Special slag cooler for heat storage secondary combustion purification plants for treating and adsorbing VOCs (volatile organic compounds) waste gas and solid waste

A solid waste, secondary combustion technology, applied in lighting and heating equipment, etc., can solve the problems of bulging, local temperature is too high, and the pipe wall is blocked by dust accumulation, so as to reduce the air leakage coefficient, stabilize the temperature gradient and reduce the temperature. effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

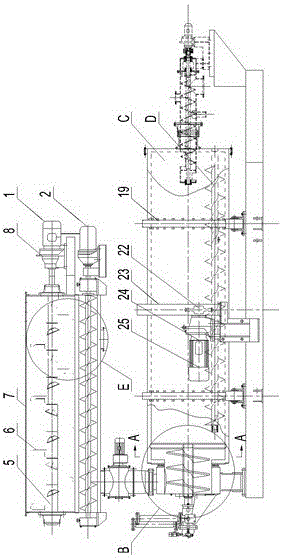

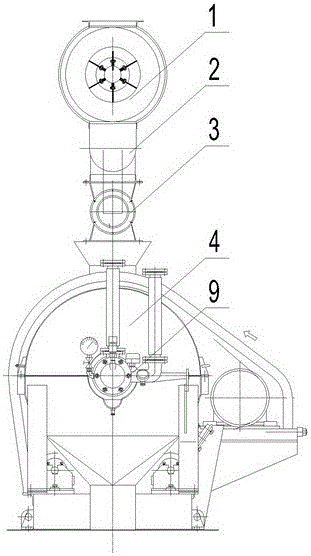

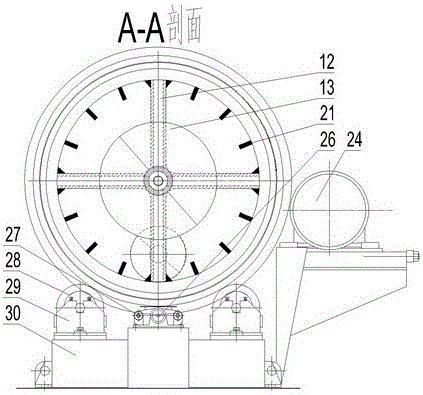

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a special cooling slag machine for treating adsorbed VOCs waste gas and solid waste heat storage secondary combustion purification device is characterized in that it includes a duster 1, a jacketed air-cooled screw conveyor 2, an air closing valve 3, and a drum Cold slag component4.

[0036] The dust blower 1 , the jacketed air-cooled screw conveyor 2 , the air closing valve 3 , and the drum cooling slag assembly 4 are connected sequentially from top to bottom.

[0037] The ash blower 1 includes an ash blower shaft 5, ash blower blades 6, a sleeve 7, and a motor reducer assembly 8. The motor reducer assembly 8 drives the ash blower shaft 5 to rotate and drives the ash blower blades 6 to rotate on the sleeve 7 .

[0038] The drum col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com