Brake lining for disc brakes

A technology of disc brakes and brake linings, applied to brake components, brake types, friction linings, etc., can solve problems such as power loss, and achieve the effects of reducing wear, uniform temperature introduction, and avoiding temperature peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

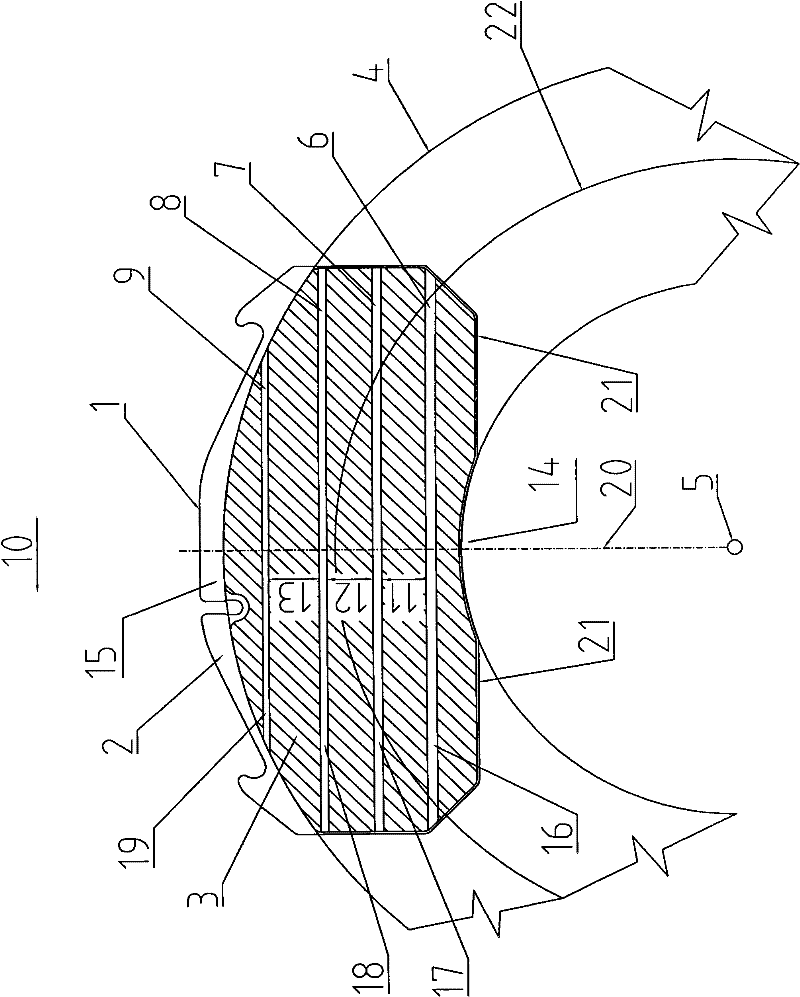

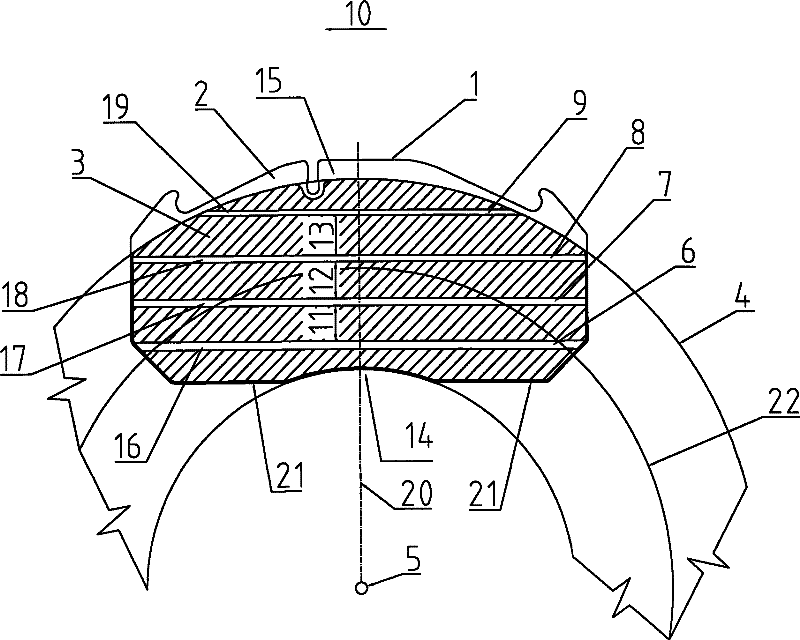

[0028] In order to clarify the mounting position of the brake shoe 1 relative to the brake disk, such a brake disk 4 is shown schematically, wherein its axis of rotation is indicated by the reference numeral 5 .

[0029] In the exemplary embodiment shown, the friction lining 3 has four indentations 6 , 7 , 8 and 9 which are substantially linear in the longitudinal extension of the friction lining 3 indicated by the double arrow 10 and are connected to each other. It extends parallel and tangentially to a concentric circle centered on the axis of rotation 5 .

[0030] The indentations 6, 7, 8 and 9 are spaced apart from one another in such a way that the respective distances between the indentations 6, 7, 8 and 9, denoted by the reference numerals 11, 12 and 13, extend from the radial inner side 14 to the radial Increased towards the outside 15. A rough rule can be that the corresponding next distance is approximately 10% larger than the preceding distance.

[0031] In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com