A thermal insulation structure for the upper part of a sapphire single crystal furnace

A sapphire single crystal furnace and insulation layer technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of fast heat dissipation, difficult temperature adjustment, unreasonable temperature field, etc., and achieve small thermal conductivity and high temperature Ease of adjustment and excellent thermal insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

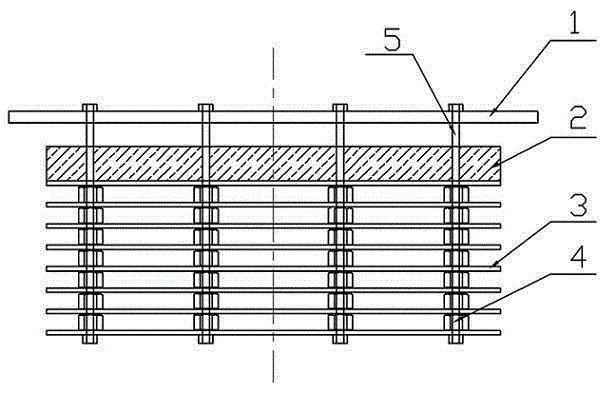

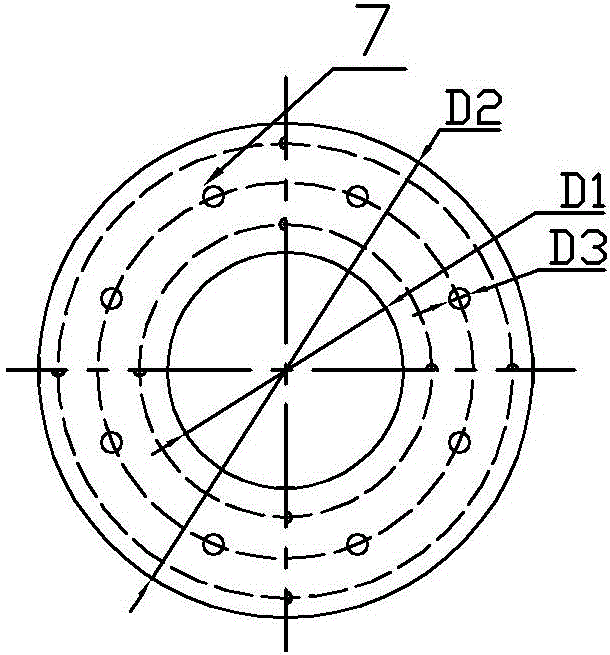

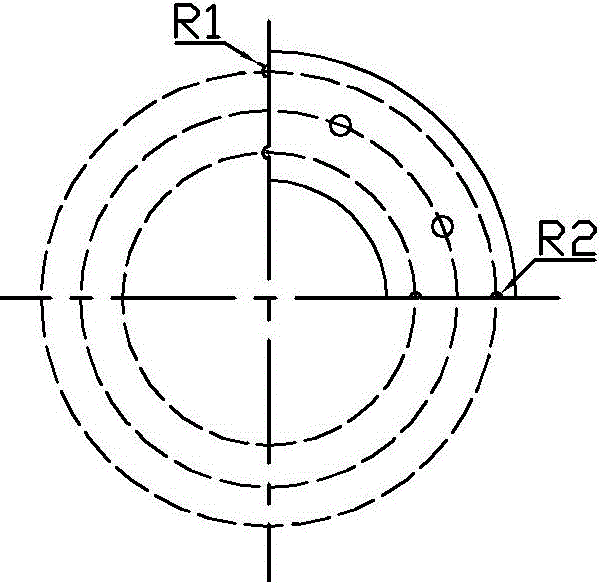

[0026] combine figure 1 , This embodiment includes a molybdenum heat shield composed of a fixed support structure 1, a zirconia insulation layer 2 and a multilayer molybdenum sheet 3. The fixed support structure 1 is made of a single-layer circular stainless steel plate, and the zirconia insulation layer 2 is made of several fan-shaped oxide Zirconium insulation bricks are spliced together, and the middle of the multi-layer molybdenum sheet 3 is provided with a gradually increasing central hole and a rectangular observation window from top to bottom. The thickness of the single-layer circular stainless steel plate is 15mm, the outer diameter is 400mm, and the inner diameter is 180mm. There are 8 molybdenum bolts 5 distributed along the circumference of the single-layer circular stainless steel plate with a diameter of 200mm. The bolt diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com