Shaft type pump device with annular water inlet groove

A technology of water inlet trough and pump device, which is applied to water supply devices, waterway systems, drainage structures, etc., can solve the problems of poor water inlet conditions, turbulence, and easy formation of vortices of impellers, so as to reduce hydraulic loss, improve water inlet flow state, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

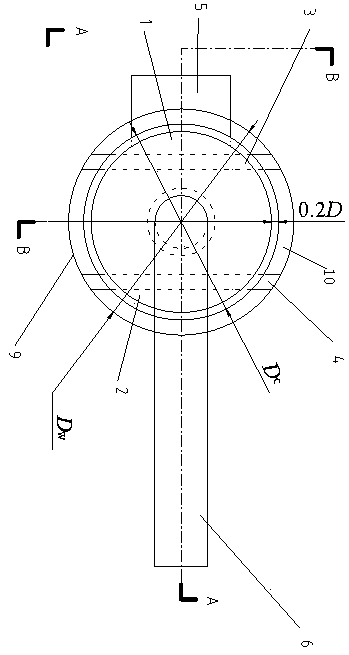

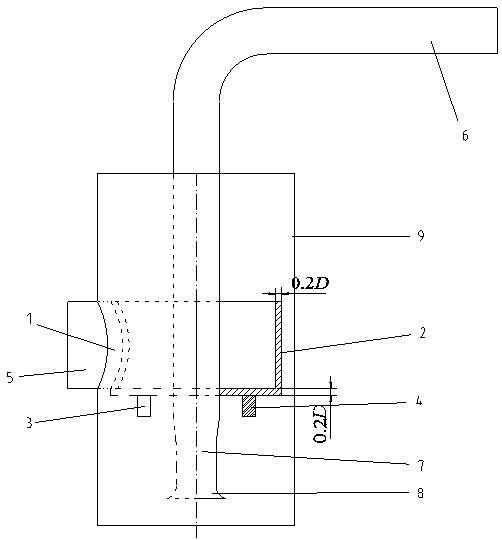

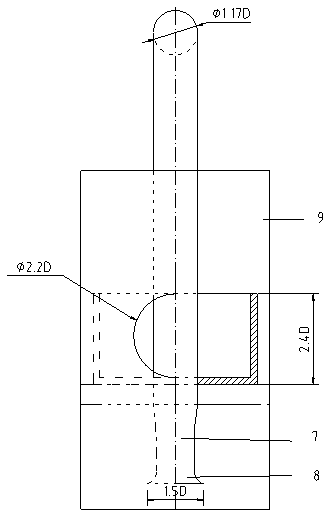

[0022] The present invention is applicable to the shaft type pump device, and the drawing is designed according to the design requirements.

[0023] A shaft type pump device with an annular water inlet tank includes a water inlet pipe 5, a water outlet pipe 6, a pump section 7, a trumpet pipe 8, and a well shaft 9, and a water uniform dish is arranged in the well.

[0024] For the convenience of installation, the uniform water dish is divided into two halves, that is, the water homogenizer 1 on the water inlet side and the water homogenizer 2 on the water outlet side. The water inlet pipe enters the water uniform dish, then overflows from the top of the water uniform dish and flows into the annular water inlet tank 10, and reaches the trumpet pipe inlet. The bottom plate thickness and side wall thickness of the uniform water dish are both 0.2D, the net height is equal to the diameter of the water inlet pipe, the outer diameter and the width of the water inlet groove are based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com