Device and method for detecting thermal migration performance of interconnected welding spots

A technology of thermal migration and temperature measurement device, applied in the field of electronic packaging, can solve problems such as difficulty in experimental design, and achieve the effects of easy promotion, good safety and reliability, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

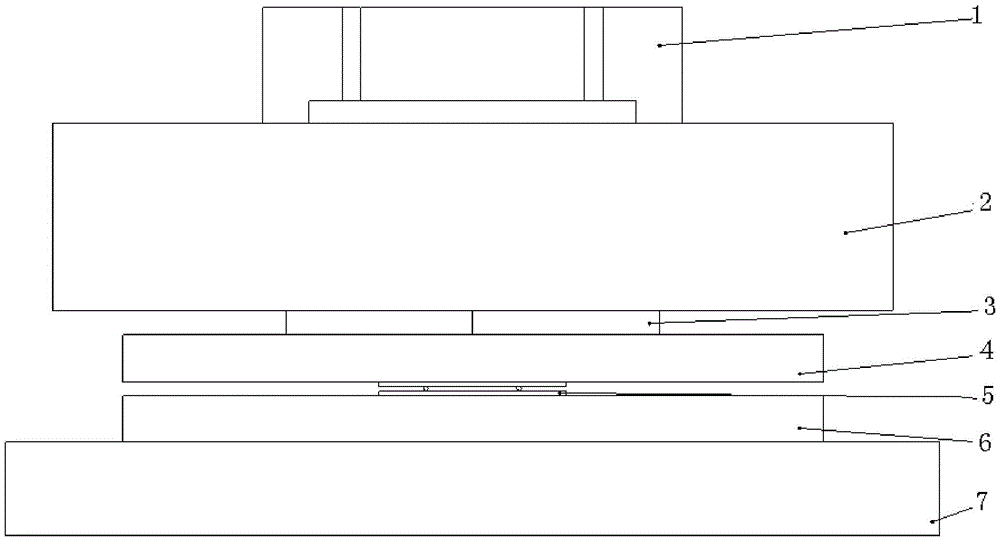

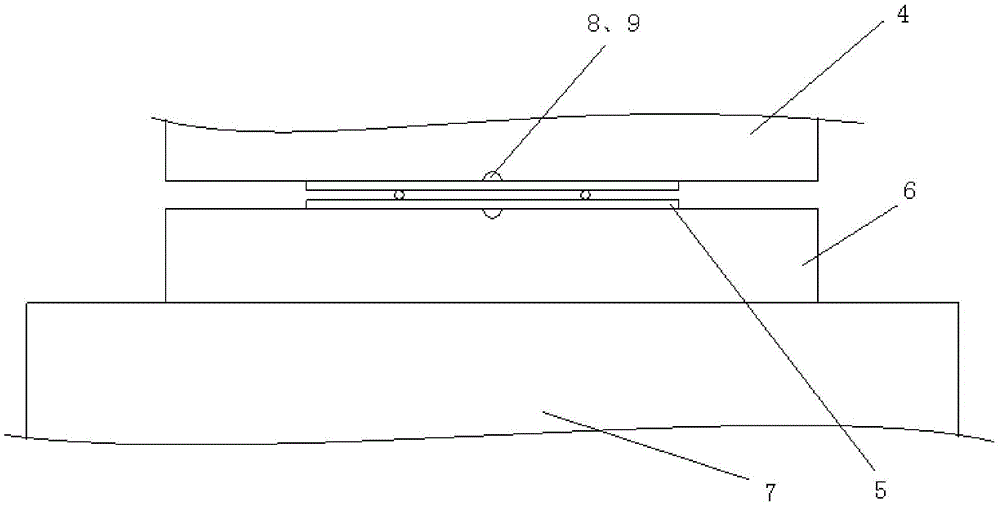

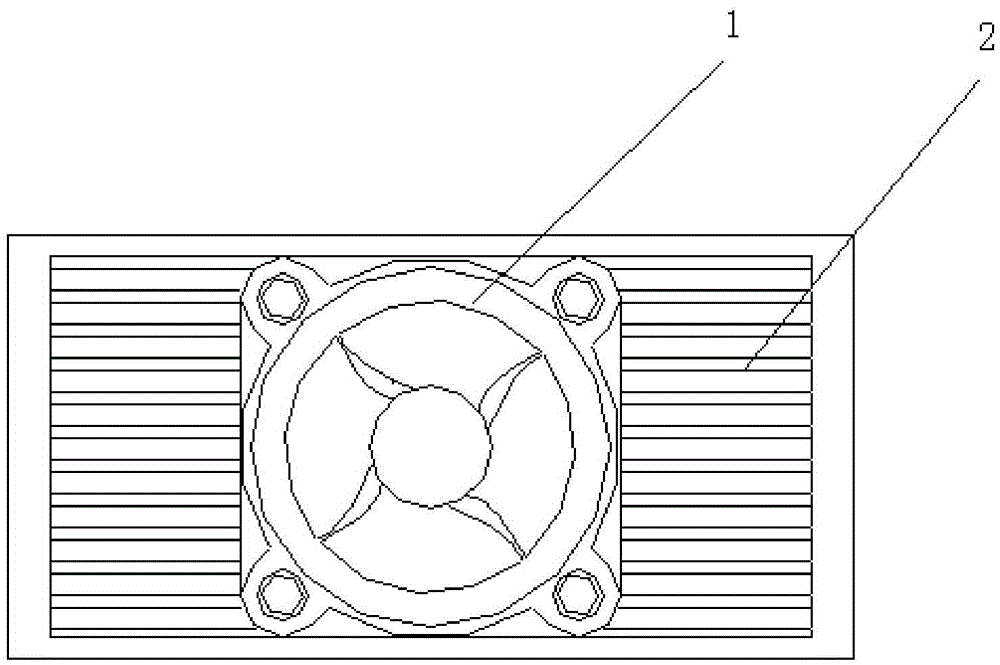

[0035] like Figures 1 to 3 shown. The invention discloses a device for detecting the thermal migration performance of interconnection solder joints. The device sequentially includes a cooling mechanism, an upper heat conducting plate 4, a lower heat conducting plate 6 and a heating plate 7 from top to bottom, that is, the cooling mechanism is arranged on the upper The upper part of the heat conduction plate 4 (aluminum material), the lower heat conduction plate 6 (aluminum material) is arranged on the top of the heating plate 7; the space between the upper heat conduction plate 4 and the lower heat conduction plate 6 is used to place the sample 5.

[0036] On the corresponding surfaces of the upper heat conduction plate 4 and the lower heat conduction plate 6, grooves 8 and 9 for embedding thermocouple probes are opened symmetrically; when the sample 5 is placed between the upper heat conduction plate 4 and the lower heat conduction plate 6, The thermocouple probe can be in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com