Soil body temperature gradient and moisture movement test device

A soil temperature and test device technology, which is applied in the fields of geotechnical engineering measurement devices and temperature gradient moisture movement test devices, can solve problems such as affecting the measurement results of water content, affecting the water conduction in the sample box, and soil sample disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

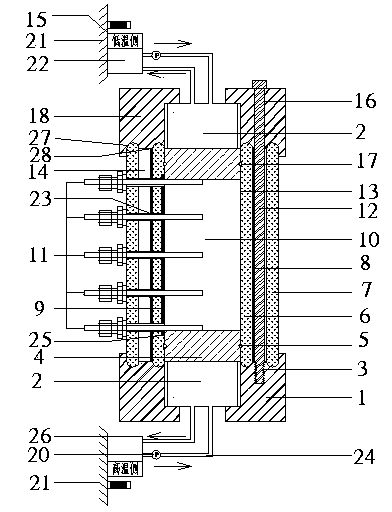

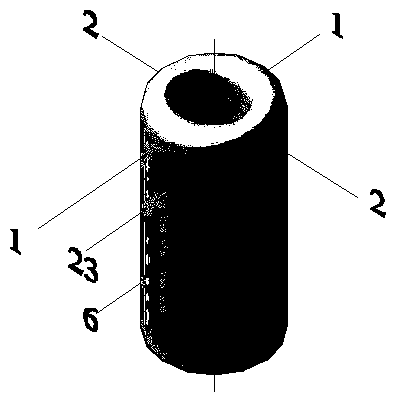

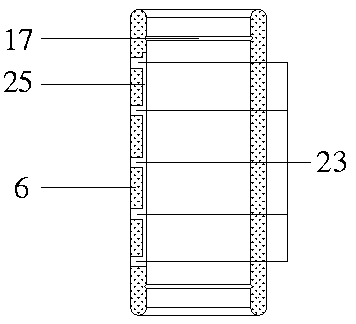

[0021] see Figure 1-8 , the local body temperature gradient moisture movement test device includes a sample chamber 13, a temperature gradient control device and a temperature and water content acquisition device. The sample chamber 13 is composed of an inner sleeve 6 , an outer sleeve 7 , an interlayer, an upper cover 18 and a lower cover 1 . Five vertical and evenly distributed round holes 23 are opened on the sides of the inner sleeve 6 and the outer sleeve 7 , and the temperature and moisture sensor probes 11 are inserted in the round holes 23 . The inner sleeve 6, the outer sleeve 7, the upper cover plate 18 and the lower cover plate 1 are tightly connected into one body by bolts 12 . The temperature gradient control device includes a lower high-temperature water bath 26, an upper low-temperature water bath 15, upper and lower heating chambers 2 placed inside the sample chamber 13, upper and lower heat transfer plates 4 placed at both ends of the sample 10, and a fully ...

Embodiment 2

[0022] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0023] see Figure 1-4 And 9, the inner sleeve 6 and the outer sleeve 7 of the sample chamber 13 in the temperature gradient moisture movement test device of the present invention are made of plexiglass material, forming a double-layer hollow interlayer structure. A thermal insulation material 8 is placed between the inner sleeve 6 and the outer sleeve 7 . The inner sleeve 6 has an inner diameter of 50mm±0.1mm, an outer diameter of 66mm±0.1mm, a height of 150mm±0.1mm, and a wall thickness of 8mm±0.2mm; the outer sleeve 7 has an inner diameter of 84mm±0.1mm and an outer diameter of 100mm± 0.1mm, height 150mm±0.1mm, wall thickness 8mm±0.2mm. There is an annular groove 17 on the inner wall of the inner sleeve 6 at a distance of 15 mm ± 0.1 mm from the upper and lower bottom surfaces, for fixing the heat transfer plate 4 . The radius of the groove is 1mm±0.1mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com