Preparation method of silicon carbide single crystal, single crystal growth furnace and heating device of single crystal growth furnace

The technology of a heating device and a crystal growing furnace is applied in the field of single crystal crystal growing furnace, the preparation of silicon carbide single crystal, and the heating device of single crystal crystal growing furnace, which can solve the problems of low control accuracy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061]The invention provides a method for preparing a silicon carbide single crystal, which is carried out by using the single crystal growth furnace described in the above technical solution, comprising the following steps:

[0062] When the pressure of the single crystal growth chamber is the second pressure, the temperature of the raw material zone is controlled to a fourth temperature by using the first heater and the second heater, and the temperature of the long-term zone is controlled by the second heater. controlling the temperature of the crystal region to be the fifth temperature, and controlling the temperature of the gas phase region to be the sixth temperature;

[0063] The axial temperature gradient of the raw material zone controlled by the first heater and the second heater is 1-3°C / min, and the axial temperature gradient of the crystal growth zone and the gas phase zone controlled by the second heater are independent The ground temperature is 2-5°C / min, and th...

Embodiment 1

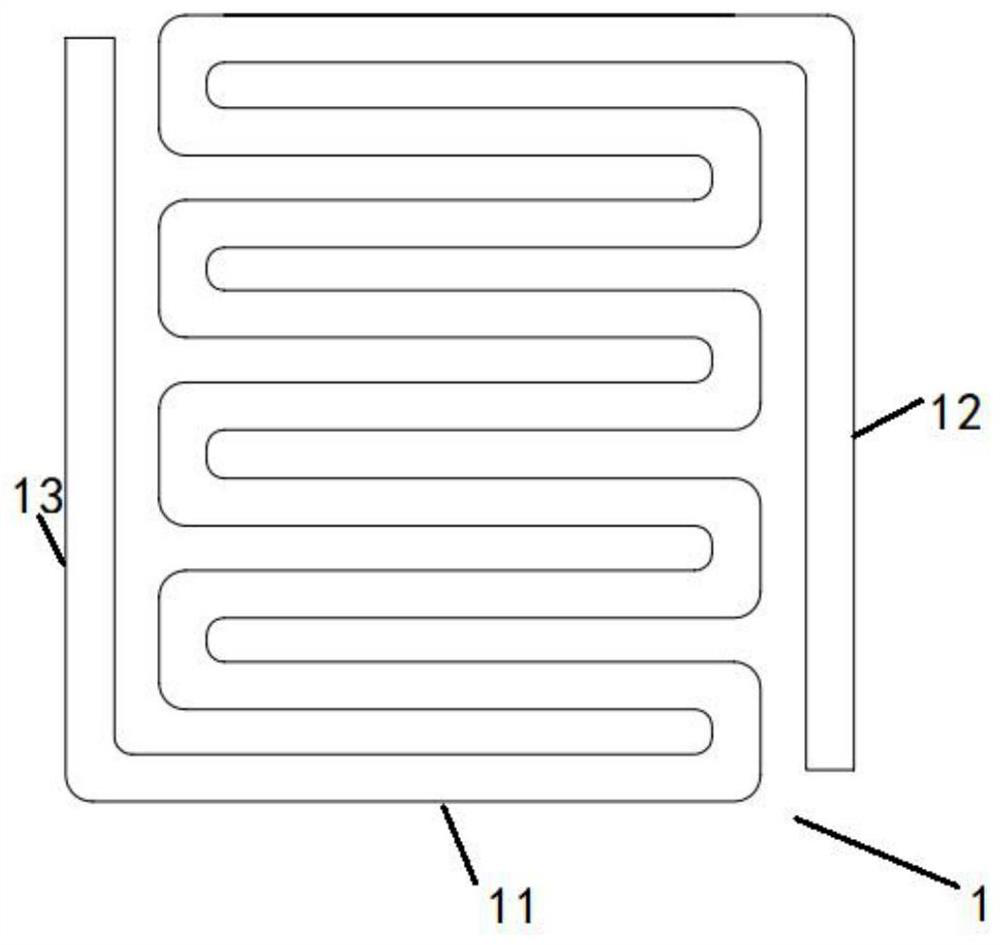

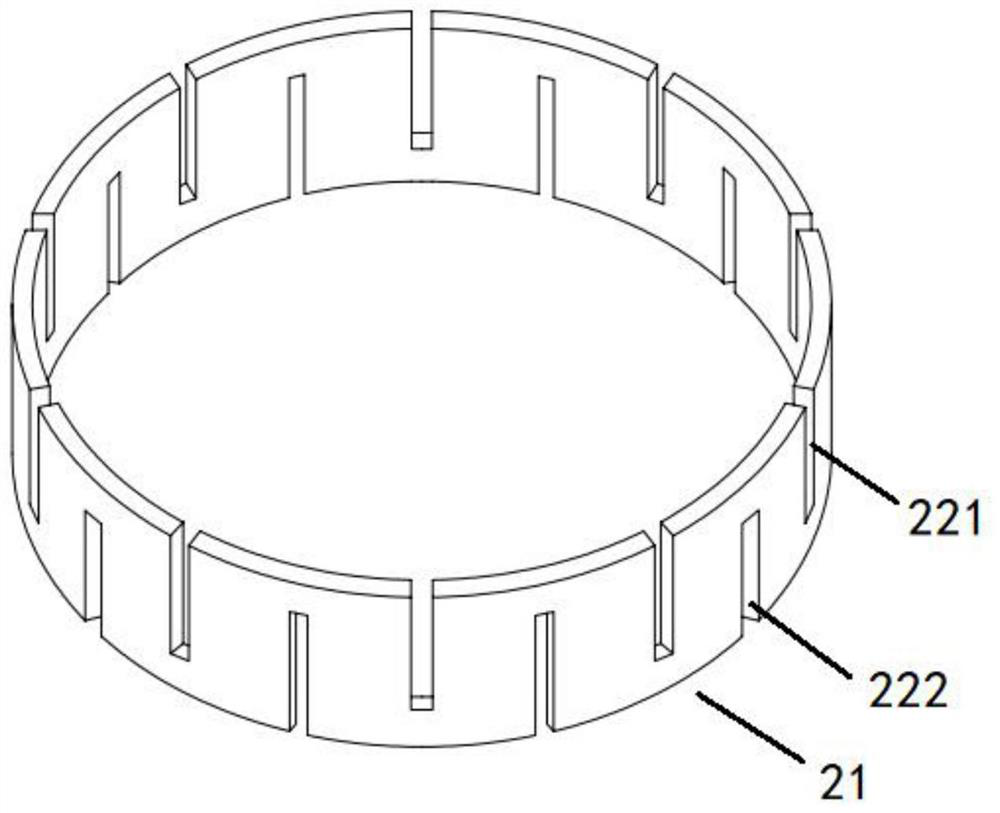

[0094] use Figure 4 For the single crystal growth furnace shown, the bottom area of the crucible is 200mm×200mm, and the height is 180mm. figure 1 The shown first heater 1, the effective heating area of the first heater 1 is 200mm×200mm, the first heater 1 is a serpentine heater, and the serpentine heater includes a serpentine heating part 11, a first linear heating part 12 and a second linear heating part 13, the length of the first linear heating part 12 and the second linear heating part 13 is 200 mm, and the serpentine heating part 11 includes 9 There are 8 straight heating sections and 8 bending heating sections, and the side wall of the crucible is placed as image 3 The two heating units shown are the first heating unit and the second heating unit from bottom to top. The inner diameters of the first heating unit and the second heating unit are both 220mm and the height is 30mm. The first heating unit and the second heating unit The distance between the first heat...

Embodiment 2

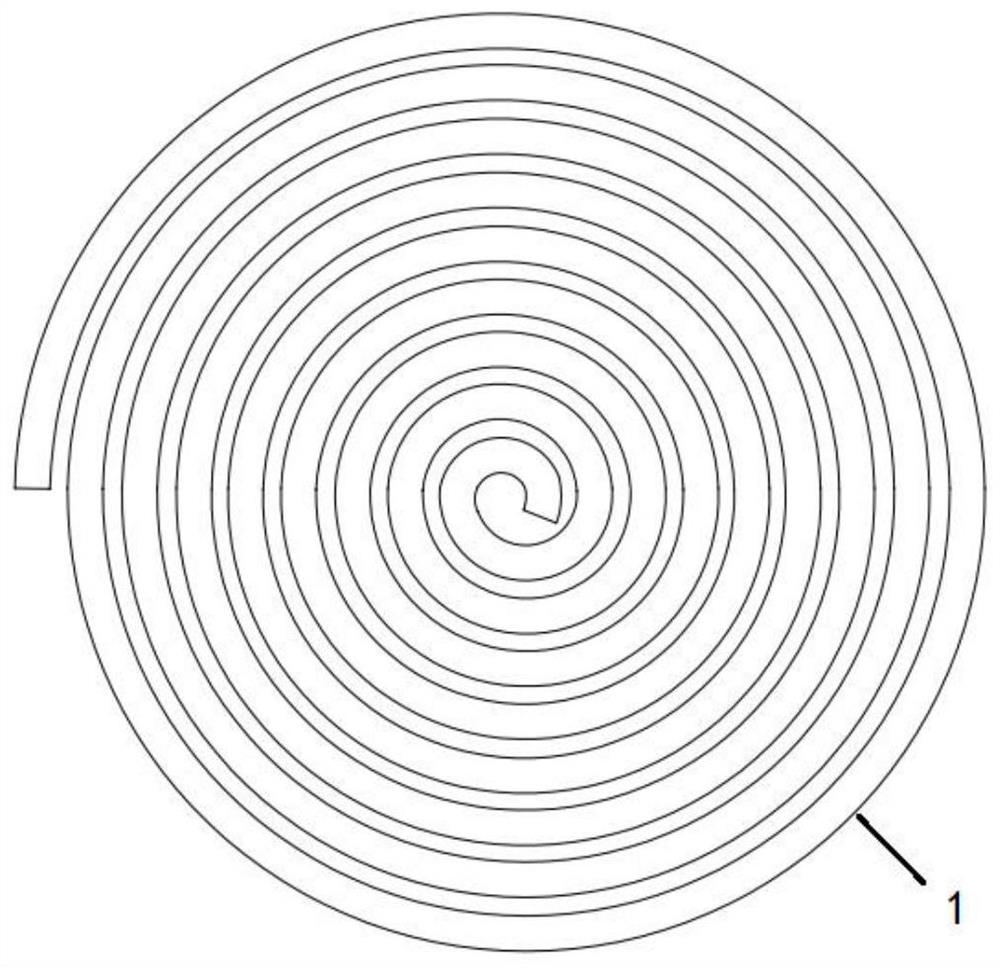

[0099] use Figure 4 For the single crystal growth furnace shown, the bottom area of the crucible is 200mm×200mm, and the height is 180mm. figure 2 The shown first heater 1, the area of the effective heating area of the first heater 1 is 200mm * 200mm, the first heater 1 is a plane spiral heater, and the crucible side wall is placed as image 3 The two heating units shown are the first heating unit and the second heating unit from bottom to top. The inner diameters of the first heating unit and the second heating unit are both 220mm and the height is 30mm. The first heating unit and the second heating unit The distance between the first heating unit and the bottom surface of the crucible is 40mm, the distance between the second heating unit and the top surface of the crucible is 40mm, and the upper slots 9 are evenly arranged on the annular heating elements of the first heating unit and the second heating unit. , 9 lower slots.

[0100] The specific process settings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com