Method and device for preventing fractionation tower salt coagulation

A fractionation tower and salt accumulation technology, which is applied in the field of preventing salt formation in fractionation towers, can solve problems such as entry and abnormal production of fractionation towers, and achieve high utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preventing salt accumulation in a fractionation tower. The distillate oil in the liquid receiving tank of the fractionation tower with a temperature of 110°C is mixed with NH 4 The mixed solution of Cl aqueous solution is extracted, and after cooling down, it enters the oil-water separation tank for oil-water separation. The oil phase is heated to the temperature when it is extracted and returns to the fractionation column tray when it is extracted, containing NH 4 The aqueous Cl phase was discharged.

Embodiment 2

[0031] A method for preventing salt accumulation in the upper fractionation tower, the distillate and NH 4 The mixed solution of Cl aqueous solution is extracted, and after cooling down, it enters the oil-water separation tank for oil-water separation. The oil phase is heated to the temperature when it is extracted and returns to the fractionation column tray when it is extracted, containing NH 4 The aqueous Cl phase was discharged.

Embodiment 3

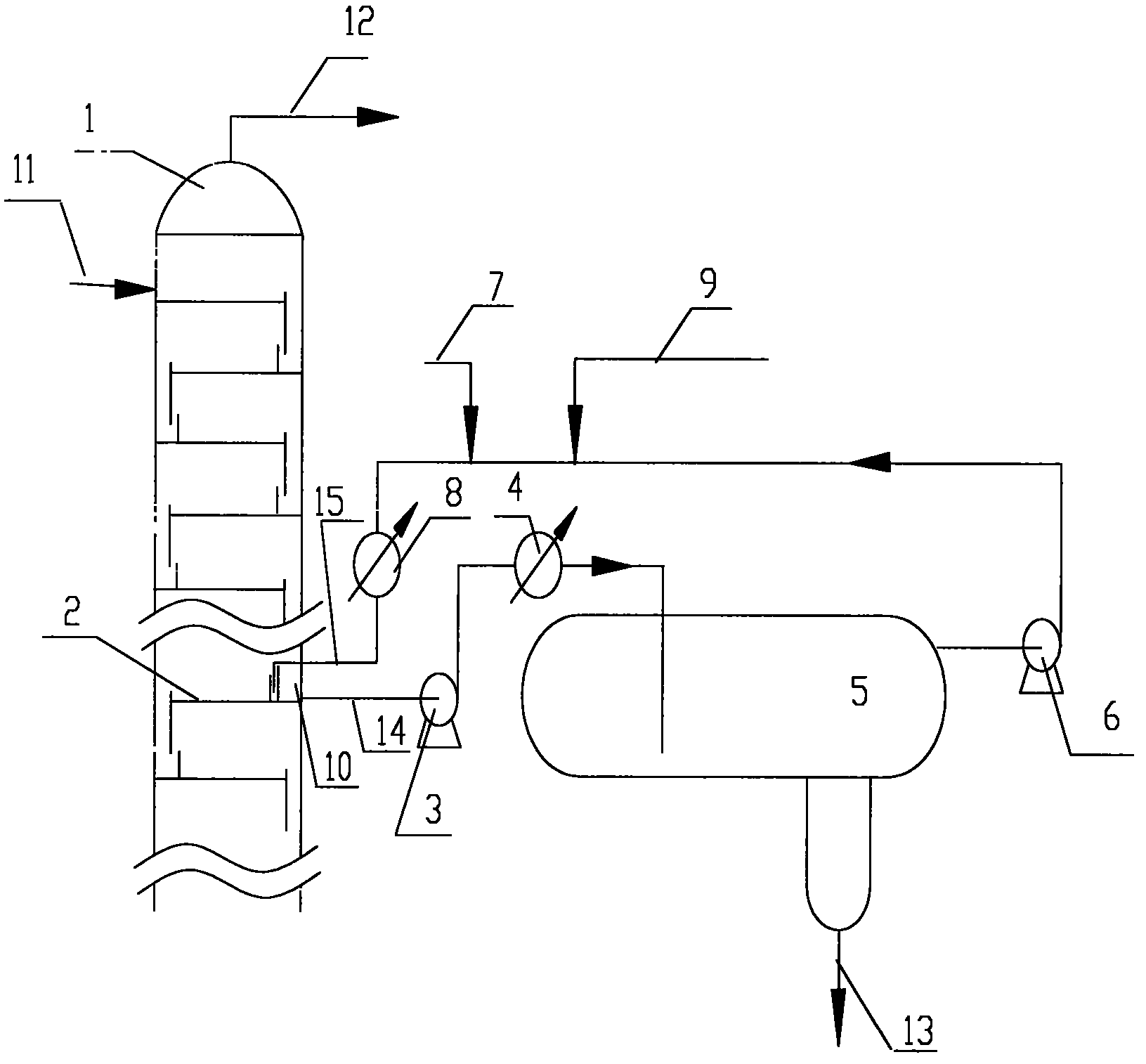

[0033] A device for preventing salt accumulation in a fractionation tower, comprising a fractionation tower 1, a tray 2, a liquid receiving tank 10, and an oil-water separation tank 5, the tray 2 and the liquid receiving tank 10 are arranged in the fractionation tower 1, and the fractionation tower 1 and the oil-water separation tank 5 is communicated, and described fractionation tower 1 is communicated with oil-water separation tank 5 by extraction pipe 14 and return pipe 15, and extraction pipe 14 and return pipe 15 are provided with heat exchanger 4 and heat exchanger 8, and extraction pipe 14 is provided with Extraction pump 3, return pump 6 is provided on return pipe 15, fresh water main inlet 7 and replacement fraction injection port 9 are provided on return pipe 15, brine outlet 13 is provided at the lower part of oil-water separation tank 5, tray 2 and receiving liquid The tank 10 is set at a temperature of 110-130° C. in the fractionation tower 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com