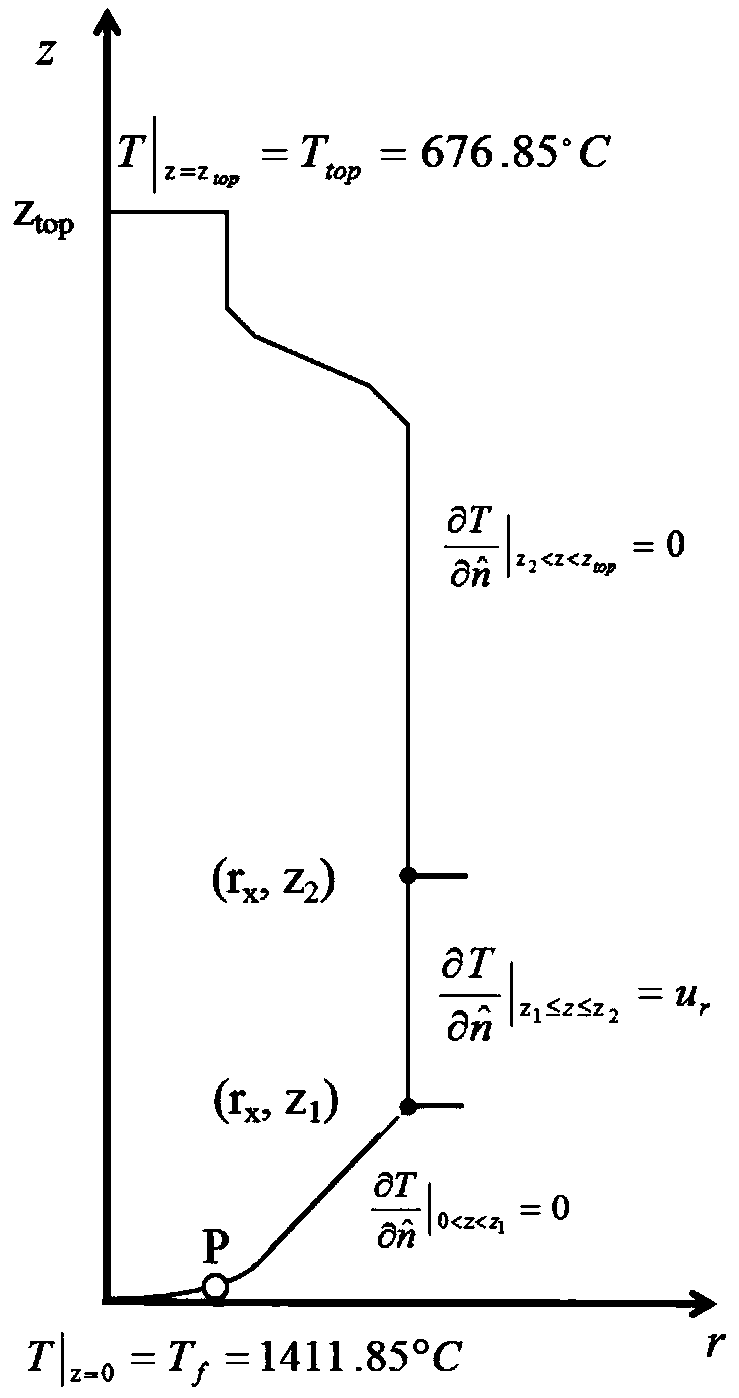

[0070] Step 1. Refer to the finite element modeling under the crystal shape, and set the reference shape and boundary conditions of the crystal in the whole process. Specifically, follow the steps below:

[0071] Step 1.1, the crystal heat conduction equation is as follows:

[0072]

[0073] In the formula Represents the spatial gradient in the cylindrical coordinate system, r represents the radius of the crystal, z represents the height of the crystal, T(r, z, t) represents the temperature at (r, z) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com