Method for ensuring uniform water inflow of water collecting basin in fan-shaped municipal sewage lifting pumping station

A technology for urban sewage and water collection tanks, which is applied in the direction of sewage removal, waterway systems, water supply devices, etc., can solve the negative impact of the safe and stable operation of urban sewage lifting pumping stations, and is affected by surrounding buildings, roads, bridges, etc. Problems such as poor inlet water flow, to ensure safe, stable and efficient operation, ensure the uniformity of flow velocity distribution, and prevent the generation of surface vortices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

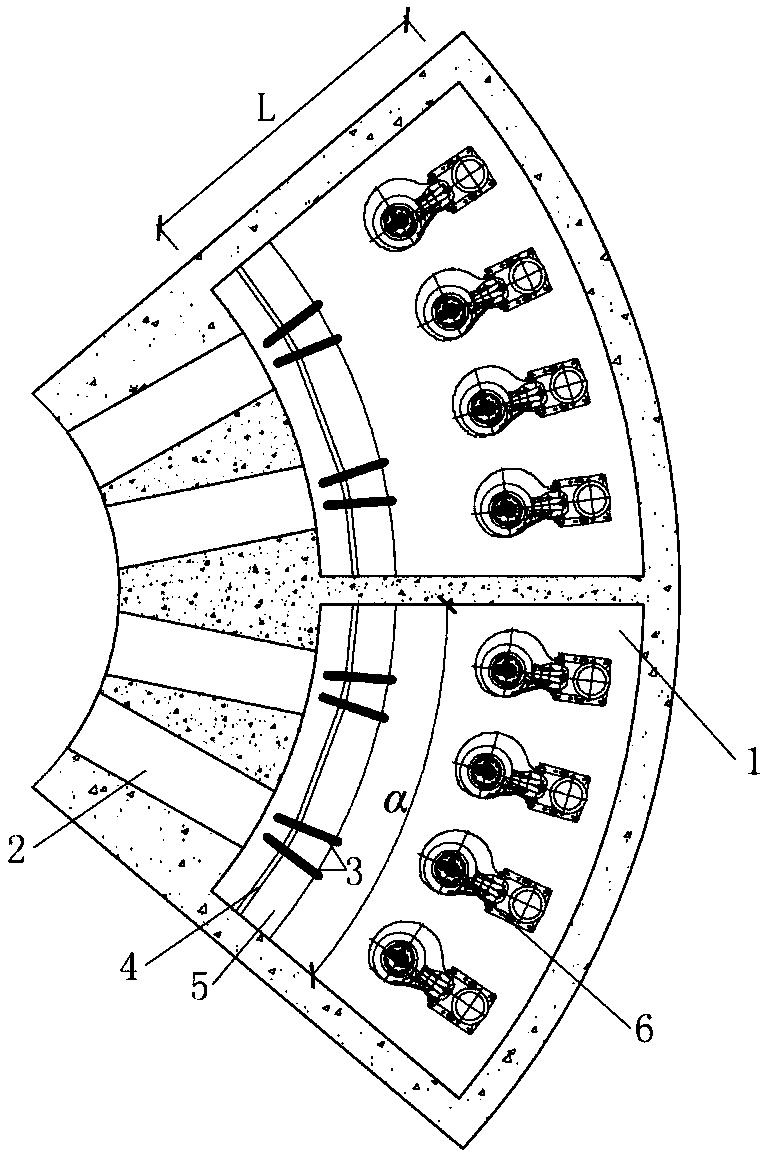

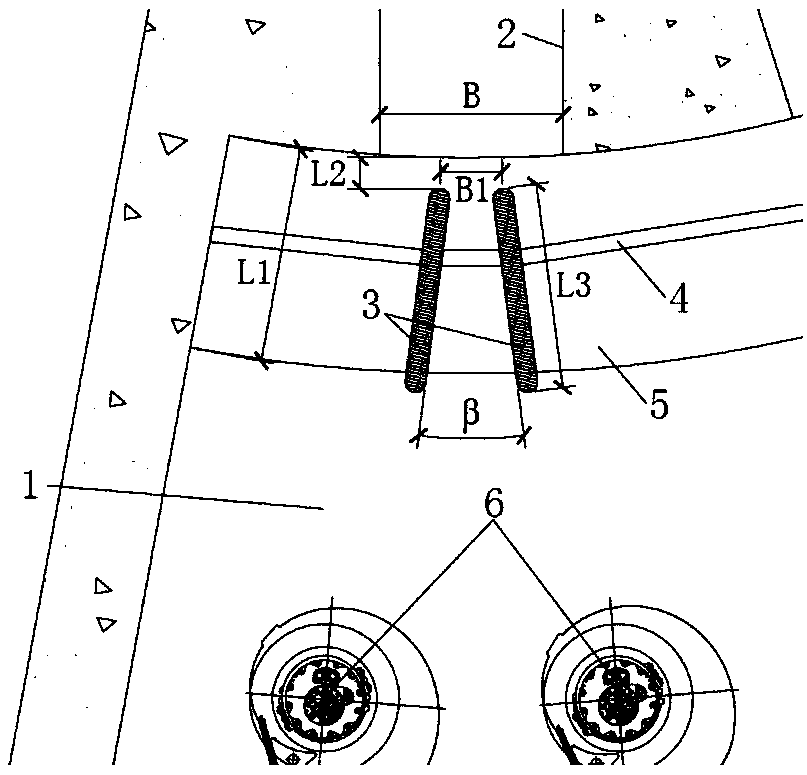

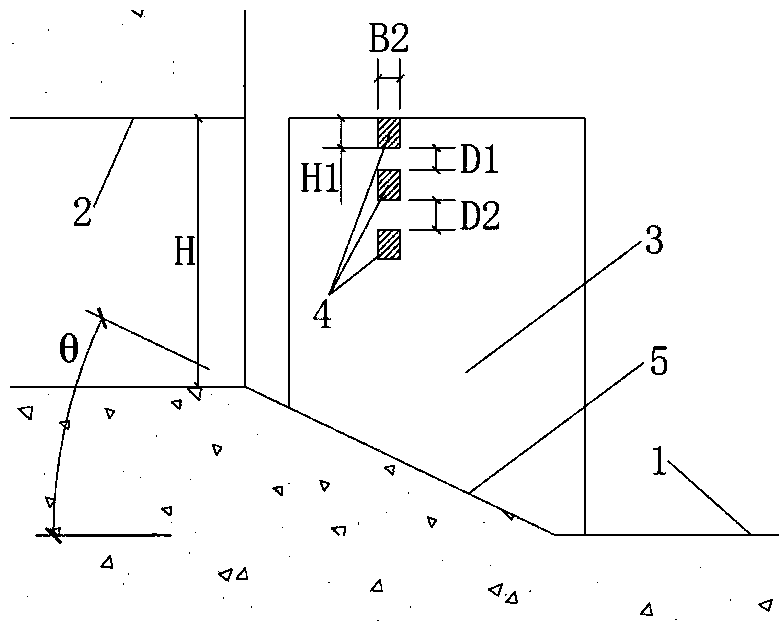

Embodiment 1

[0059] The number of sumps is M=2, the length of the radial side walls on both sides of the sumps is L=9.0m, and the included angle is α=40°. The number of inlet box culverts 2 corresponding to each sump is N=2, and the width B=K1×(α / 360)×L=1.8m and K1=0.9, height H=0.2L=1.8m, horizontal length L1=0.233L=2.1m, slope angle θ=25° of the slope section in the sump , the number of 3 sets of eight-shaped diversion piers corresponding to each sump is N1=2, the front end of the eight-shaped diversion piers 3 is facing the outlet of the water inlet box culvert 2 and the distance between them is L2=0.0333L=0.3m, a single diversion pier The length of the flow pier L3=0.222L=2m, the distance between the front ends of the eight-shaped flow diversion pier 3 and the two pier B1=0.333B=0.6m, the included angle β=15° and K2=0.75, the number of folded beams 4 S=3, The height H1=0.111H=0.2m, the width B2=0.075L3=0.15m of the rectangular section of the folded beam 4, the vertical distance between...

Embodiment 2

[0061] The combined rectification device described in this embodiment is different from Embodiment 1 in that: the width B=1.75m and K1=0.875 of the water inlet box culvert 2, the height H=0.222L=2m, the slope section in the sump Horizontal length L1=0.2L=1.8m, slope angle θ=30°, the distance between the front end of the splayed diversion pier 3 and the outlet of the water inlet box culvert 2 L2=0.02L=0.18m, the length of a single diversion pier L3= 0.2L=1.8m, the distance between the front ends of the eight-shaped diversion pier 3 and the two piers B1=0.2B=0.35m, the included angle β=20° and K2=1.0, the height of the rectangular section of the multi-layer folded beam 4 H1=0.1H= 0.2m, width B2=0.05L3=0.09m, vertical distance D1=0.75H1=0.15m, D2=H1=0.2m between two adjacent beams; font-shaped diversion piers 3 and folded beams 4 are made of reinforced concrete materials .

Embodiment 3

[0063] The combined rectifying device described in this embodiment differs from Embodiments 1 and 2 in that: the width of the water inlet box culvert 2 is B=1.7m and K1=0.85, the height H=0.3L=2.7m, the water inlet box The horizontal length L1=0.3L=2.7m from the outlet of the culvert 2 to the slope section 5 at the bottom of the sump 1, the slope angle θ=20°, and the distance L2=0.05L between the front end of the eight-shaped diversion pier 3 and the outlet of the culvert 2 of the water inlet box =0.45m, the length of a single diversion pier L3=0.3L=2.7m, the distance between the front ends of the eight-shaped diversion pier 3 and two piers B1=0.4B=0.68m, the included angle β=12° and K2=0.6, the folded beam 4 The height of the rectangular section is H1=0.148H=0.4m, the width B2=0.1L3=0.27m, the vertical distance between two adjacent beams is D1=0.75H1=0.3m, D2=H1=0.4m.

[0064] Such as Figure 4 As shown, the three-dimensional flow numerical simulation method is used to compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com