Ship protection structure and construction method

A technology for protecting structures and construction methods, applied in the field of ships, can solve problems such as increased navigation resistance, inability to prevent fouling, and short duration, and achieve the effects of improving transportation capacity, reducing marine fouling biological adhesion, and reducing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

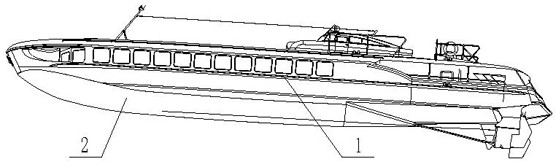

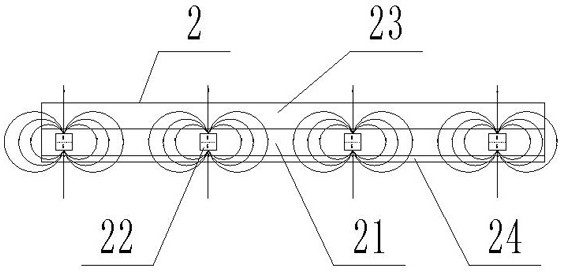

[0048] A ship protection structure 2, the ship includes a hull 1, and the ship protection structure 2 includes a protective layer 21 arranged on the outer surface of the hull 1 below the waterline;

[0049] Magnetic blocks 22 that generate a magnetic field are distributed in the protection layer 21 .

[0050] The line connecting the two magnetic poles of the magnetic block 22 is perpendicular to the outer surface of the hull 1 .

[0051] A heating layer 23 is also provided between the protective layer 21 and the outer surface of the hull 1 .

[0052] The heating layer 23 is heated to the Curie point of the magnetic block 22 during operation.

[0053] The magnetic blocks 22 are distributed in the protective layer 21 in the form of a Fibonacci sequence. The hull 1 includes a lowest point, and the magnetic blocks 22 are distributed in the protective layer 21 in a Fibonacci sequence with the lowest point of the hull 1 as the center point.

[0054] The protection structure also ...

Embodiment 2

[0058] A ship protection structure 2, the same as the first embodiment will not be repeated;

[0059] in

[0060] The magnetic block 22 can be the most common neodymium iron boron magnet, and its Curie point is 320°C-460°C, and the protective layer 21 can be a paint layer; organic silicon coating is used as the base material, such as Zhengzhou Qiangqing paint Co., Ltd. W61-600 and above paints, when using, fix the grid and arrange the magnetic blocks 22, then adjust the magnetism, or arrange them directly according to the required north and south poles; use paint to encapsulate the grid and the magnetic blocks 22; The magnetic block 22 can be mixed into the silicone coating, coated directly on the hull 1, and after drying, the internal magnetic block 22 can be adjusted to the overall magnetization / magnetic pole by a magnetization device.

[0061] And the heating layer 23 can use silicon carbon wire as the heating wire.

Embodiment 3

[0063] A construction method for the ship protection structure 2 described in Embodiment 1, comprising:

[0064] Select the outer surface below the waterline of the hull 1 and attach the heating layer 23 thereon, and then attach the grid of the protective layer 21 to the heating layer 23; the grid is based on two Fibonacci spirals Separation arrangement is carried out, one of the baselines is clockwise, the other baseline is counterclockwise, the two groups of baselines are mutually fitted, and the magnetic block 22 is arranged in the grid; the lowest point of the selected hull 1, two Fibonacci The helix line is the baseline and the lowest point of the hull 1 is the center point;

[0065] After the arrangement is completed, the magnetic block 22 is magnetized by a magnetizing device;

[0066] Fill the protective layer 21 in the gap between the two groups of baselines with the magnetic block 22 through the arrangement device; and use the magnetization device to magnetize the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com