Auxiliary heating method and device and single crystal furnace for growing single crystals with induction heating czochralski method

A technology of auxiliary heating and induction heating, applied in the auxiliary heating of induction heating Czochralski method to grow single crystal, single crystal furnace field, can solve the problem of insufficient growth power and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

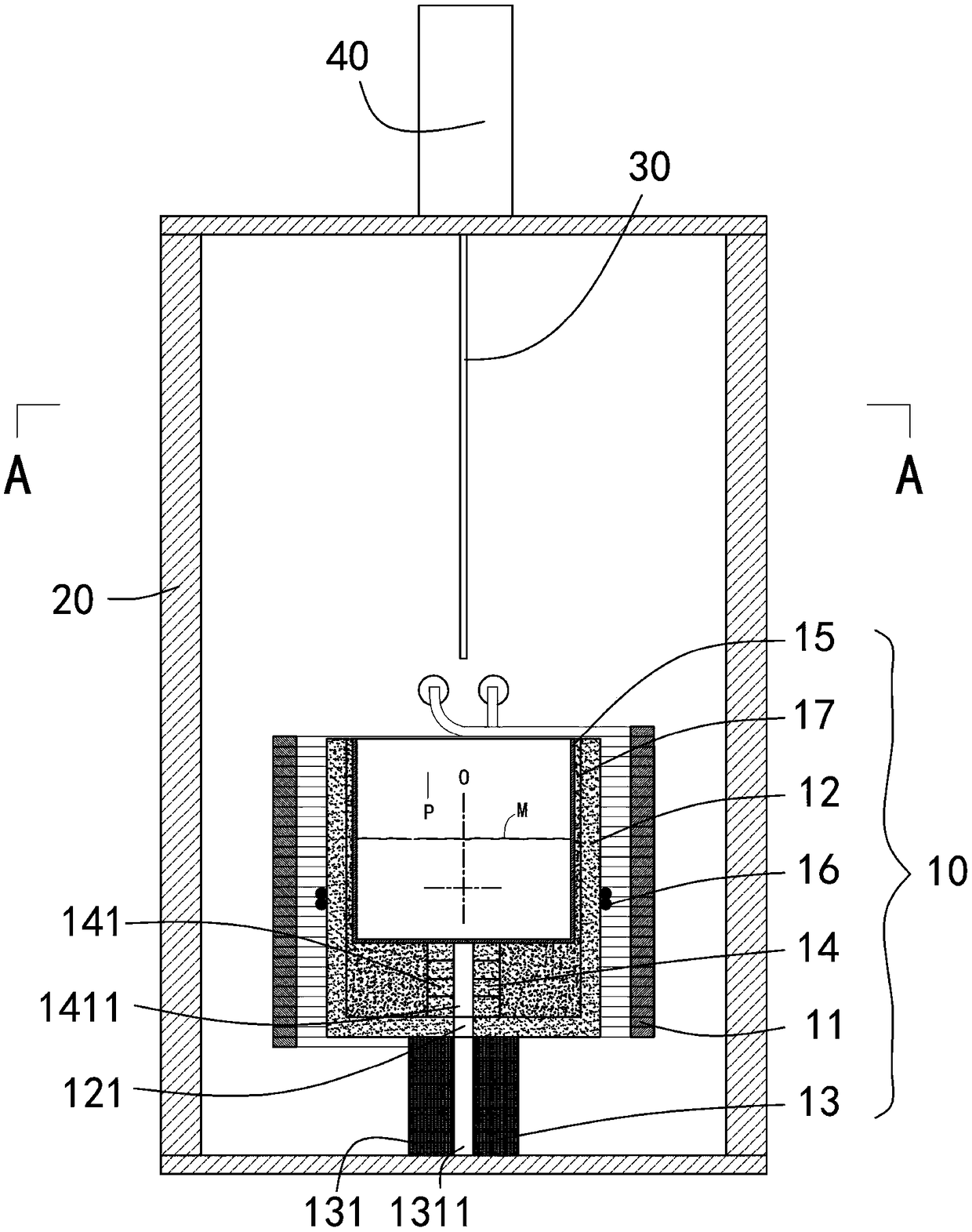

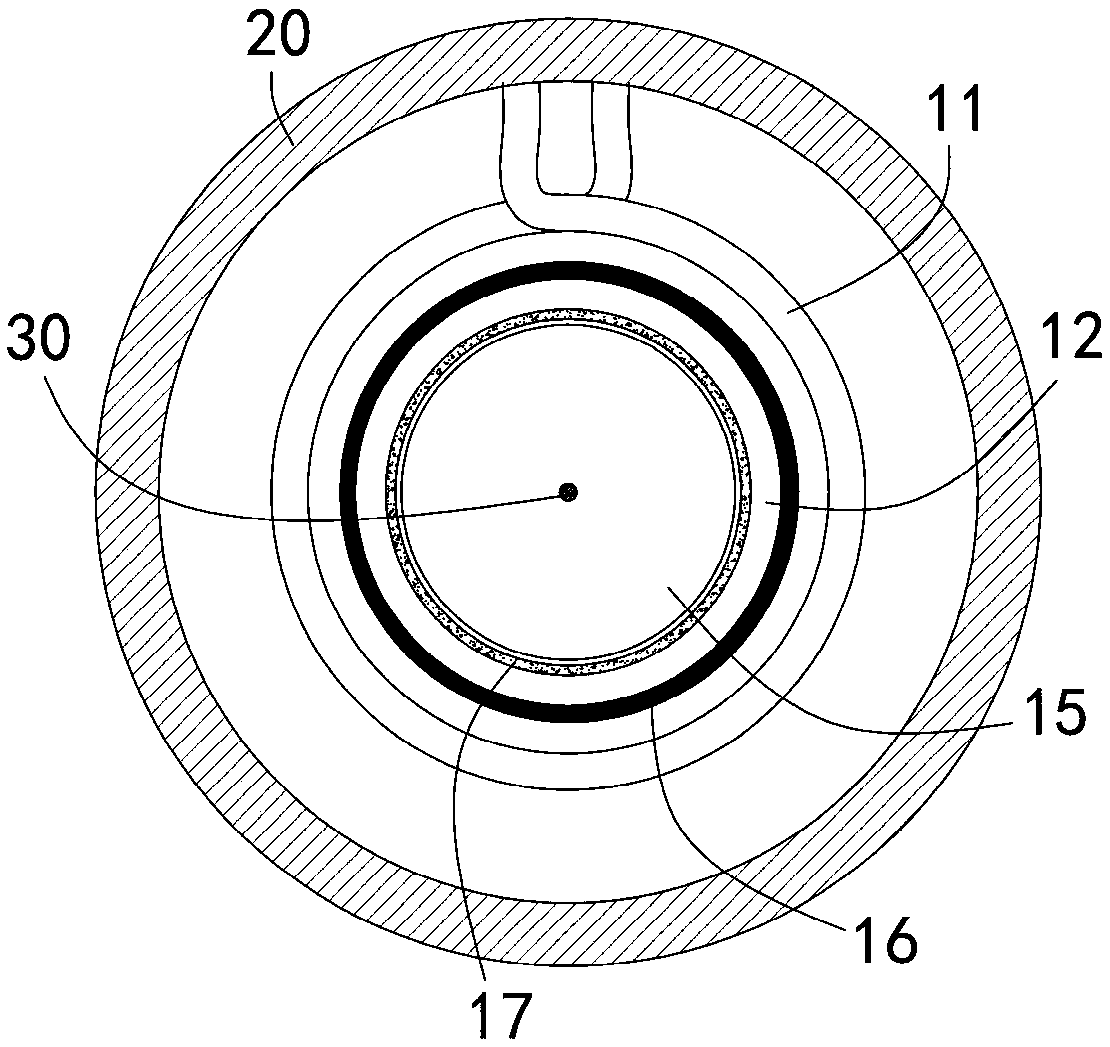

[0038] Example 1: growing lithium tantalate (LT) crystals, an iridium gold crucible 15 with a diameter of 160mm and a height of 100mm, charged with 14Kg, and growing 4-inch crystals. The auxiliary heating wire 16 is platinum, the cross-sectional thickness of the auxiliary heating wire 16 is 0.5 mm, and the cross-sectional height of the auxiliary heating wire 16 is 2 mm. Straight, the growth interface is slightly convex, and the reference rate of crystal growth raw materials is 63%.

Embodiment 2

[0039] Example 2: growing lithium tantalate (LT) crystals, an iridium gold crucible 15 with a diameter of 160 mm and a height of 100 mm was charged with 14Kg, and a 4-inch crystal was grown. The auxiliary heating wire 16 is a nickel strip, the cross-sectional thickness of the auxiliary heating wire 16 is 1.0 mm, and the cross-sectional height of the auxiliary heating wire 16 is 2 mm. The position of the auxiliary heating wire 16 is at two-thirds of the height from the crucible 15 top. Straight, the growth interface is slightly convex, and the utilization rate of crystal growth materials is 64%.

[0040] The steps in the methods of the embodiments of the present invention can be adjusted, combined and deleted according to actual needs.

[0041] The modules or units in the device of the embodiment of the present invention can be combined, divided and deleted according to actual needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com