Patents

Literature

62results about How to "Avoid lateral flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

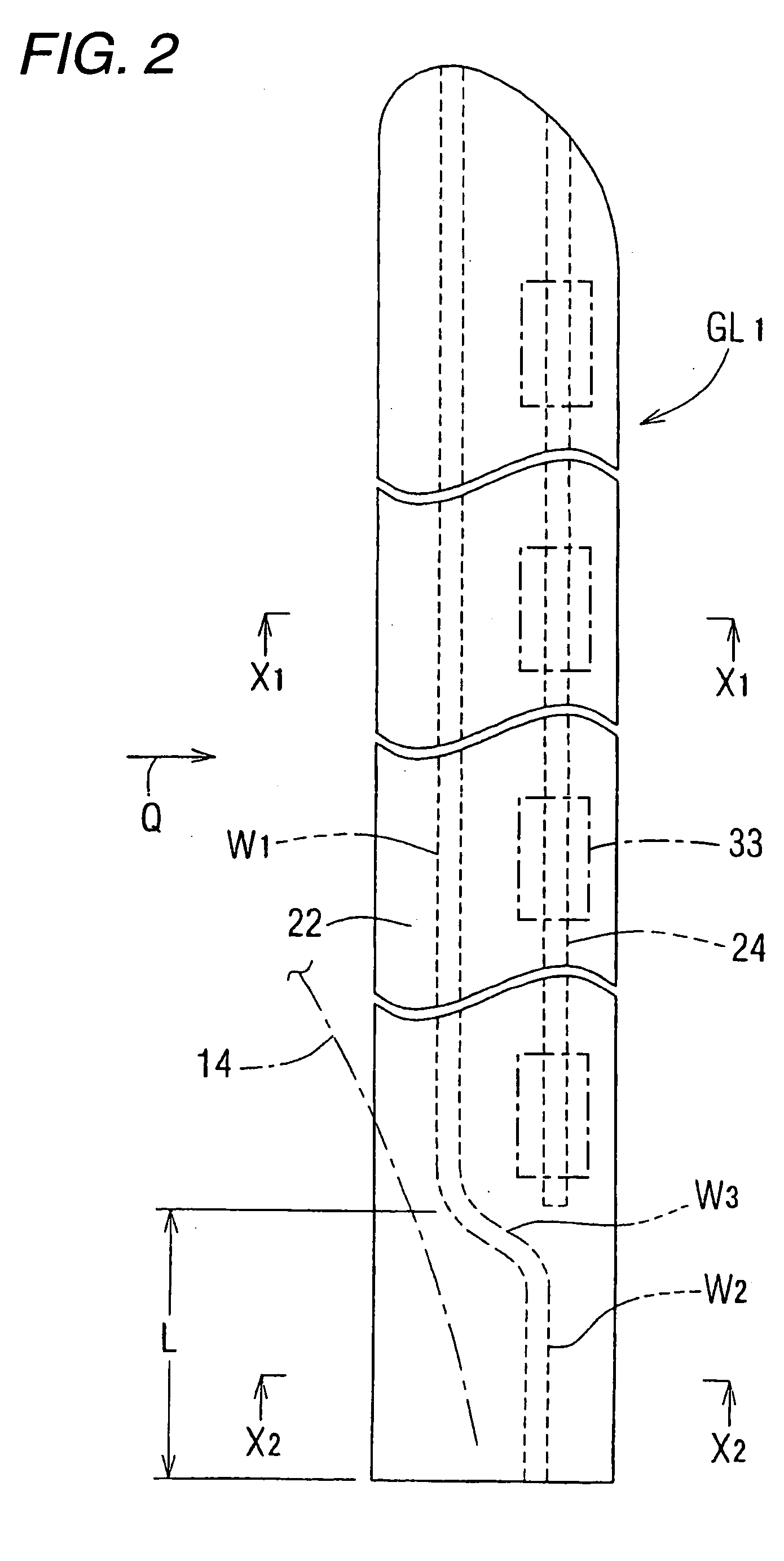

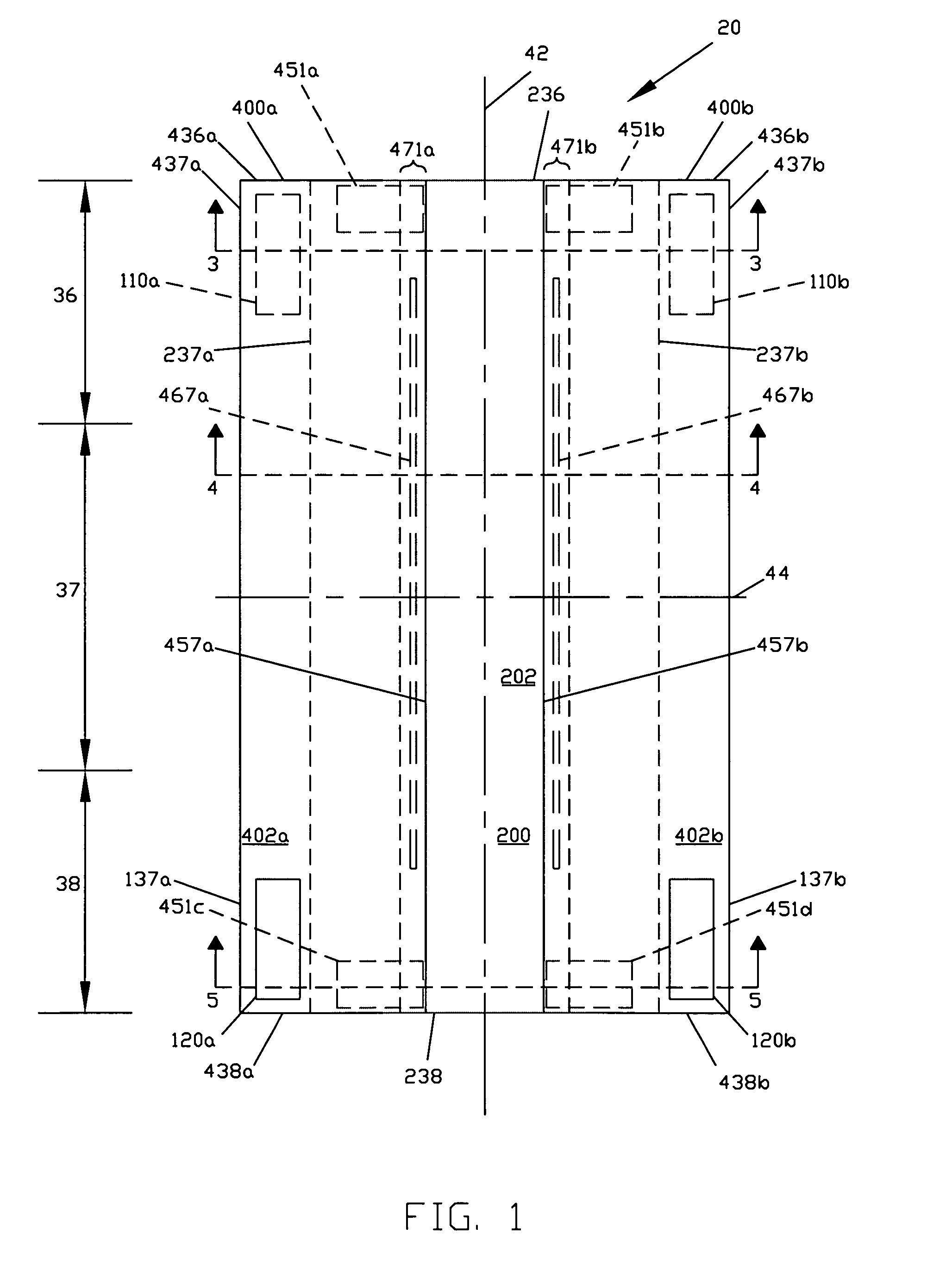

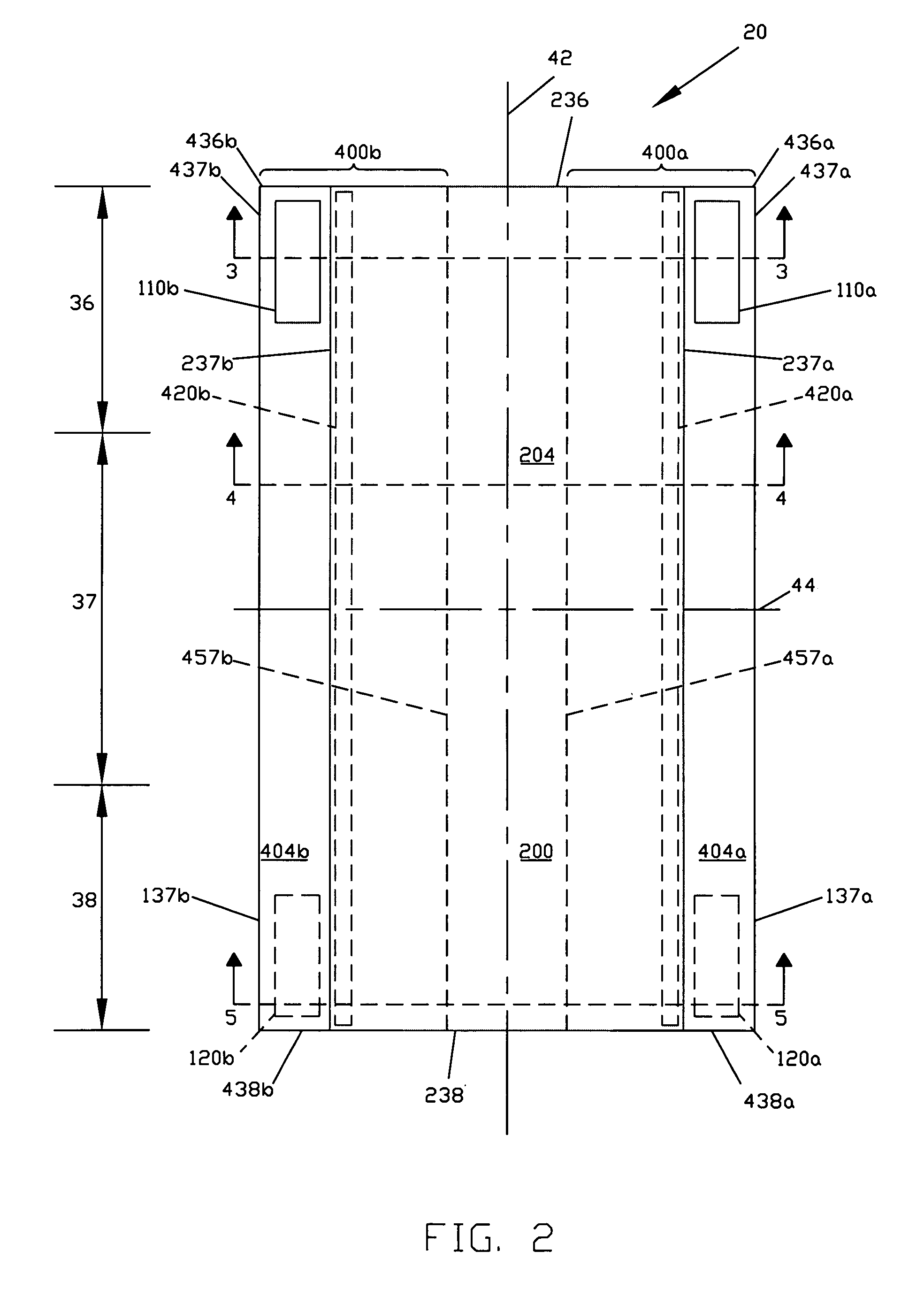

Disposable absorbent article having barrier cuff strips

A disposable absorbent article includes two laterally opposing longitudinally extending barrier cuff strips attached to an interior surface of an absorbent assembly in laterally opposing attachment zones. Each barrier cuff strip may include a water-impermeable layer and may be extensible. A longitudinally extending elastic gathering member is attached to each barrier cuff strip adjacent to its proximal edge. When the article is worn, the elastic gathering members contract and raise the barrier cuff strips to form side barriers. The absorbent assembly includes an absorbent core that may contain superabsorbent particles, which may be contained inside pockets. A portion of the absorbent assembly such as the portion that lies between the barrier cuff strip attachment zones may be extensible and may include a water-impermeable layer. The laterally opposing attachment zones may act as dams preventing a lateral flow of liquid bodily waste.

Owner:THE PROCTER & GAMBLE COMPANY

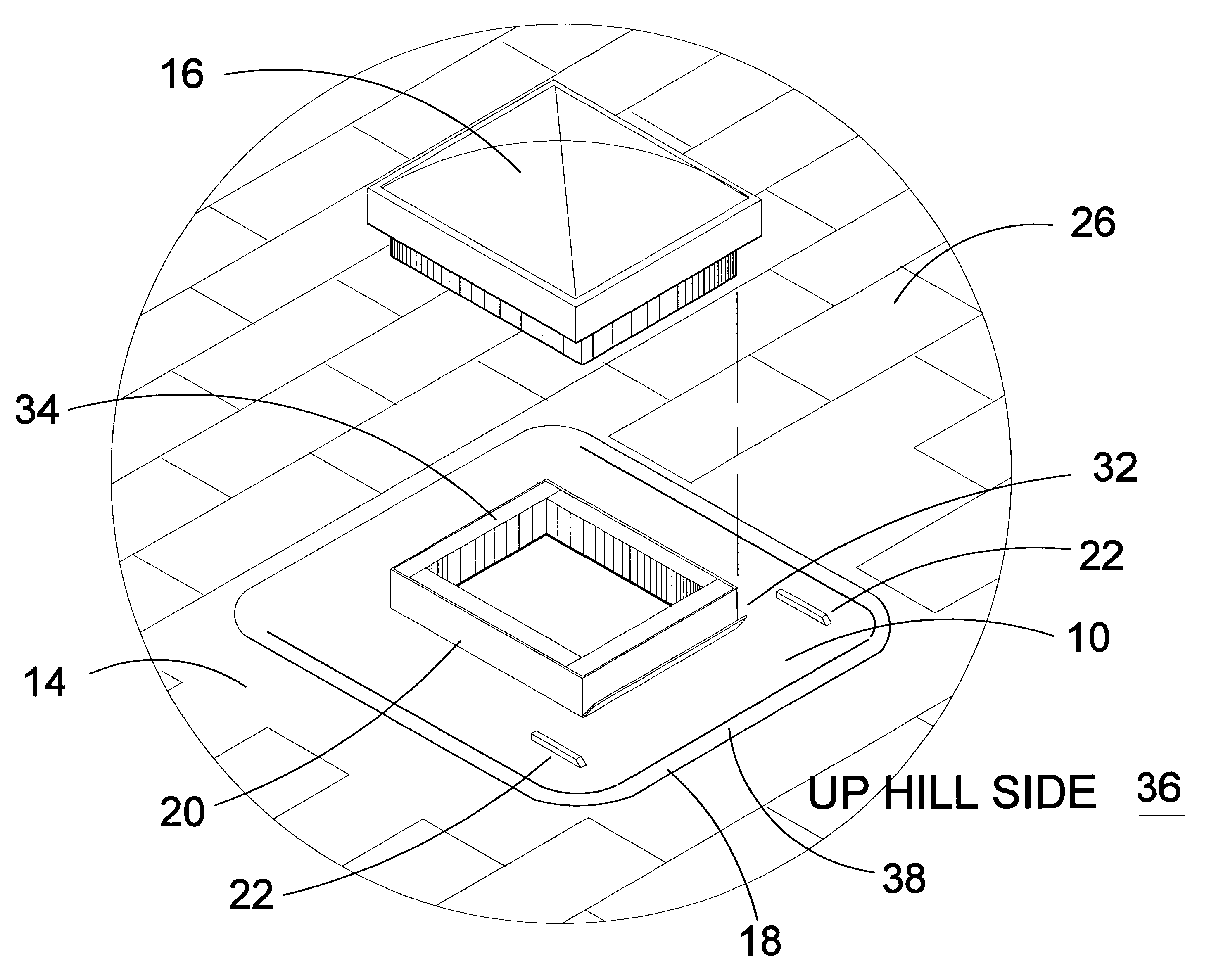

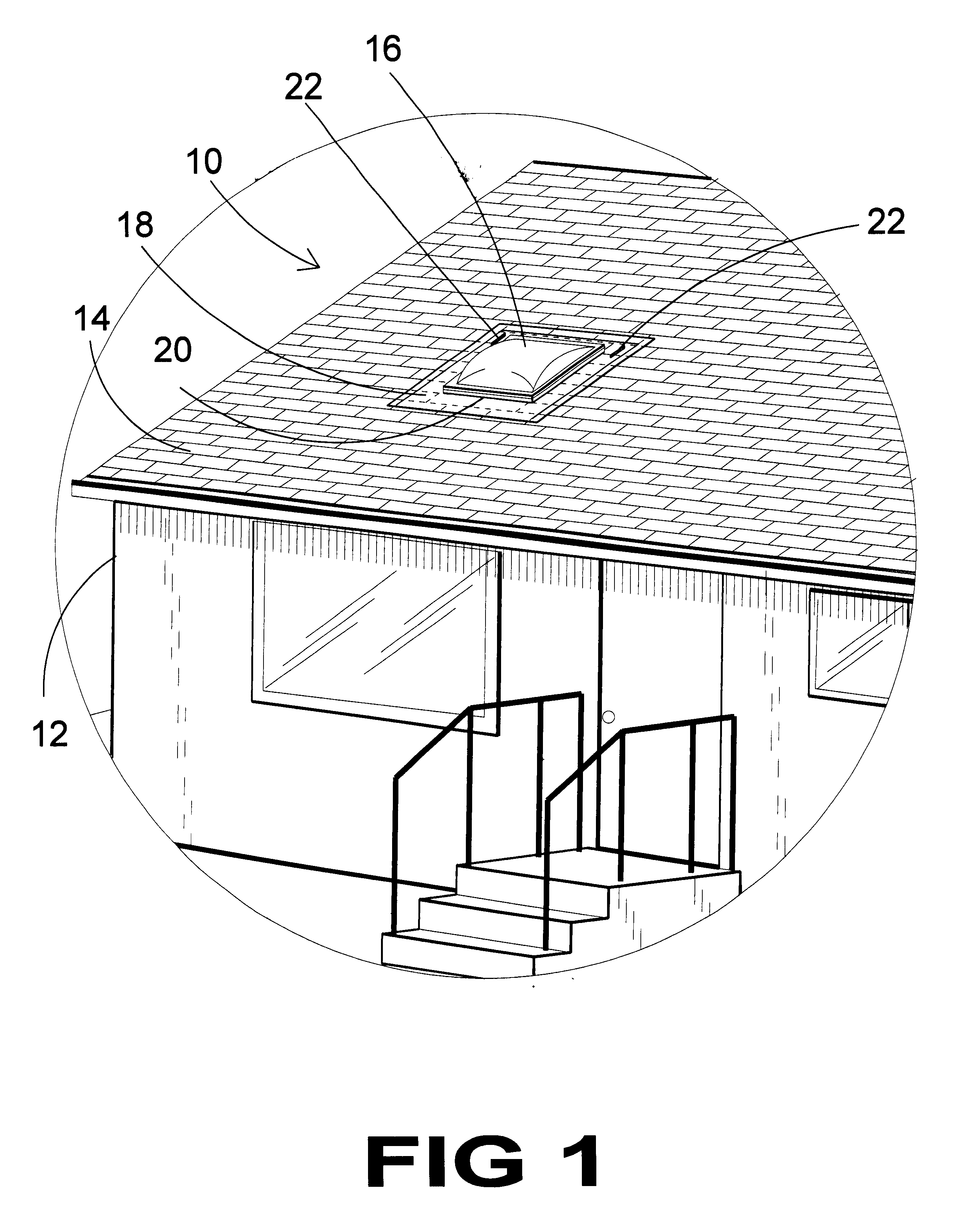

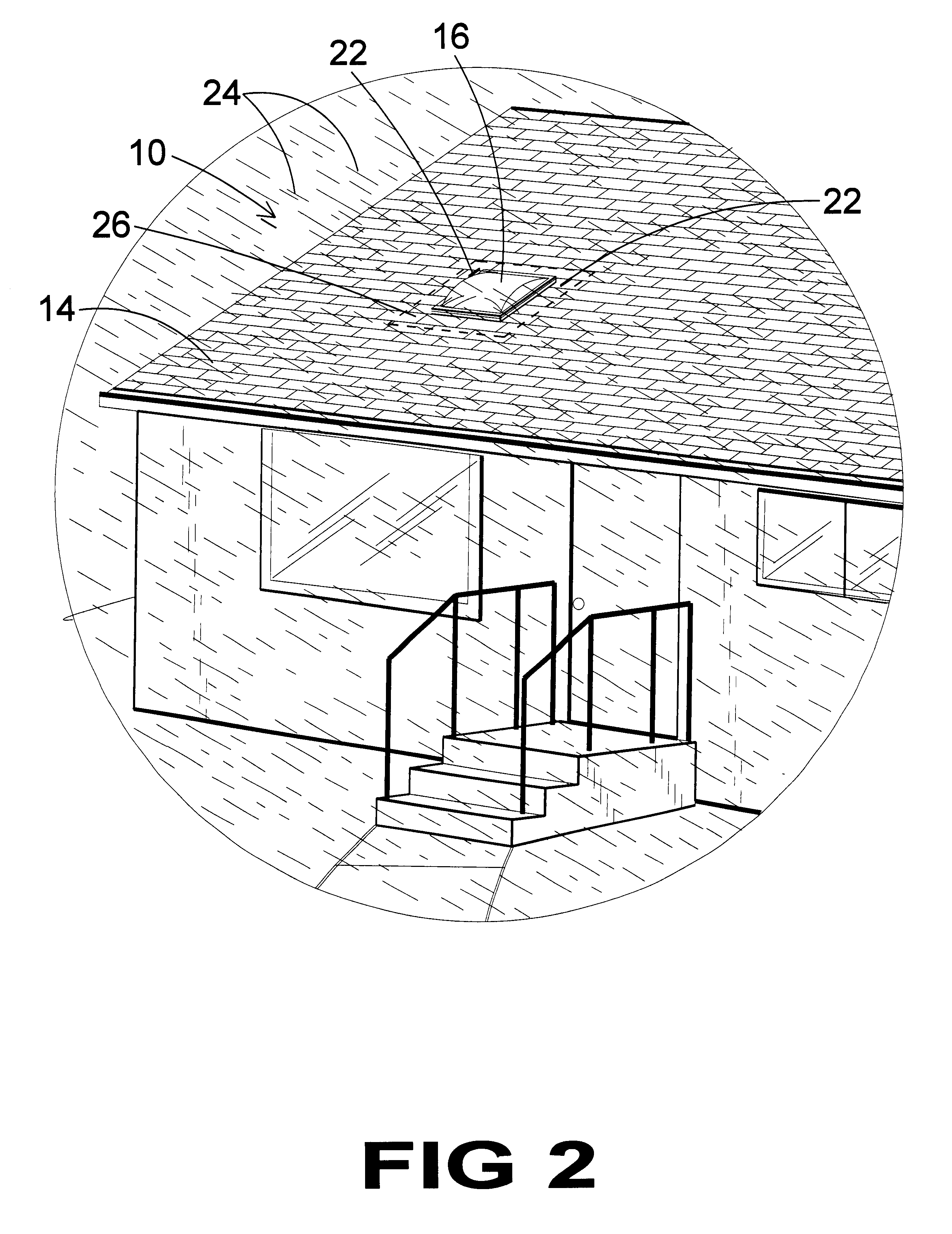

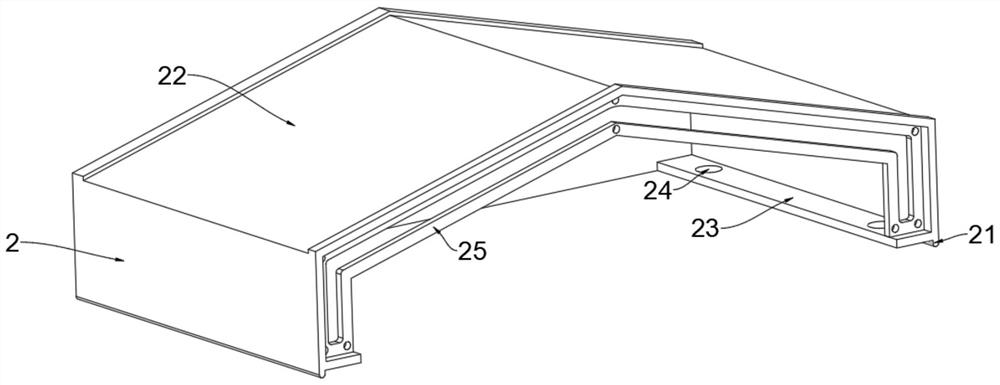

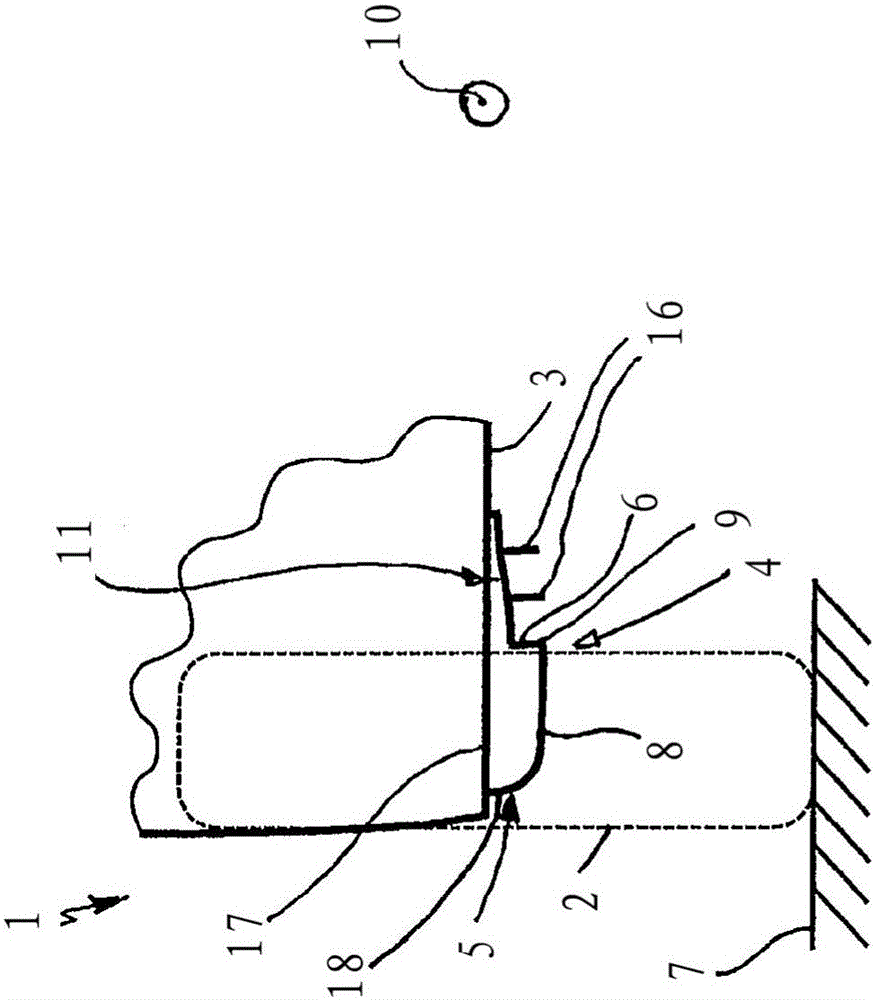

Skylight membrane with diverter

InactiveUS6354046B1Prevent leakageAvoid lateral flowBuilding roofsRoof covering using slabs/sheetsMembrane configurationEngineering

The present invention 10 discloses an elastomeric skylight membrane molded as a single piece comprising a planar element 18 for sealably engaging roof sheathing 26 and a centrally positioned collar element 20 for sealably engaging the rough opening framing members 34. The skylight collar membrane 20 is inserted over the framed rough opening for a skylight 16 having the elastomeric collar element tightly engaging the framing members 34 and of substantially the same height as the rough opening frame members. The planar element 18 engages the roof sheathing 26 and is fixedly attached thereto by any means well known within the art. Positioned across the up slope side 36 of the collar 20 is an angularly protruding edge 32 for preventing water from wicking between the skylight frame 34 and the skylight membrane 10. To prevent lateral flow from the up slope edge 36 of the skylight 16 there are two spaced apart ridges 22 transversely positioned to the turnback collar sides extending above and below the horizontal edge 30 of the up slope side 36. The diverter ridges 22 spaced away form the turnback side 32 obstruct lateral water flow returning it to a downhill flow. The planar element 18 further has a bead 38 on three sides near its periphery that will redirect any water that has accumulated between the skylight membrane and shingles to a downward flow.

Owner:SWEARINGEN MICHAEL R

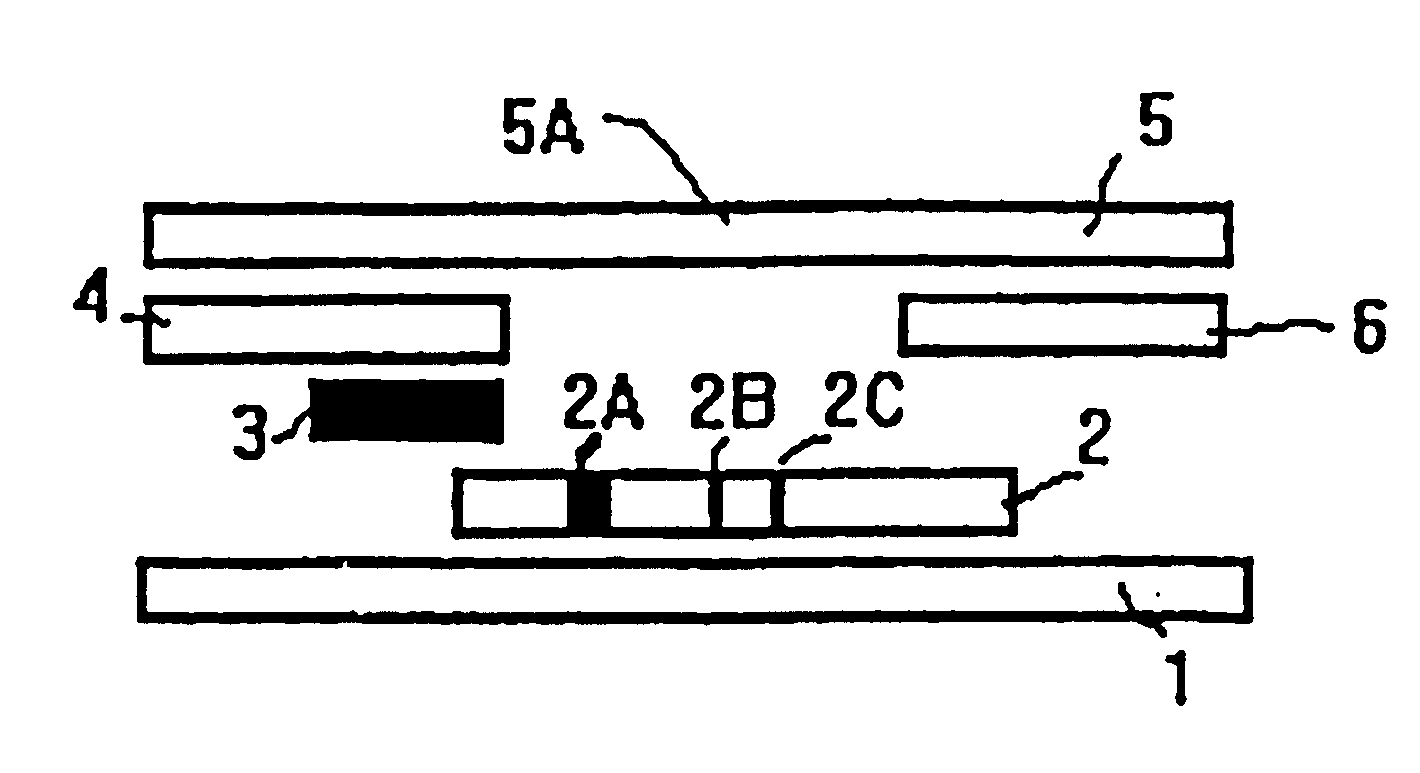

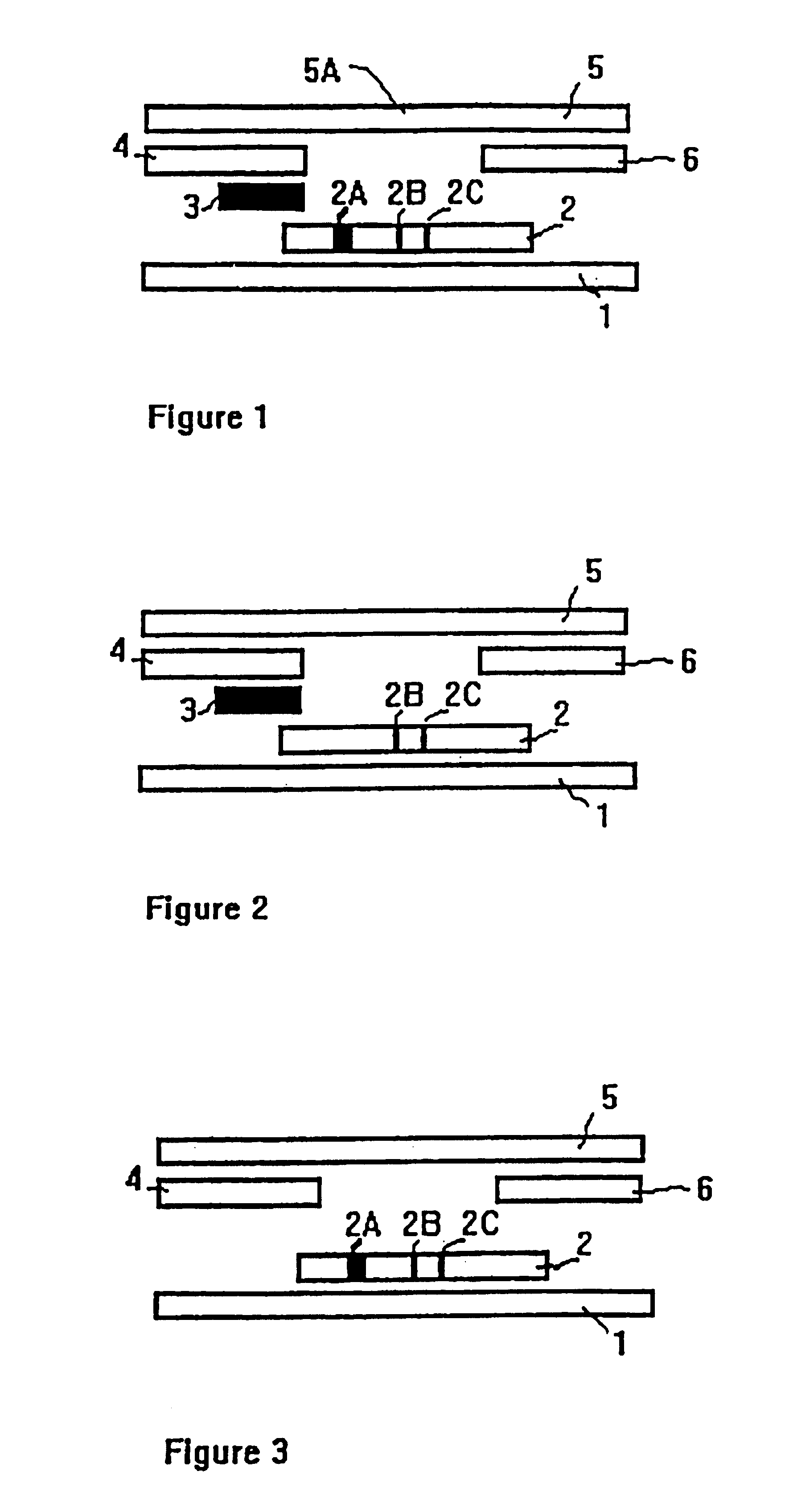

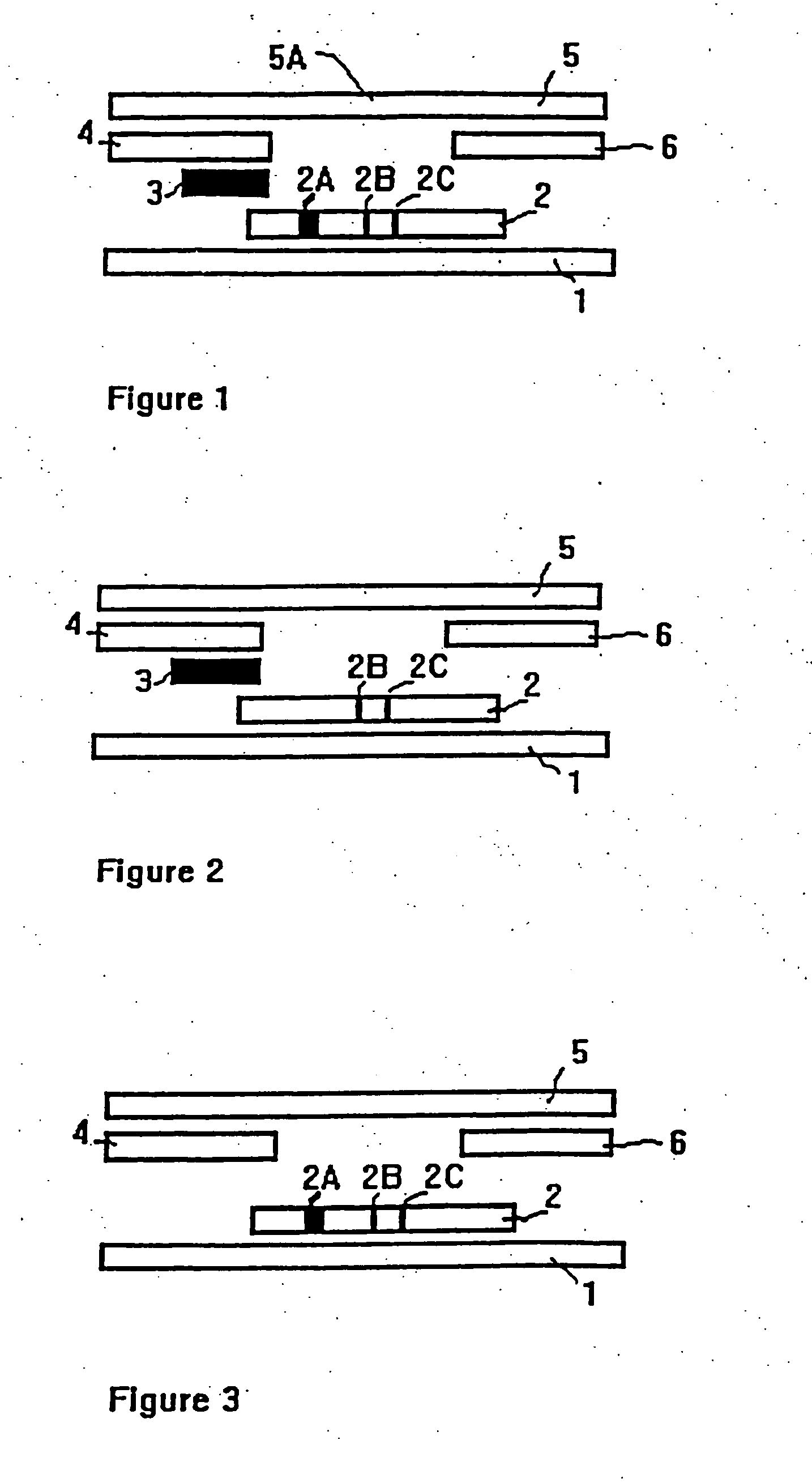

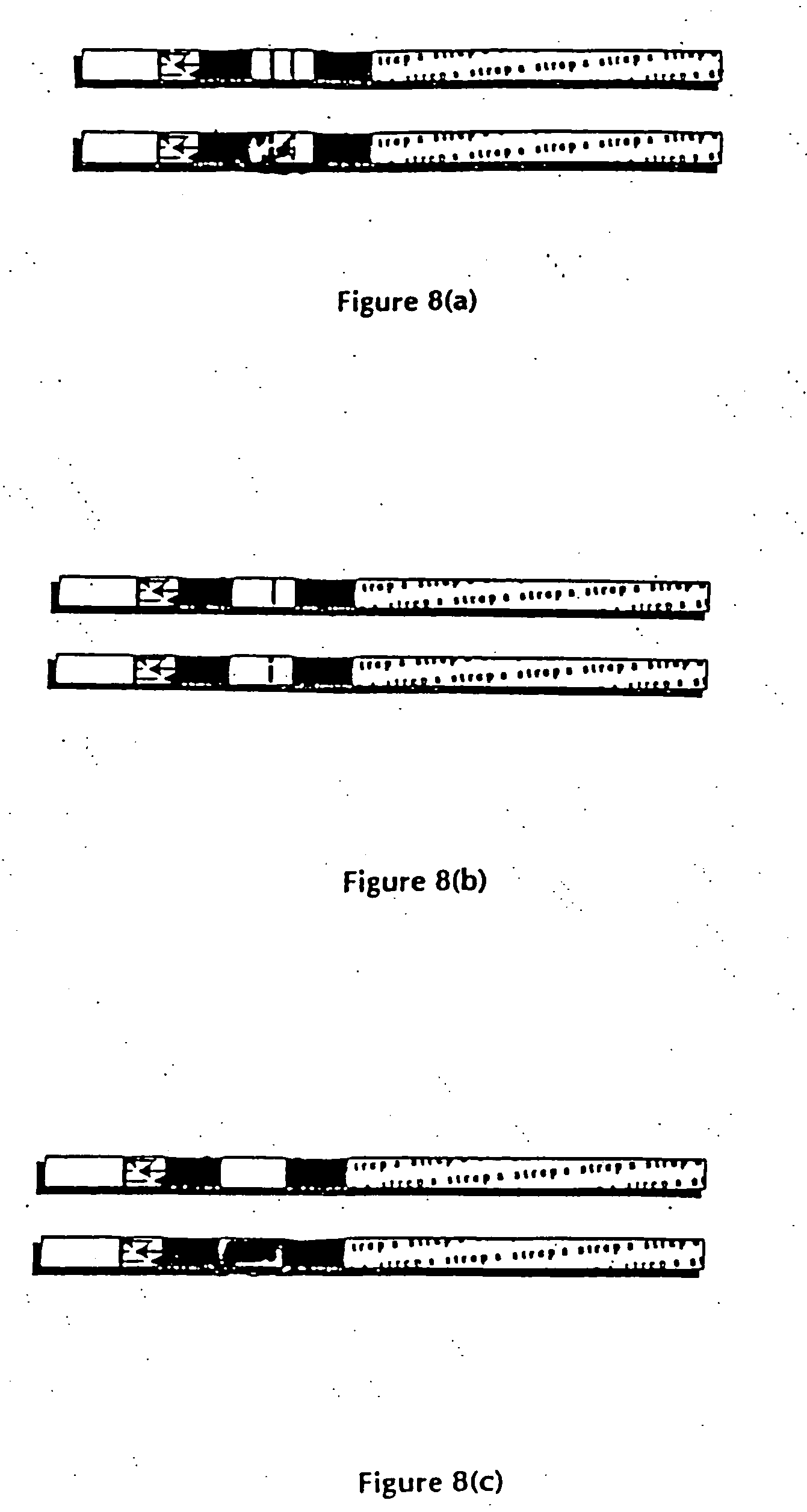

Methods of use of one step immunochromatographic device for Streptococcus A antigen

InactiveUS6979576B1Reduce the numberLess manipulationBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenReagent

A method to determine the presence or absence of Streptococcus Group A antigen in a sample, comprising the following steps: extracting the antigen from the sample in an assay chamber with two or less extraction reagents, wherein the two reagents may be added to the assay chamber in no particular sequence; introducing a lateral flow immunochromatographic assay device into the extraction reagents containing the extracted antigen without further addition of reagents or manipulation of the sample; forming an antigen-indicator labeling reagent complex; and determining the presence or absence of the antigen in the sample by the presence or absence of a signal formed by the binding of the antigen-indicator labeling reagent complex to an indicator capture reagent specific for said antigen-indicator labeling reagent complex.

Owner:SEKISUI DIAGNOSTICS

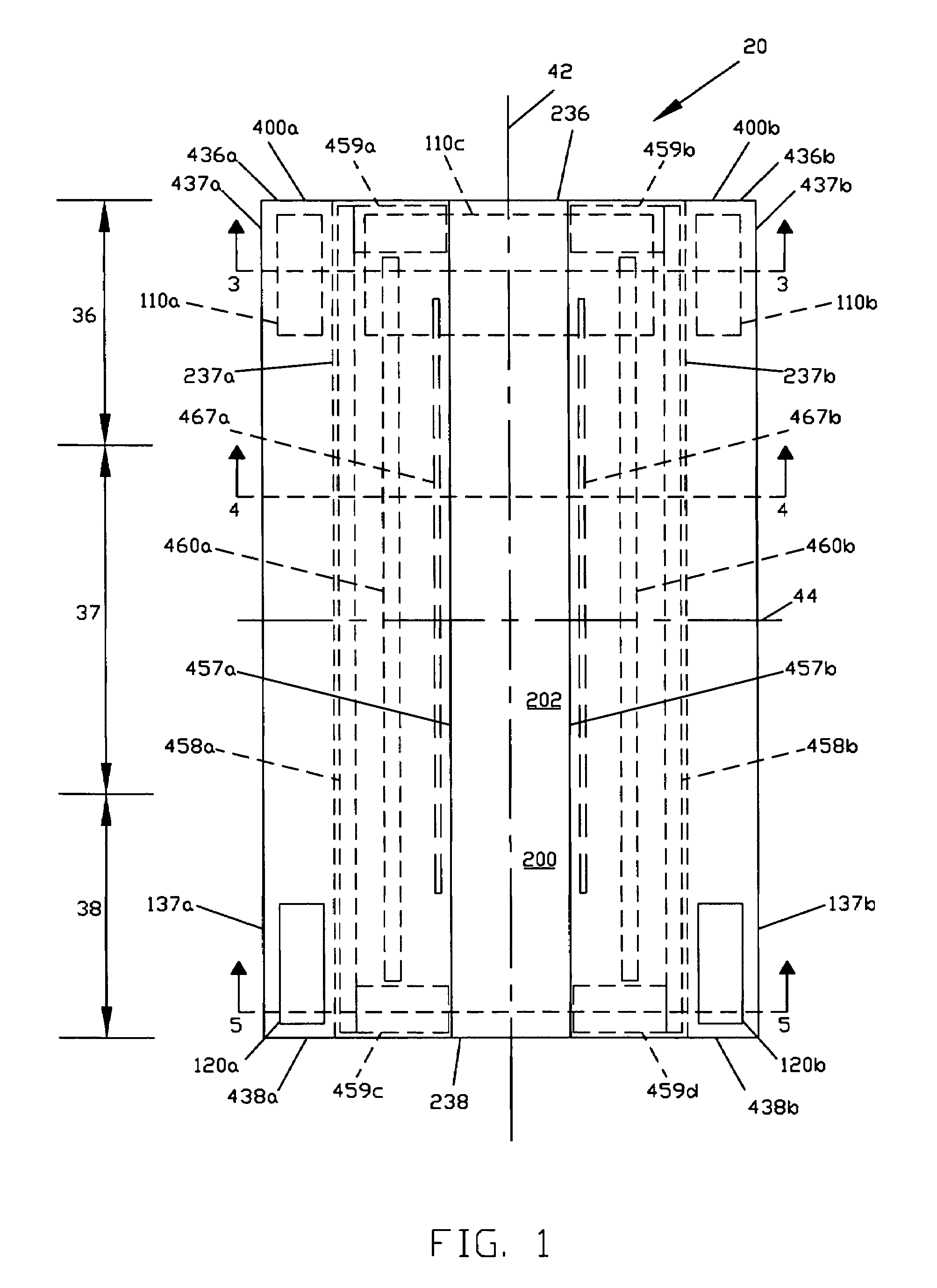

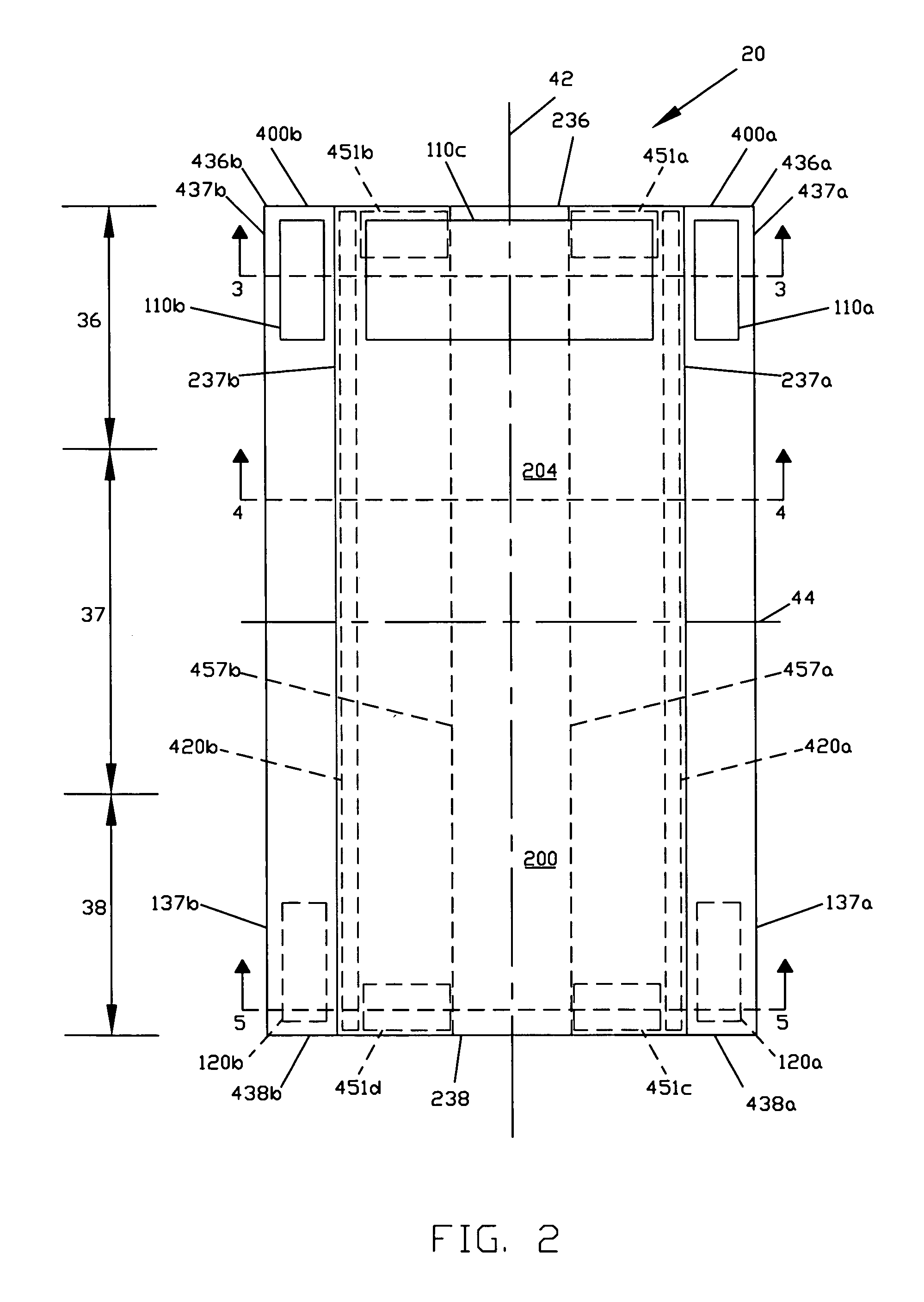

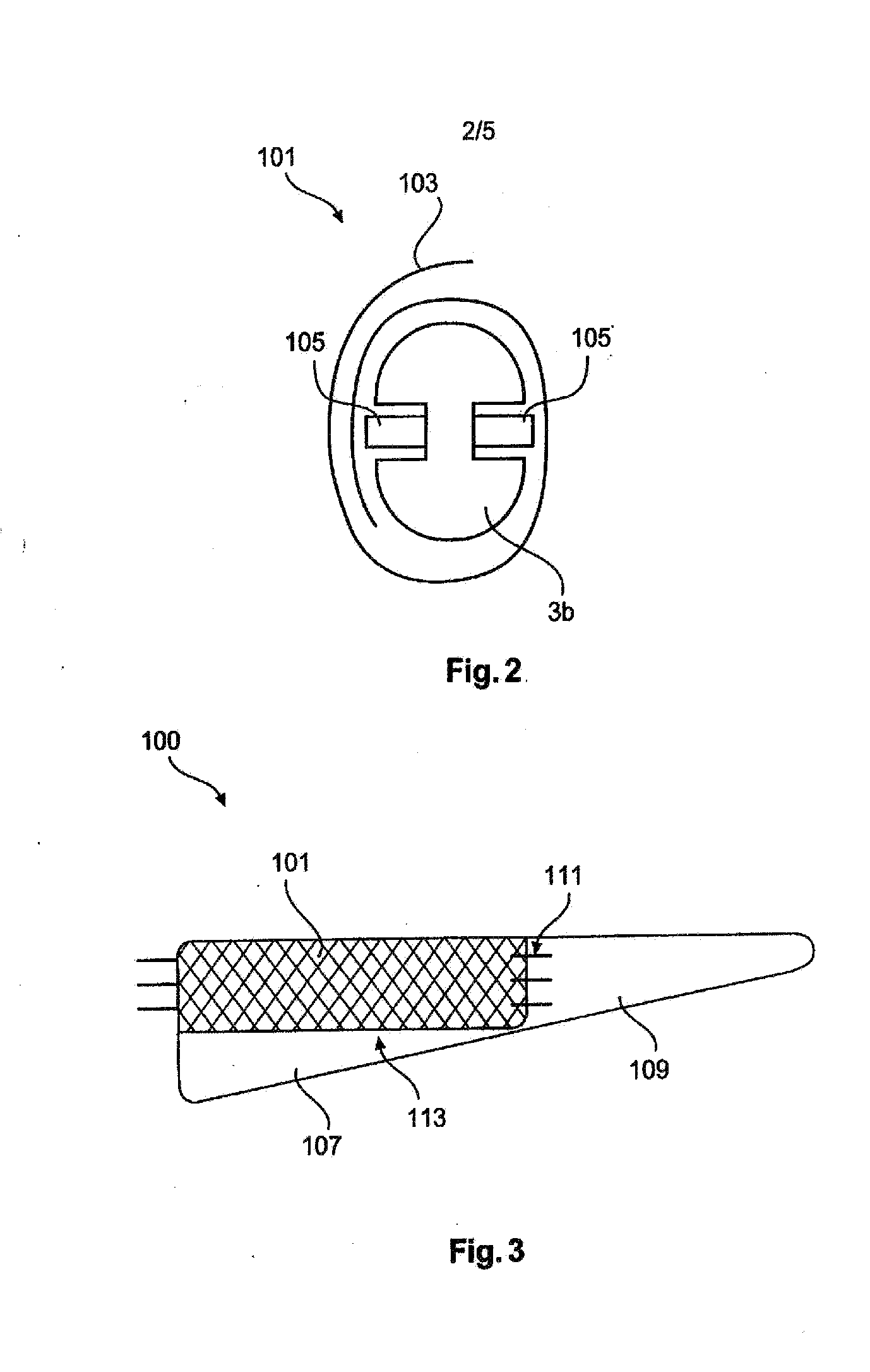

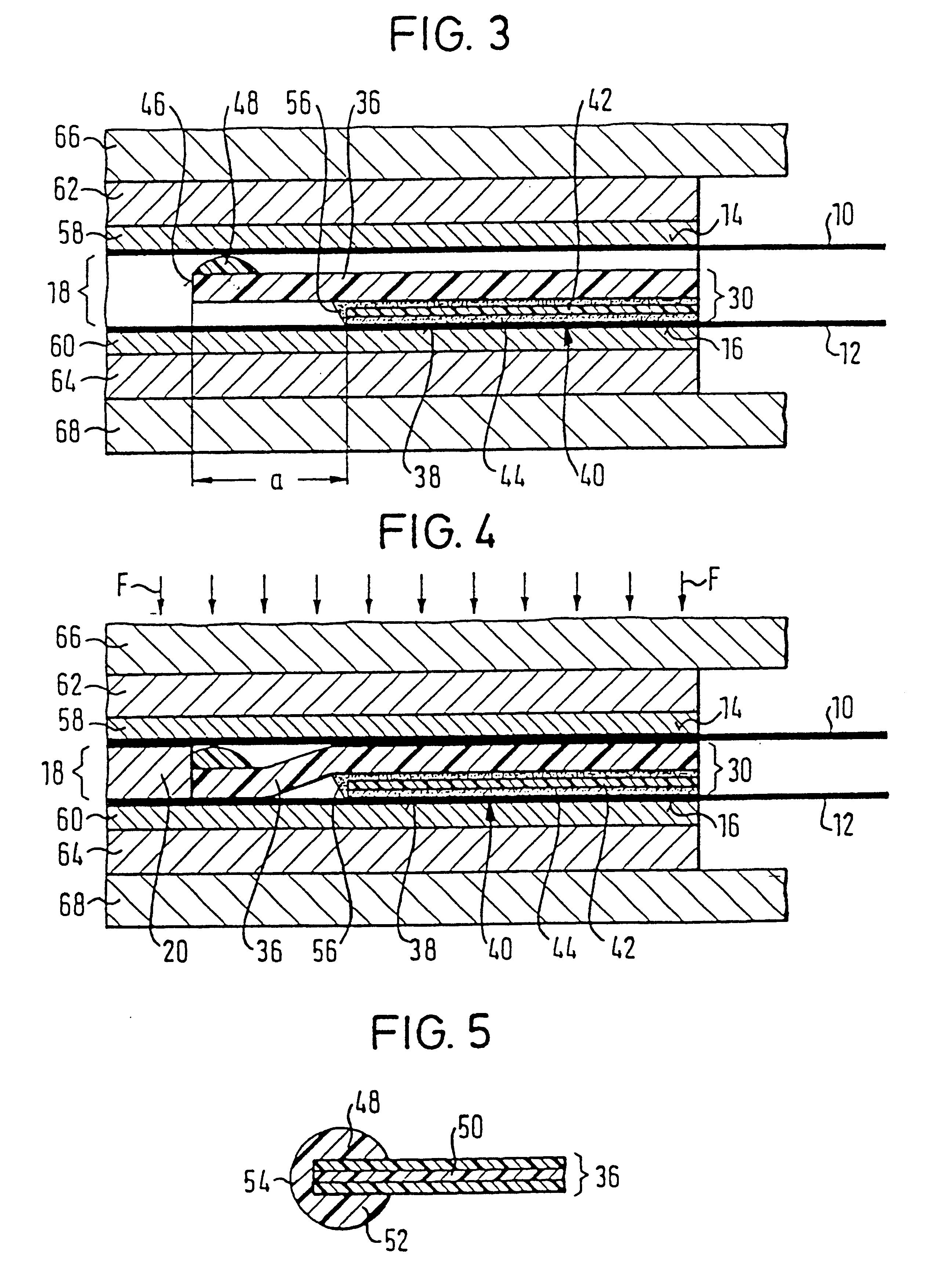

Disposable absorbent article having dual layer barrier cuff strips

A disposable absorbent article includes two laterally opposing longitudinally extending barrier cuff strips attached to an absorbent assembly in laterally opposing attachment zones. Each barrier cuff strip includes an upper layer and a lower layer at least between its proximal edge and the attachment zones. A longitudinally extending elastic gathering member is attached to each barrier cuff strip adjacent to its proximal edge. When the article is worn, the elastic gathering members contract and raise the barrier cuff strips to form side barriers. The absorbent assembly includes an absorbent core that may contain superabsorbent particles, which may be contained inside pockets. A portion of the absorbent assembly such as the portion that lies between the barrier cuff strip attachment zones may be extensible and may include a water-impermeable layer. The laterally opposing attachment zones may act as dams preventing a lateral flow of liquid bodily waste.

Owner:PROCTER & GAMBLE CO

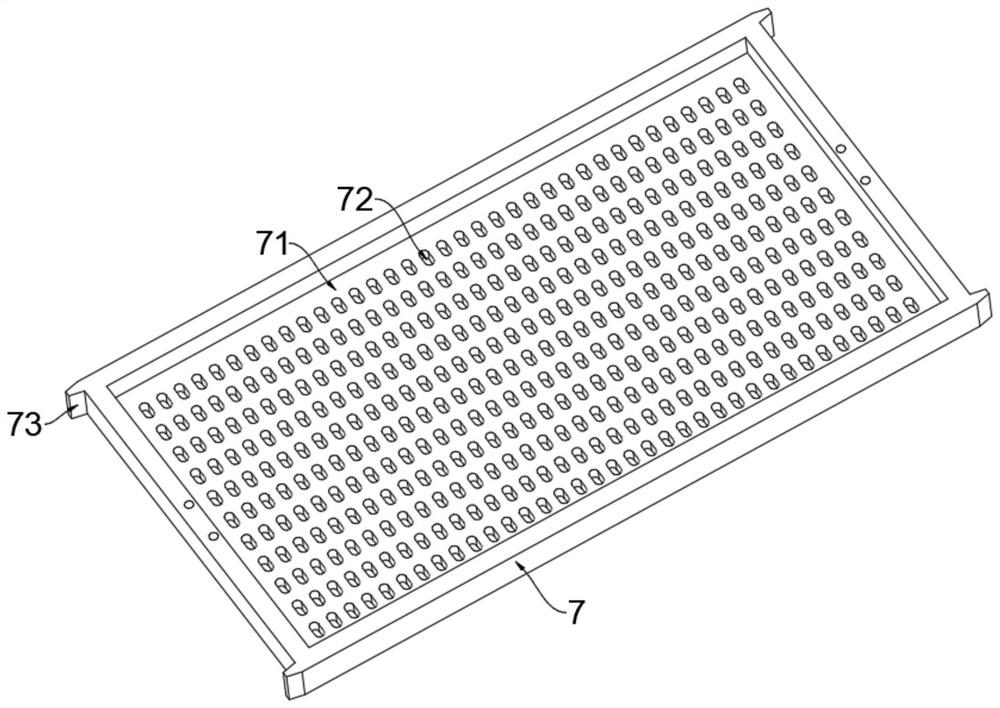

Filter Cleaning Head

InactiveUS20080047885A1Reduce forceReduce widthMembrane filtersLoose filtering material filtersSuspended particlesEngineering

A filtering device has a filter element disposed between the inlet and the outlet of the device. The inlet surface of the filter element is prone to clogging by suspended particles, e.g. waste, carried with the incoming raw fluid. The invention provides a cleaning head for the filtering device, comprising a basis and a nozzle movably mounted thereon. The cleaning head basis is mounted on a driving mechanism so that the nozzle can scan the inlet surface parallel thereto, and can clean the inlet surface by means of a backwash flow passing through the filter element into the nozzle under a cleaning pressure differential created by connecting the nozzle to a low-pressure outlet. The nozzle maintains, during scanning, permanent contact with the inlet surface so that lateral flow directly into the nozzle is essentially prevented despite variations of distance between the cleaning head basis and the inlet surface during the scanning.

Owner:ARKAL FILTRATION SYST C S

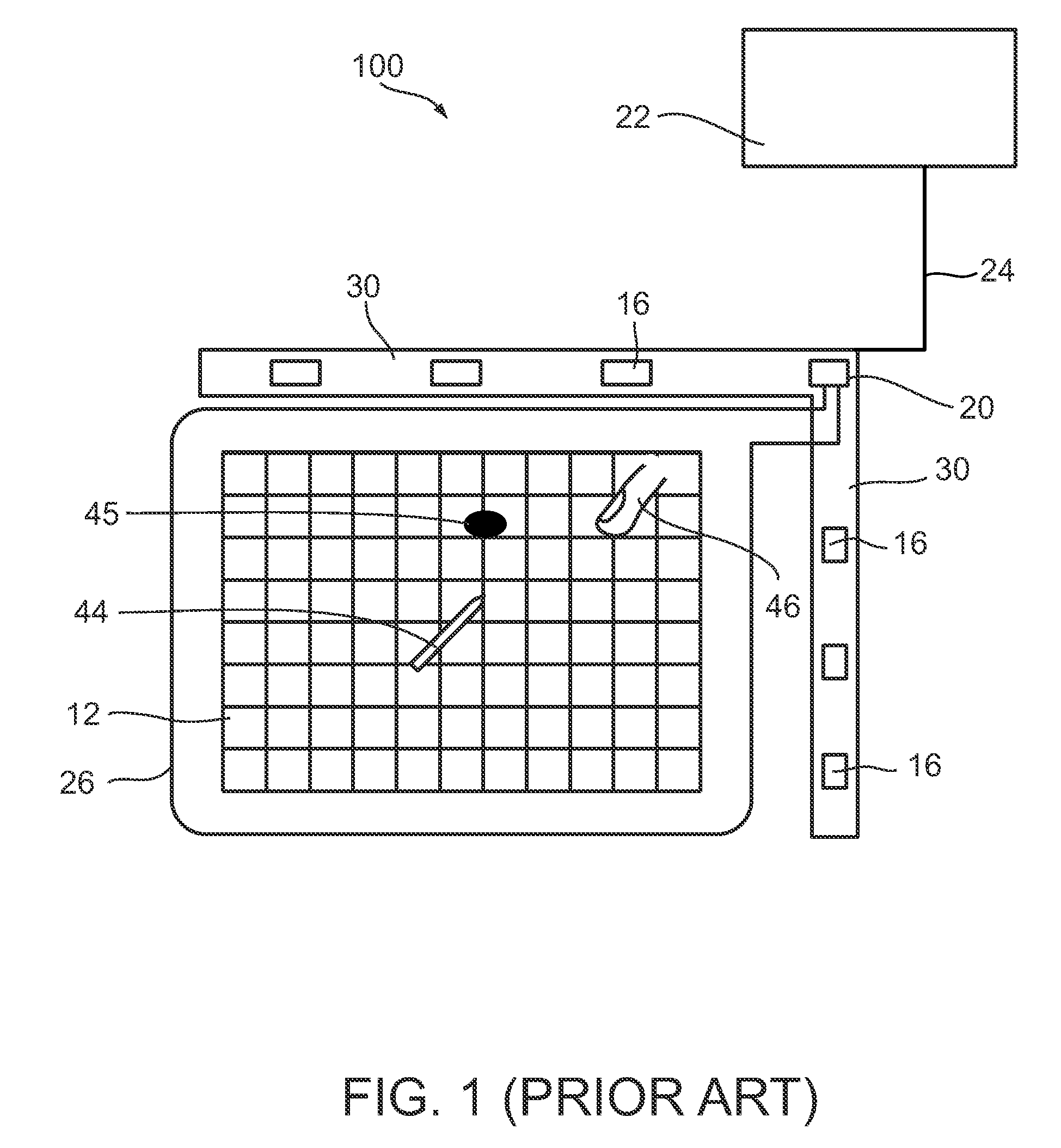

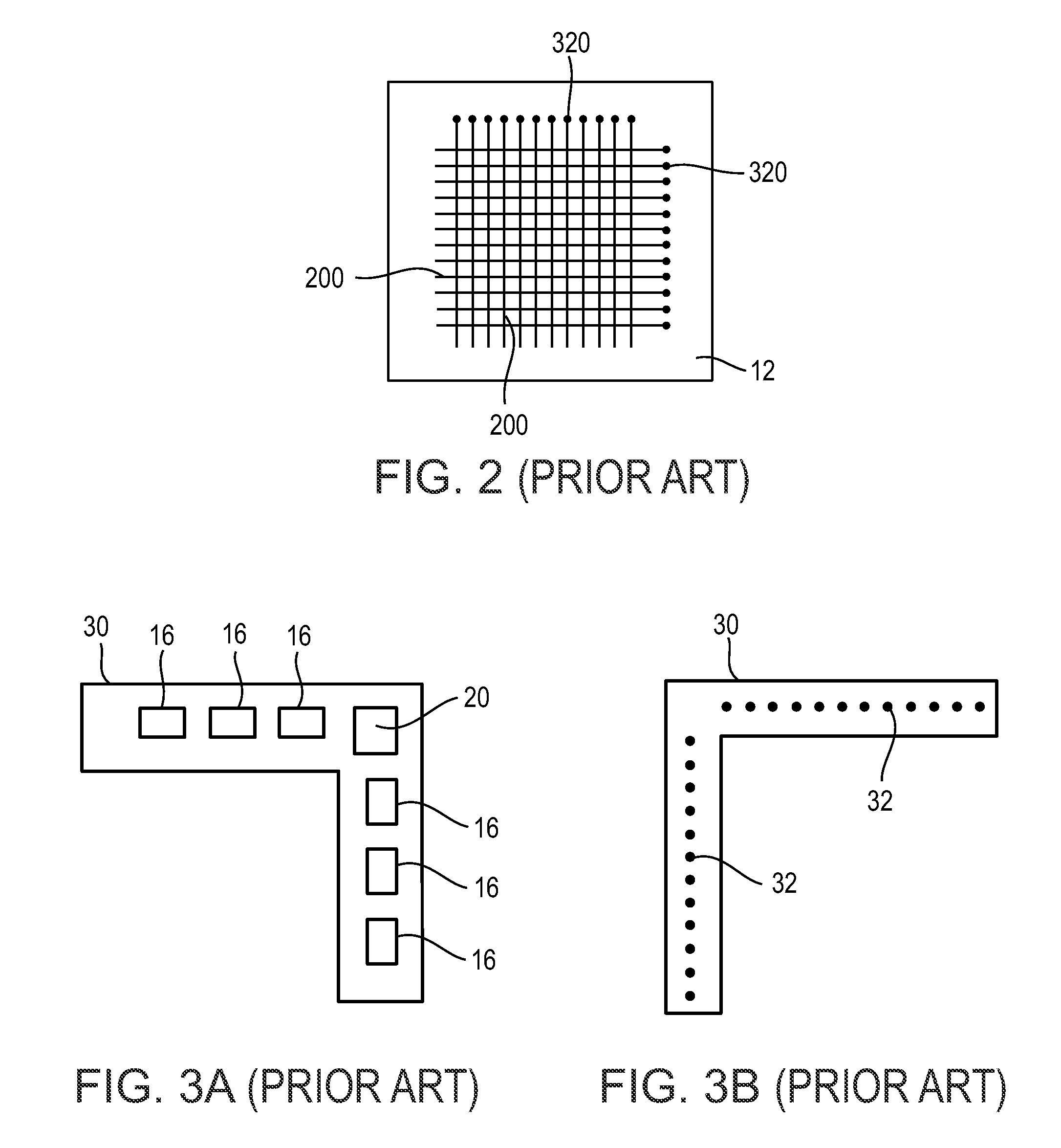

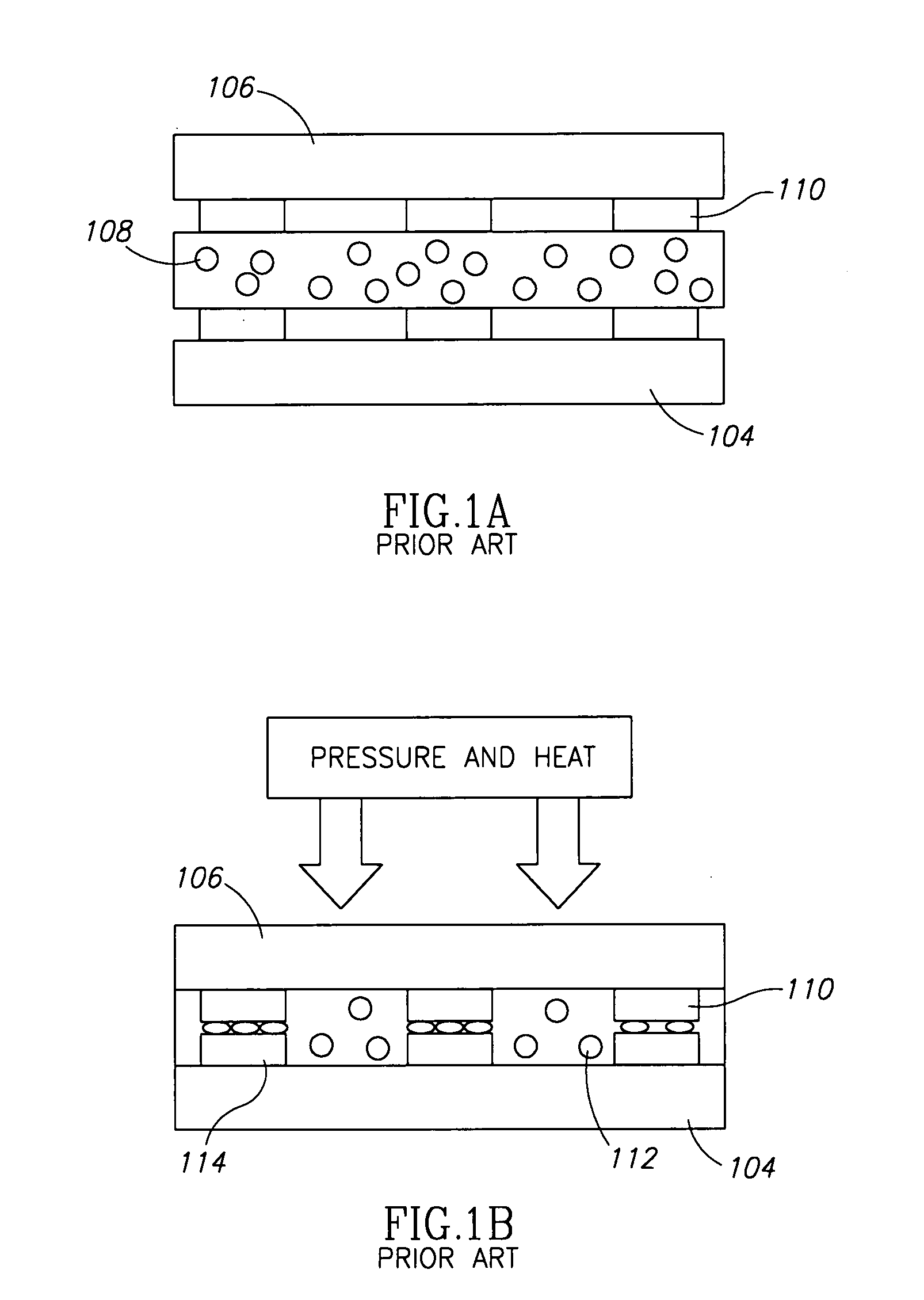

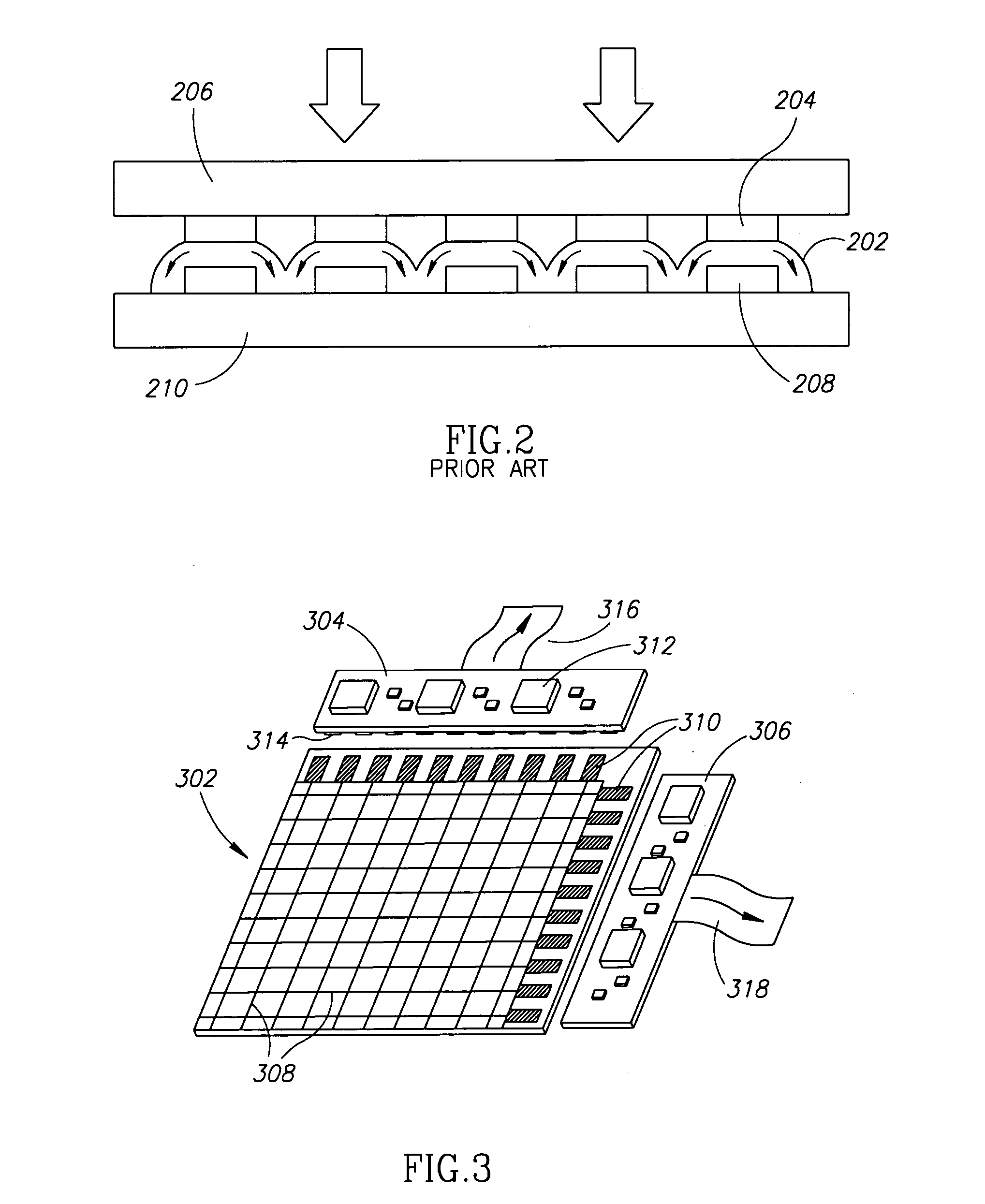

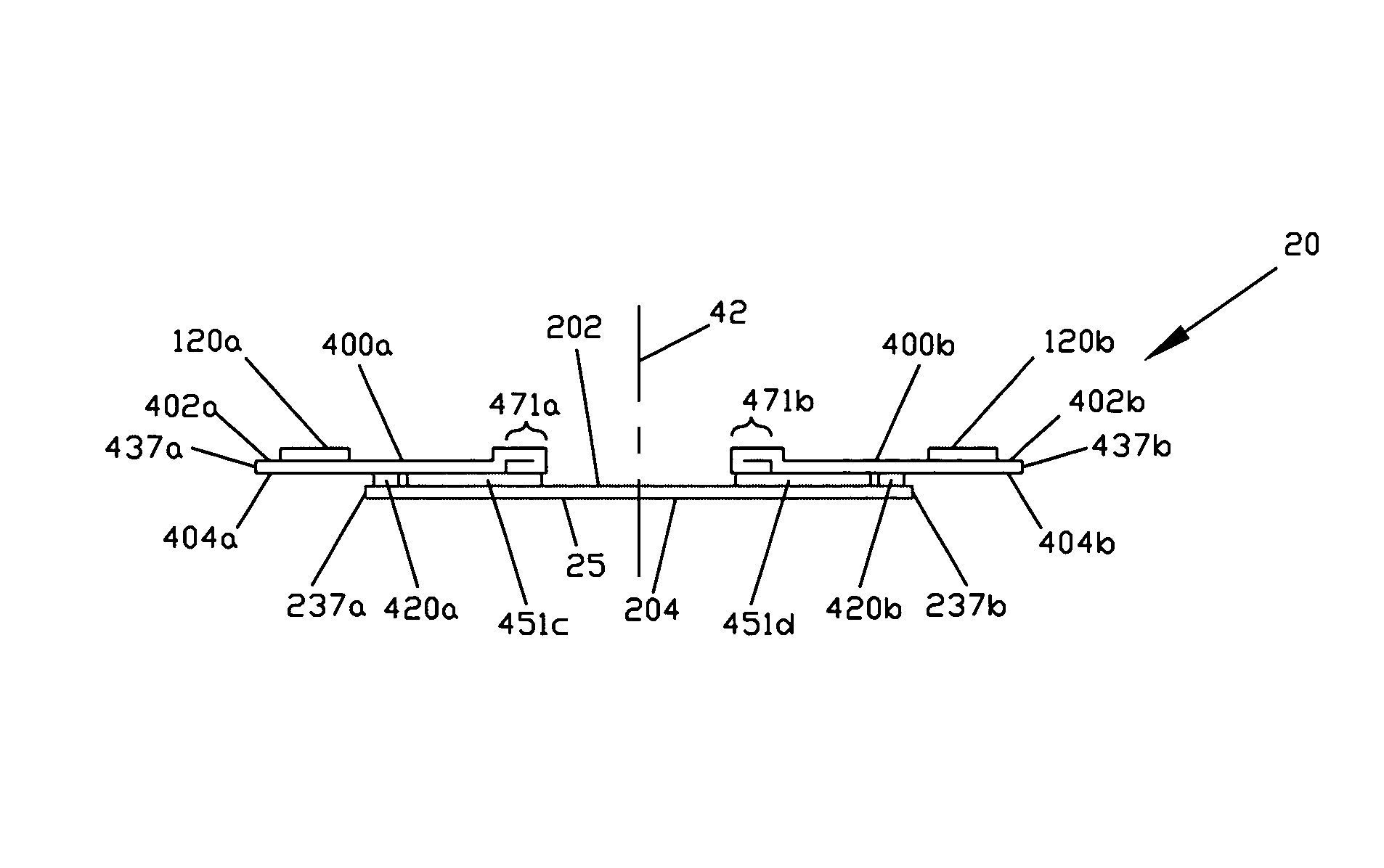

Method for assembling a digitizer sensor

A digitizer assembly includes a transparent sensor patterned with conductive elements within at least one layer, a PCB or the like patterned with conductive elements positioned along at least one edge of the transparent sensor, wherein the conductive elements at least partially match the conductive elements on the transparent sensor, and a double sided adhesive positioned between the transparent sensor and the PCB operative to mount the PCB on to the transparent sensor.

Owner:N TRIG

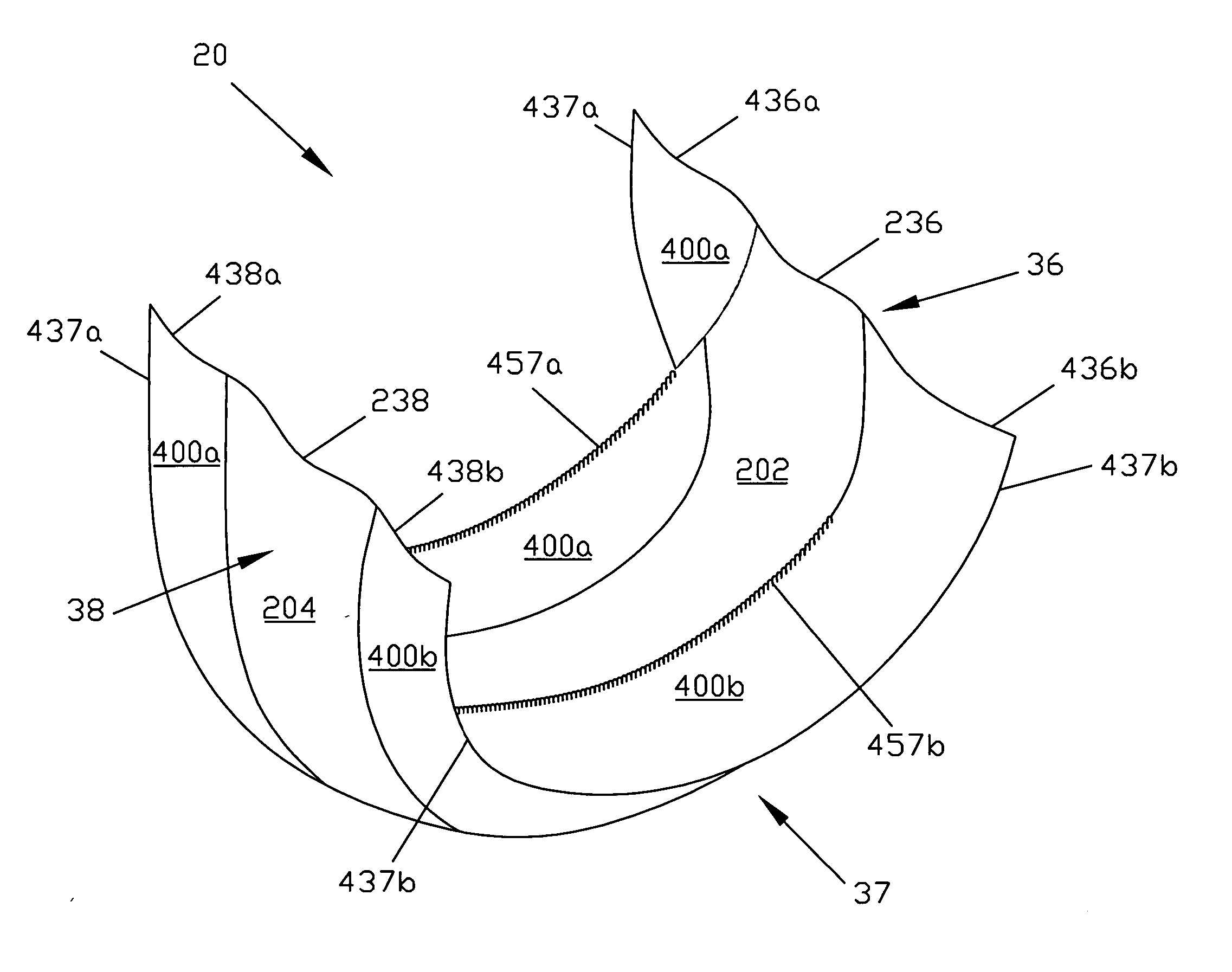

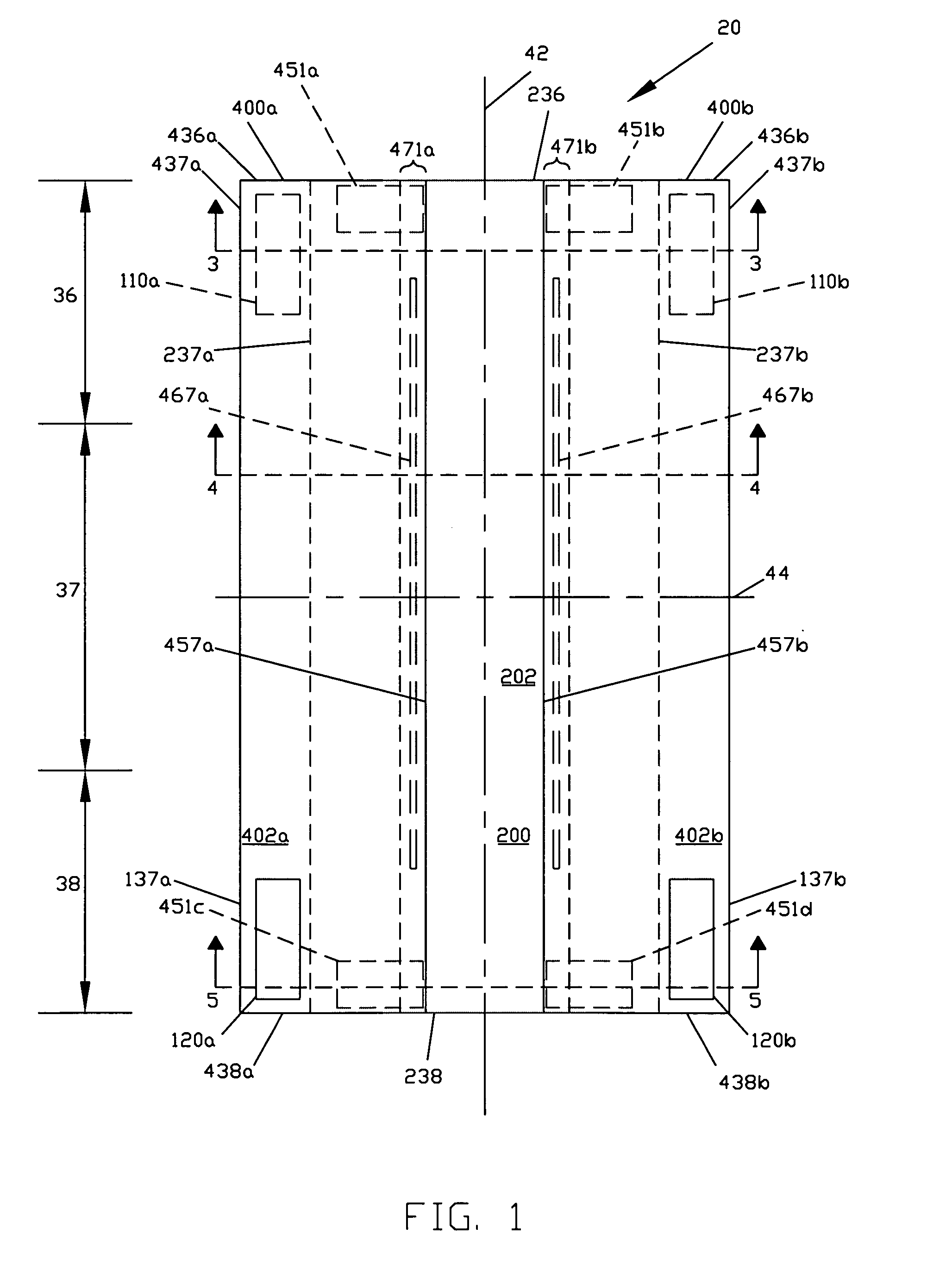

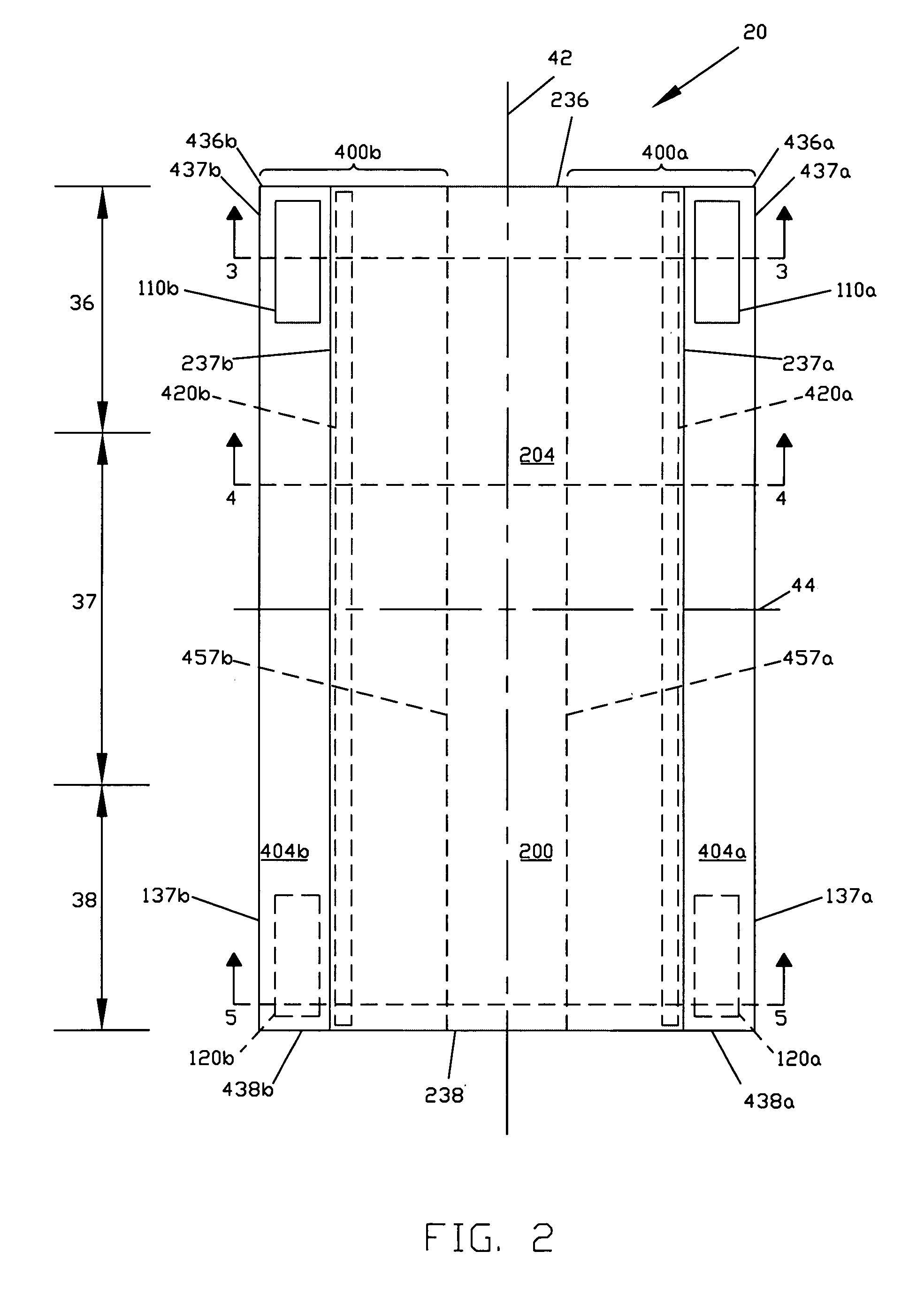

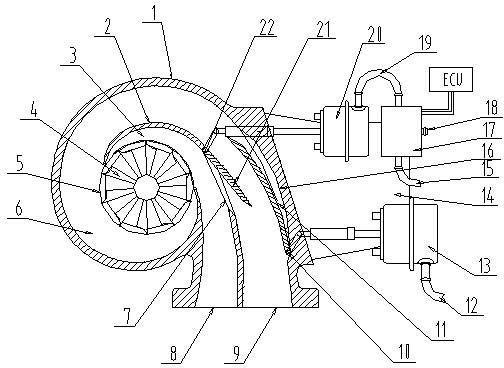

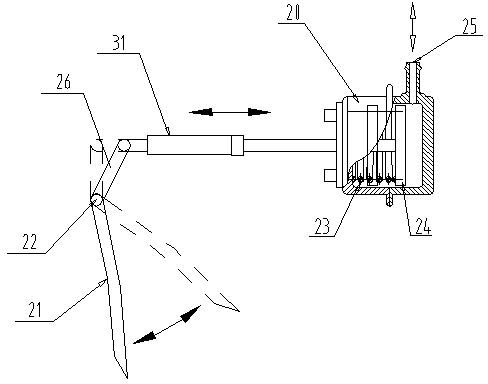

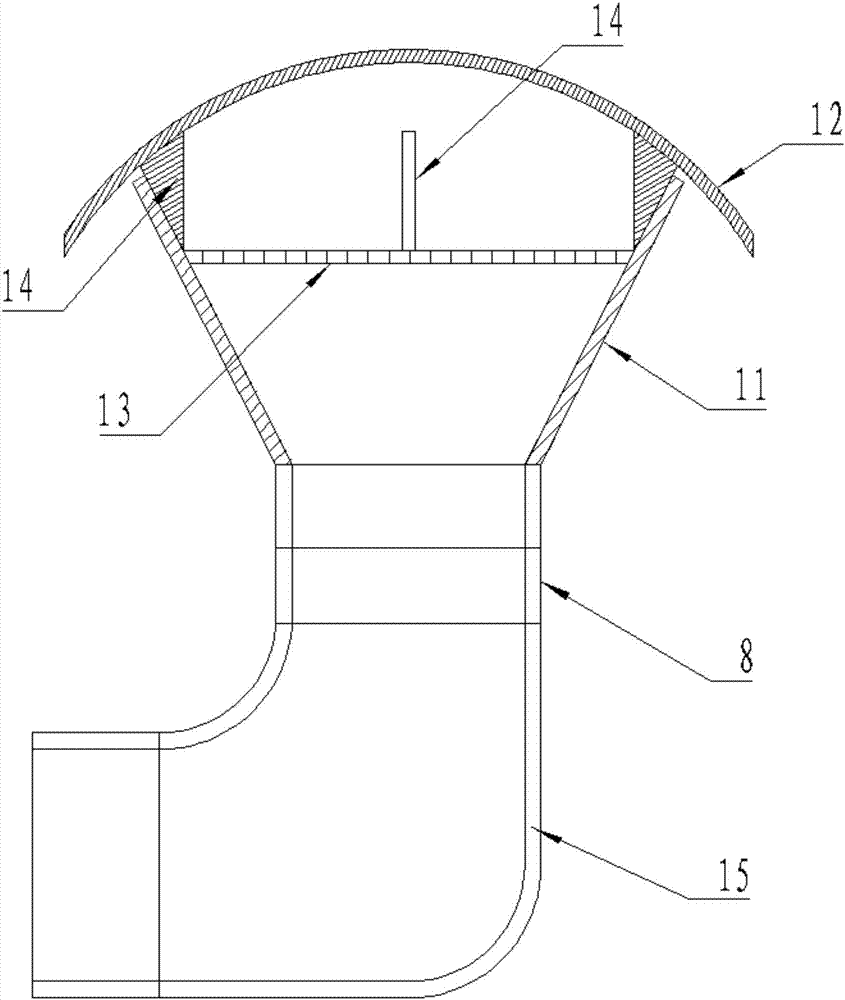

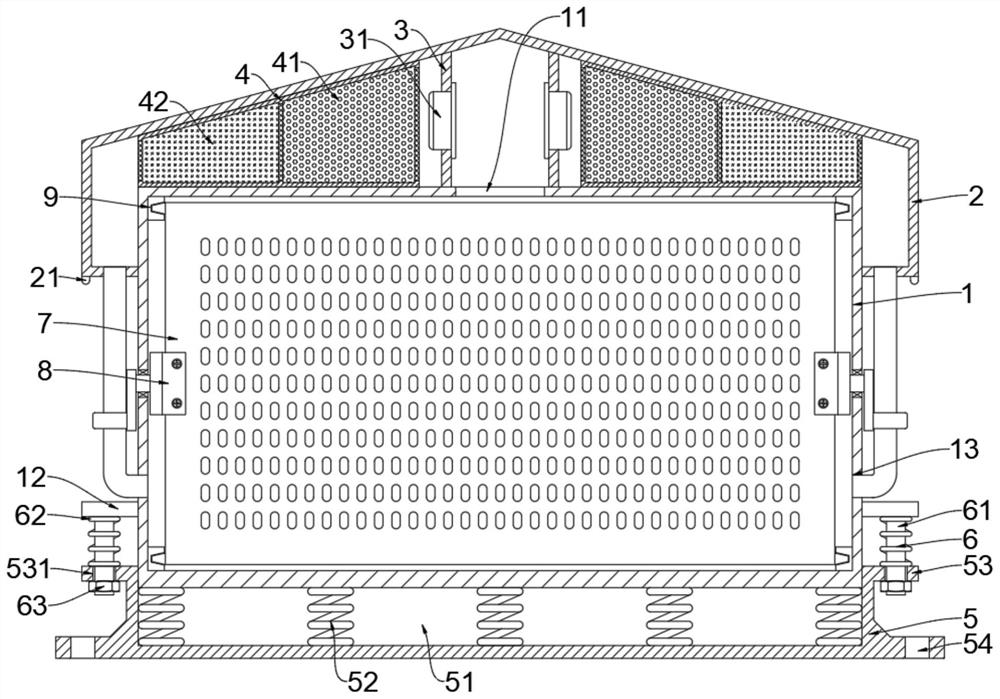

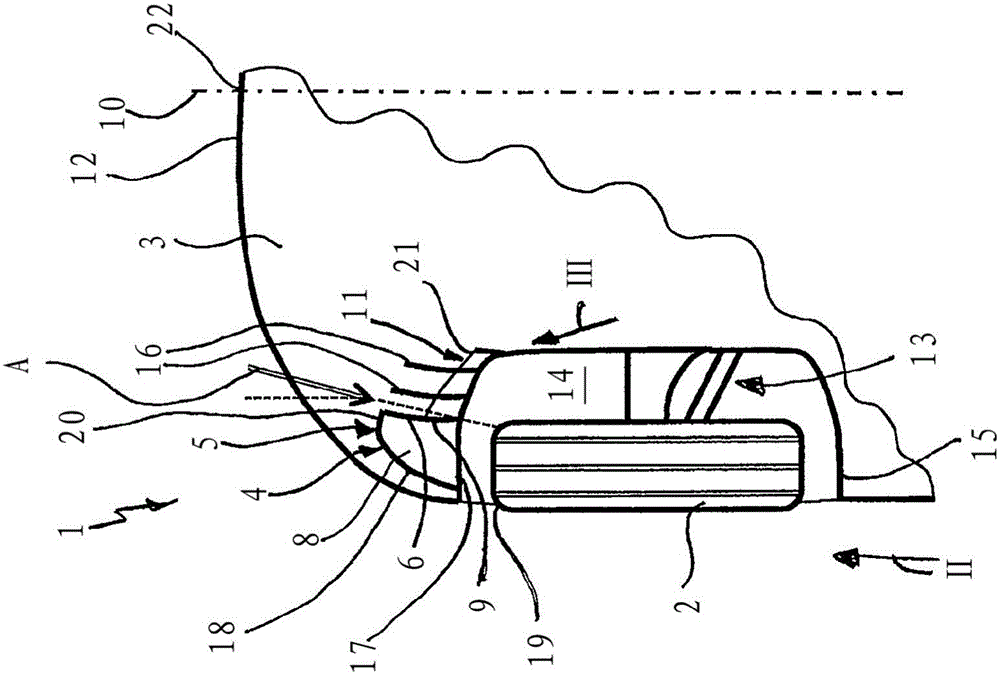

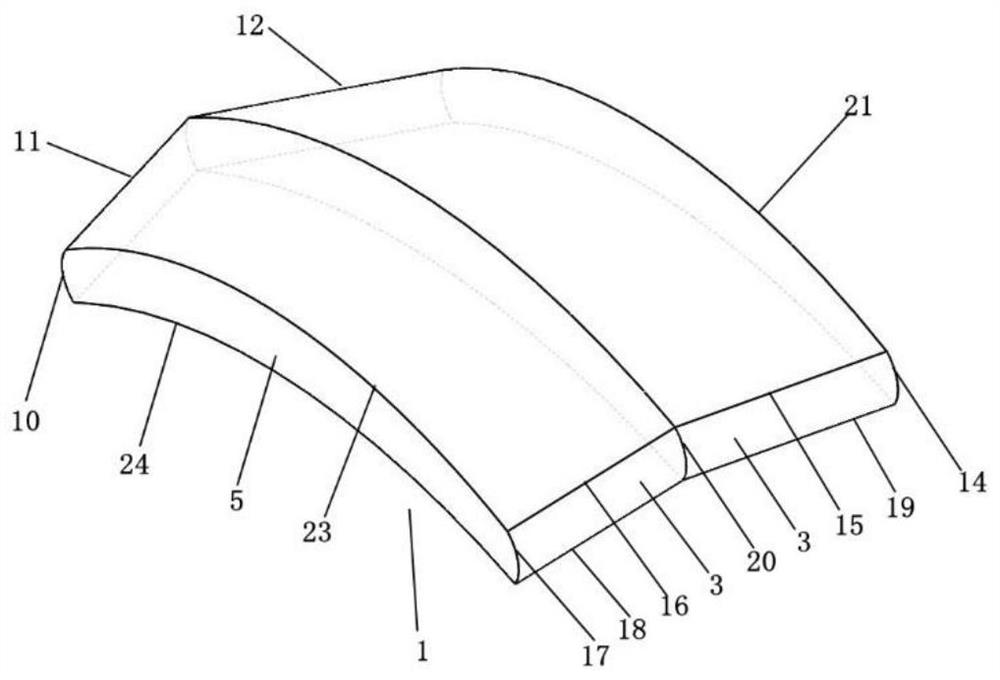

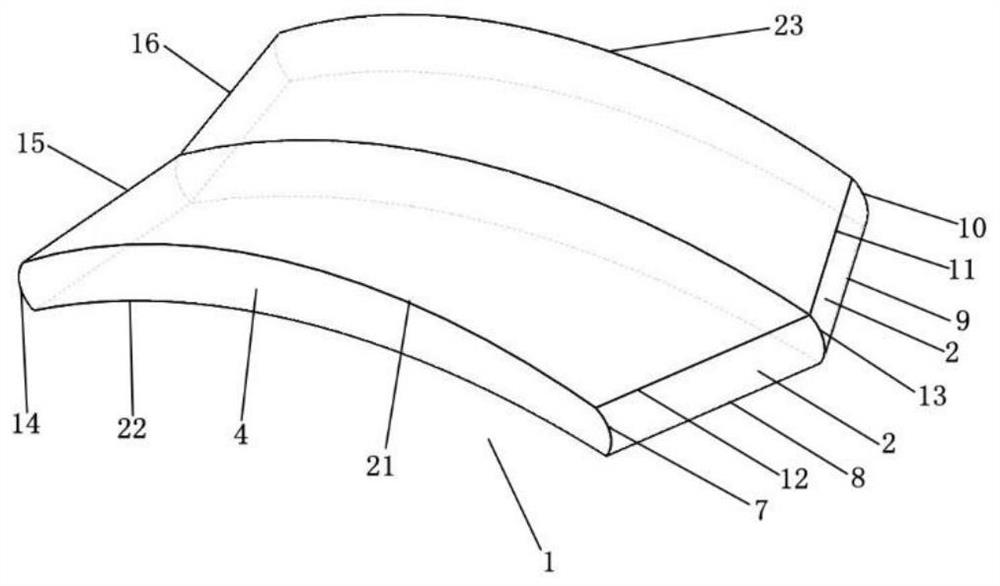

Staged flow-adjustable turbine shell

ActiveCN102536433AAvoid lateral flowReduce flow frictionInternal combustion piston enginesEngine componentsLow speedInlet flow

The invention discloses a staged flow-adjustable turbine shell, which comprises a turbine shell body. A turbine assembly and a waste gas inlet flow channel are mounted in the turbine shell body; an air inlet which is communicated with the waste gas inlet flow channel is arranged on the turbine shell body; an intermediate wall is disposed in the waste gas inlet flow channel and divides the waste gas inlet flow channel into an inner flow channel and an outer flow channel; a first valve device which can close the outer flow channel is disposed in the outer flow channel; and the intermediate wall is provided with a second valve device which can realize connection or disconnection of the inner flow channel and the outer flow channel. Waste gas energy is utilized sufficiently, rotation speed of a turbine rotor is increased, air inlet quantity of an engine in low speed work conditions is improved, so that the engine can apply more work, low speed torsion of the engine is increased, the low speed torque of the engine well matches with the low speed work conditions of the engine, and dynamic property and transient responsibility of the engine in low speed work conditions are improved.

Owner:康跃科技(山东)有限公司

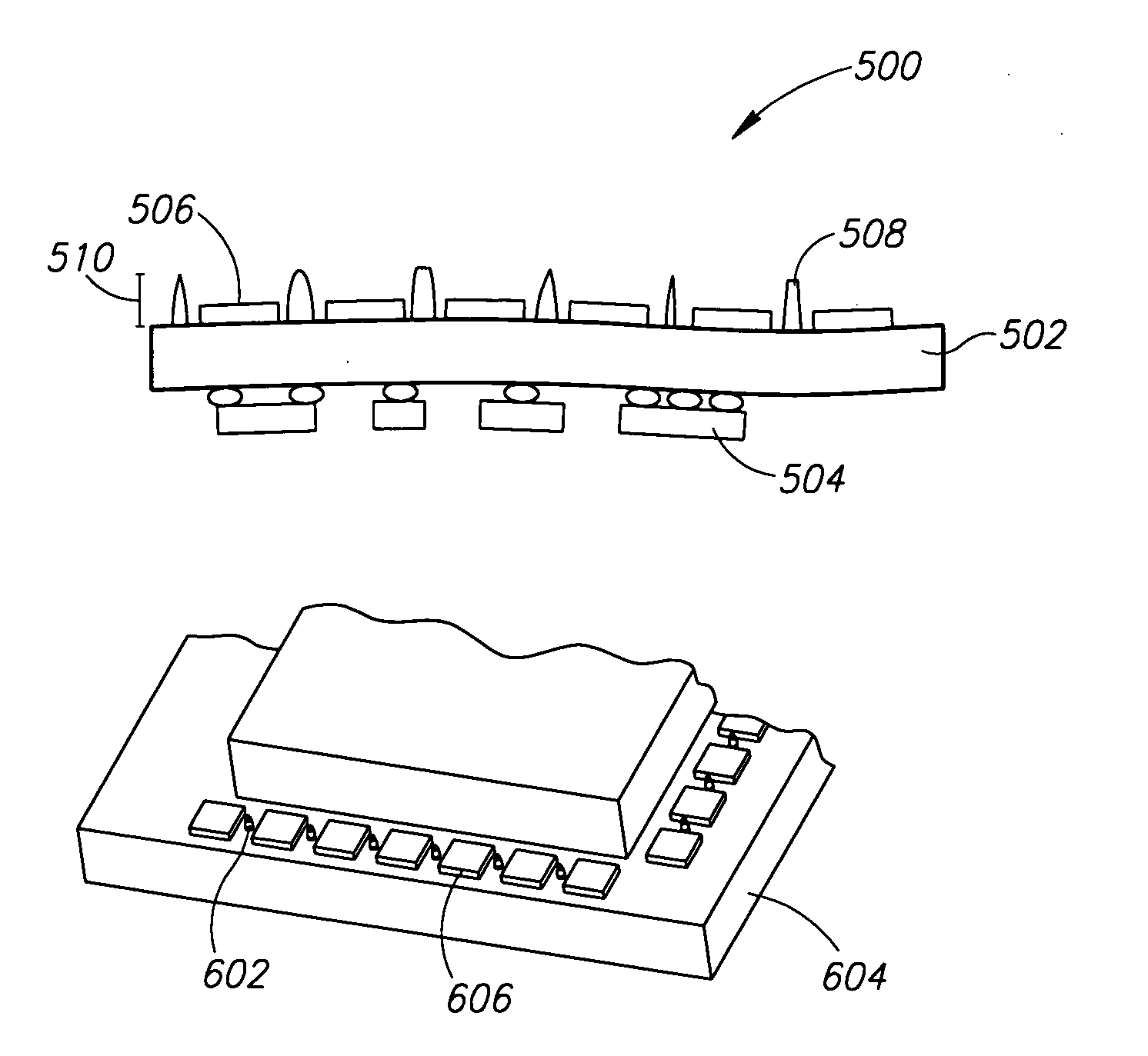

Methods for Manufacturing a Sensor Assembly

ActiveUS20070292983A1Reduce riskAvoiding any lateral conductancePrinted circuit assemblingElectrically conductive connectionsEngineeringConductive materials

Owner:MICROSOFT TECH LICENSING LLC

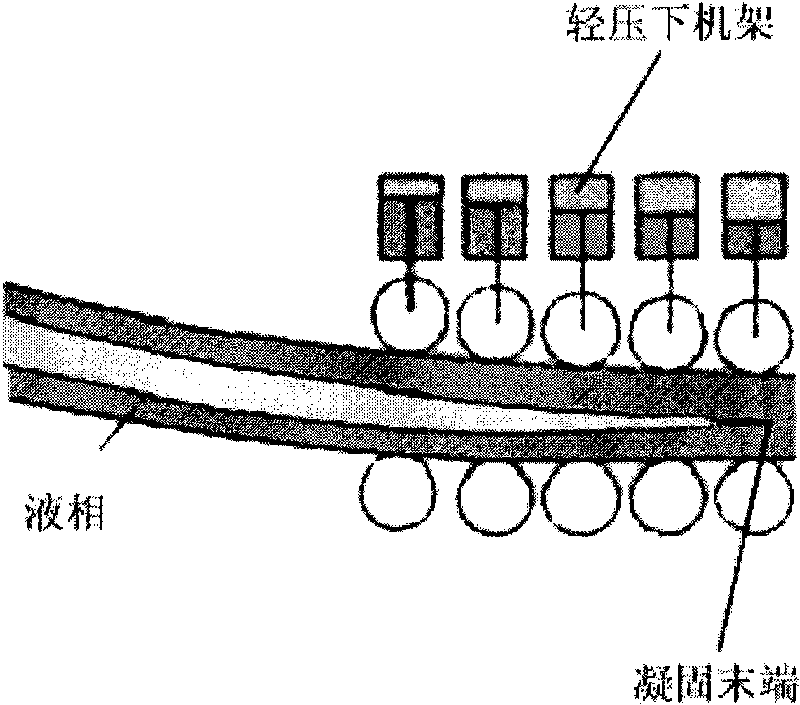

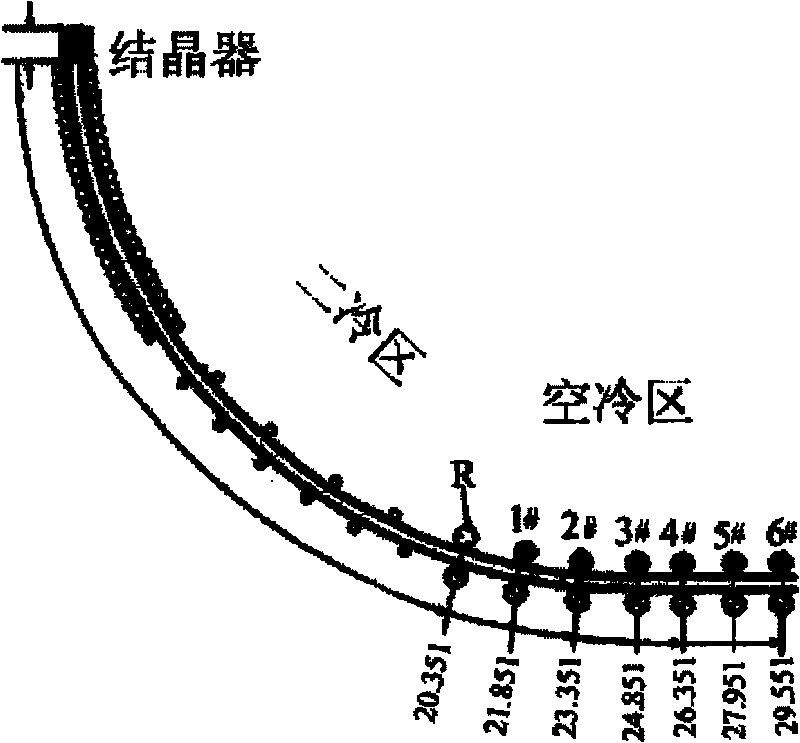

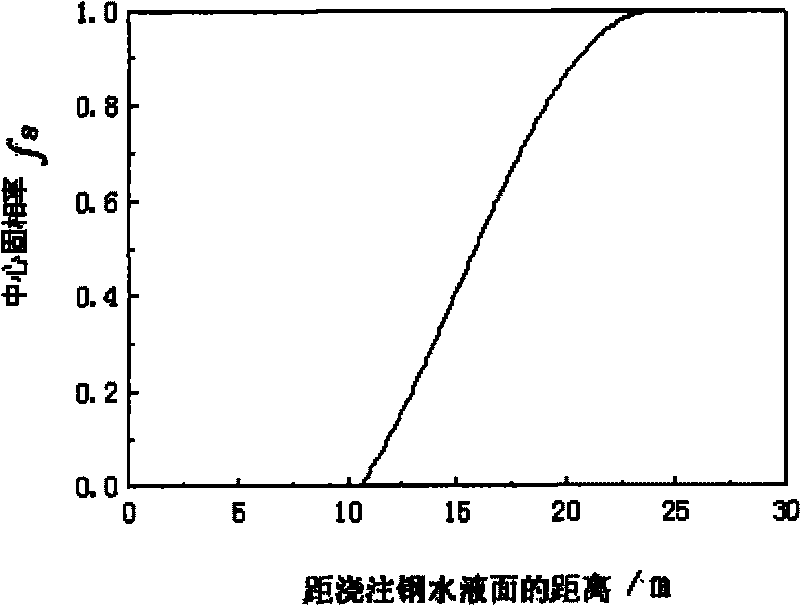

Axle steel continuous casting method

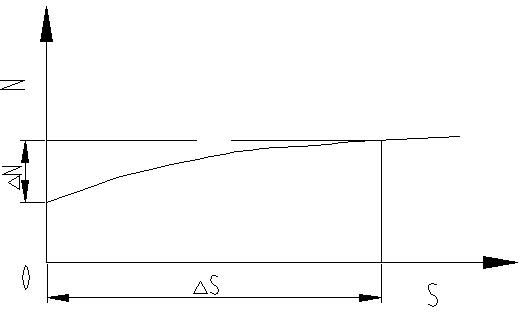

The invention relates to an axle steel continuous casting method. The method comprises the following steps of: pouring molten steel to a crystallizer from a pouring box to form an axle steel casting blank which is not fully solidified; and then withdrawing the axle steel casting blank which is not fully solidified from the crystallizer at a withdrawing speed v and sequentially going through a secondary cooling zone and an air cooling zone to obtain a fully solidified axle steel casting blank. The method also comprises a soft press process for utilizing at least one of the plurality of soft press stands sequentially arranged on the air cooling zone to perform soft reduction on the axle steel casting blank which is not fully solidified, and the central solid fraction fs of the axle steel casting blank which is not fully solidified in the soft press process is kept at 0.2 to 0.95. Soft press is carried out on the axle steel casting blank which is not fully solidified with the central solid fraction of 0.2 to 0.95, internal gaps formed by casting blank shrinkage can be eliminated or reduced to prevent the intergranular solute-enriched molten steel from laterally flowing to a casting blank center, and the intergranular solute- enriched molten steel of a liquid phase center is induced to flow along the opposite direction of the blanking withdrawing direction, solute elements are redistributed in the molten steel, and the center segregation is improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

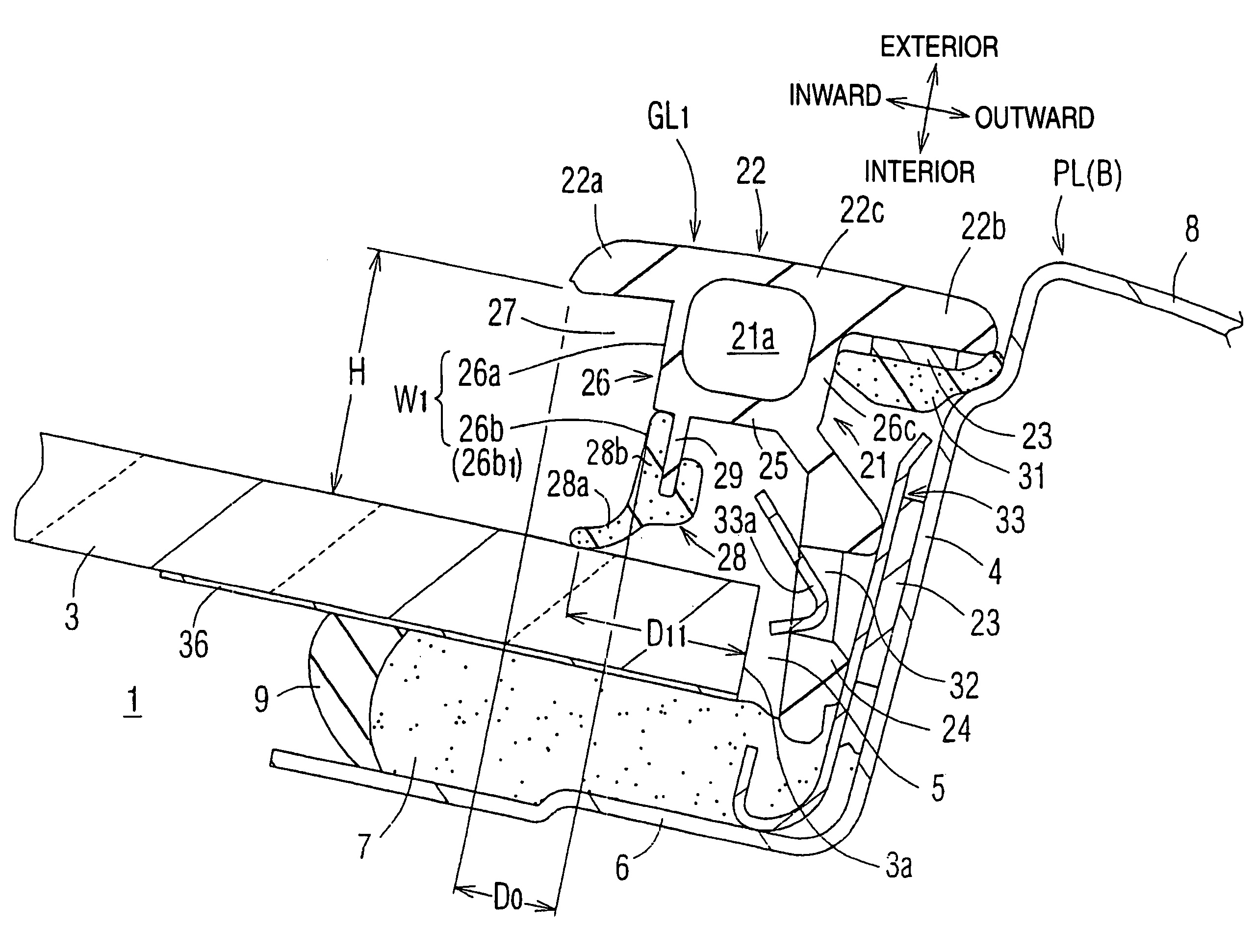

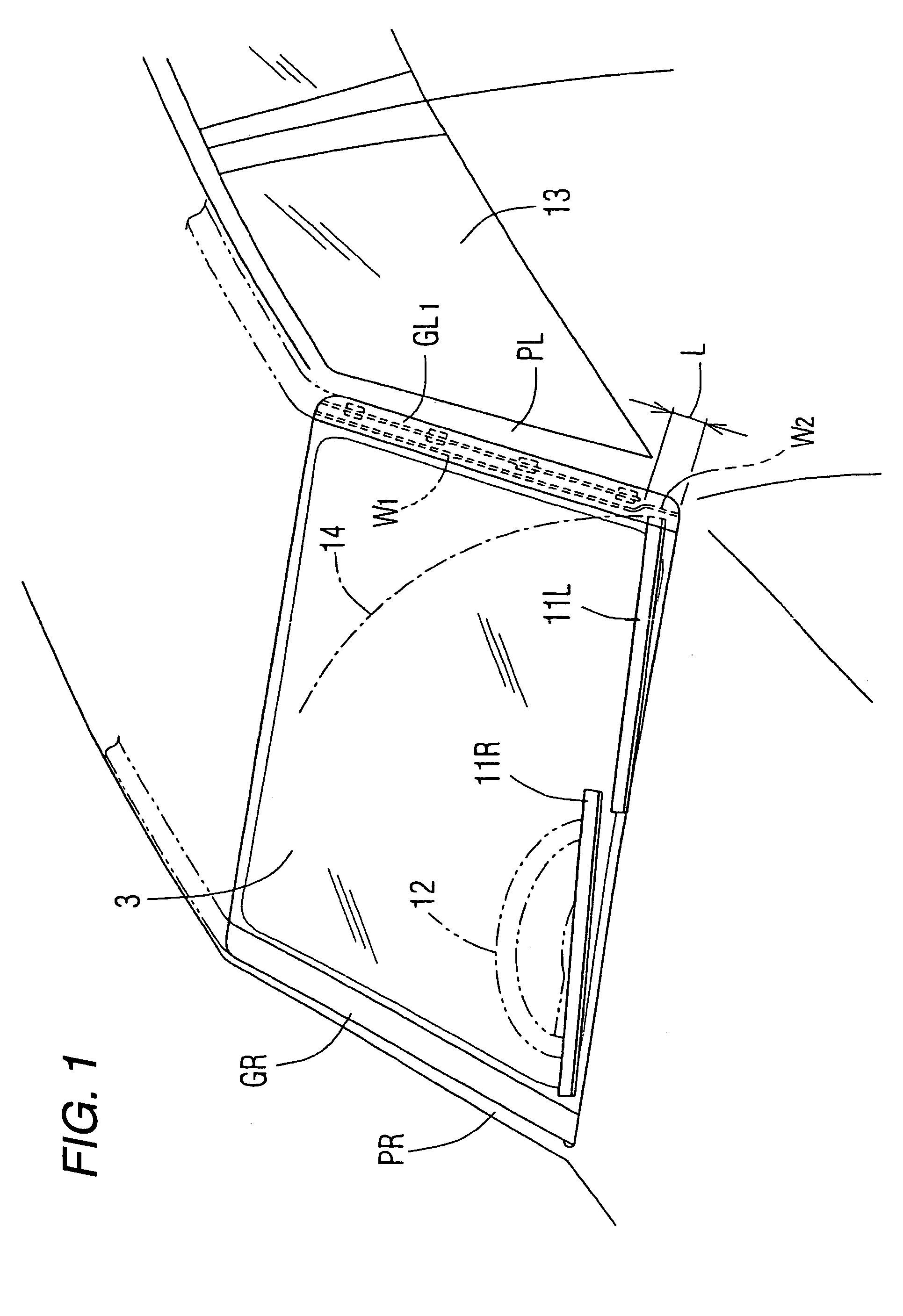

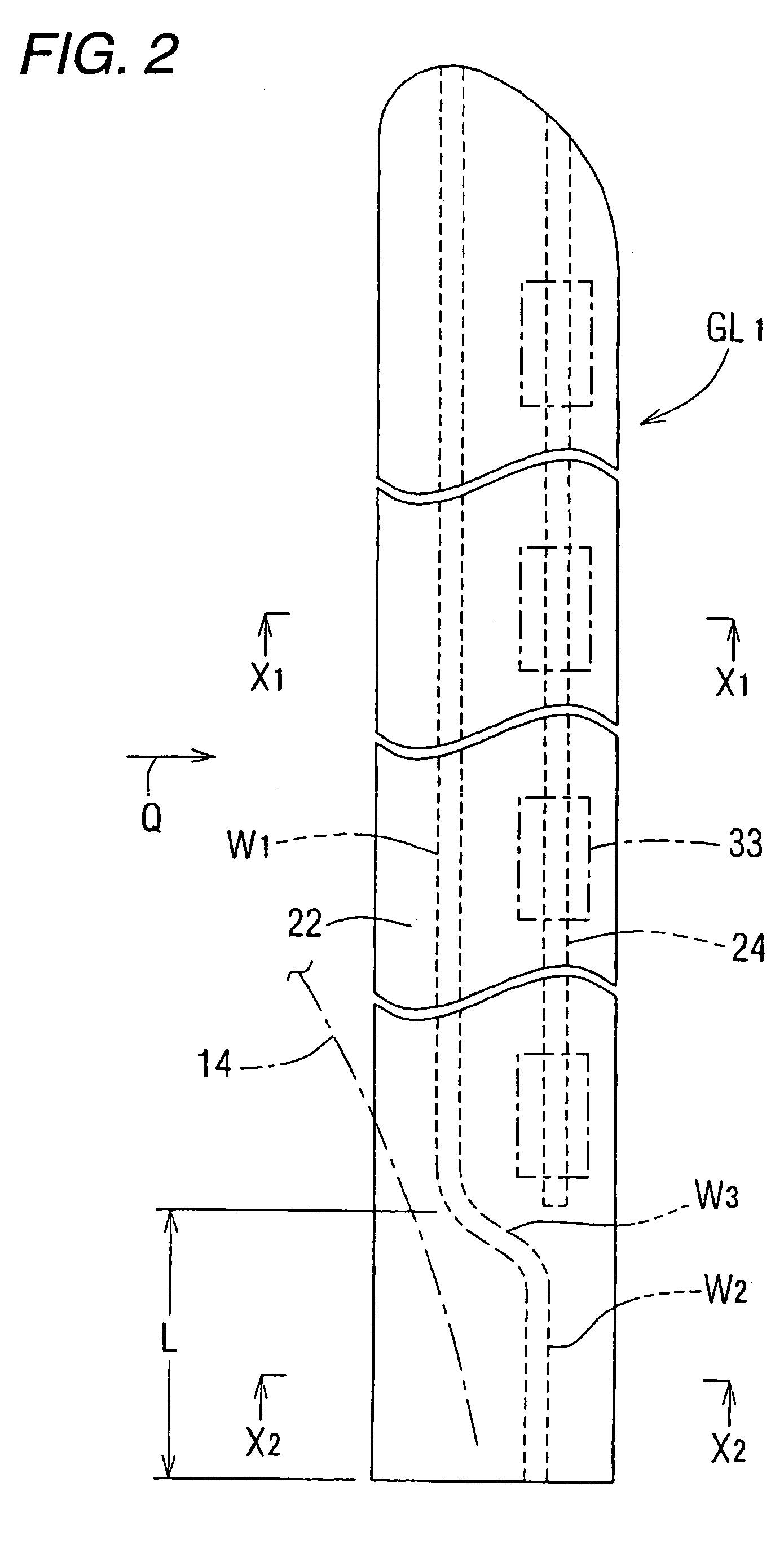

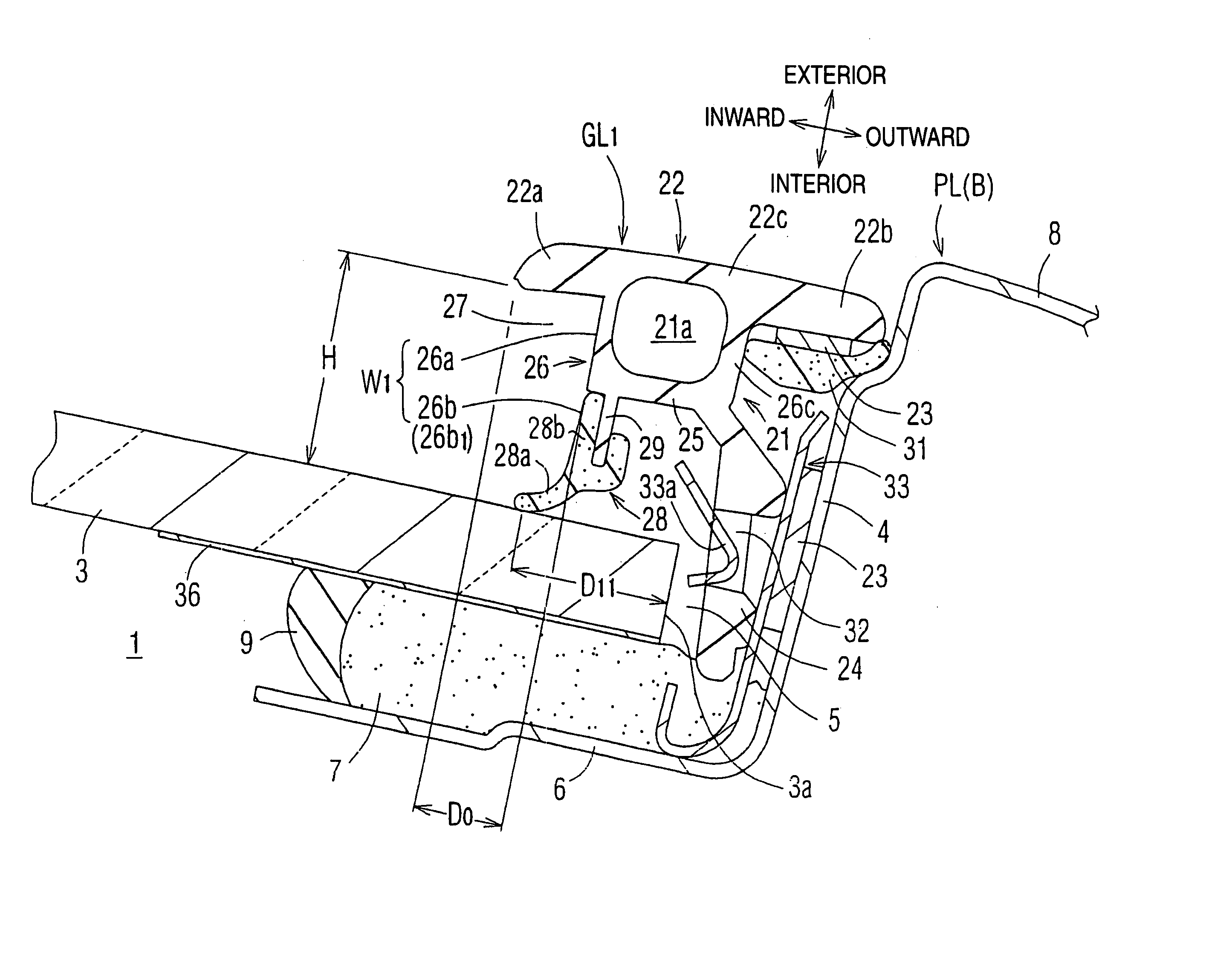

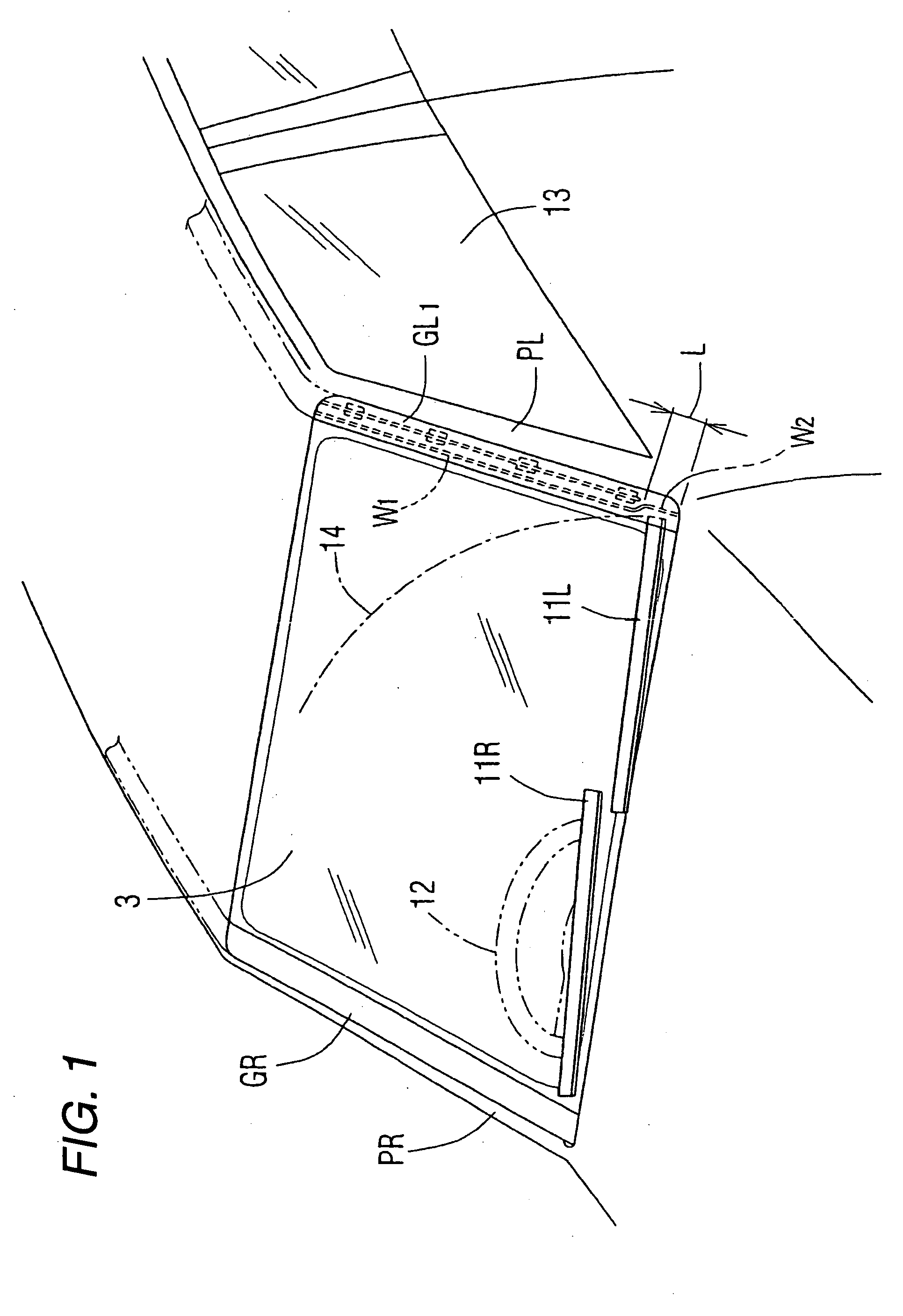

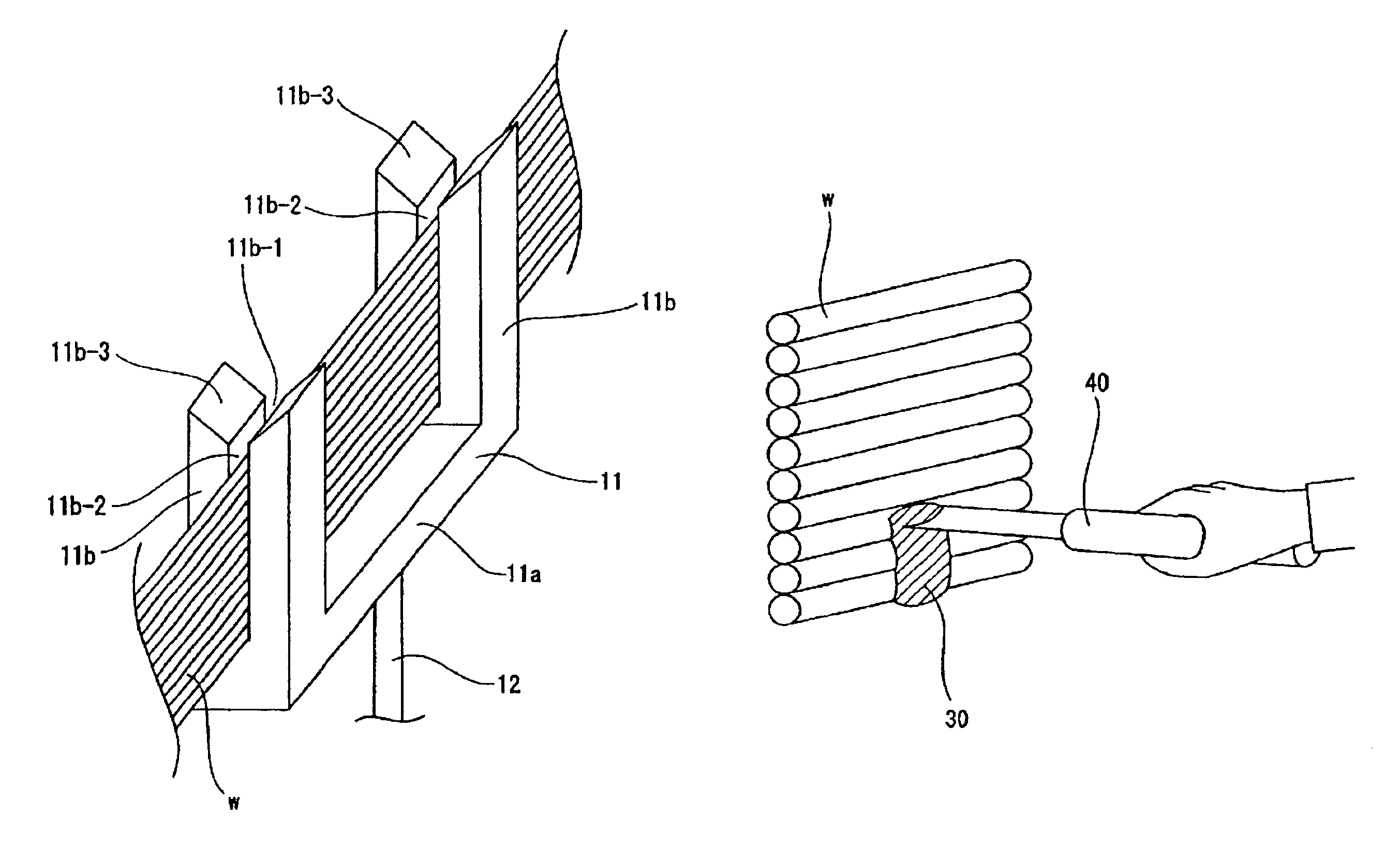

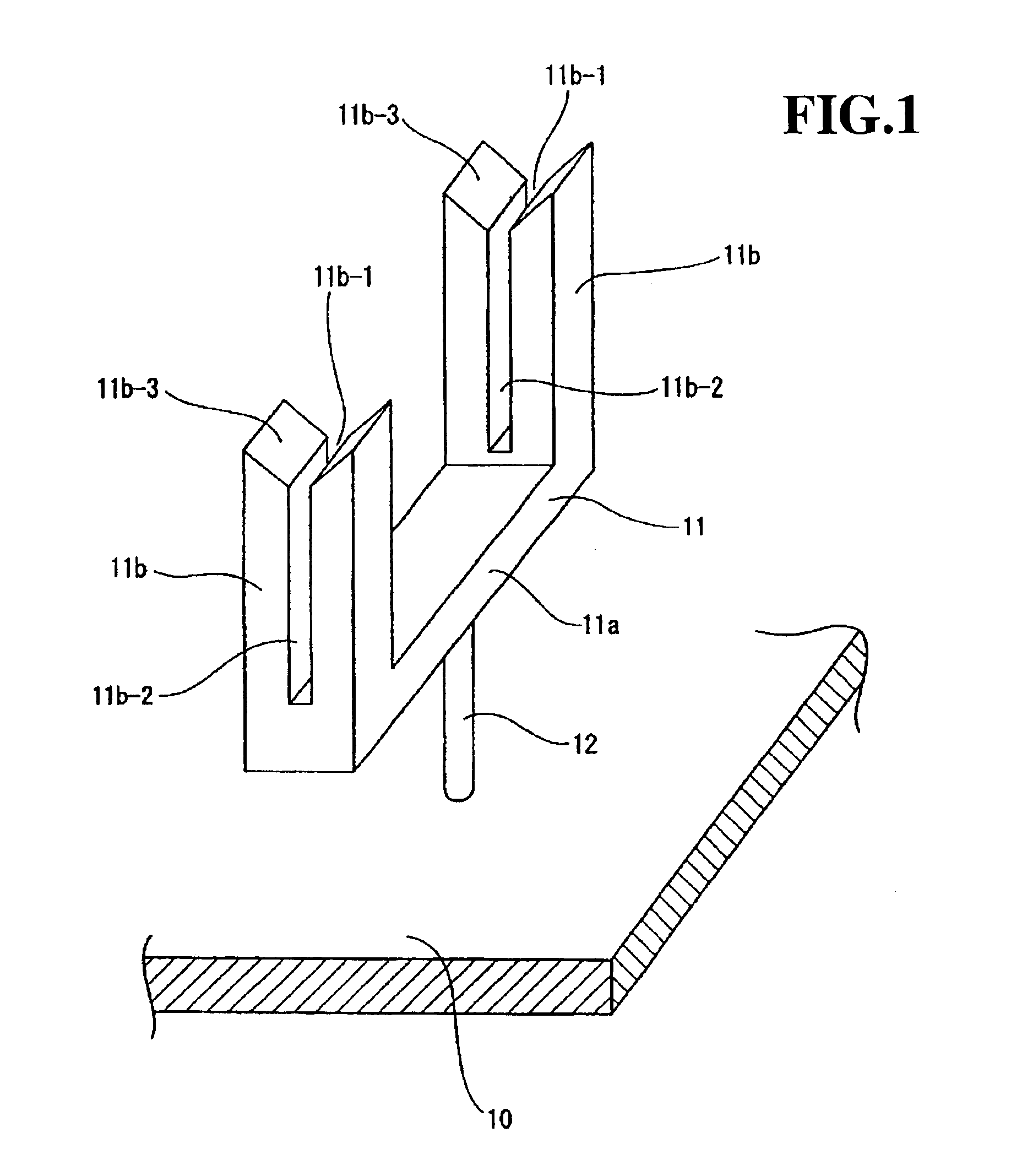

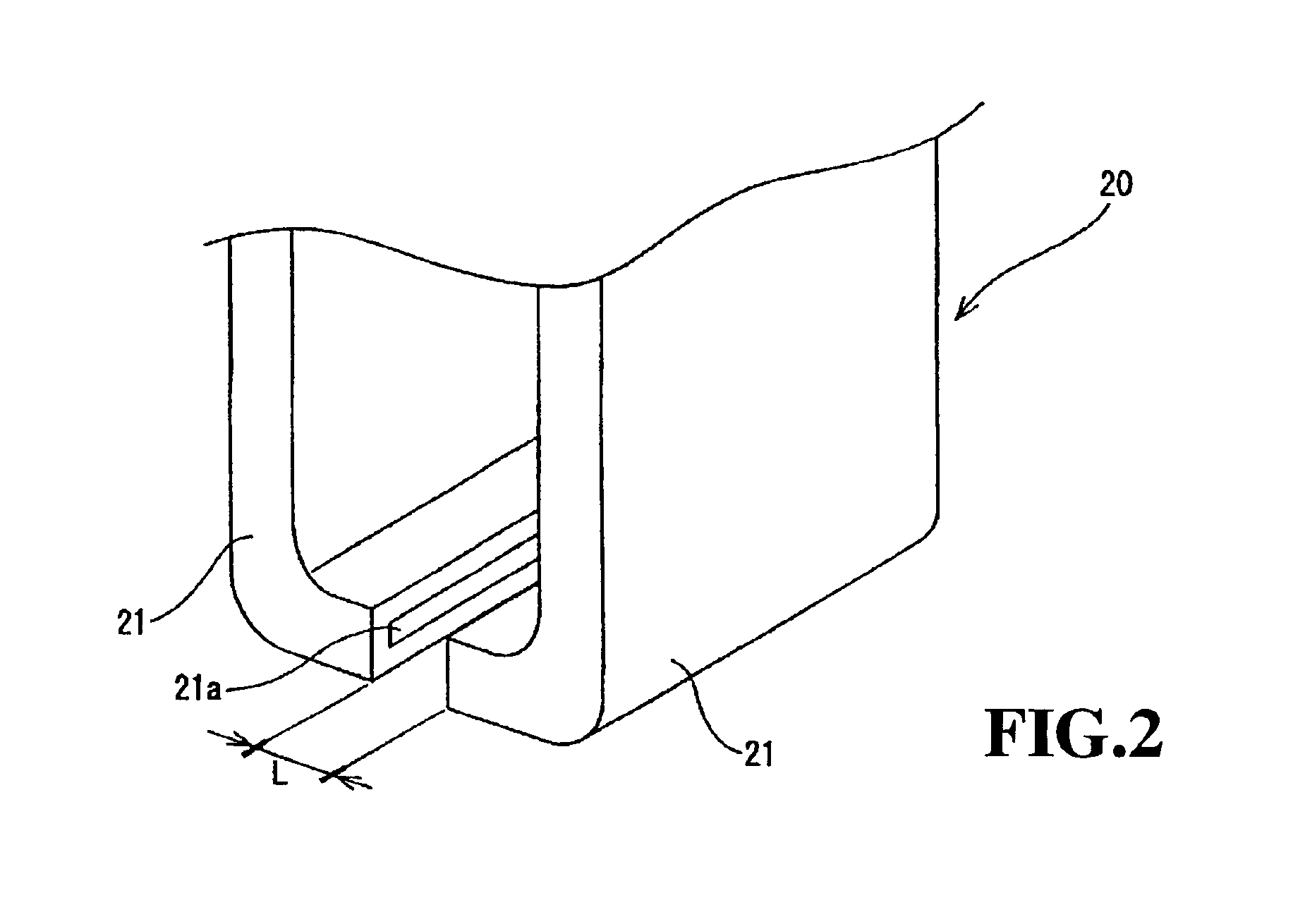

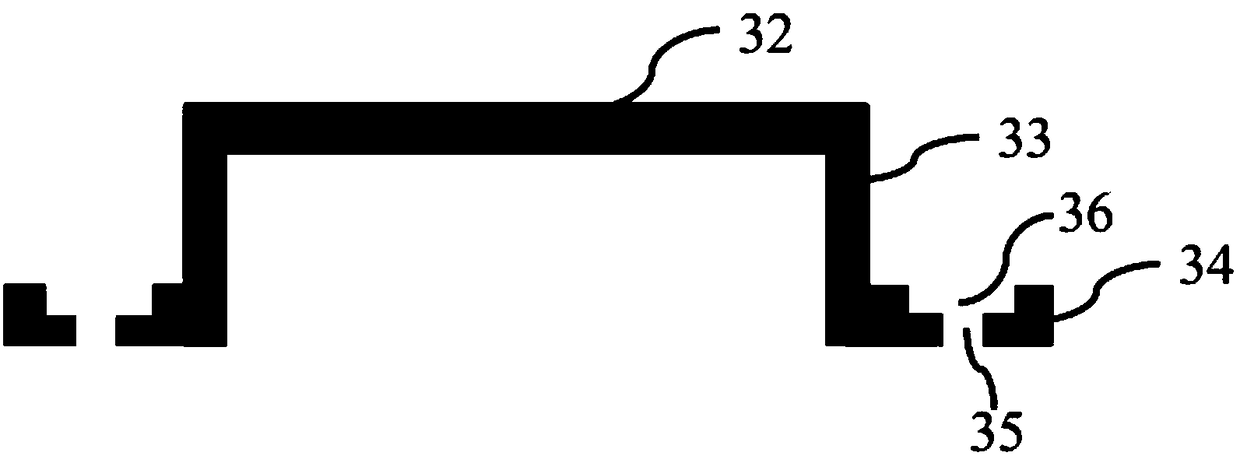

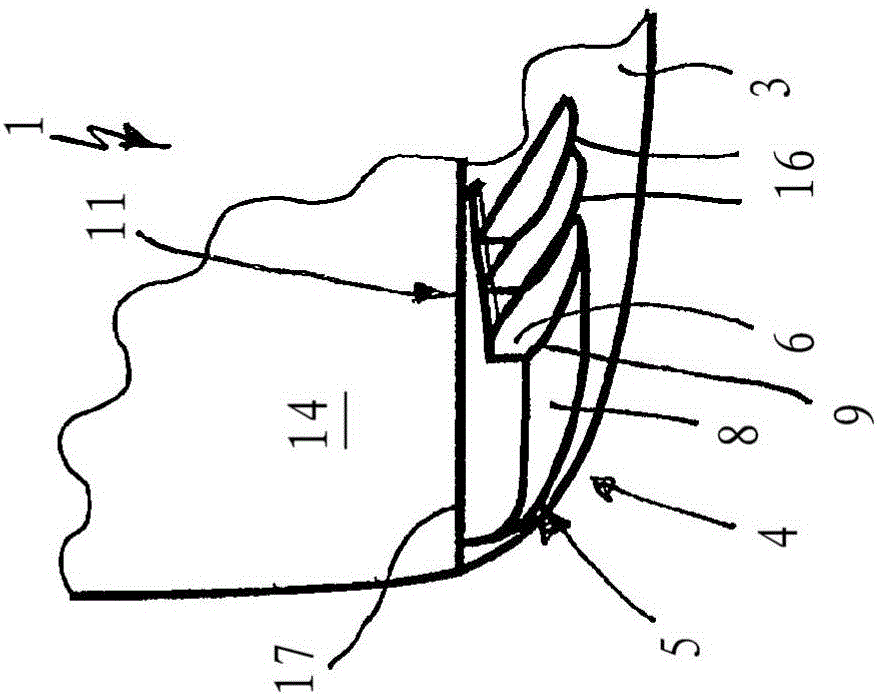

Front pillar garnish

ActiveUS7118169B2Wide field of viewSufficient volumeVehicle seatsWindowsMechanical engineeringTroffer

A front pillar garnish includes an ornamental head portion having an inward end, a groove wall protruding the ornamental head portion toward a window pane and defining a rain water gutter in cooperation with a surface of the window pane, and amounting leg portion protruding from the ornamental head portion toward a gap between the window pain and a front pillar for mounting the front pillar garnish. The groove wall includes first and second groove walls respectively positioned at an upper side and a lower side in a longitudinal direction of the front pillar garnish. A maximum distance in a direction toward an outer peripheral end face of the window pane from the inward end of the ornamental head portion to the second groove wall is larger than a maximum distance from the inward end of the ornamental head portion to the first groove wall.

Owner:TOKAI KOGYO CO LTD +1

Front pillar garnish

A front pillar garnish includes an ornamental head portion having an inward end, a groove wall protruding the ornamental head portion toward a window pane and defining a rain water gutter in cooperation with a surface of the window pane, and amounting leg portion protruding from the ornamental head portion toward a gap between the window pain and a front pillar for mounting the front pillar garnish. The groove wall includes first and second groove walls respectively positioned at an upper side and a lower side in a longitudinal direction of the front pillar garnish. A maximum distance in a direction toward an outer peripheral end face of the window pane from the inward end of the ornamental head portion to the second groove wall is larger than a maximum distance from the inward end of the ornamental head portion to the first groove wall.

Owner:TOKAI KOGYO CO LTD +1

Method of use of one step immunochromatographic device for streptococcus a antigen

InactiveUS20060154315A1Reduce the numberLess manipulationBiological testingImmunoassaysReagentSTREPTOCOCCUS ANTIGEN

A method to determine the presence or absence of Streptococcus Group A antigen in a sample, comprising the following steps: extracting the antigen from the sample in an assay chamber with two or less extraction reagents, wherein the two reagents may be added to the assay chamber in no particular sequence; introducing a lateral flow immunochromatographic assay device into the extraction reagents containing the extracted antigen without further addition of reagents or manipulation of the sample; forming an antigen-indicator labeling reagent complex; and determining the presence or absence of the antigen in the sample by the presence or absence of a signal formed by the binding of the antigen-indicator labeling reagent complex to an indicator capture reagent specific for said antigen-indicator labeling reagent complex.

Owner:GENZYME CORP

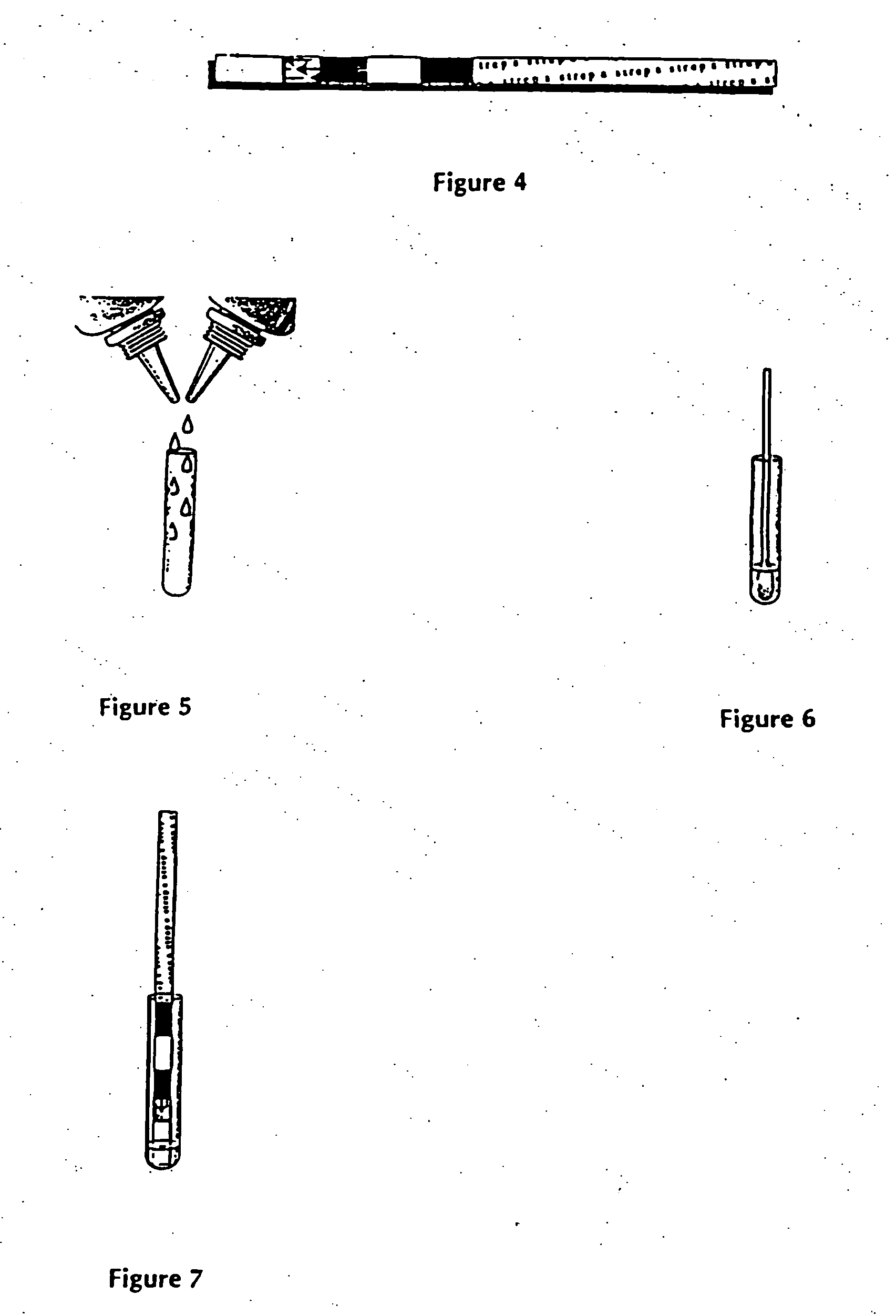

Method and apparatus for waterproofing a wire harness

InactiveUS6930252B2Avoid flowWater infiltration is eliminatedLine/current collector detailsInsulated cablesEngineeringGrommet

Owner:SUMITOMO WIRING SYST LTD

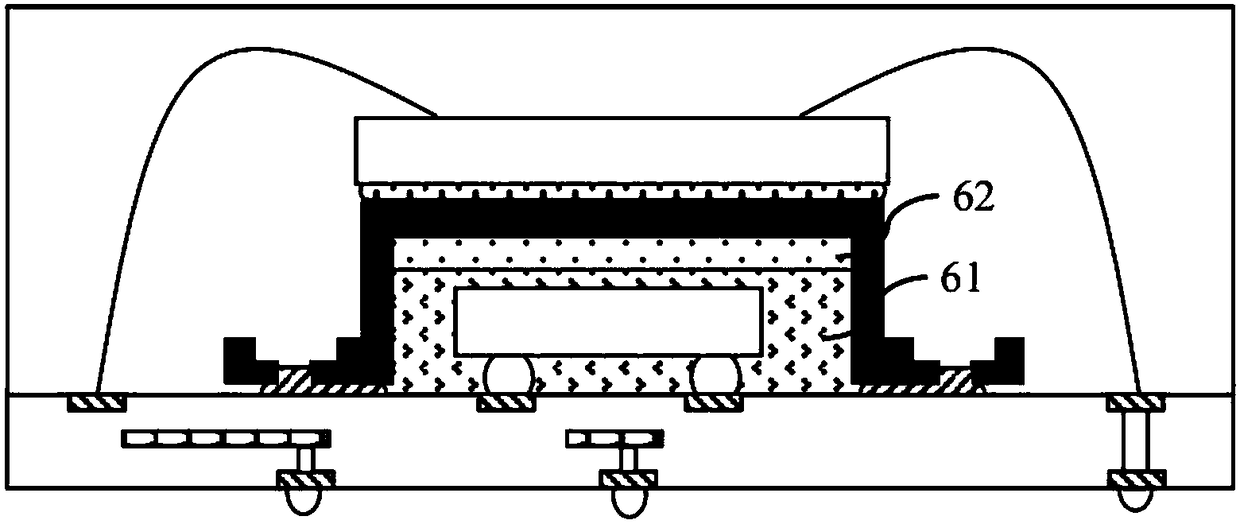

Fingerprint recognition chip device

ActiveCN108417540AAvoid loadReduce loadMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringFingerprint

The invention provides a fingerprint recognition chip device. A support cover achieves the electric shielding of a sealed first chip (sensitive chip), and can prevent load on the first chip when a fingerprint recognition chip is pressed. An elastic material layer and a rigid material layer further reduce the load on the first chip when the fingerprint recognition chip is pressed. The annular channel and the via hole of the welding portion of the support cover can sufficiently prevent the lateral flow of excess welding flux or bonding resin on a substrate. The support of a protrusion in the groove prevents the disconnection of the welding portion of the support cover when pressed.

Owner:合肥源康信息科技有限公司

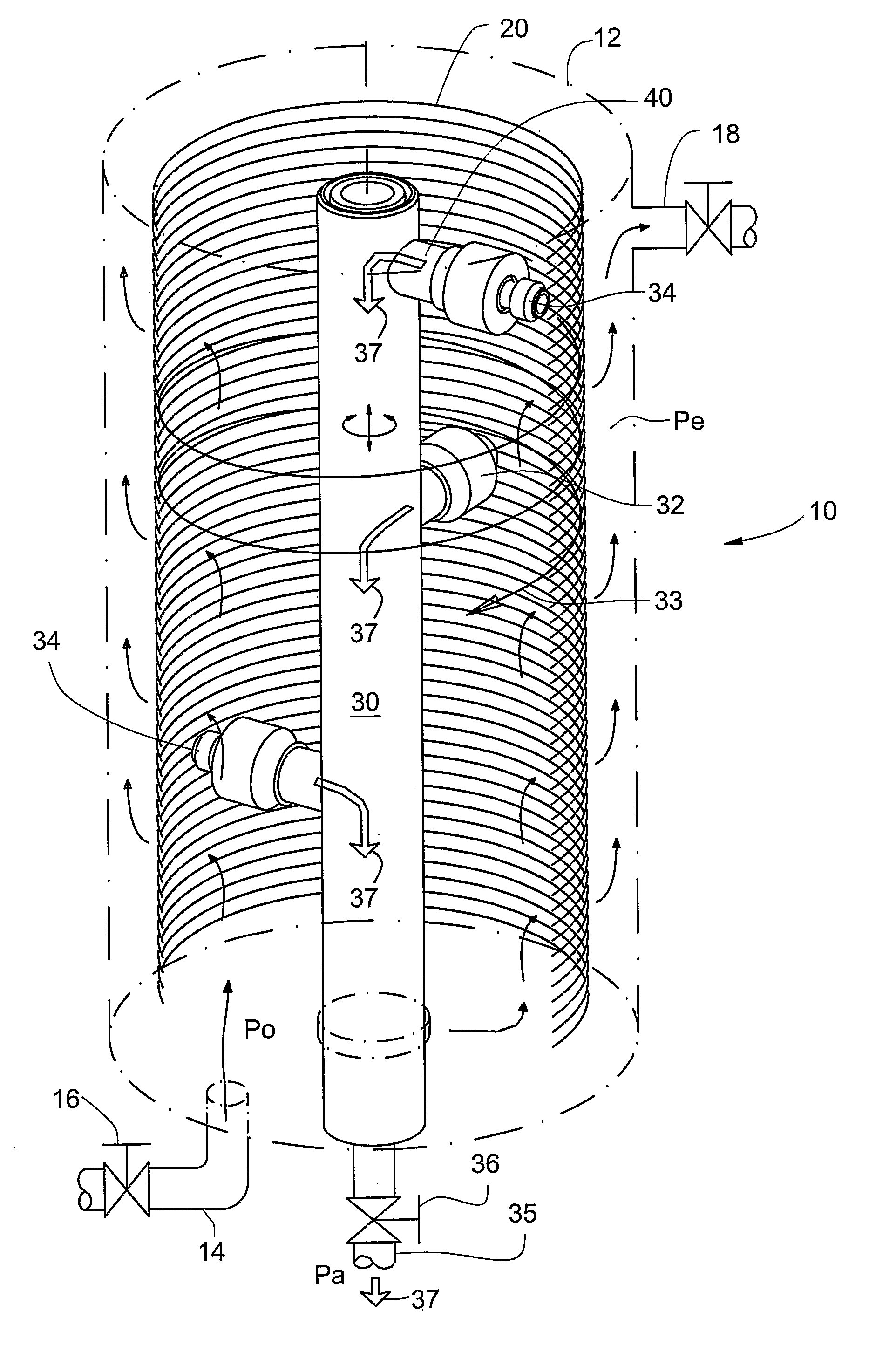

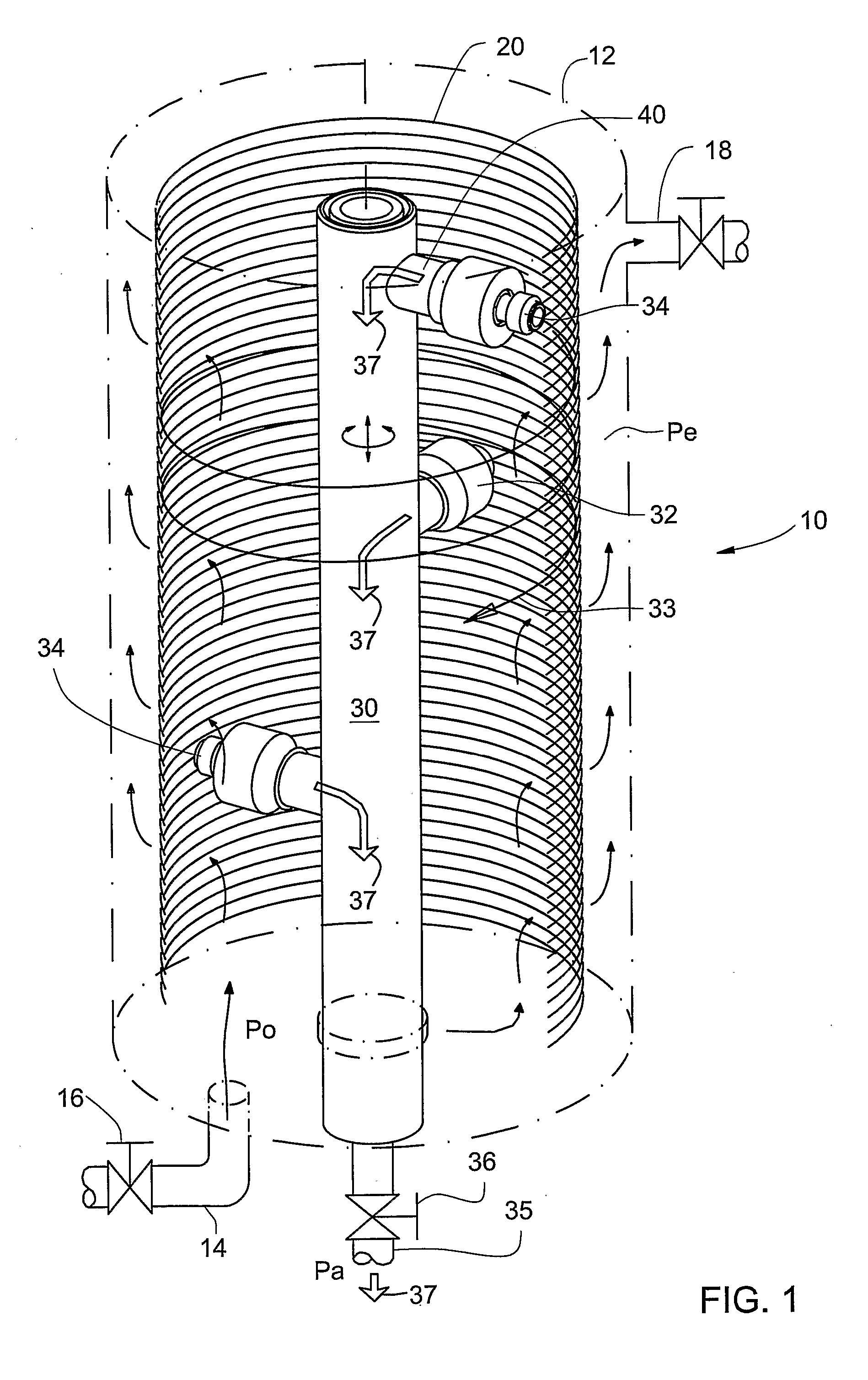

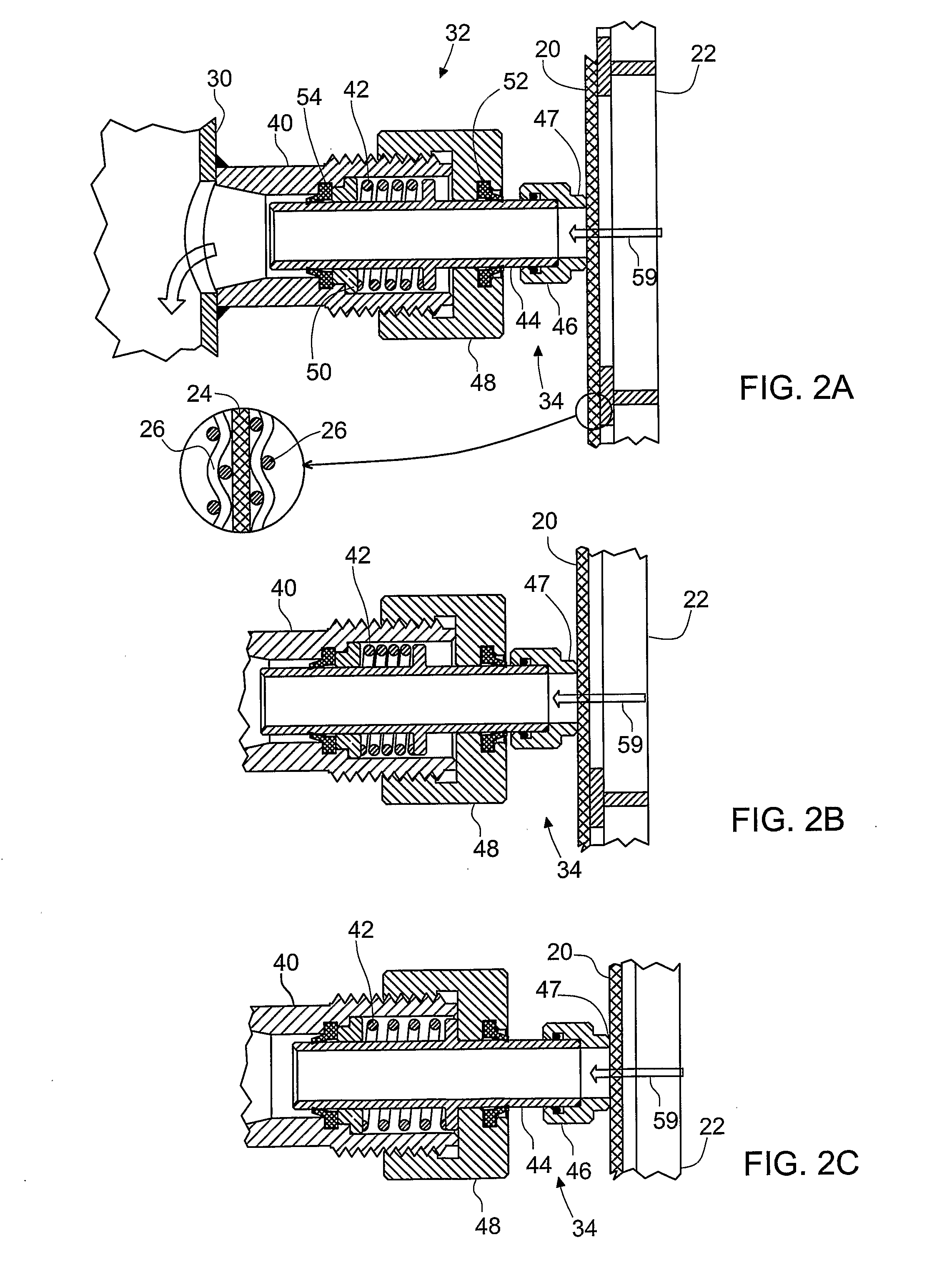

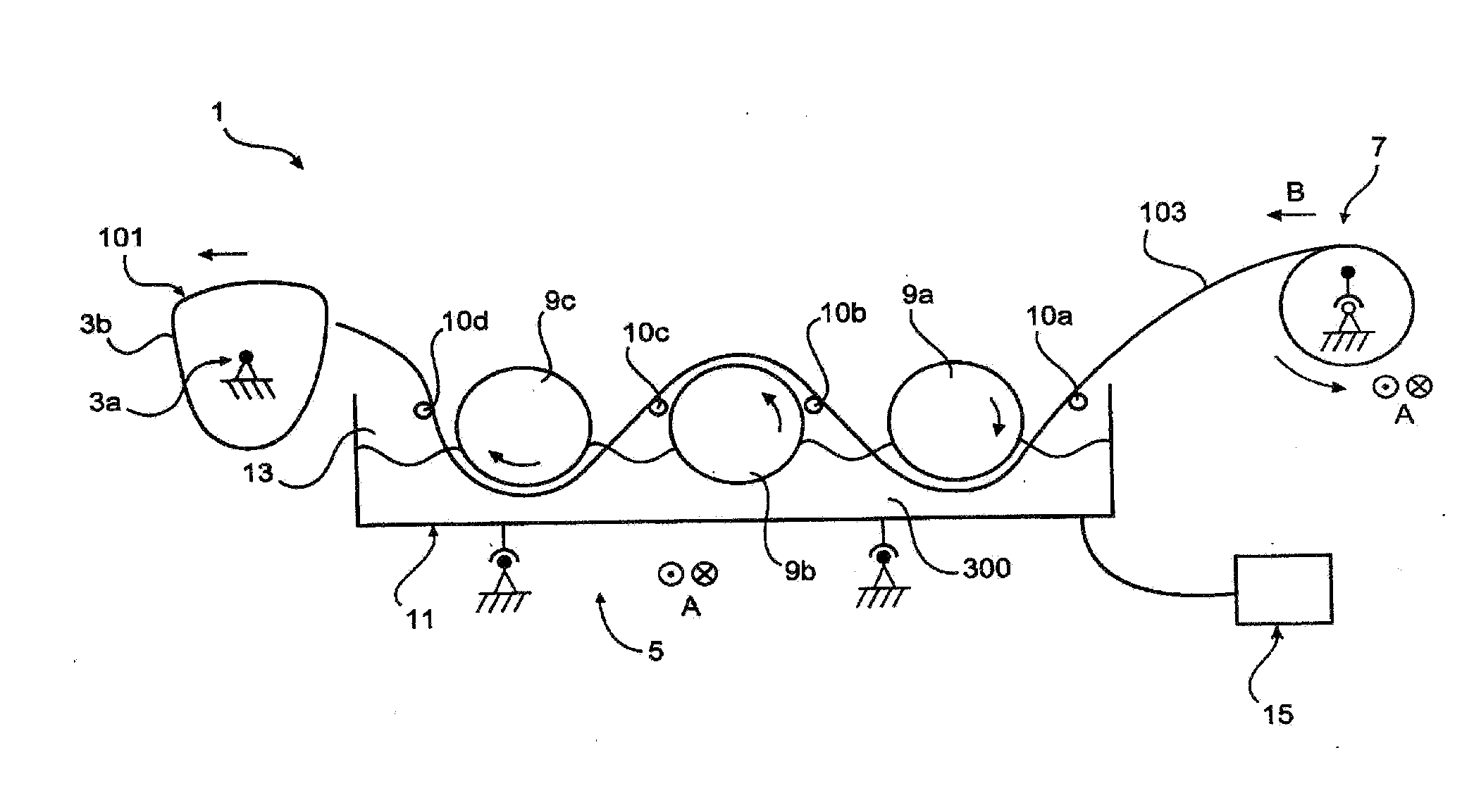

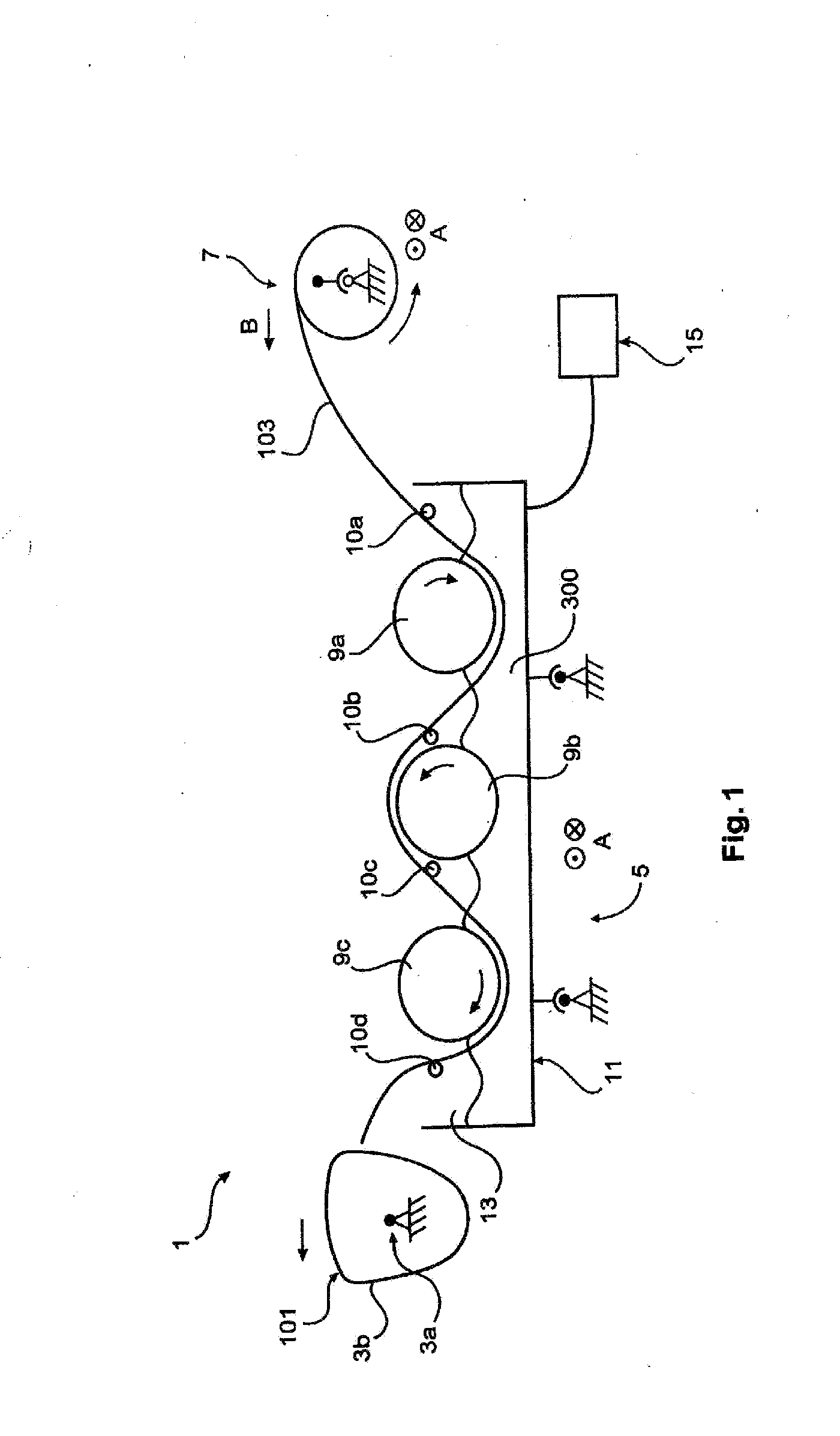

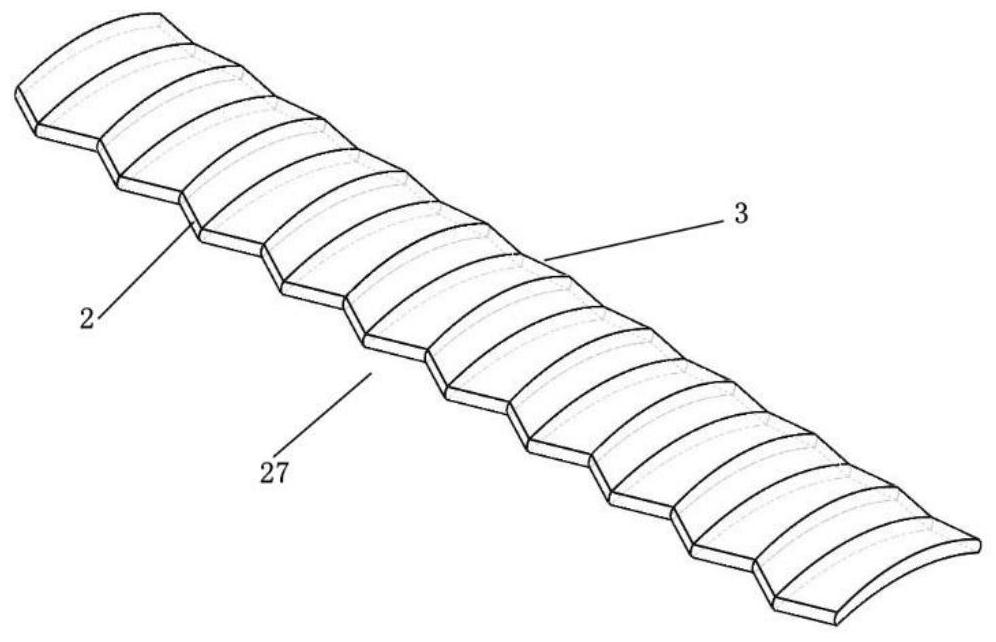

Apparatus and method to manufacture semi-finished products for wind power installation rotor blades as well as rotor blade and wind power installations

InactiveUS20150266250A1Reduce intensityImprove economyPump componentsFinal product manufactureEngineeringFibrous composites

An apparatus to manufacture semi-finished blade end products for wind power installation rotor blades with a winding mandrel which can be rotated for rolling up preferably ribbon-like fiber composite materials.An impregnating device, which can move along the winding mandrel to impregnate the fiber composite material before it is rolled up, preferably be a magazine device which moves synchronously with the impregnating device along the winding mandrel to provide the fiber composite material.

Owner:WOBBEN PROPERTIES GMBH

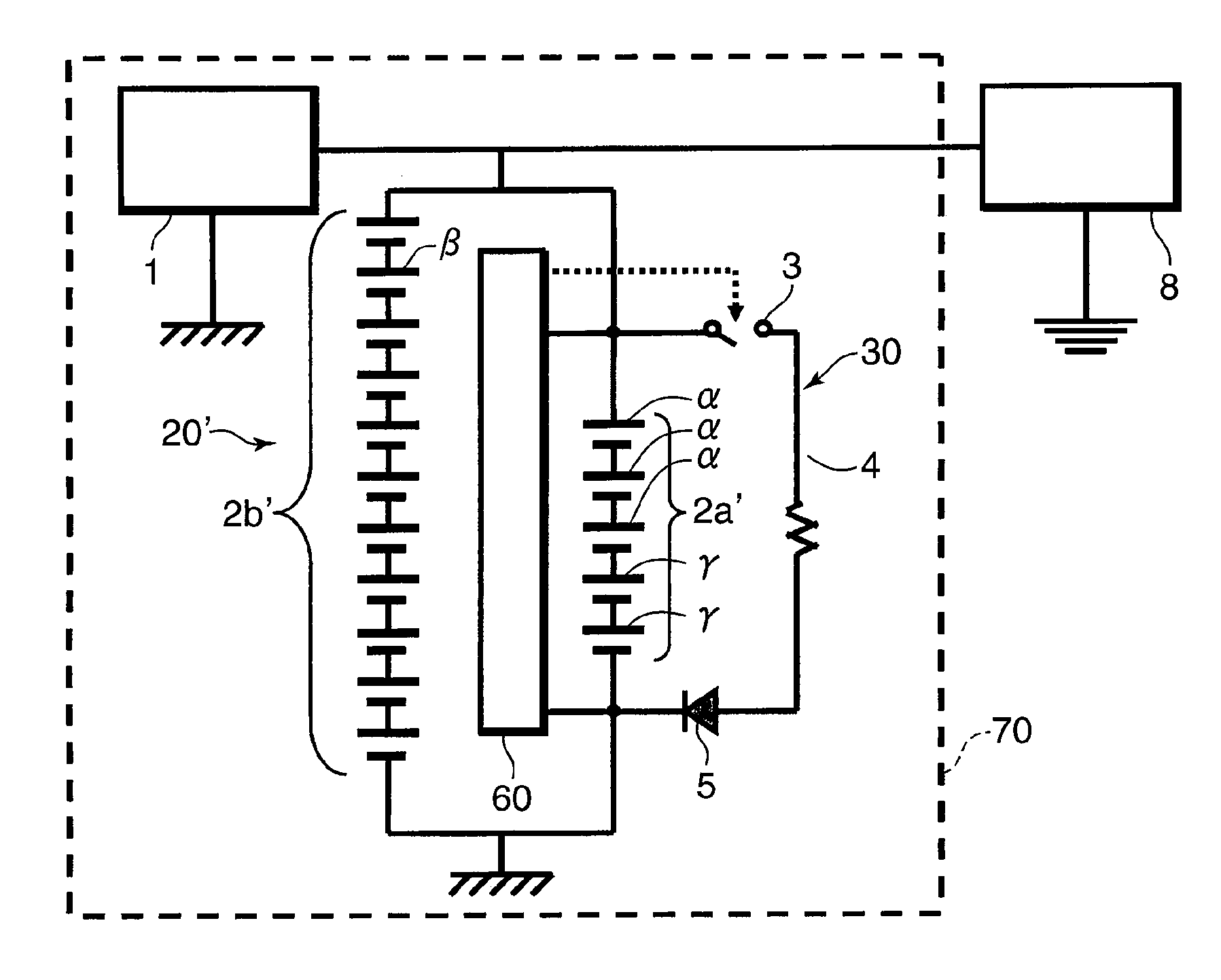

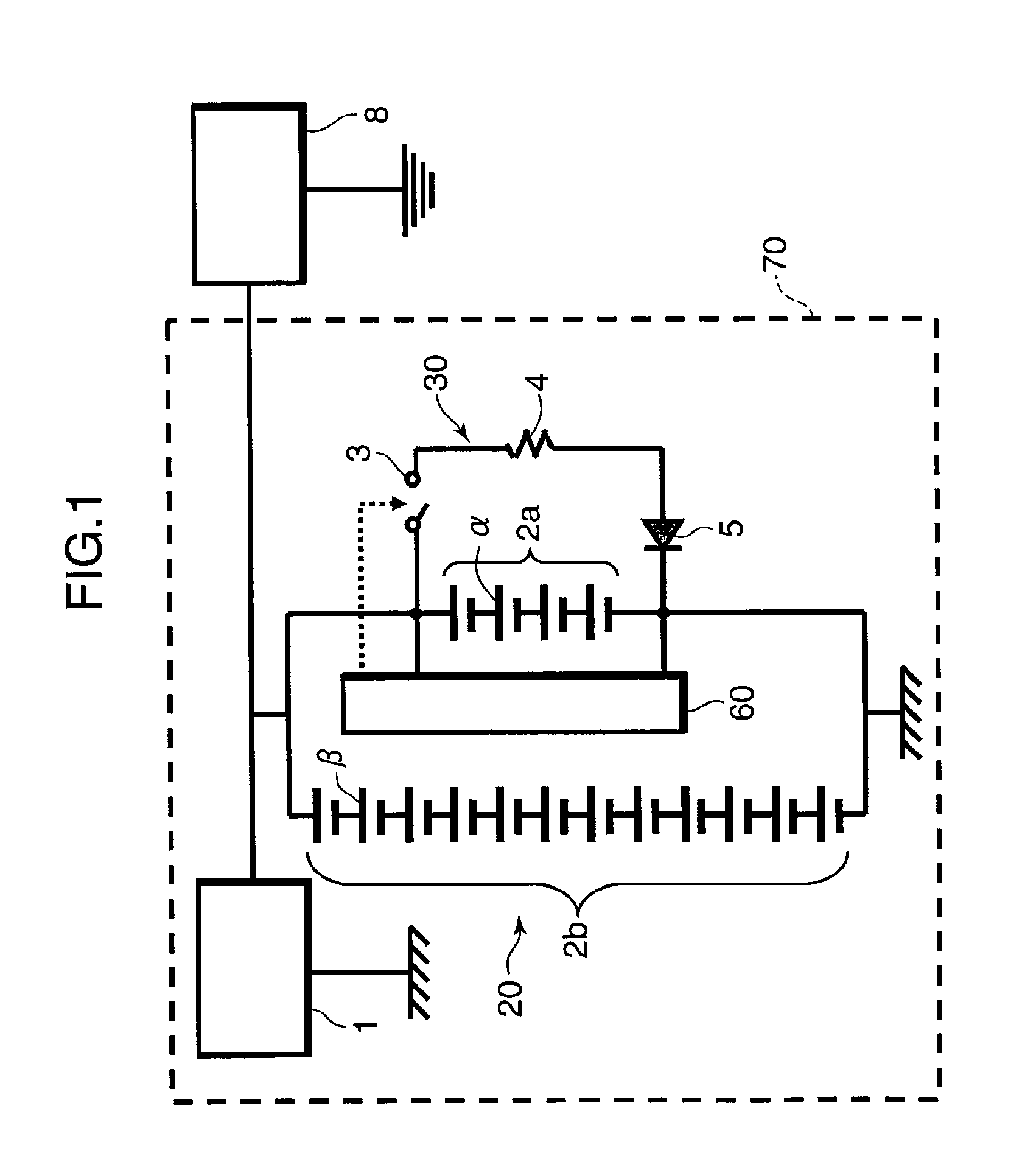

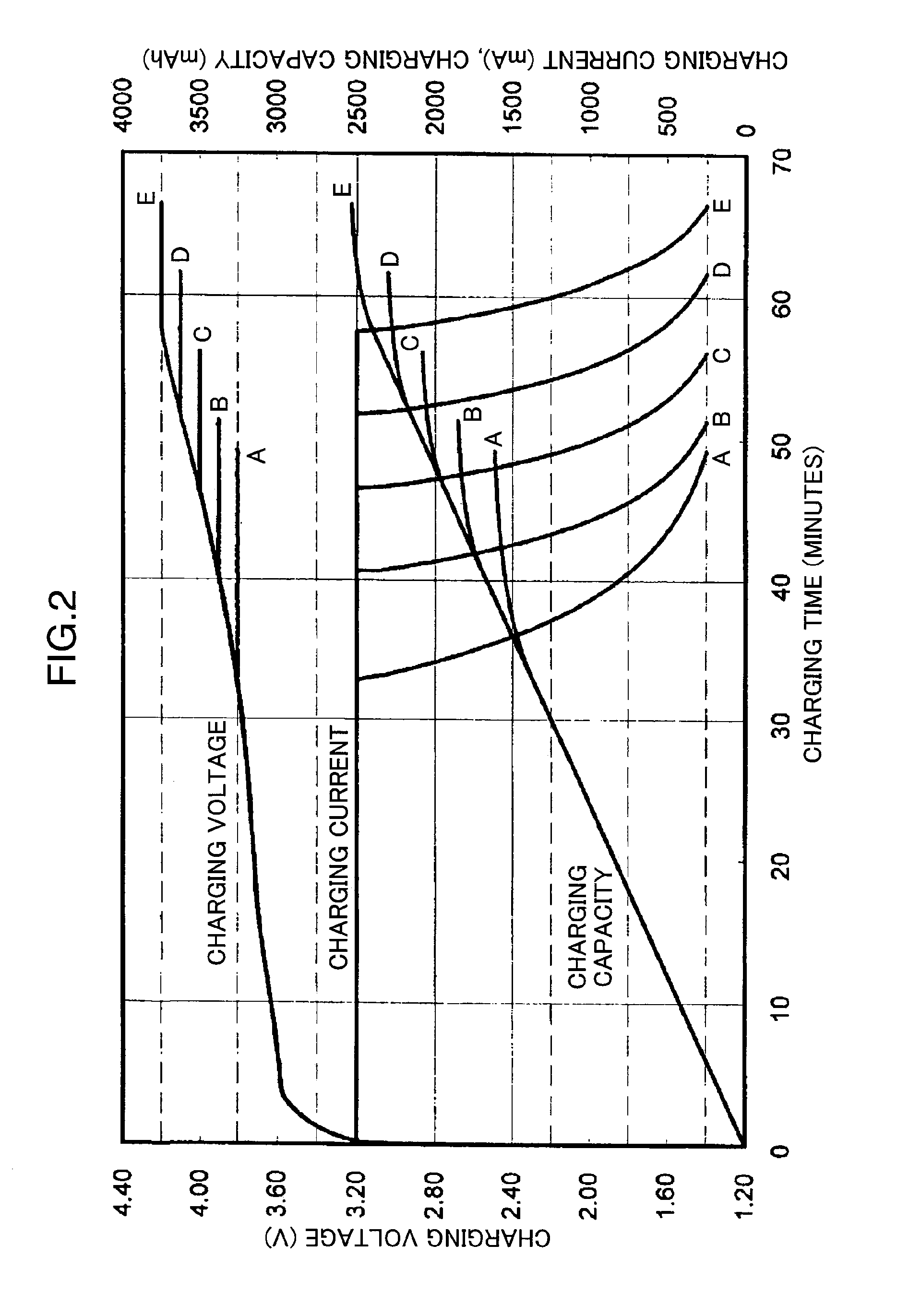

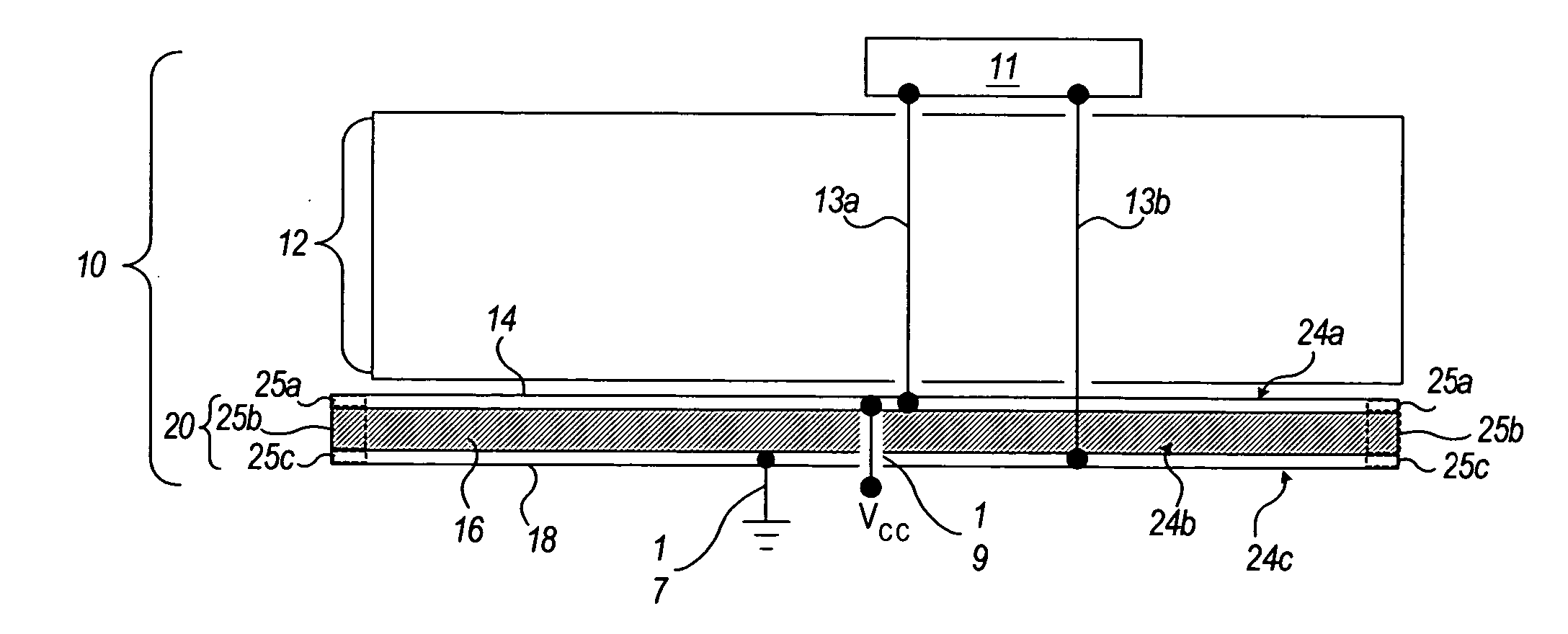

Power supply system and cell assembly control method

InactiveUS20100194342A1Avoid deformationIncrease energy densityAlkaline accumulatorsCell electrodesCell assemblyEngineering

The power supply system of this invention includes a cell assembly in which a first assembled battery, formed from a plurality of first cells connected in series, and a second assembled battery, formed from a plurality of second cells connected in series, are connected in parallel, and a generator. An average charging voltage V1 of a first assembled battery is smaller than an average charging voltage V2 of a second assembled battery. The power supply system further has a forced discharge unit capable of forcibly discharging the first assembled battery, and a control unit for measuring a voltage of the first assembled battery, and forcibly discharging the first assembled battery when the foregoing voltage reaches a forced discharge start voltage Va using the forced discharge unit until reaching a forced discharge end voltage Vb.

Owner:PANASONIC CORP

A method for manufacturing a pixel ink storage trough and application thereof

ActiveCN105118932AHydrophobicGuaranteed shapeSolid-state devicesSemiconductor/solid-state device manufacturingNanotechnologyElectrode material

The invention is applicable to the technical field of print displaying, and provides a method for manufacturing a pixel ink storage trough and application thereof. The method for manufacturing the pixel ink storage trough comprises the following steps: a TFT backboard is provided; the TFT backboard is coated with a lyophobic layer; the lyophobic layer is sequentially subjected to baking drying processing and lyophilic processing to form a lyophobic layer with lyophilic performance; pixel electrode materials are deposited on the lyophobic layer; the electrode materials are subjected to solidification processing to obtain a patterned electrode; and the lyophobic layer is enabled to form the pixel ink storage trough with lyophobicity around the patterned electrode.

Owner:TCL CORPORATION

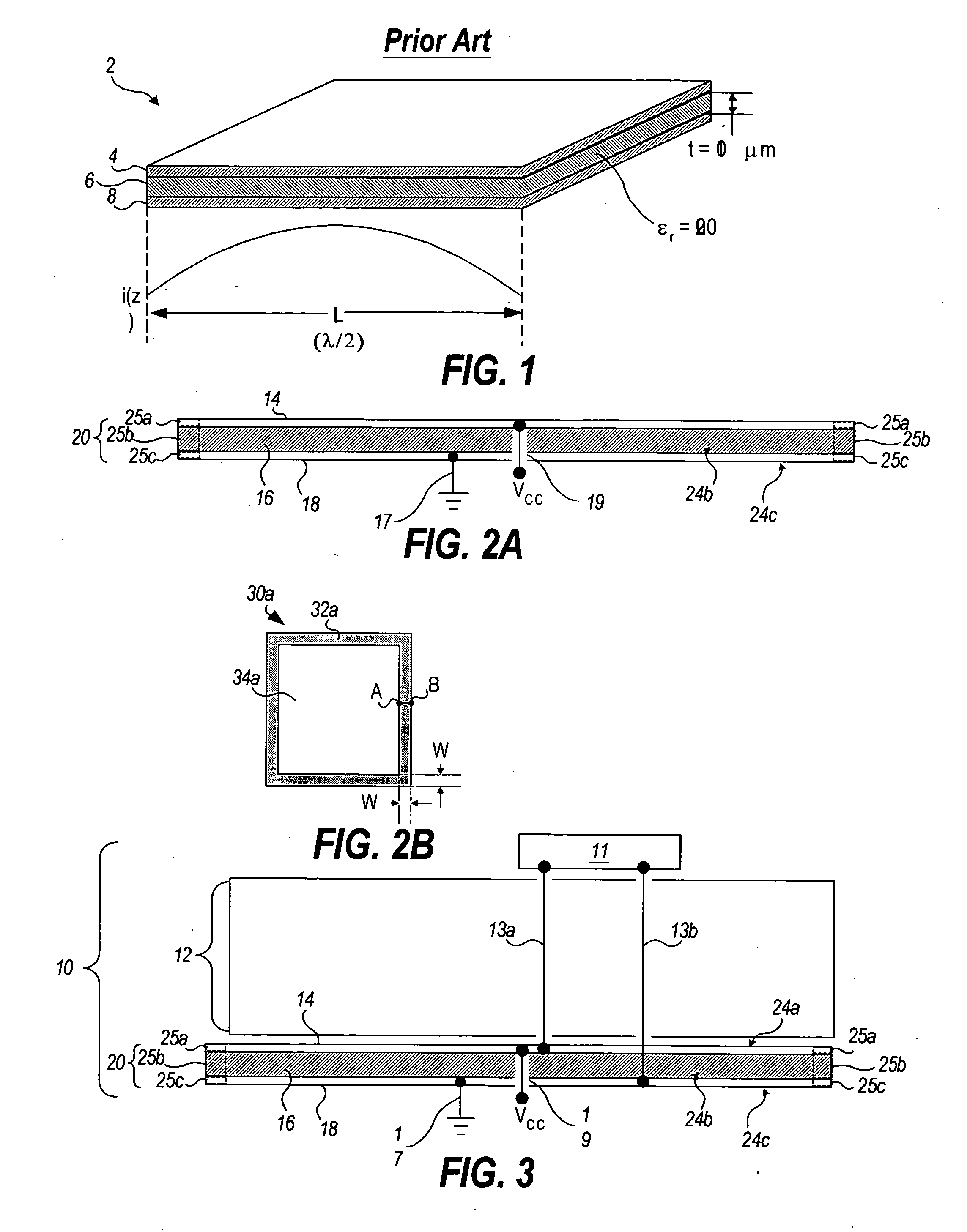

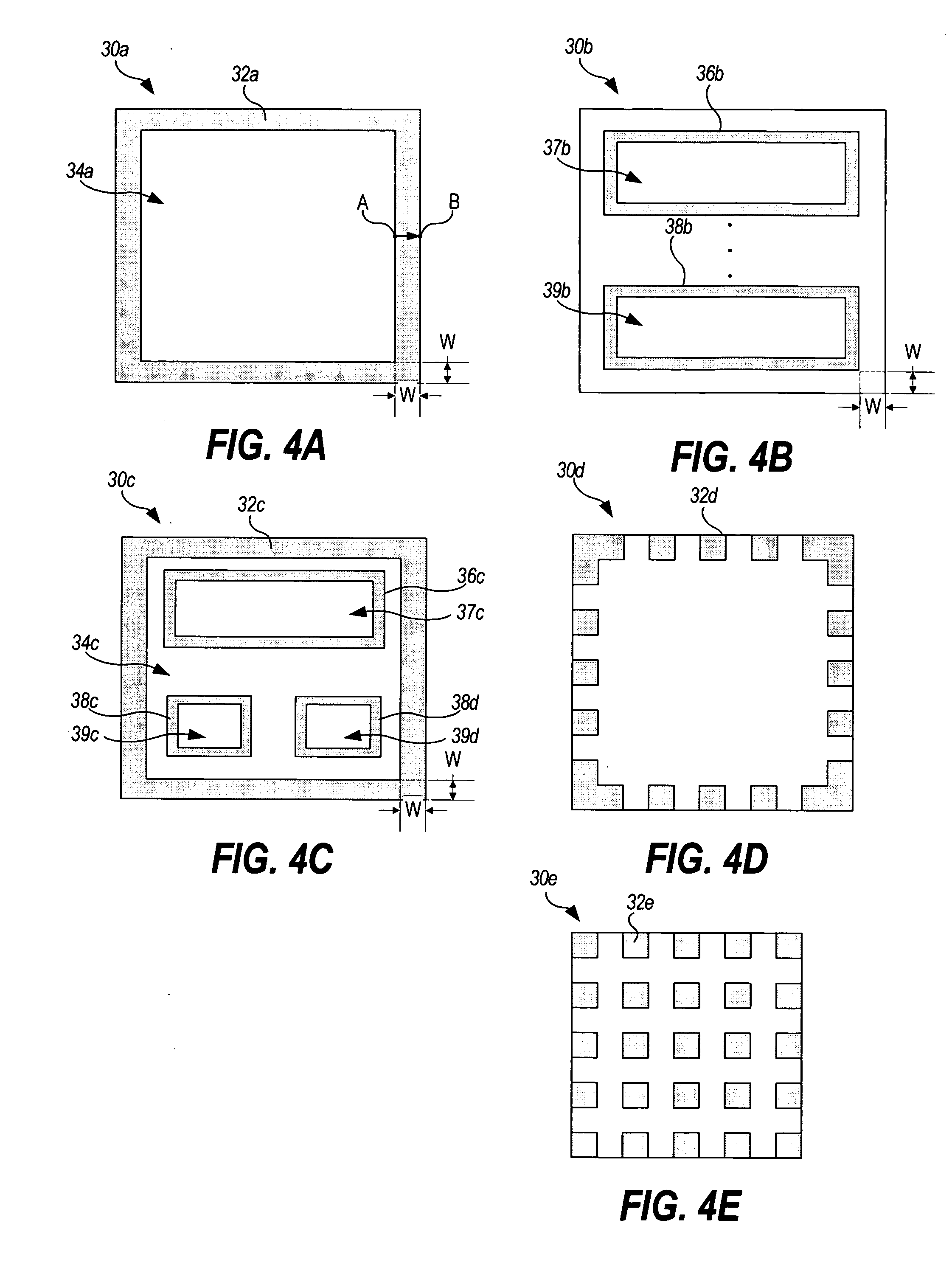

Integral charge storage basement and wideband embedded decoupling structure for integrated circuit

InactiveUS20070029675A1Limitation on frequencyLimit charge transportSemiconductor/solid-state device detailsCross-talk/noise/interference reductionRadiation lossCapacitance

A capacitive structure and technique for allowing near-instantaneous charge transport and reliable, wide-band RF ground paths in integrated circuit devices such as integrated circuit dies, integrated circuit packages, printed circuit boards, and electronic circuit substrates is presented. Methods for introducing resistive loss, dielectric loss, magnetic loss, and / or radiation loss in a signal absorption ring implemented around a non-absorptive area of one or more conductive layers of an integrated circuit structure to dampen laterally flowing Electro-Magnetic (EM) waves between electrically adjacent conductive layers of the device are also presented.

Owner:GEOMAT INSIGHTS

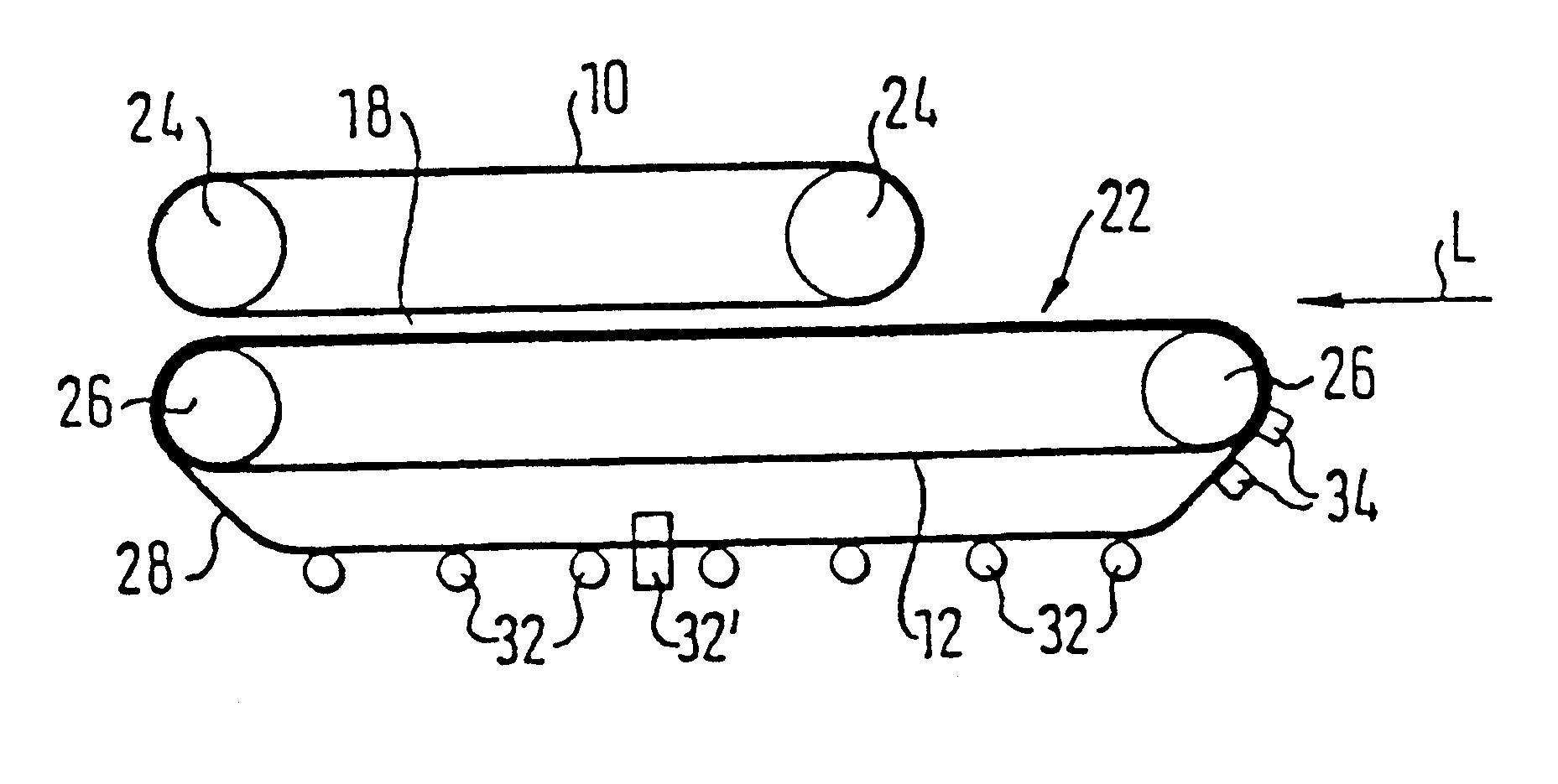

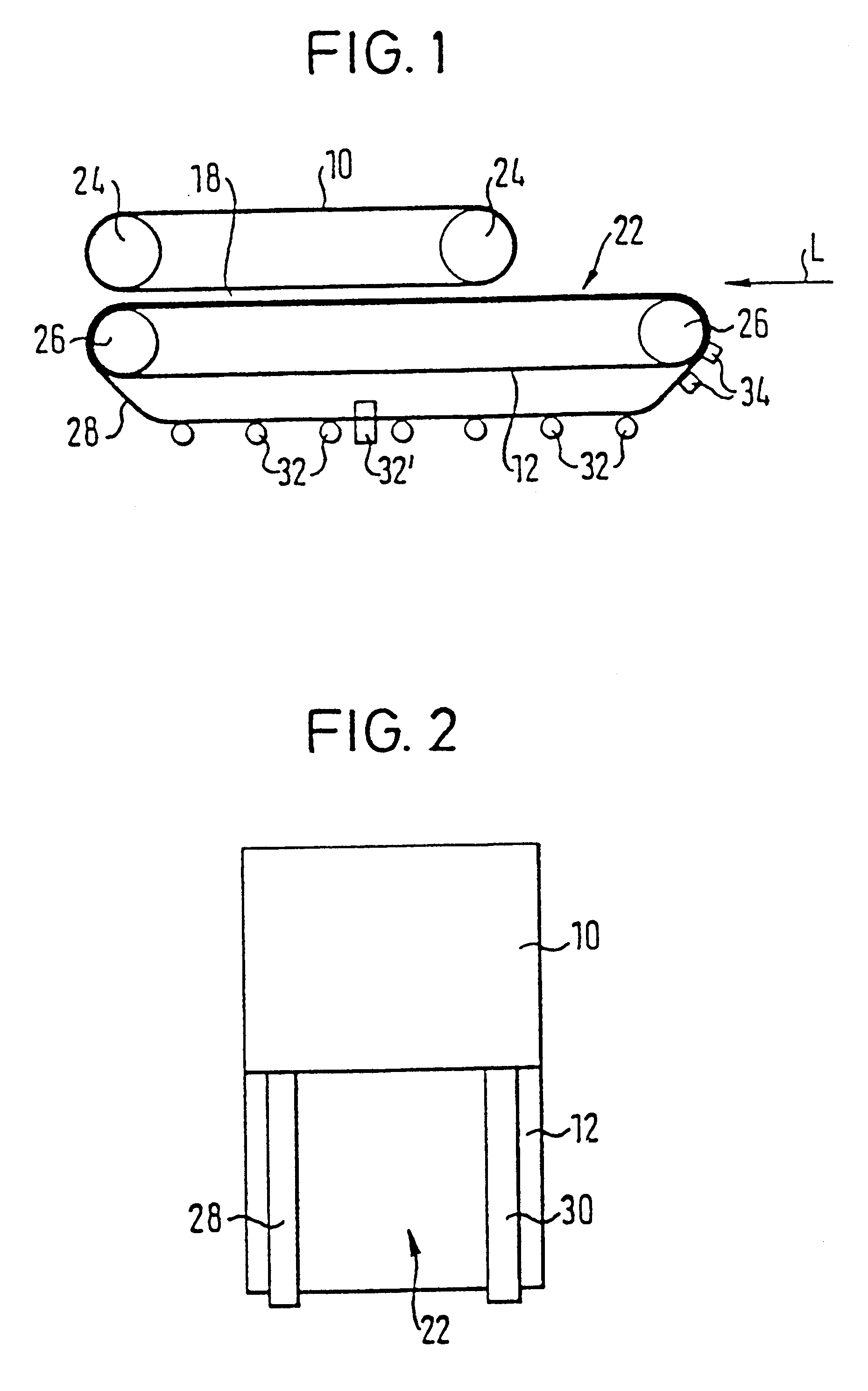

Device for continuous production of plate-shaped products

InactiveUS6322346B1Increase adhesive frictionMore complicatedDough-sheeters/rolling-machines/rolling-pinsConfectioneryBand shapeStatic friction

The invention relates to a device for the continuous production of plate-shaped products, comprising two endless strips which are positioned one above the other and can be driven. A working gap is formed between the sides of said endless strips, said sides being adjacent to one another and each being conveyed via a support surface. The starting material for processing is conveyed through said working gap which is bordered on each side by an accompanying strip. Said accompanying strip is situated along said working gap between the two endless strips and moves with them, consisting of a flexible sealing strip which has a friction surface on at least one face, said face facing towards an endless strip. Said friction surface increases the static friction between the flexible sealing strip and the endless strip.

Owner:VALMET PANELBOARD

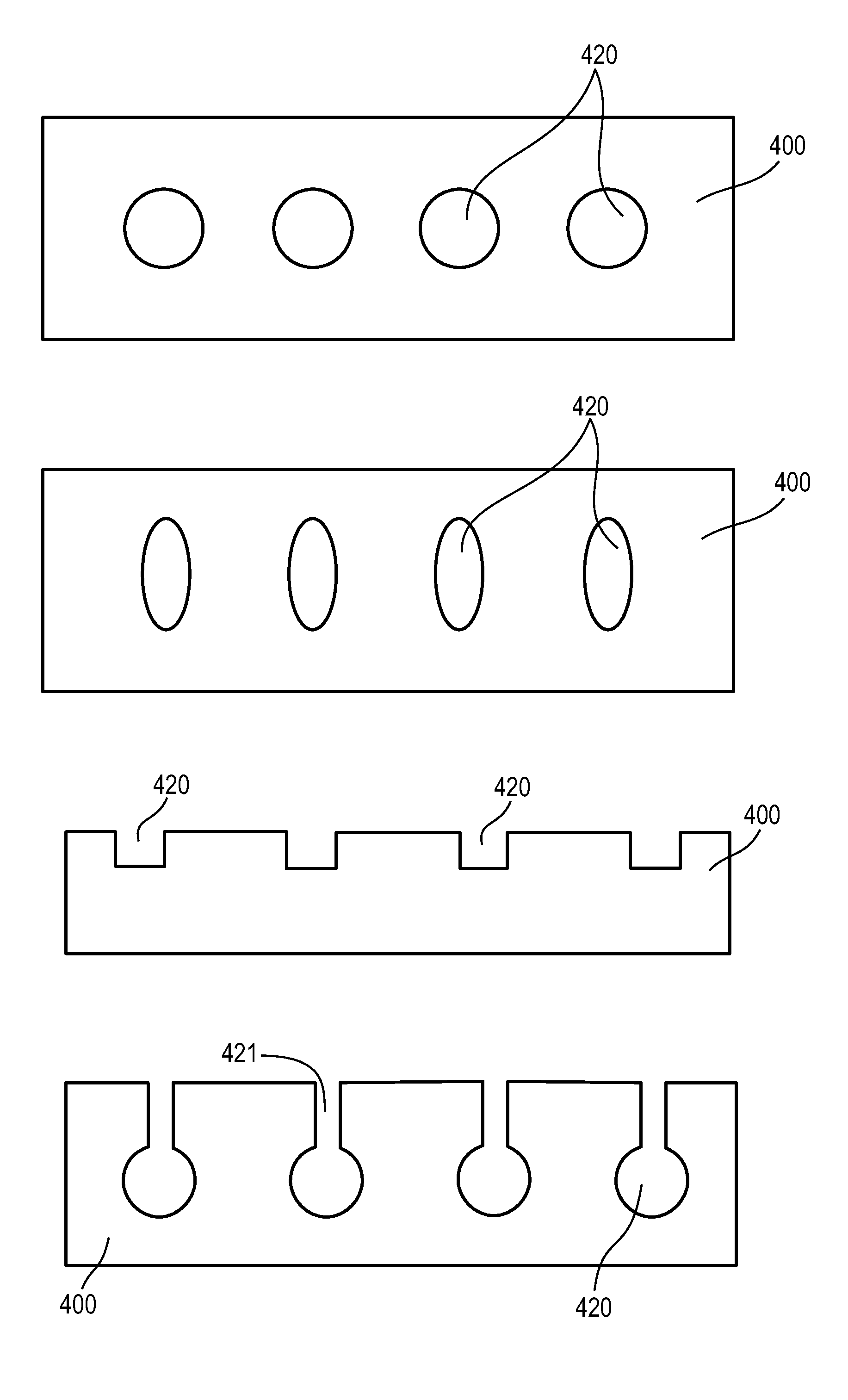

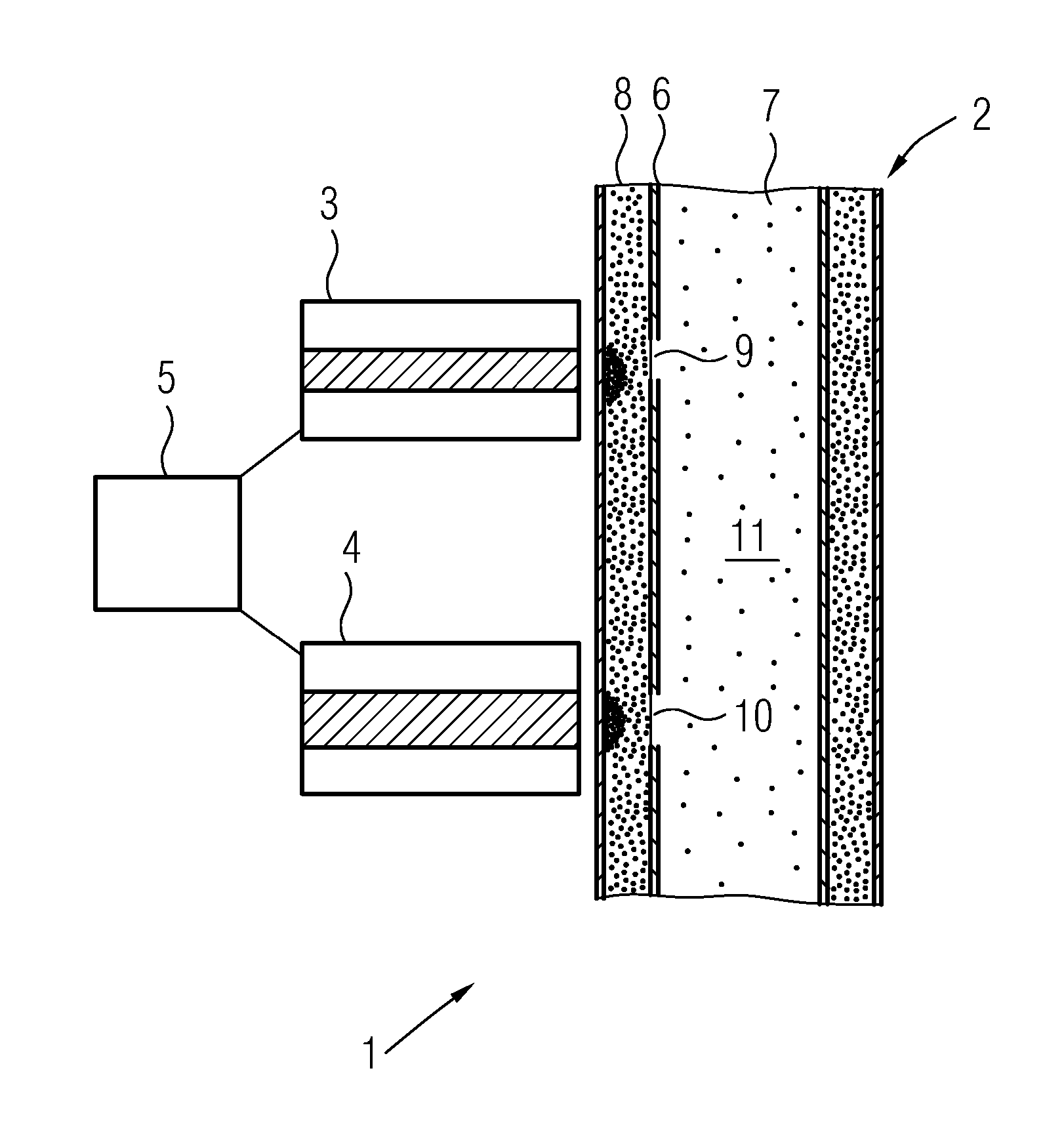

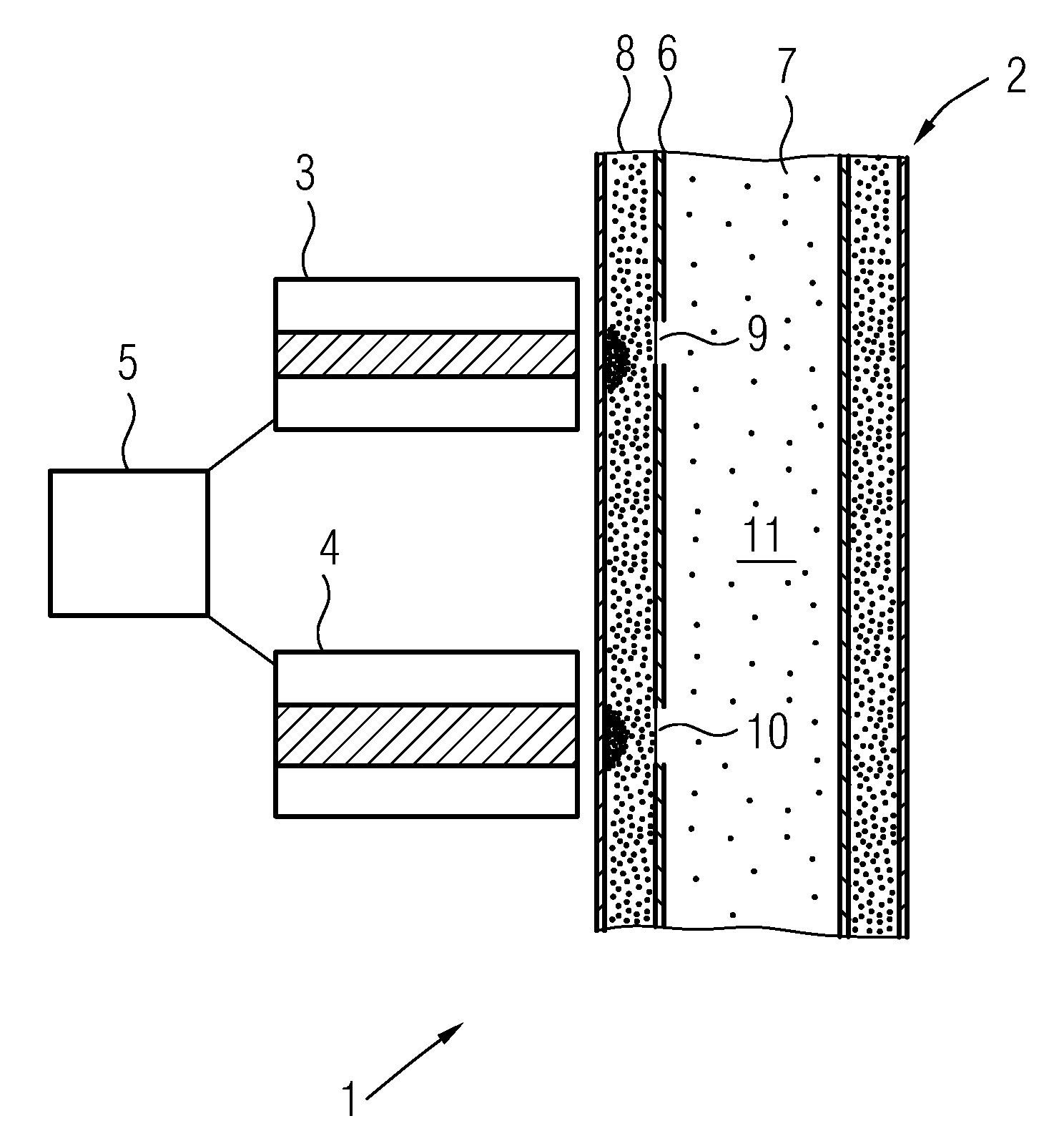

Device for separating ferromagnetic particles from a suspension

InactiveCN102215975AEasy to separateGuaranteed uptimeMagnetic separationInterior spaceNuclear engineering

Device for separating ferromagnetic particles from a suspension, having a reactor (2) through which the suspension can flow, with at least one magnet (3, 4) arranged on the outside of the reactor (2), wherein the reactor (2) has an interior space (7) and an exterior space (8) surrounding the former, wherein the interior space (7) and exterior space (8) are separated from one another by an insert (6), and the insert (6) has at least one opening (9, 10) near the at least one magnet (3, 4).

Owner:SIEMENS AG

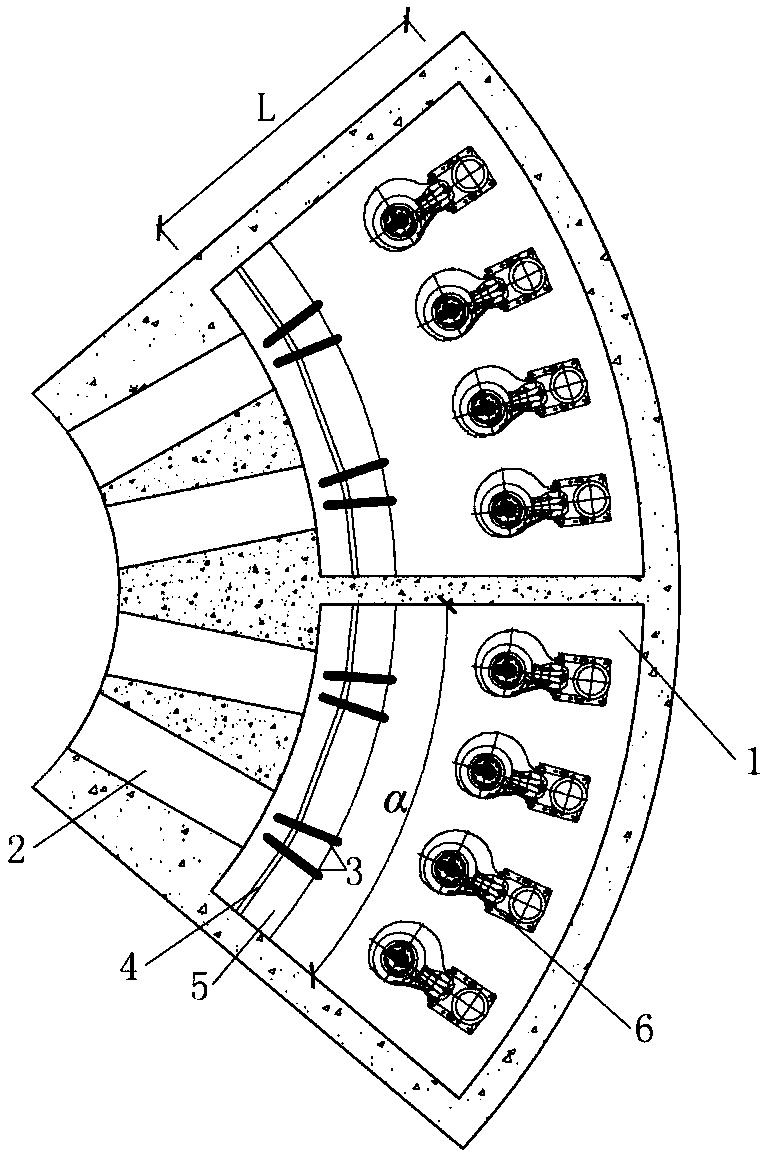

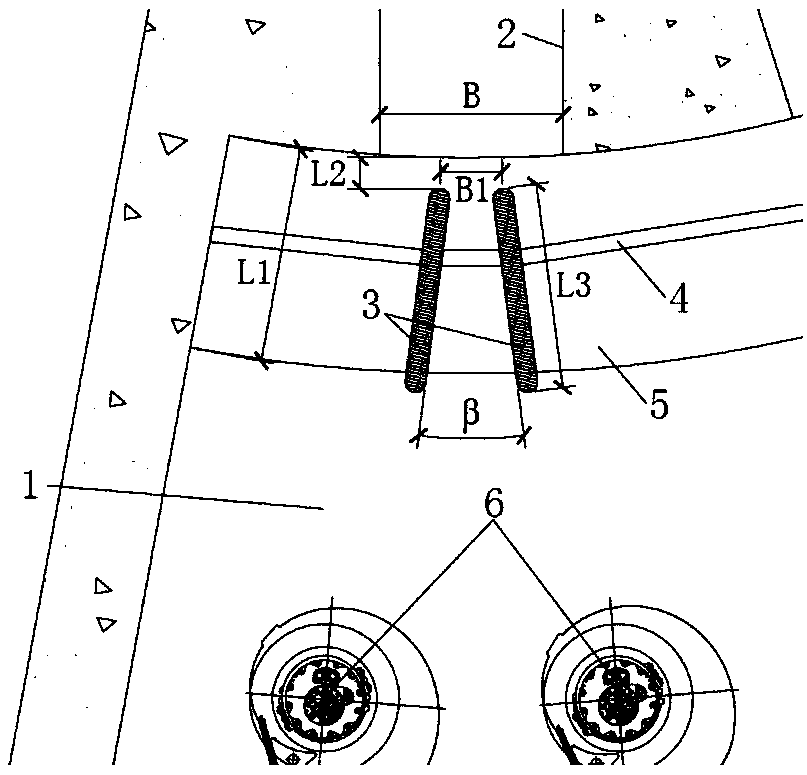

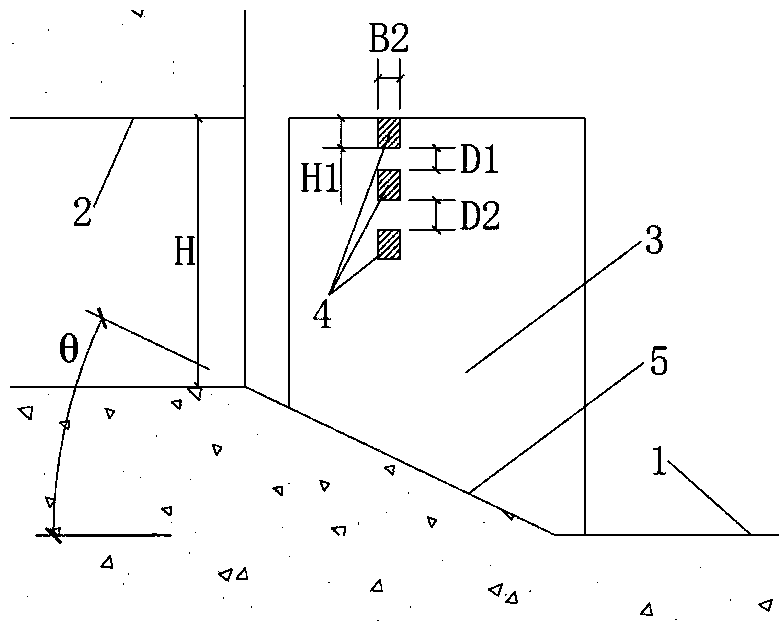

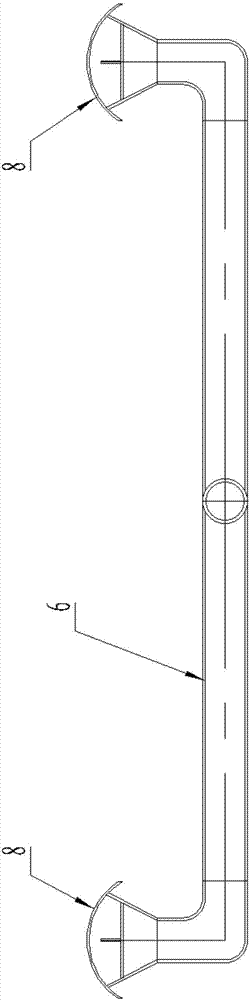

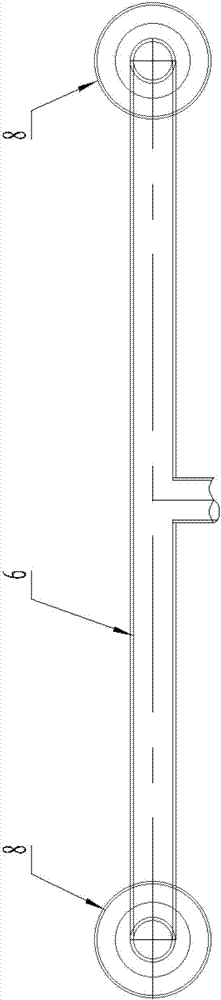

Method for ensuring uniform water inflow of water collecting basin in fan-shaped municipal sewage lifting pumping station

ActiveCN109056987AImprove water flowIncrease bottom velocitySewerage structuresSewage drainingMunicipal sewageEngineering

The invention discloses a method for ensuring uniform water inflow of a water collecting basin of a fan-shaped municipal sewage lifting pumping station. A combined rectifying device consisting of a figure-eight-shaped diversion pier and a folding beam is arranged at the front end of the water collecting basin of the fan-shaped municipal sewage lifting pumping station. The method for ensuring uniform water inflow of a water collecting basin of a fan-shaped municipal sewage lifting pumping station adopts the combined rectifying device consisting of the figure-eight-shaped diversion pier and thefolding beam to achieve effects of improving the water inflow state of the water collecting basin of the lifting pumping station, and effectively ensuring the uniformity of flow velocity distributionon a horizontal plane and the sound inflow state on a vertical plane of the incoming flow of pump units of the fan-shaped municipal sewage lifting pumping station. The method for ensuring uniform inflow of a water collecting basin of a fan-shaped municipal sewage lifting pumping station has the advantages of being high in engineering application value for ensuring safety, reliability and efficiency of the pumping station, simple in structure and convenient to construct and manufacture, and is suitable for promoting and using in the design and renovation of a municipal sewage lifting pumping station in the form of a fan-shaped pump room structure.

Owner:HOHAI UNIV

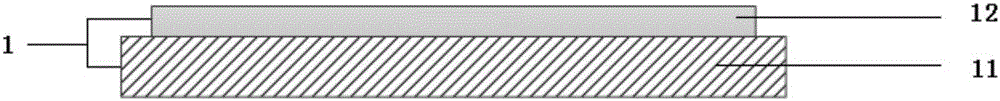

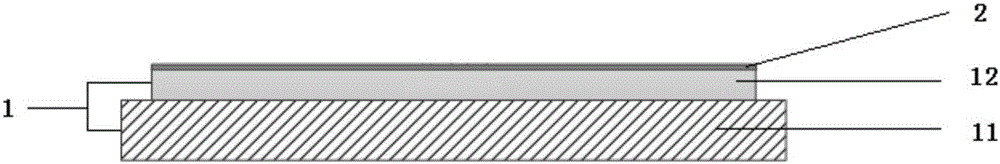

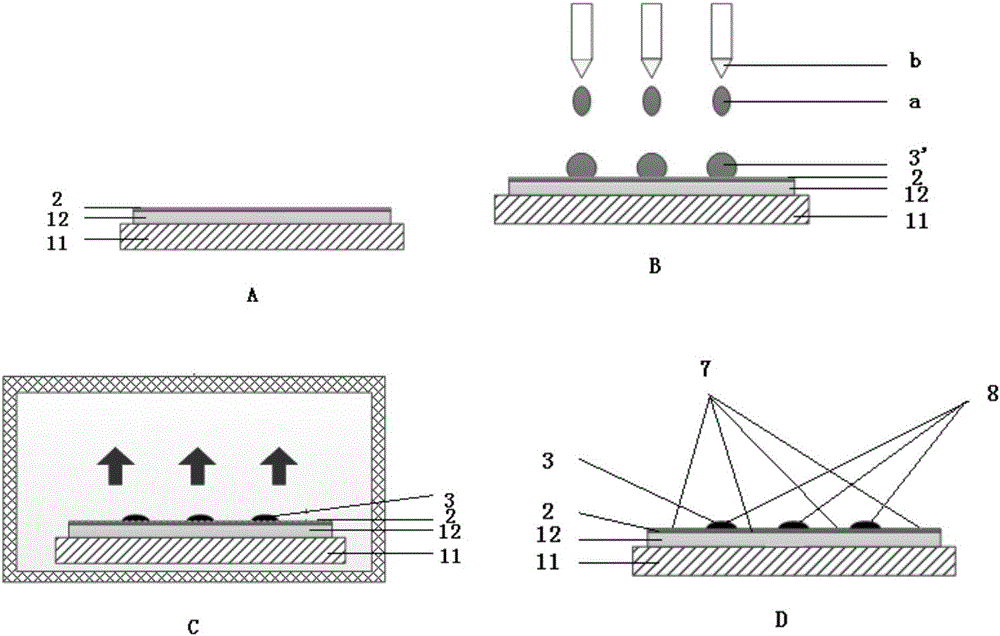

Overflow water distributor and system for uniformly renewing water in water pool

The invention discloses an overflow water distributor and a system for uniformly renewing water in a water pool. The overflow water distributor comprises a water distributor shell (11) and a water distributor cap (12). The water distributor shell (11) is of a conical cylinder structure. The water distributor cap (12) is of a sheet structure. The outer portion of the bottom end of the water distributor shell (11) is covered with the water distributor cap (12). A strip-shaped gap for water flow to pass through is formed between the bottom end of the water distributor shell (11) and the water distributor cap (12). By means of the system for uniformly renewing the water in the water pool, uniformity and stability of an internal circulation system in the water storage pool can be improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

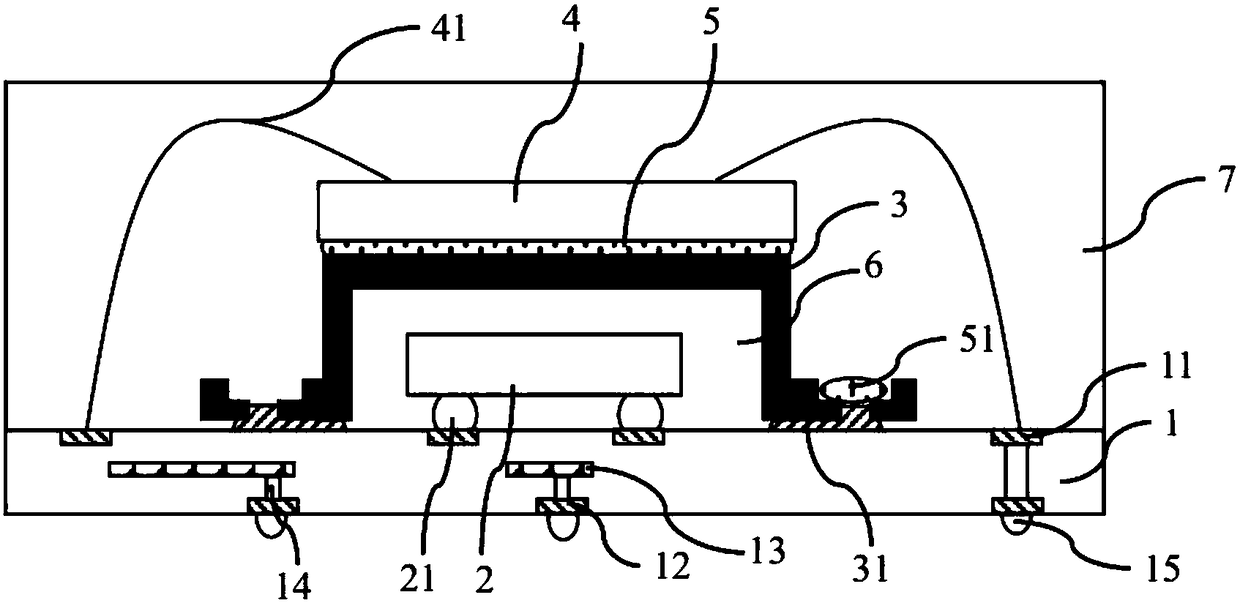

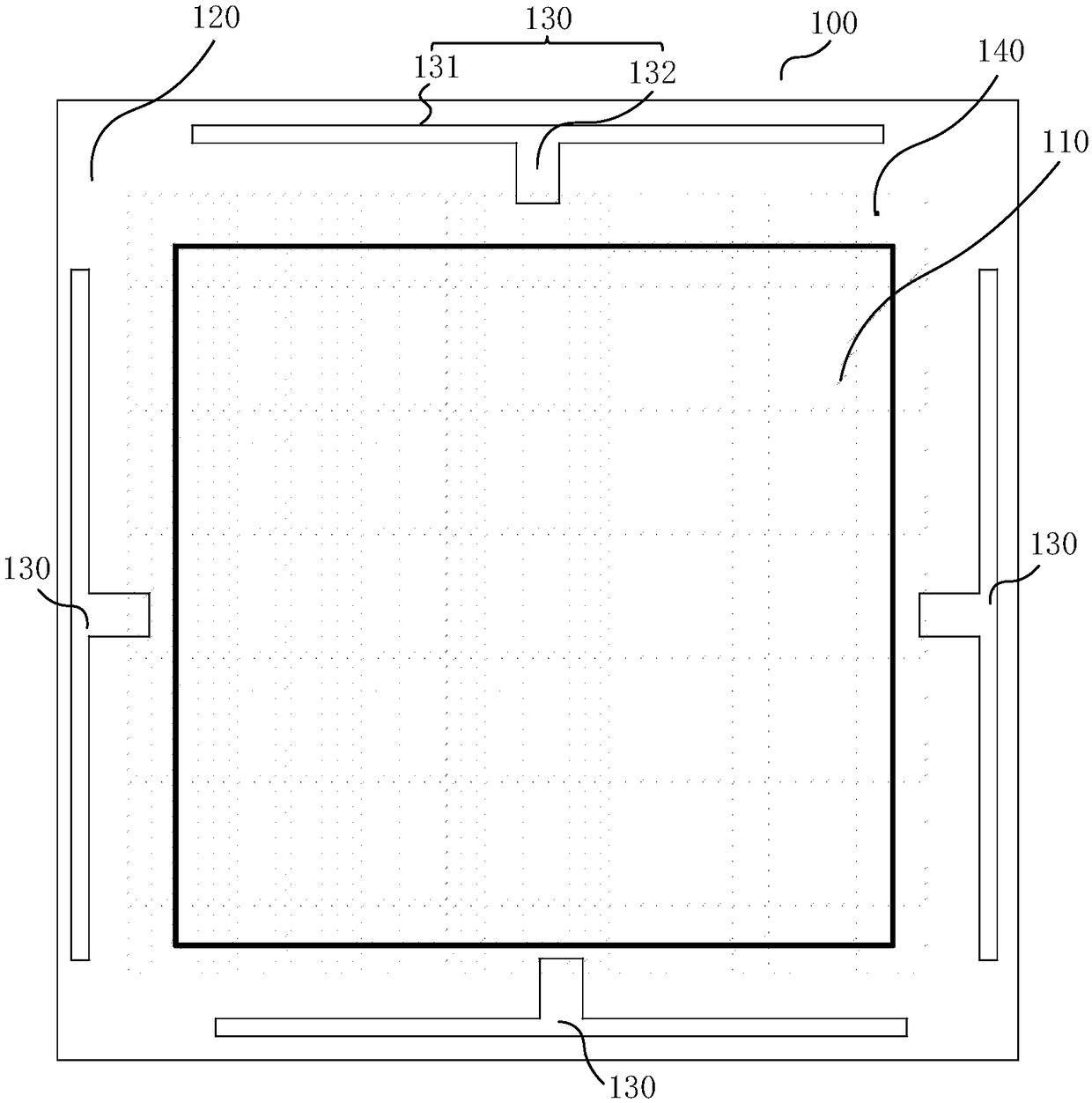

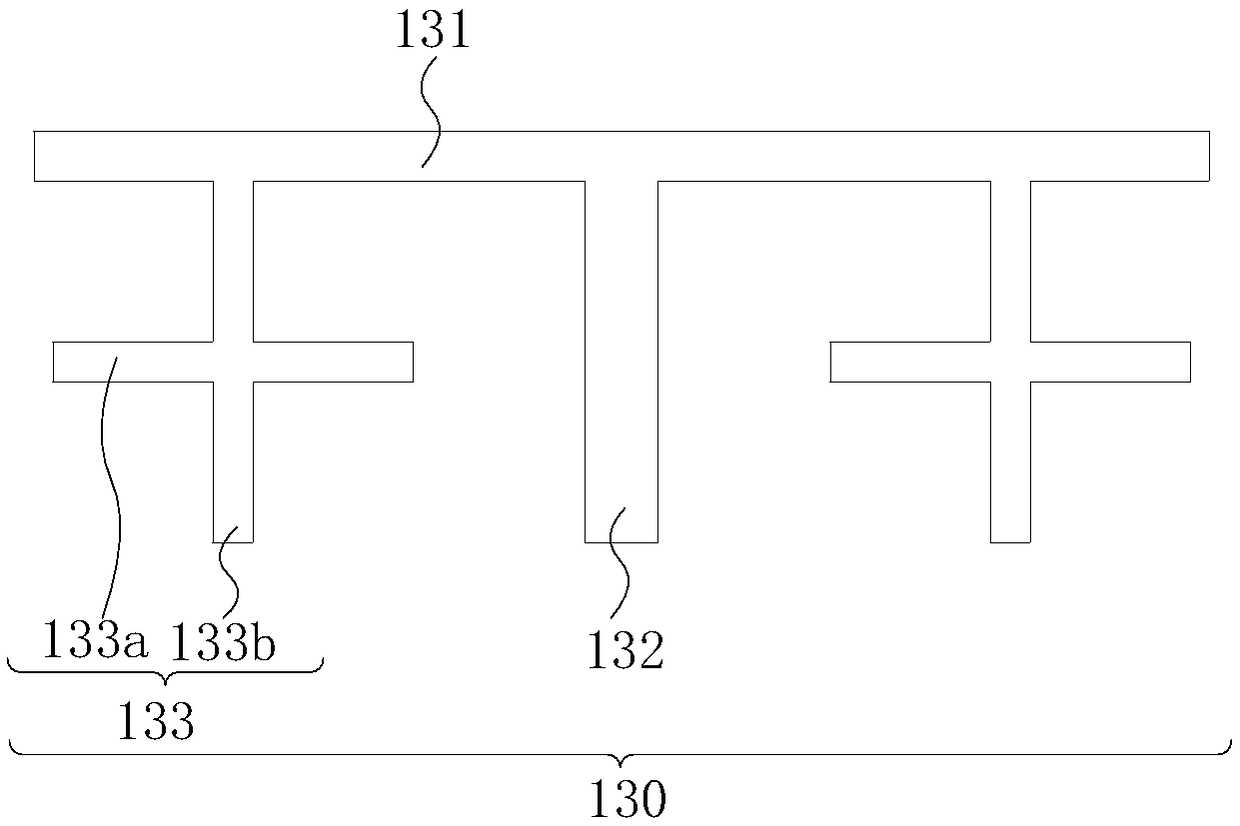

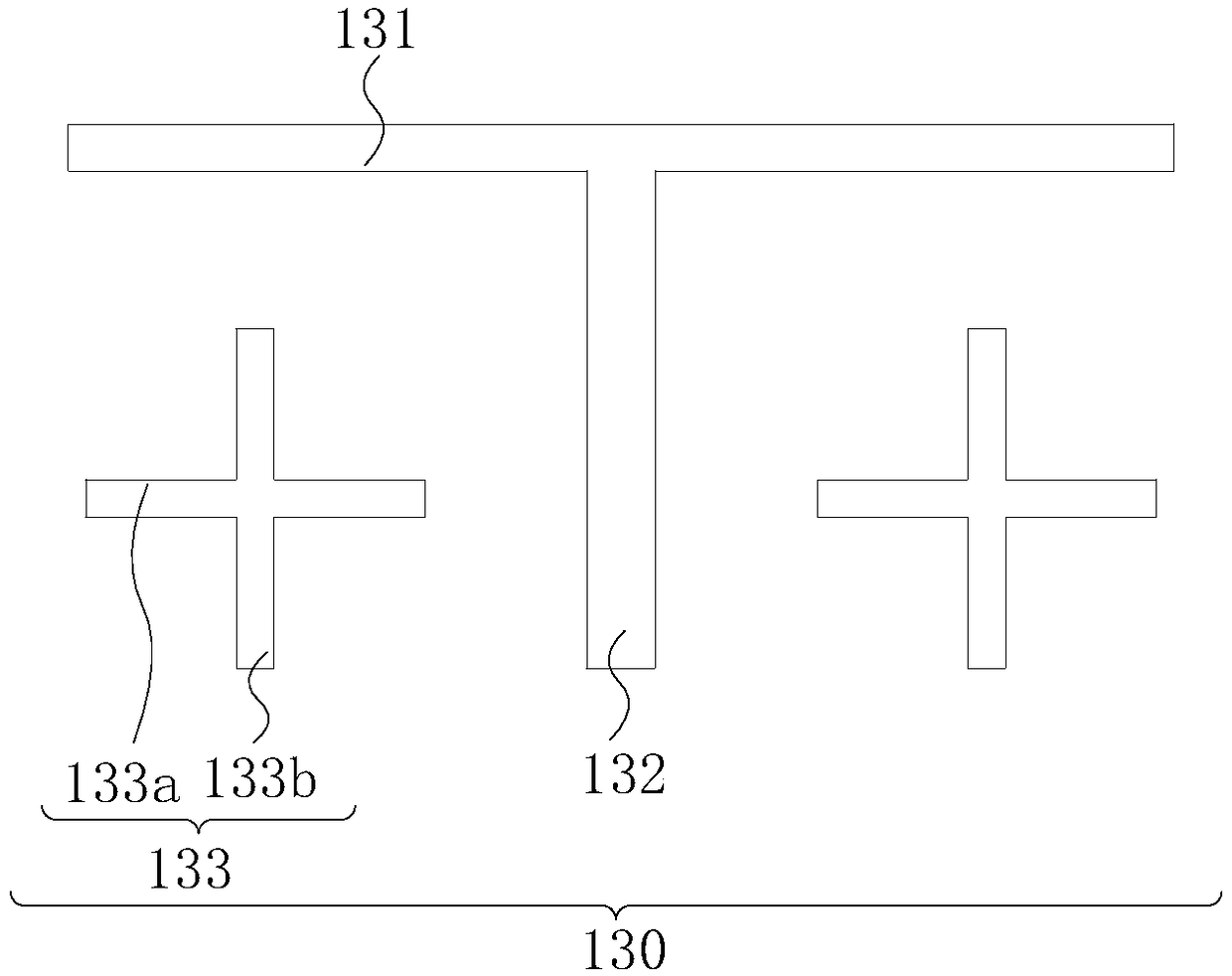

Barrier structure, display panel and display device

PendingCN109445198AImprove the display effectAvoid lateral flowNon-linear opticsDisplay deviceComputer science

The invention discloses a barrier structure, a display panel and a display device. The barrier structure is formed on the display panel; the display panel is divided into a display area and a non-display area, and comprises an alignment layer at least covering the display area; the barrier structure is arranged in the non-display area and surrounds the alignment layer; the barrier structure comprises a main barrier and a first sub barrier, one end of the first sub barrier is connected with the main barrier and the other end of the first sub barrier extends to the alignment layer. With the arrangement of the first sub barrier, transverse flowing of the alignment layer is improved effectively, coating precision of the alignment liquid process is improved, and display effect of the display panel is also improved.

Owner:HKC CORP LTD

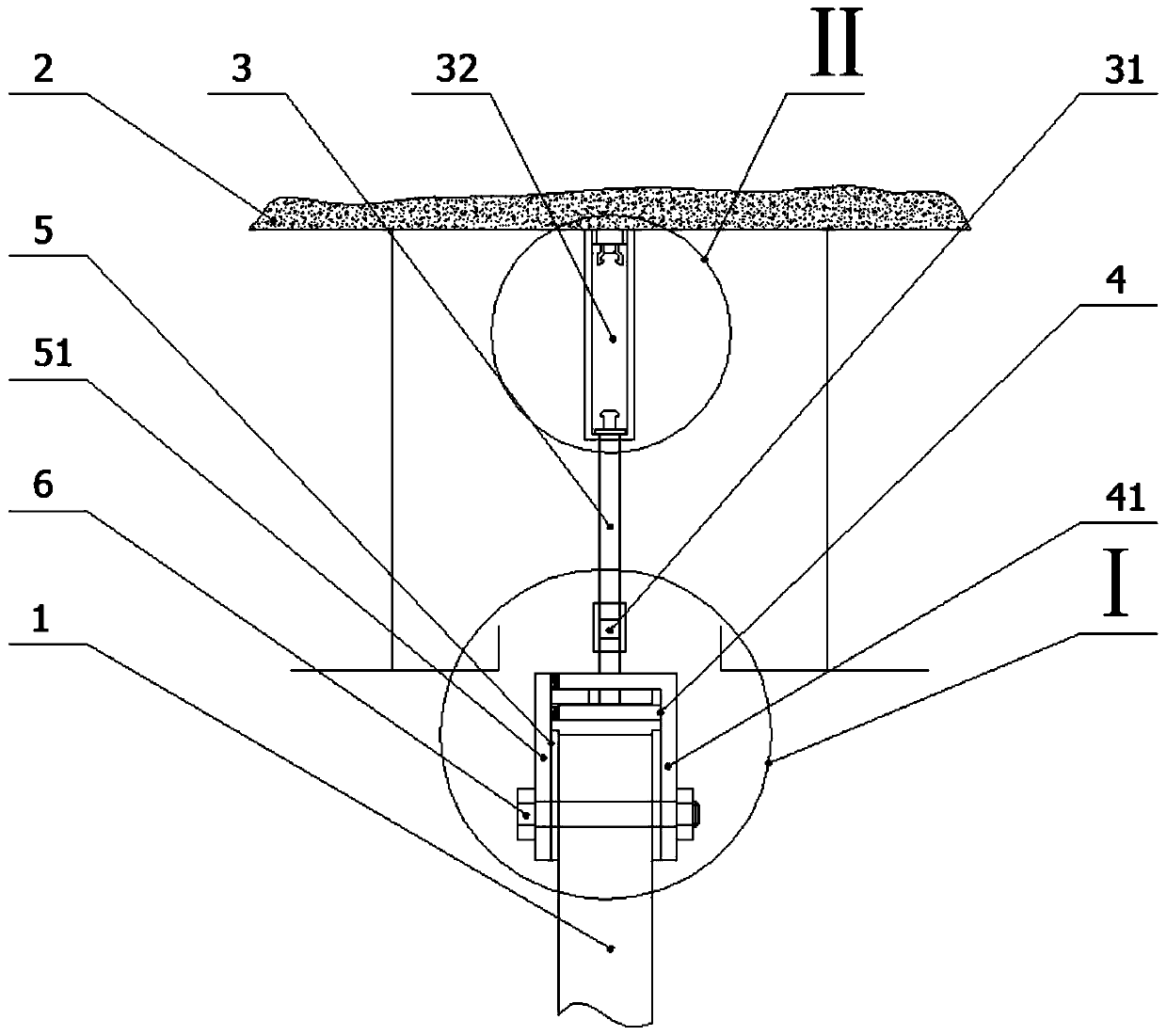

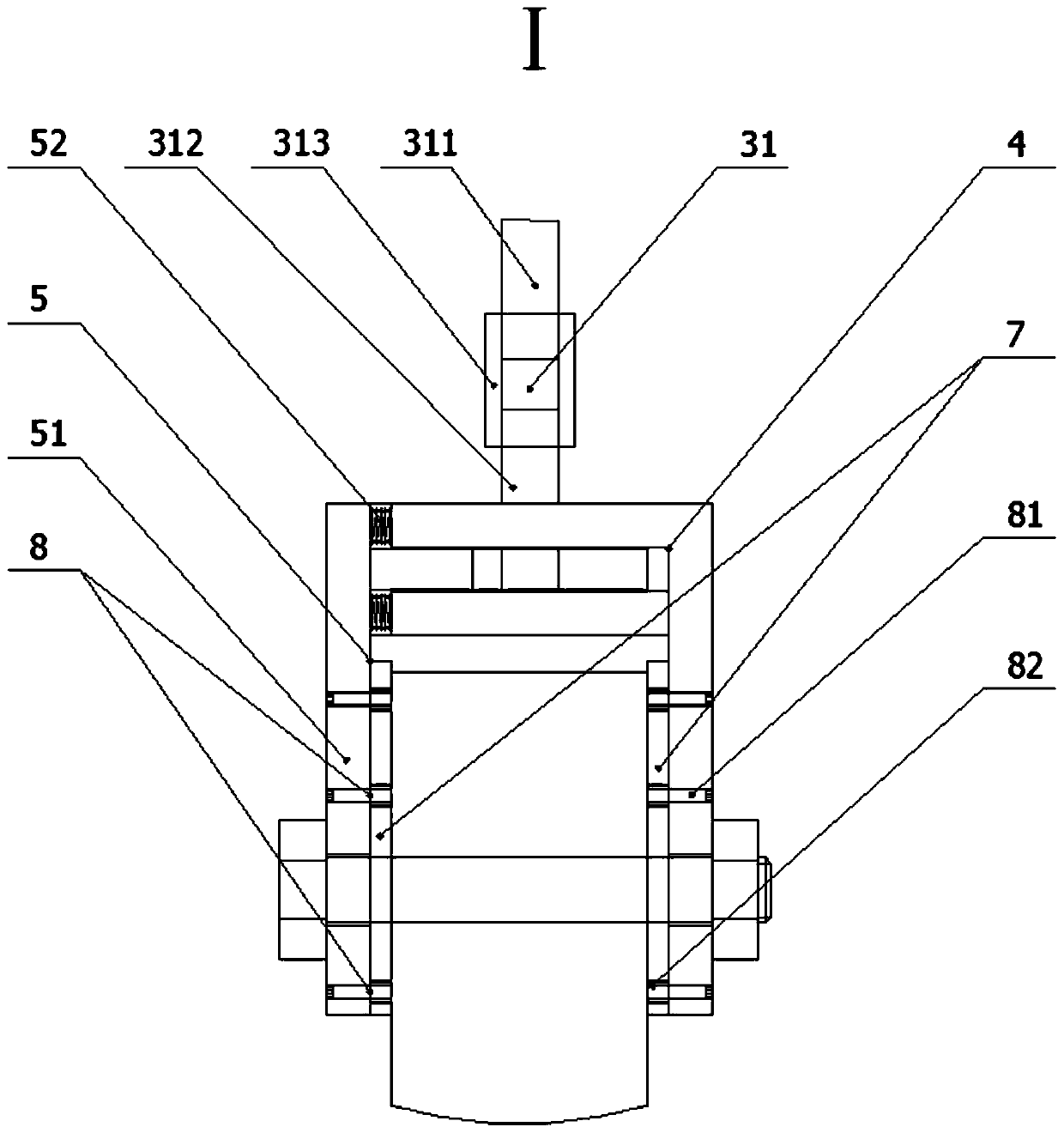

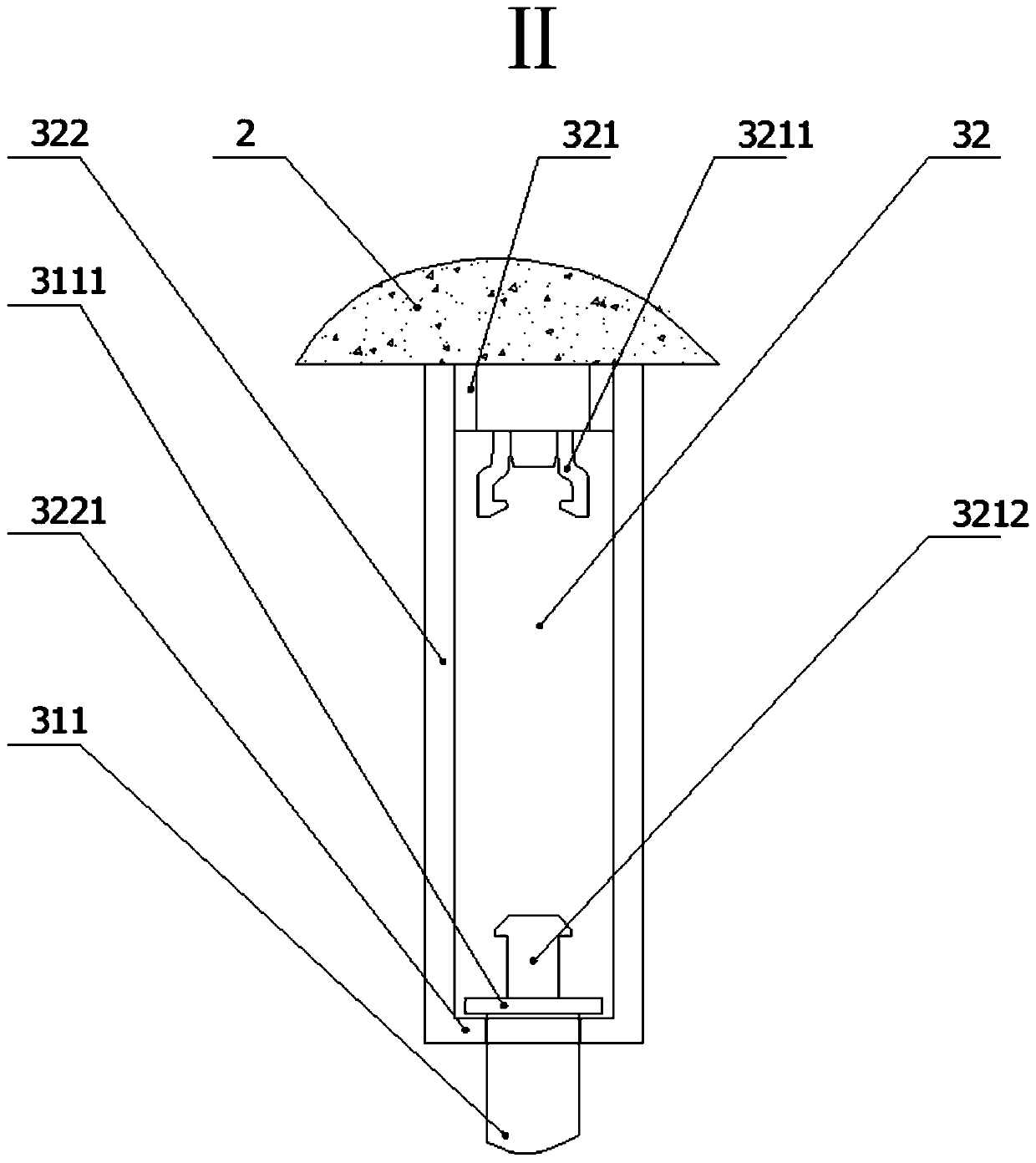

Mounting structure used for ceiling screen and mounting method thereof

PendingCN111441492AImprove the quality of look and feelIntegrity guaranteedCeilingsBuilding material handlingCombustionStructural engineering

The invention discloses a mounting structure used for a ceiling screen. The structure comprises a smoke deflector used for blocking horizontal flowing of smoke and hot gas generated by combustion, a bearing base face used for bearing the ceiling screen, a hanging assembly fixedly connected with the bearing base face, a main hooking assembly, a sub hooking assembly and a thread connecting part. Themounting structure has the beneficial effects that firstly, the smoke deflector and a roof face are subjected to lifting connection, adjusting is convenient, the main hooking assembly and the sub hooking assembly can achieve rapid mounting, mounting accuracy can be effectively improved, mounting efficiency is effectively improved, manpower cost is saved, finally, the main hooking assembly and thesub hooking assembly are mounted below a roof ceiling structure, integrality of the ceiling structure is ensured, remaining procedures of later-period repair and fine repair can be reduced, and the appearance quality of the ceiling screen can be effectively improved.

Owner:GOLD MANTIS CONSTR DECORATION

Disposable absorbent article having barrier cuff strips

A disposable absorbent article includes two laterally opposing longitudinally extending barrier cuff strips attached to an interior surface of an absorbent assembly in laterally opposing attachment zones. Each barrier cuff strip may include a water-impermeable layer and may be extensible. A longitudinally extending elastic gathering member is attached to each barrier cuff strip adjacent to its proximal edge. When the article is worn, the elastic gathering members contract and raise the barrier cuff strips to form side barriers. The absorbent assembly includes an absorbent core that may contain superabsorbent particles, which may be contained inside pockets. A portion of the absorbent assembly such as the portion that lies between the barrier cuff strip attachment zones may be extensible and may include a water-impermeable layer. The laterally opposing attachment zones may act as dams preventing a lateral flow of liquid bodily waste.

Owner:PROCTER & GAMBLE CO

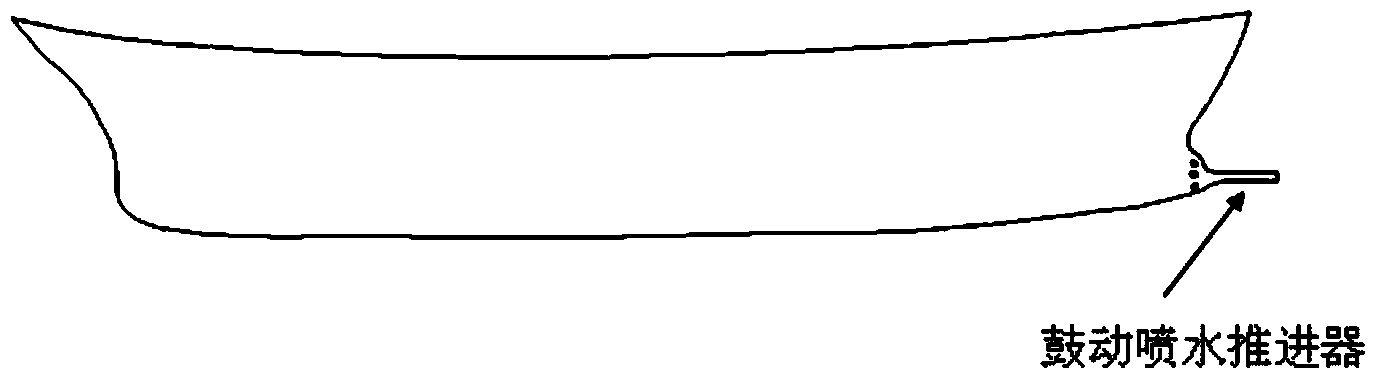

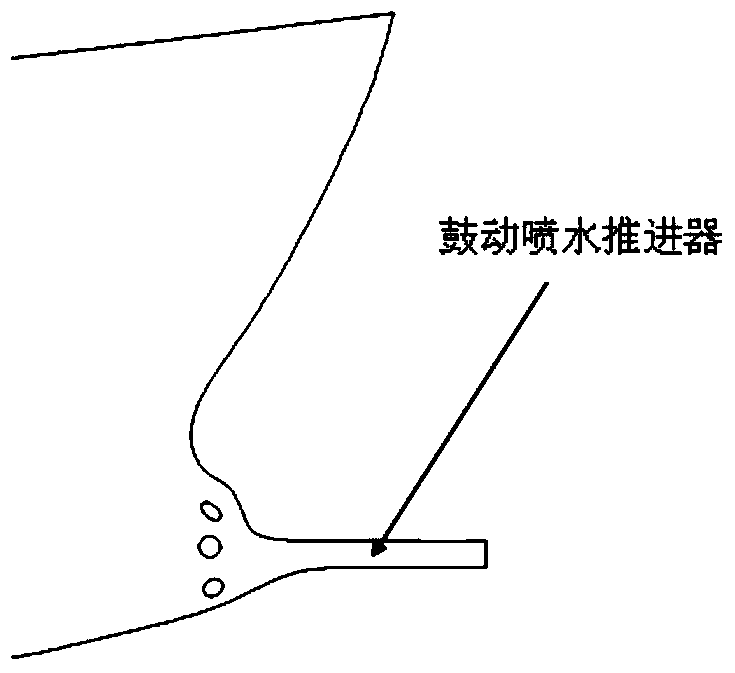

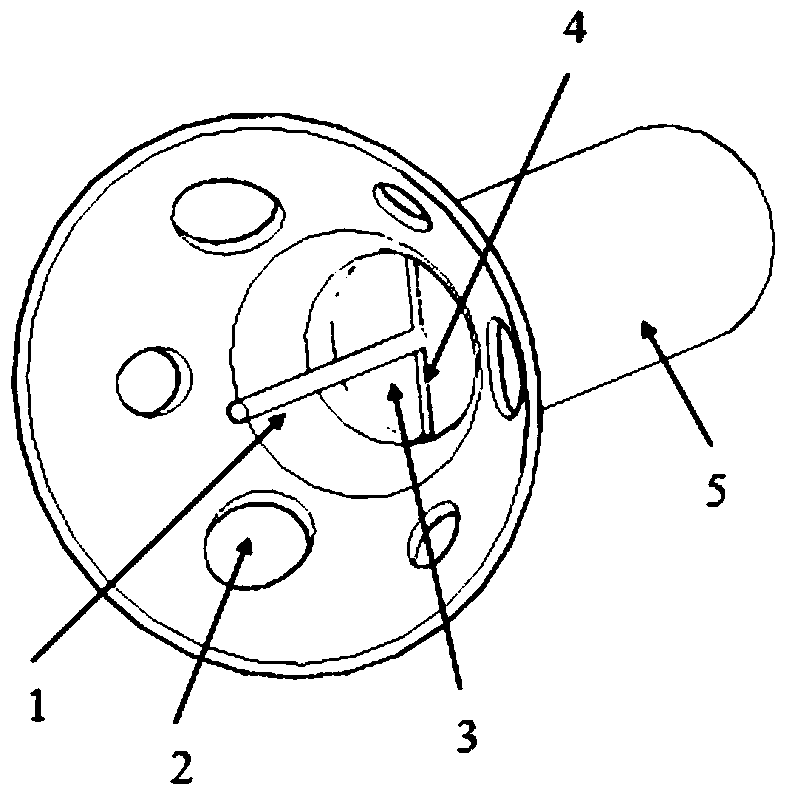

Agitating water jet propeller

InactiveCN104015909AGuaranteed sailing performanceAvoid the effects of wakePropulsive elementsPump-jetWater flow

The invention provides an agitating water jet propeller which comprises a water jet barrel, a reciprocating type spindle, a rotating shaft and vanes. The water jet barrel comprises a straight barrel portion and a horn barrel portion, wherein water inlets are formed in the horn barrel portion, the large end of the horn barrel portion is fixed to one end of a ship body, and the small end of the horn barrel portion is connected with the horn barrel portion. The end of the reciprocating type spindle is connected with the middle of the rotating shaft, two slide grooves are formed in the inner wall of the straight barrel portion, and the two ends of the rotating shaft are respectively arranged in the two slide grooves. The vanes comprise the first vane and the second vane, wherein the first vane and the second vane are connected through a connecting piece, the first vane and the second vane can rotate relative to the connecting piece, two connecting rings are arranged on the connecting piece, and the connecting piece sleeves the rotating shaft through the connecting rings. The agitating water jet propeller can avoid effects of stern wake on the premise of guaranteeing ship navigation performance, can push water flow to move backwards in the axial direction, can avoid horizontal flow, reduces energy loss and improves the propelling efficiency.

Owner:HARBIN ENG UNIV

Control box with high protection performance for antenna erection

ActiveCN112498249AAvoid accumulationAvoid turbulenceDispersed particle separationVehicle componentsActivated carbonStructural engineering

The invention discloses a control box with high protection performance for antenna erection, relates to the technical field of antenna erection, and aims to solve the problems that a conventional control box is relatively weak in protection capability due to a simple box body structure, and internal elements of the conventional control box are easy to damage under severe weather conditions. A protective top cover is installed outside the upper end of the box body, supporting plates are installed in the protective top cover, fans are installed on the inner sides of the two supporting plates, adehumidification box is installed on one sides of the supporting plates, the dehumidification box is filled with a drying agent and activated carbon, and a damping support is installed at the bottom of the box body. Second connecting plates are arranged on the two sides of the damping support correspondingly, a vent groove is formed in the top end of the box body, first connecting plates are arranged on the two sides of the box body correspondingly, damping supporting columns are installed between the first connecting plates and the second connecting plates, and an installing plate is installed in the box body.

Owner:ANHUI HENGNUO ELECTROMECHANICAL SCI & TECH

Vehicle having air-guiding arrangement

ActiveCN106458271AAvoid lateral flowInclined flow reductionVehicle body stabilisationAerodynamics improvementMarine engineering

Owner:BAYERISCHE MOTOREN WERKE AG

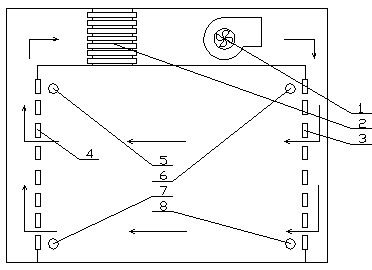

Method for monitoring humidity of storage battery electrode plate curing chamber

ActiveCN103219540AUnderstand and control humidity conditionsSpeed up convectionFinal product manufactureSecondary cells manufactureBattery electrodeWaste management

The invention discloses a method for monitoring the humidity of a storage battery electrode plate curing chamber. The storage battery electrode plate curing chamber comprises a convection air chamber and a recirculation air chamber, wherein the convection air chamber is positioned in the recirculation air chamber, the right side wall and the left side wall of the convection air chamber are respectively provided with air inlet opening valves and air outlet opening valves, the recirculation air chamber is internally provided with a steam inlet and a circulating fan, the plurality of air inlet opening valves and the air outlet opening valves are available, each air inlet opening valve and each air outlet opening valve are arranged along the horizontal direction, and the plurality of air inlet opening valves and the plurality of air outlet opening valves are respectively and evenly distributed on the right side wall and the left side wall of the convection air chamber; and the convection air chamber is provided with four humidity monitoring probes for timely knowing the humidity condition of the curing room.

Owner:天能集团贵州能源科技有限公司

Cross-flow fan blade based on bionics

ActiveCN112049817AReduce energy consumptionEasy to movePump componentsRadial flow pumpsBiomimeticsFan blade

The invention discloses a cross-flow fan blade based on bionics. The blade is formed by arranging a plurality of blade units in the axial direction of an impeller, the front edges of the blade units protrude, the rear edges of the blade units are concave inwards, the middle portions of the sides, close to the front edges, of the upper surfaces of the blade units are higher than the two sides, themiddle portions of the sides, close to the rear edges, of the upper surfaces of the blade units are lower than the two sides, and the middle portions of the sides, close to the front edges, of the upper surfaces of the blade units are higher than the middle portions of the sides, close to the rear edges, of the upper surfaces of the blade units. By the adoption of the cross-flow fan blade based onbionics, airflow flowing of the front edge and rear edge of the blade can be improved, an eccentric vortex moves downwards, the efficiency of a cross-flow fan is improved, and energy consumption is reduced.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com