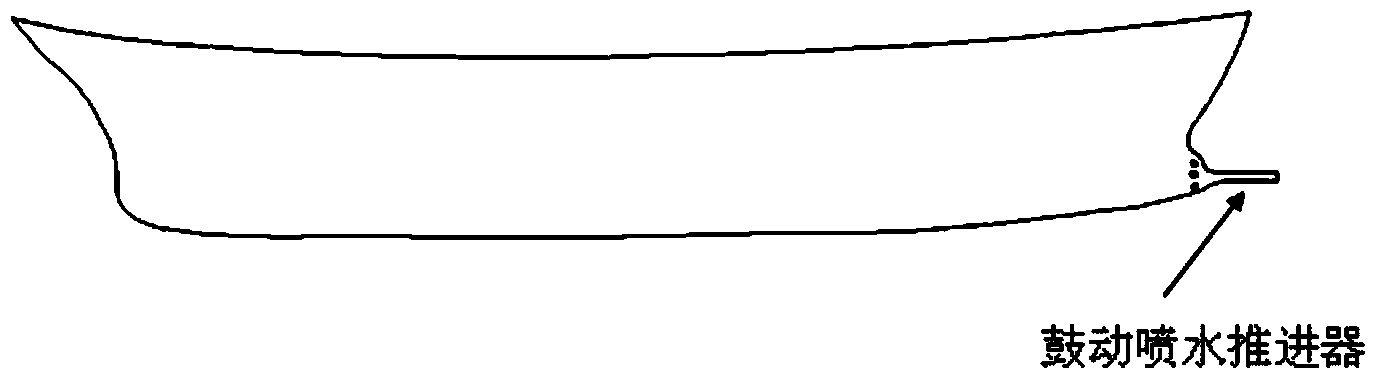

Agitating water jet propeller

A technology of water jet propellers and blades, which is applied in the direction of ship propulsion, propulsion parts, ship parts, etc., can solve problems such as energy loss and large resistance, and achieve the effects of reducing energy loss, avoiding lateral flow, and avoiding stern wake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

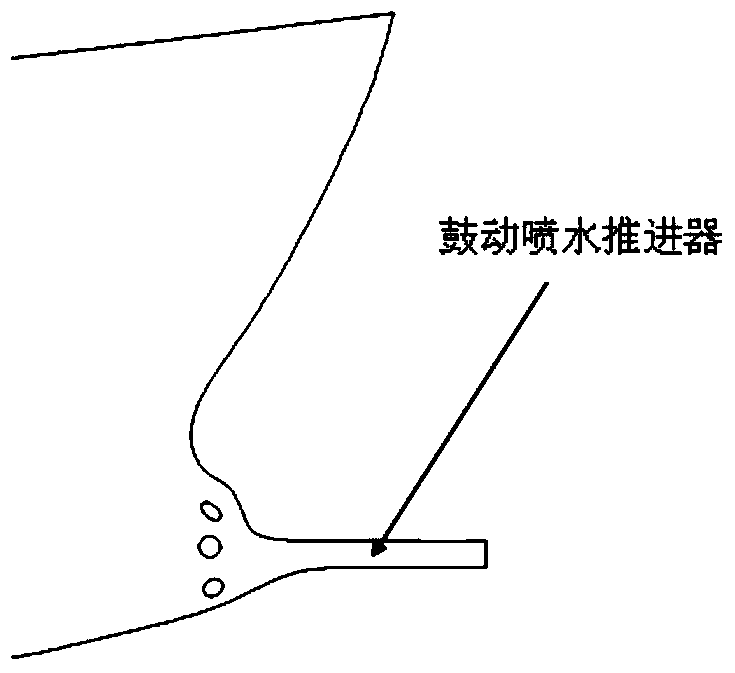

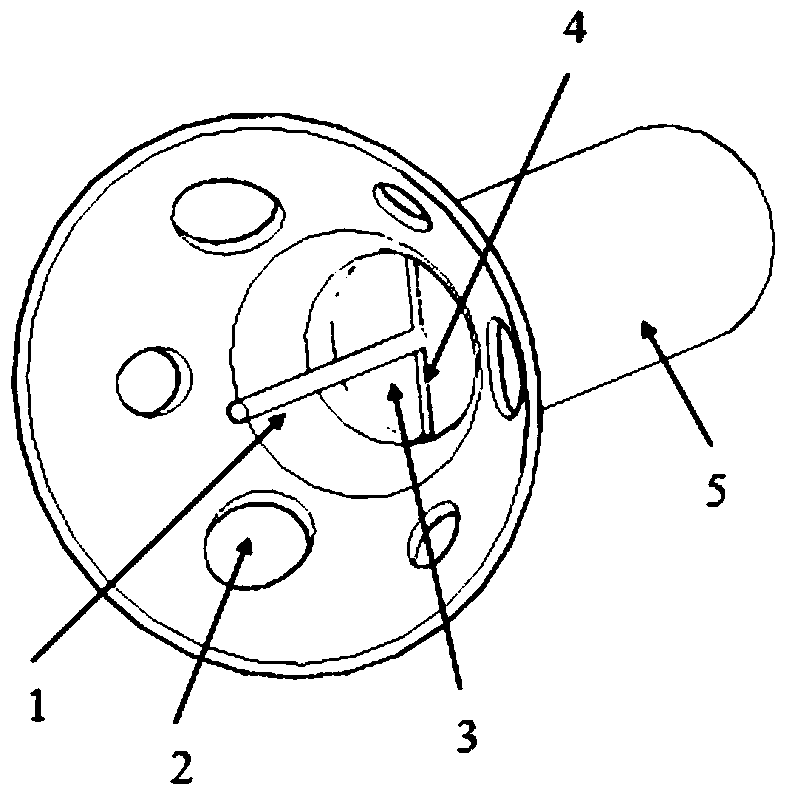

[0028] combine Figure 1-13 , add a water spray tube to the agitating propeller, the longitudinal rotation axis is fixed on the reciprocating main shaft, the two ends are connected with the water spray tube chute, the agitating propeller moves forward and backward along the water spray tube chute, and the water flows into the spray nozzle through the water inlet hole at the front end of the water spray tube The water cylinder, through the relative movement of the water flow and the agitation propeller, the two agitation blades rotate around the rotation axis under the action of the water flow, thereby periodically opening and closing. When the main shaft moves forward, the agitating blades move against the flow, and the blades are closed under the action of fluid, similar to a ship rudder; when the main shaft moves backward, the blades are opened under the action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com