Device and method for preparing high-purity single crystal germanium by Czochralski method

A single crystal germanium and pulling method, which is applied in the direction of self-melt pulling method, single crystal growth, single crystal growth, etc., can solve the problems of pulling off the crystal rod from the liquid level, uncontrolled crystal pulling, dislocation, etc. Achieve the effect of avoiding crystal cracking, good crystallization performance, and speeding up the rate of chemical material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

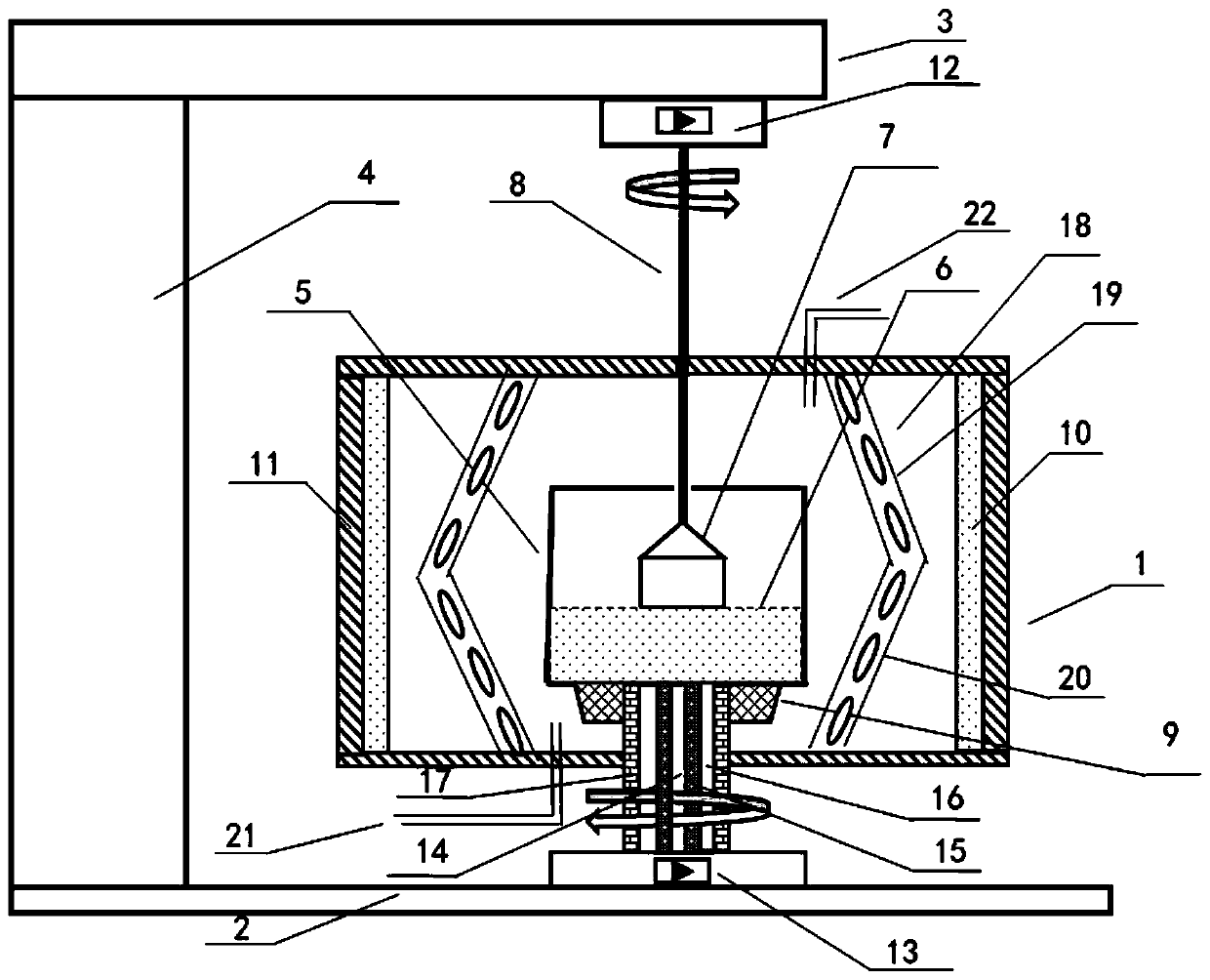

[0055] A method for preparing high-purity single-crystal germanium according to a specific embodiment of the present invention uses 7N high-purity germanium as a seed crystal and 5N germanium obtained by zone melting as a raw material, comprising the following steps:

[0056] S1: Vacuumize, first place 5N germanium raw material in the crucible 5, vacuumize the crucible 5 for 1-2 times, fill the nitrogen gas from the intake pipe 21 at 1-6L / min, the purity of the nitrogen gas introduced is greater than 5N, and the tail gas Collect and process at the air outlet pipe 22;

[0057] S2: In the chemical material stage, gradually increase the power heating of the heating device 18 high-frequency eddy current induction coil in the early stage, and at the same time turn on the auxiliary heating device 16 to heat the raw material to the first temperature, and keep the power at a stable power in the middle stage. After heating for 30-60 minutes, the later stage The chemical power is reduce...

Embodiment 1

[0066] use figure 1 The device, the angle between the upper heater 19 and the lower heater 20 is 120 °. Both the upper heater 19 and the lower heater 20 are composed of three heating coils connected in series, and the power of a single heating coil is 10-30KW.

[0067] The raw material used is 5N germanium after zone smelting, and the product impurity content, ppm, is as follows:

[0068] Impurities Mg Al Ca Fe co Ni Cu Zn In Pb content <0.05

<0.05

<0.1

<0.05

<0.02

<0.02

<0.01

<0.05

<0.01

<0.02

[0069] (1) Put 5 kg of 5N zone molten germanium raw material in the crucible 5, and place it in the single crystal pulling furnace 1; vacuumize the crucible 5 twice with vacuum equipment, and then fill it with nitrogen gas at 4 L / min to keep the low pressure condition;

[0070] (2) Chemical material stage: In the early stage, gradually increase the power heating of the high-frequency eddy current induction coil unt...

Embodiment 2

[0081] use figure 1 The device, the angle between the upper heater 19 and the lower heater 20 is 120 °. Both the upper heater 19 and the lower heater 20 are composed of three heating coils connected in series, and the power of a single heating coil is 10-30KW.

[0082] The raw material used is 5N germanium after zone smelting, and the product impurity content, ppm, is as follows:

[0083] Impurities Mg Al Ca Fe co Ni Cu Zn In Pb content <0.03

<0.05

<0.1

<0.03

<0.02

<0.02

<0.02

<0.05

<0.01

<0.02

[0084] (1) Put 5kg of 5N zone molten germanium raw material in the crucible 5, and place it in the single crystal pulling furnace 1; vacuumize the crucible 5 twice with vacuum equipment, and then fill it with nitrogen at 5L / min to keep the low pressure condition;

[0085] (2) Chemical material stage: In the early stage, gradually increase the power heating of the high-frequency eddy current induction coil until it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com