Patents

Literature

30results about How to "Solve the lock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

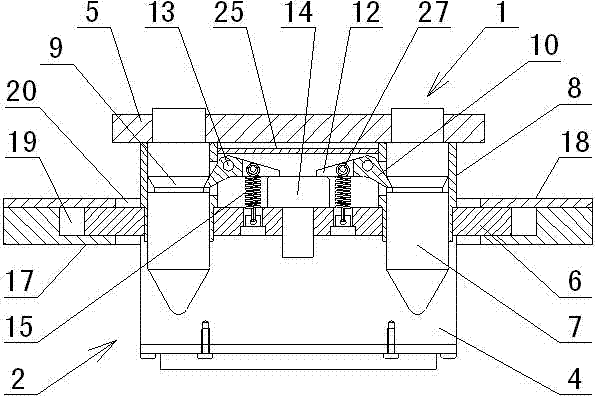

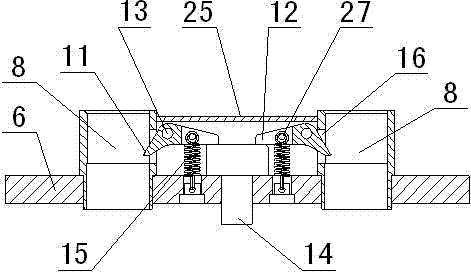

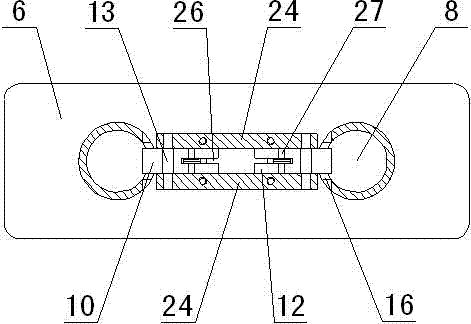

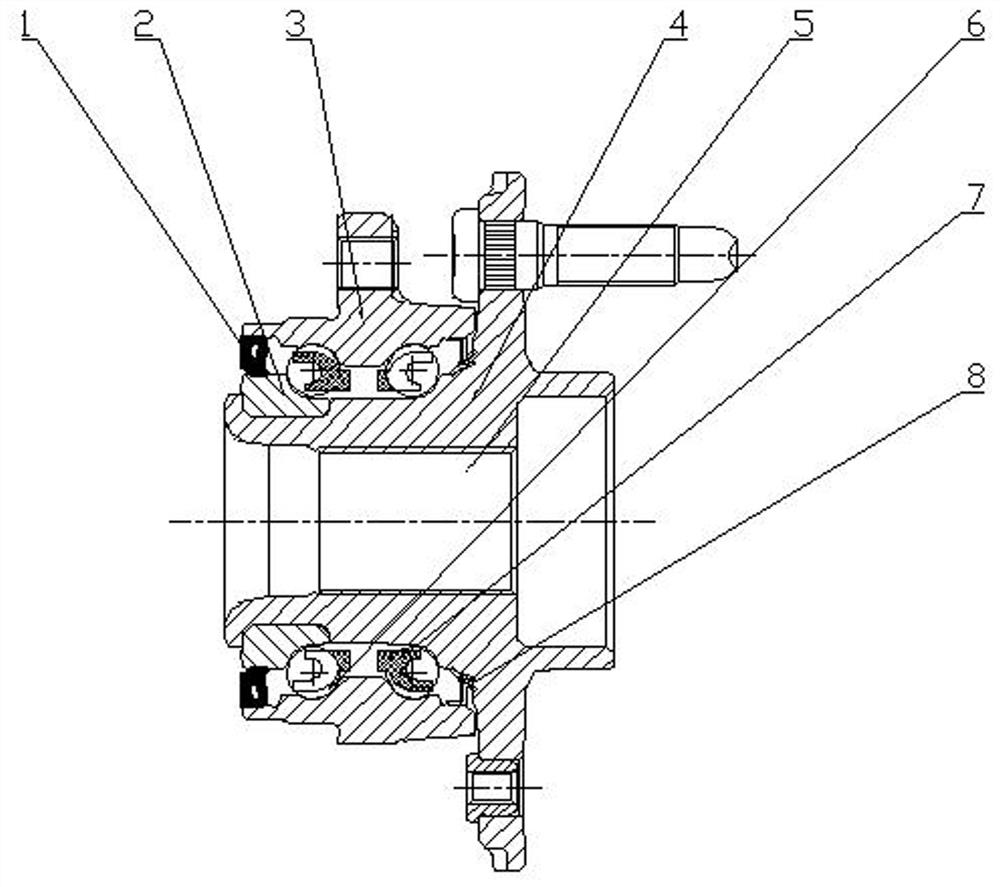

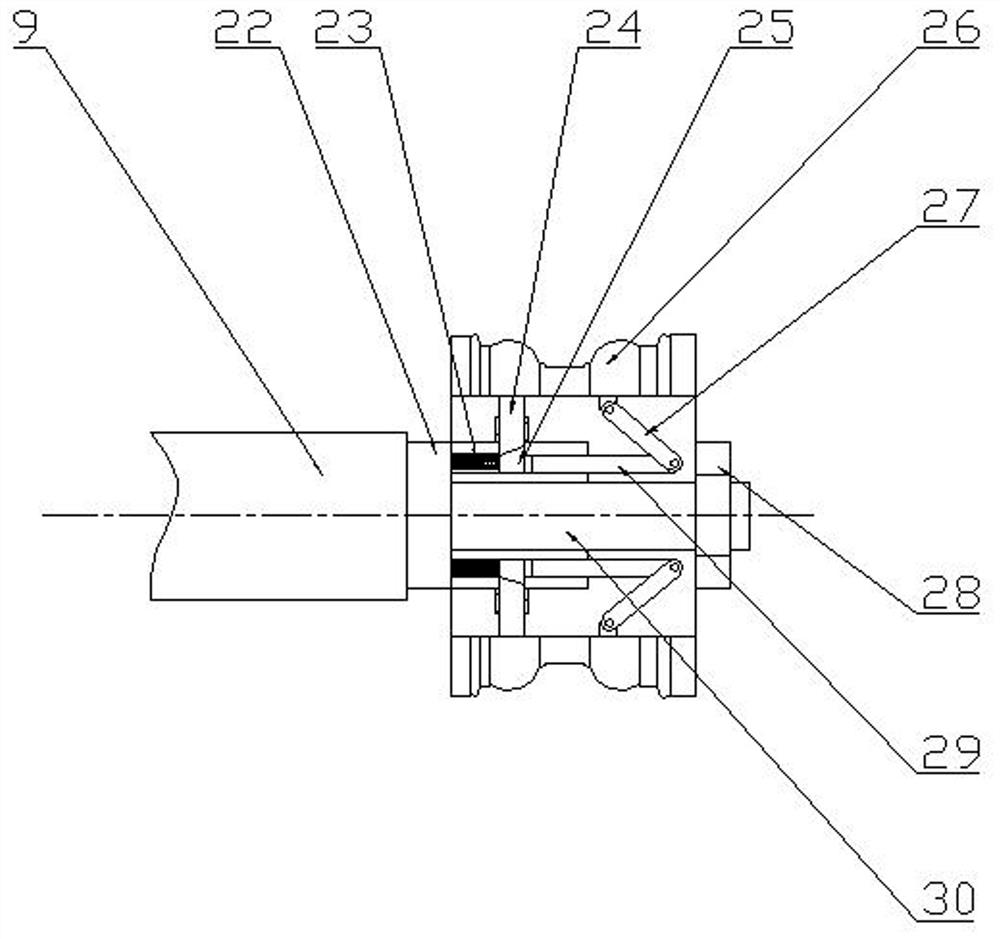

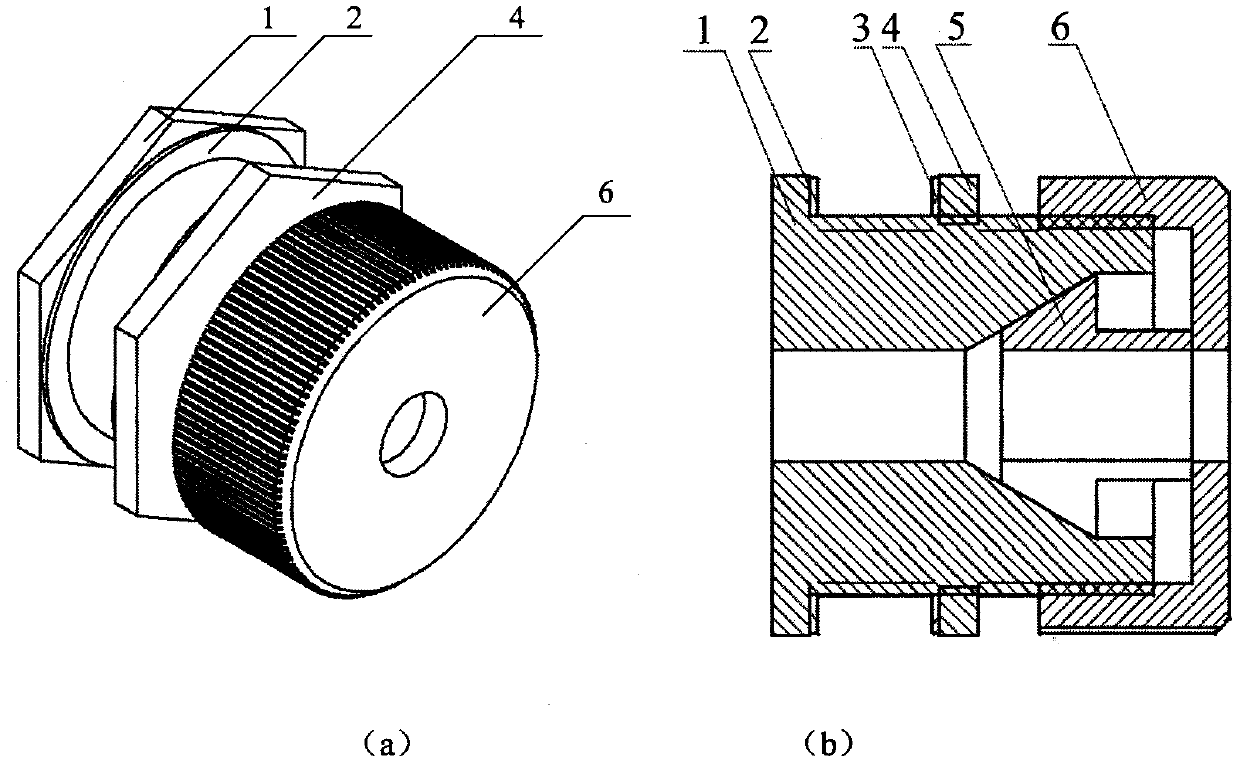

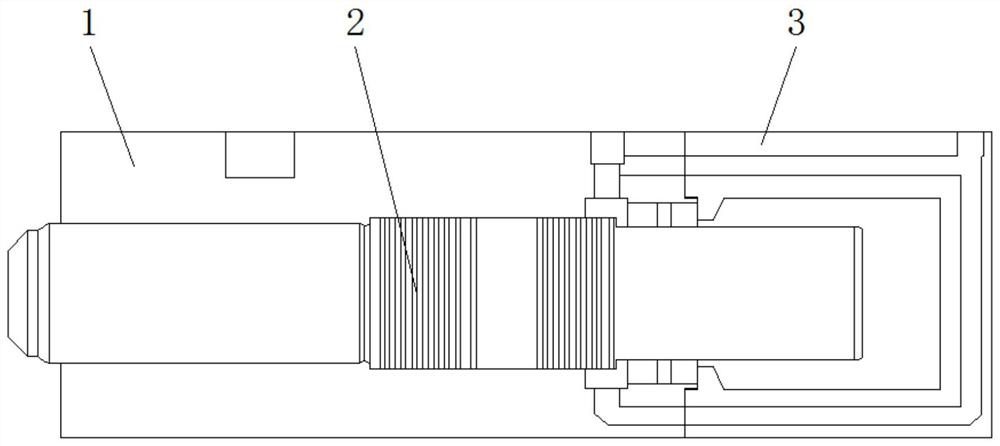

Movable connector with self-locking device

ActiveCN102354854ASolve the lack of locking deviceAddress reliabilityCoupling device detailsLocking mechanismSelf locking

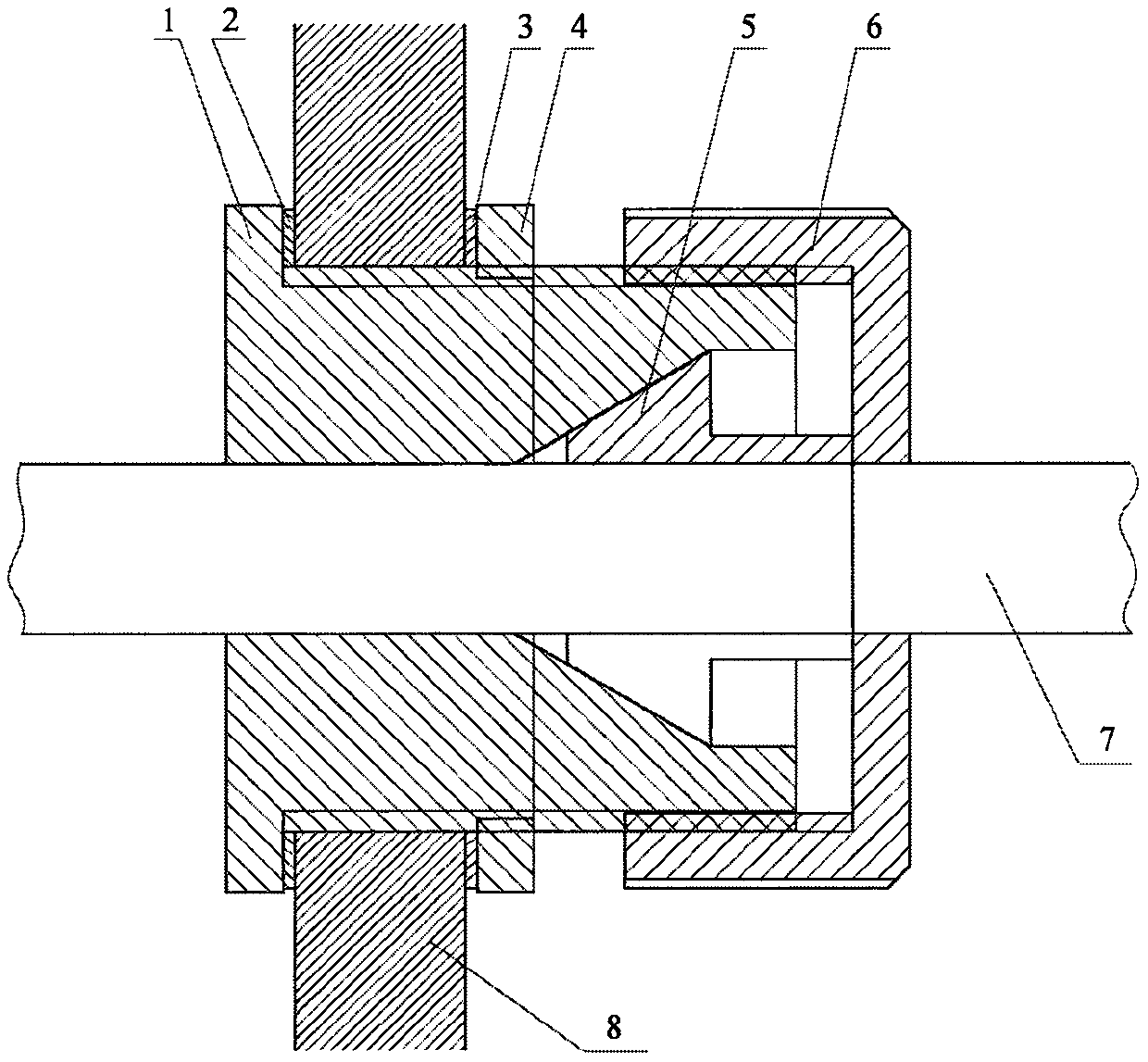

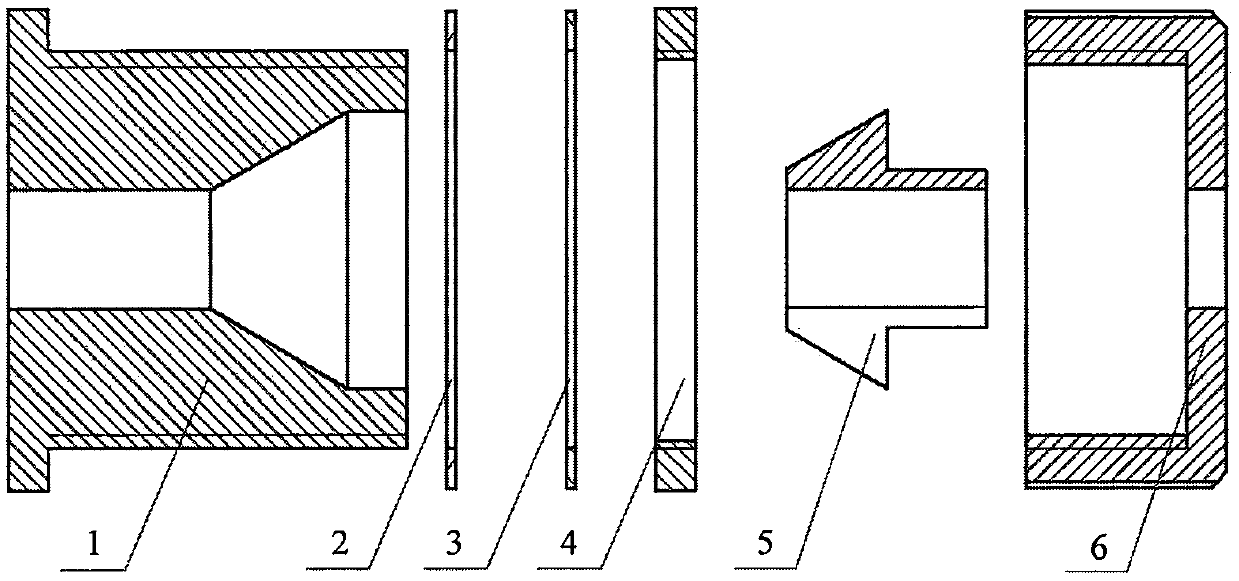

The invention discloses a movable connector with a self-locking device. The movable connector is characterized in that a plug mounting board is provided with a guide post pair; locking grooves with annular structures are arranged on the guide posts; a socket mounting board arranged on a movable seat is provided with a guide cylinder pair and a locking mechanism; the locking mechanism comprises a pair of symmetrically arranged locking claw; one end of the locking claw is a lock hook; the side wall of the locking mechanism close to the guide cylinder is provided with a window adaptive with the lock hook; when the movable connector is connected and locked, the lock hook passes through the window, and the end part of the lock hook is located in the locking grooves on the guide posts. By usingthe movable connector, the problems that the movable connector is lack of a locking device and the connection reliability is weak, and the connector is not convenient to use because that the connector is locked or unlocked with the aid of tools in the prior art, can be effectively solved. The movable connector provided by the invention is stable in connection and good in reliability, can be self-locked after the connector is plugged, and can be unlocked without any tools, thus, the use is very convenient.

Owner:杭州泰宏新能源技术有限公司

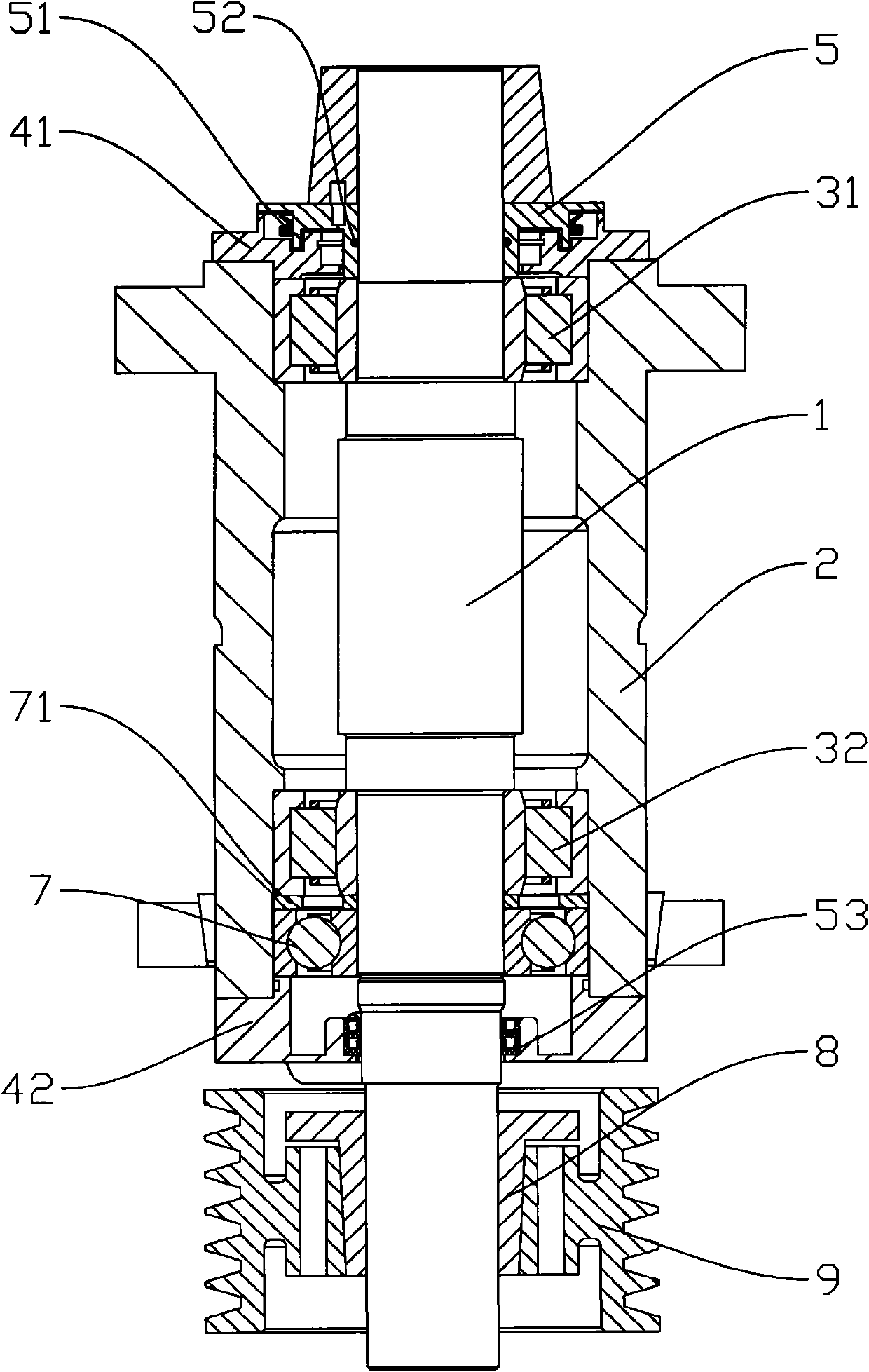

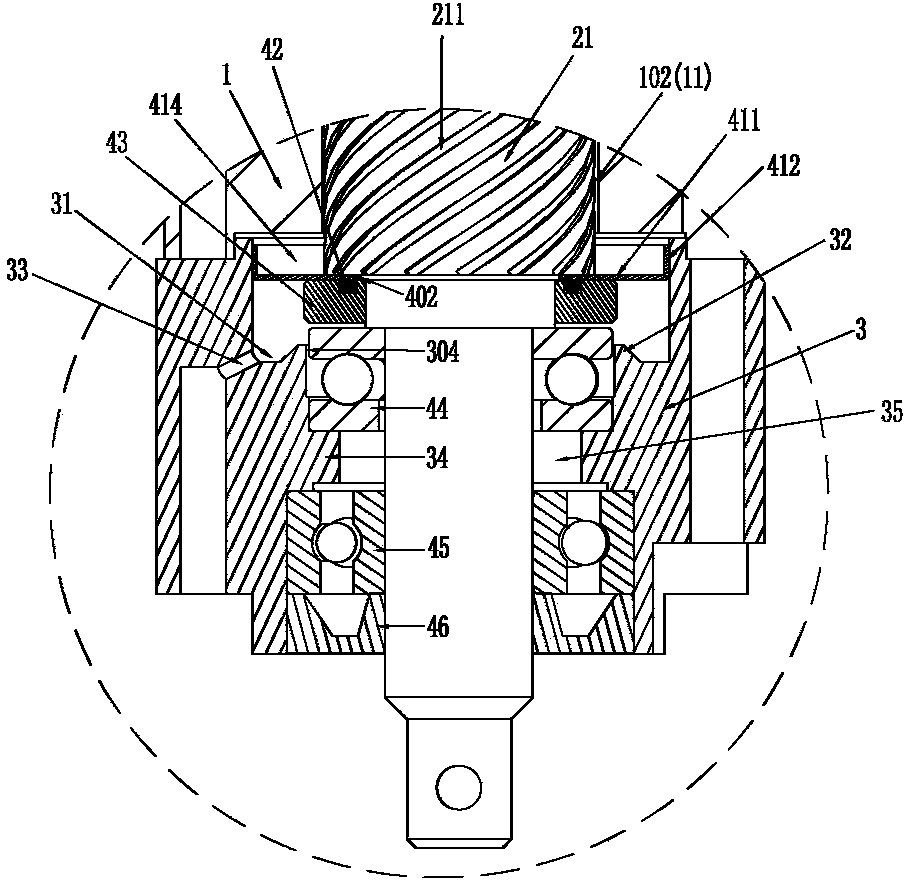

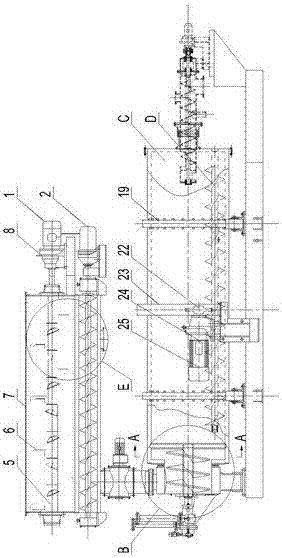

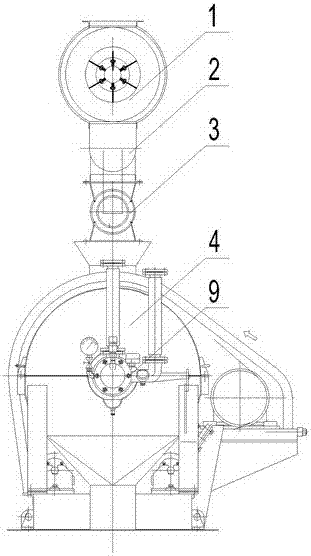

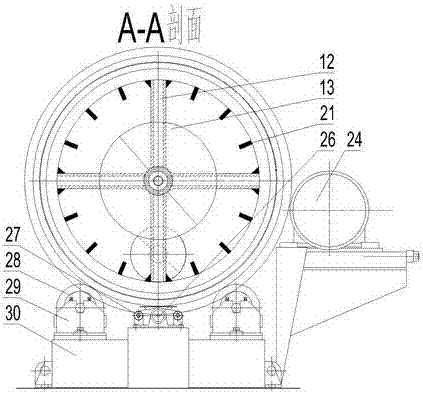

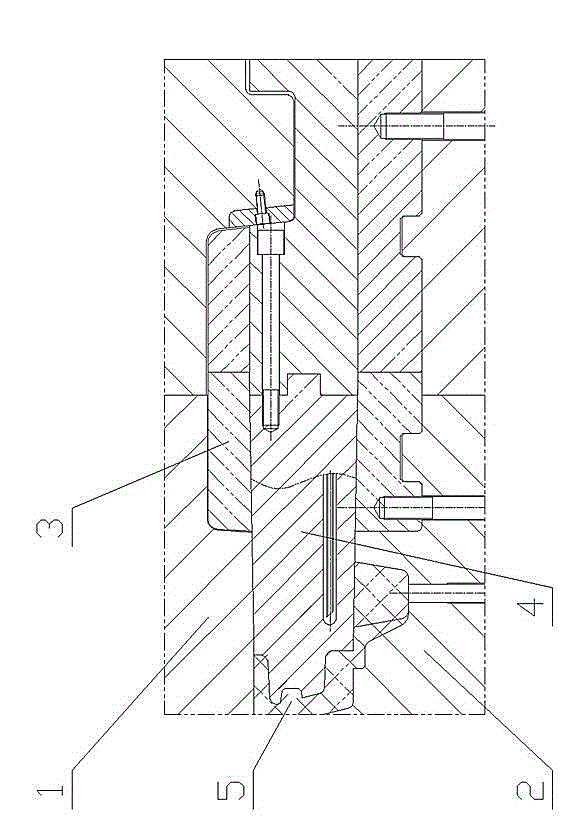

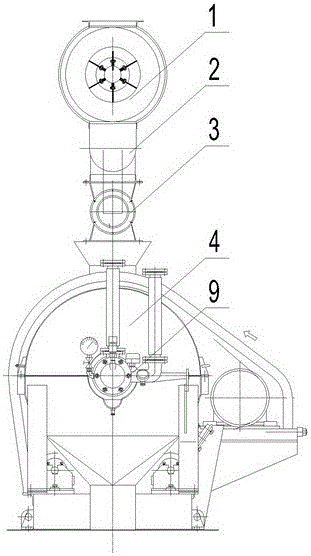

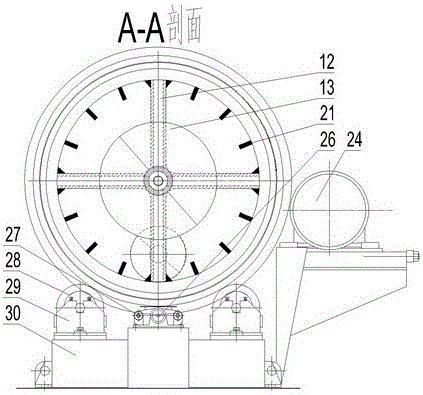

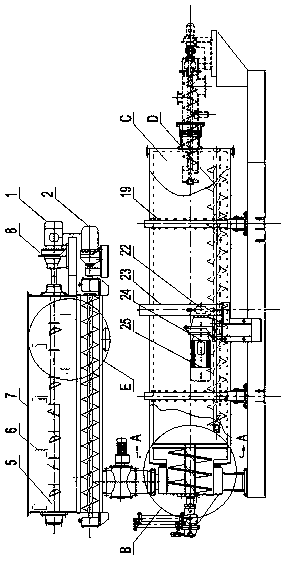

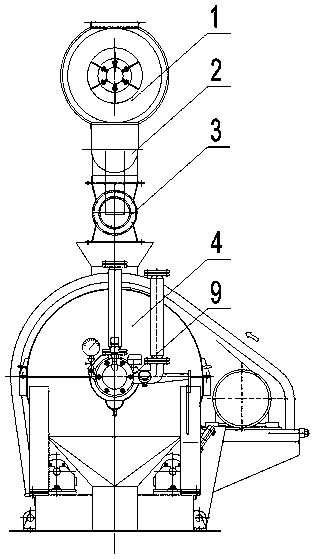

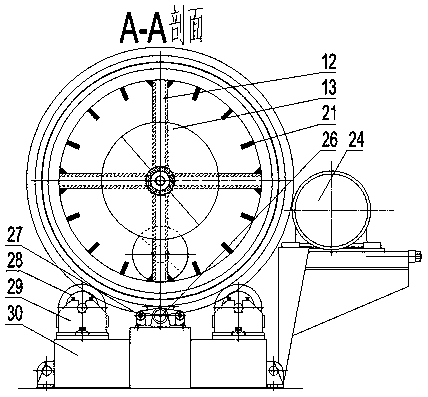

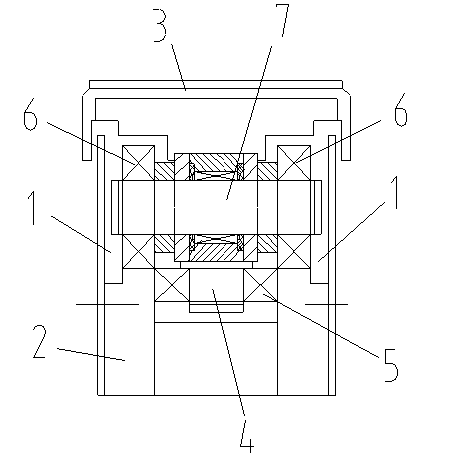

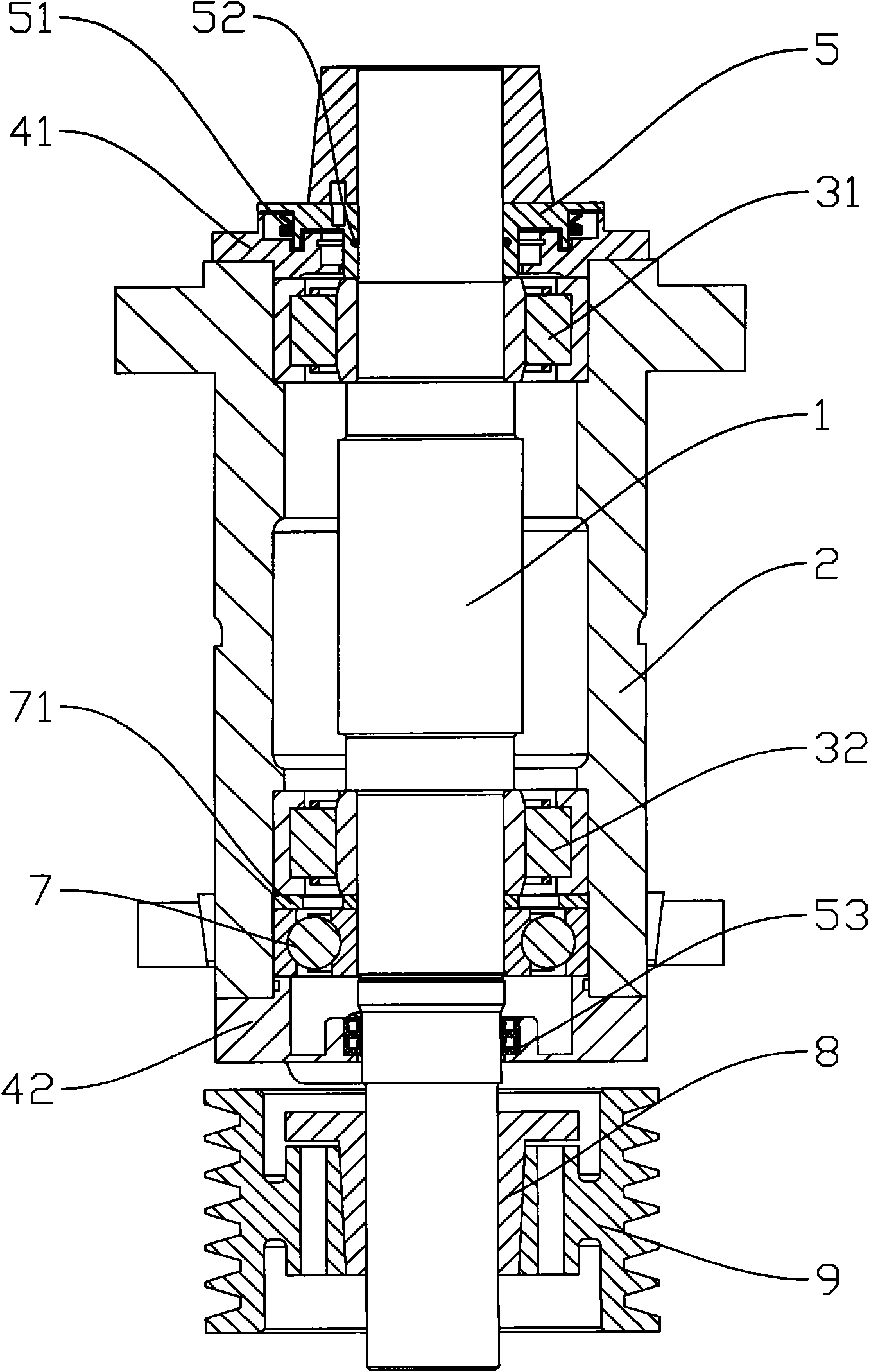

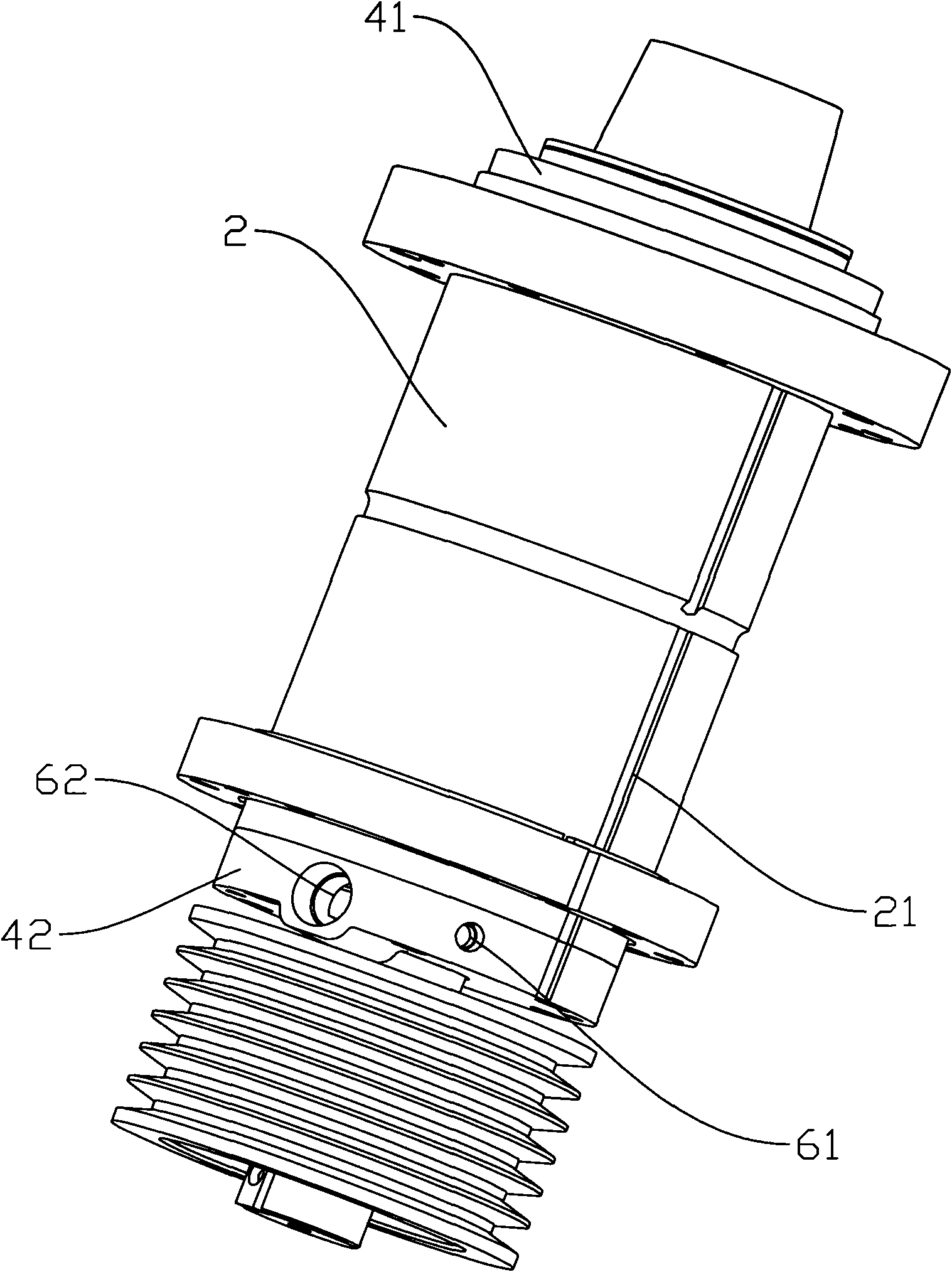

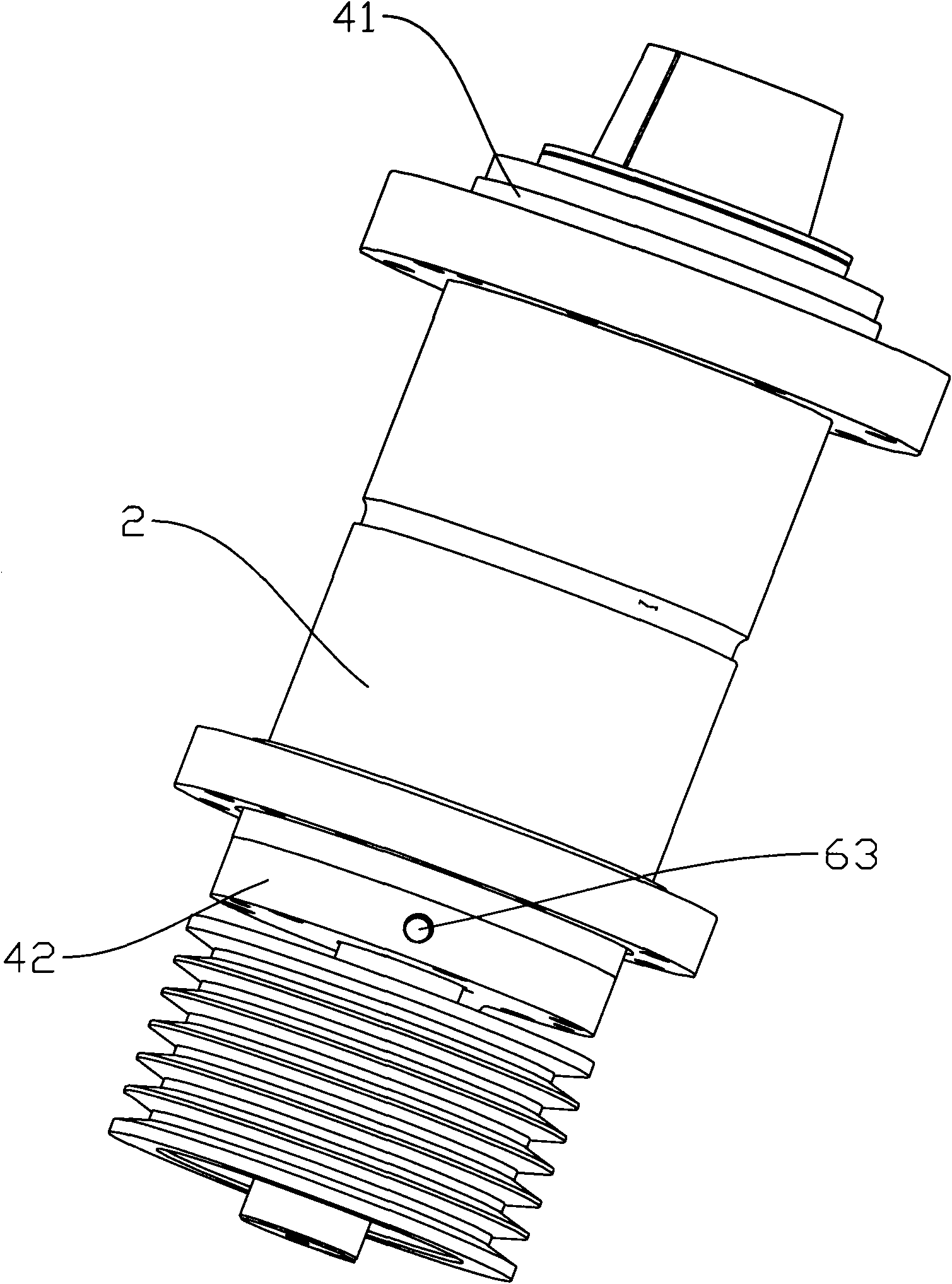

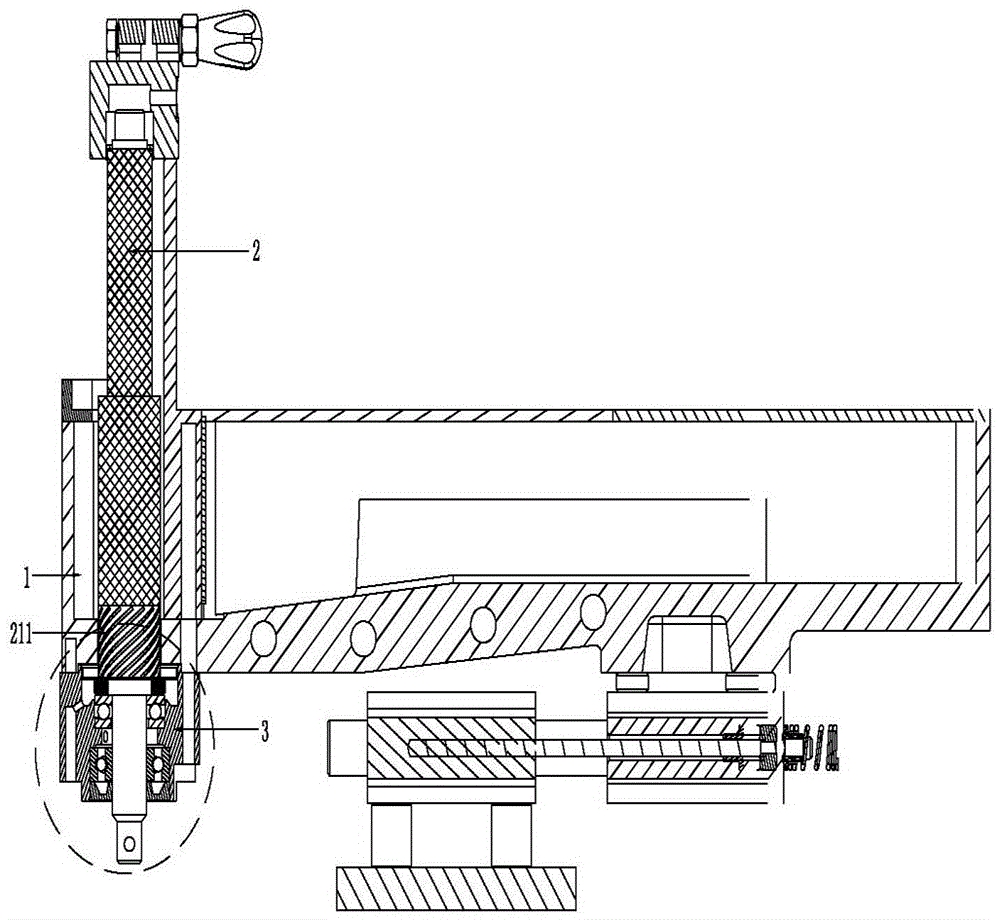

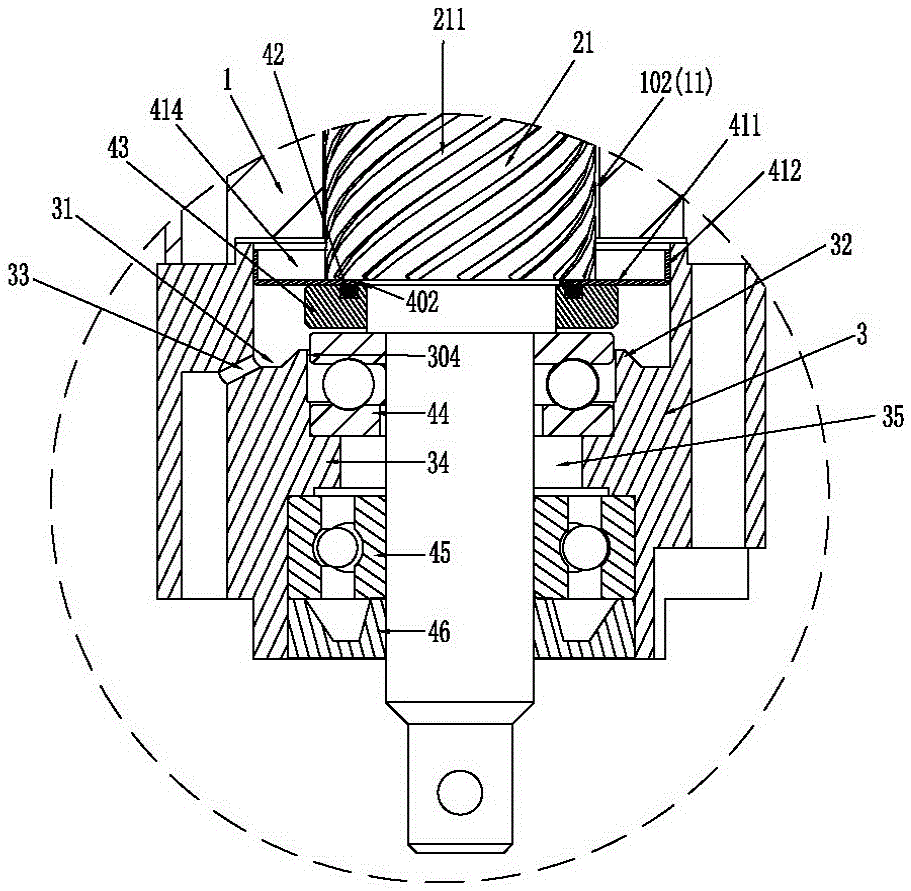

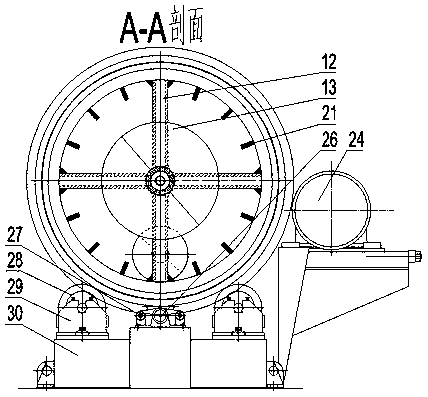

Main shaft system of vertical shaft type sand maker

ActiveCN102000617ASolve the problem of spindle lockExtended service lifeEngine sealsGrain treatmentsLine shaft

The invention discloses a main shaft system of a vertical shaft type sand maker, comprising a main shaft and a shaft sleeve, wherein the main shaft is positioned in the shaft sleeve through a bearing; bearing covers combined by axial positioned bearings are arranged at the upper end and the lower end of the shaft sleeve; a sealing structure is arranged between the bearing cover and the main shaft; and a lubricating structure is arranged on the shaft cover and comprises a thin oil inlet, an oil return hole and a grease inlet which are arranged on the side wall body of the bearing cover. The main shaft system has reasonable, novel and unique structure and operates stably at high rotating speed; by lubricating and combining thin oil with grease, the problem that the main shaft is locked can be effectively solved and the service lives of the bearing and other parts can be prolonged; and in addition, during bearing assembly, the bearing sleeve is electromagnetically heated so as to ensure the assembly precision and bring convenience to the assembly process.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

Leakage-proof device of gluing mechanism of edge bonding machine

ActiveCN104138826AReduce glue storageReduce the possibility of glue leakageLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a leakage-proof device of a gluing mechanism of an edge bonding machine. The leakage-proof device comprises a glue supplying box, a gluing shaft, a glue supplying wheel seat, a sealing cover between the glue supplying wheel seat and the gluing shaft, an O-shaped sealing ring and a bearing, wherein the gluing shaft comprises a gluing shaft working part and a gluing shaft connecting part, which are fixedly connected with each other, a spiral lifting groove of which the spiral direction is opposite to the rotating direction of the gluing shaft is formed in the outer wall surface of the gluing shaft working part, and the sealing cover is used for receiving leaked glue; glue is actively elevated into the glue supplying box from a receiving groove and a long and thin gap by rotation of the lifting groove in a rotating process of the gluing shaft, so that a condition that glue enters the bearing to cause locking is effectively avoided, and even if a sealing element is slightly abraded, the gluing mechanism can work normally; besides, only the O-shaped sealing ring needs to be replaced while a high-temperature bearing is not required to be replaced during maintenance, so that the maintaining cost is low; with the leakage-proof device, the problems that a traditional gluing device frequently suffers from bearing locking and maintaining trouble and the like are effectively solved.

Owner:NANXING MACHINERY CO LTD

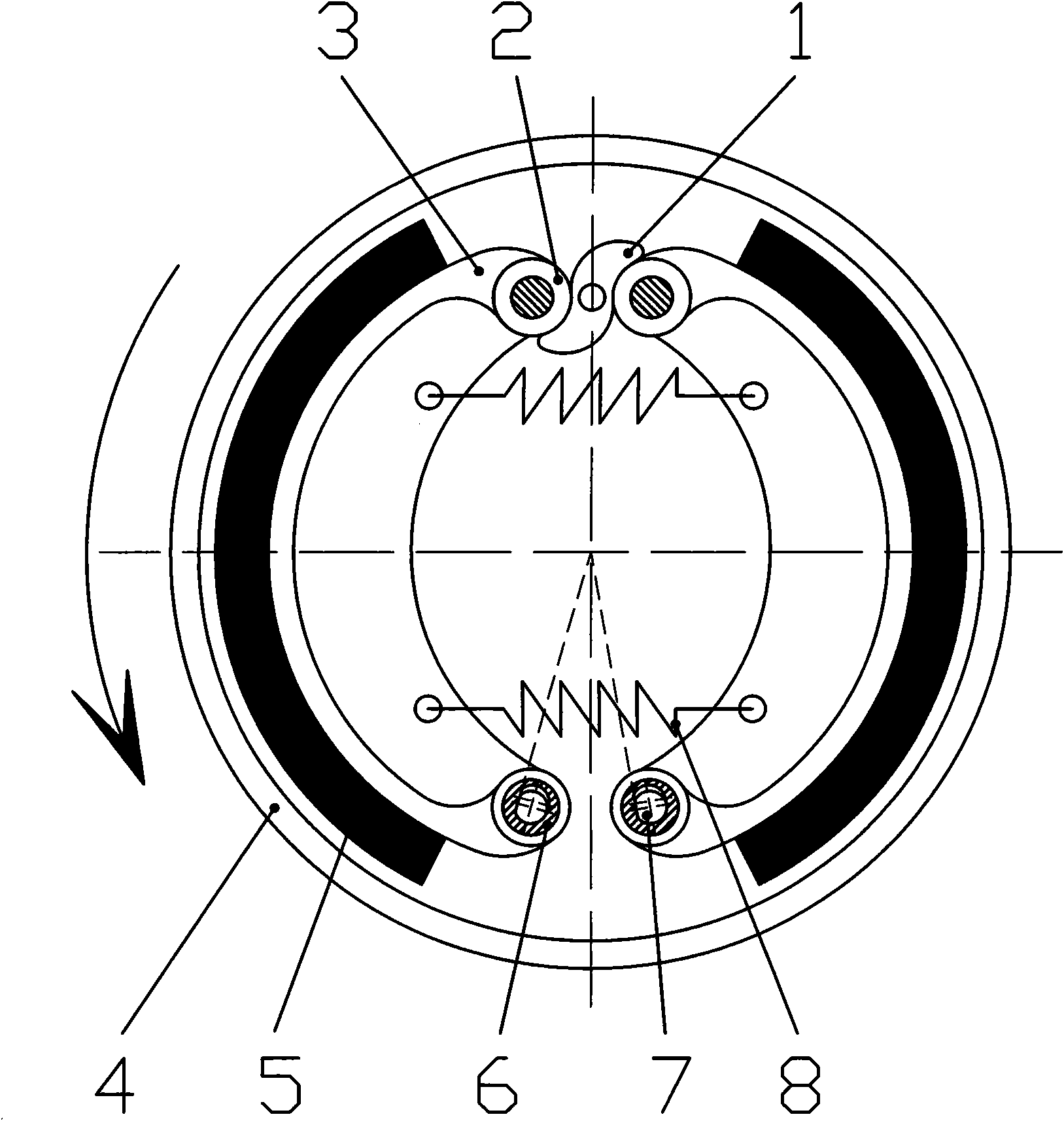

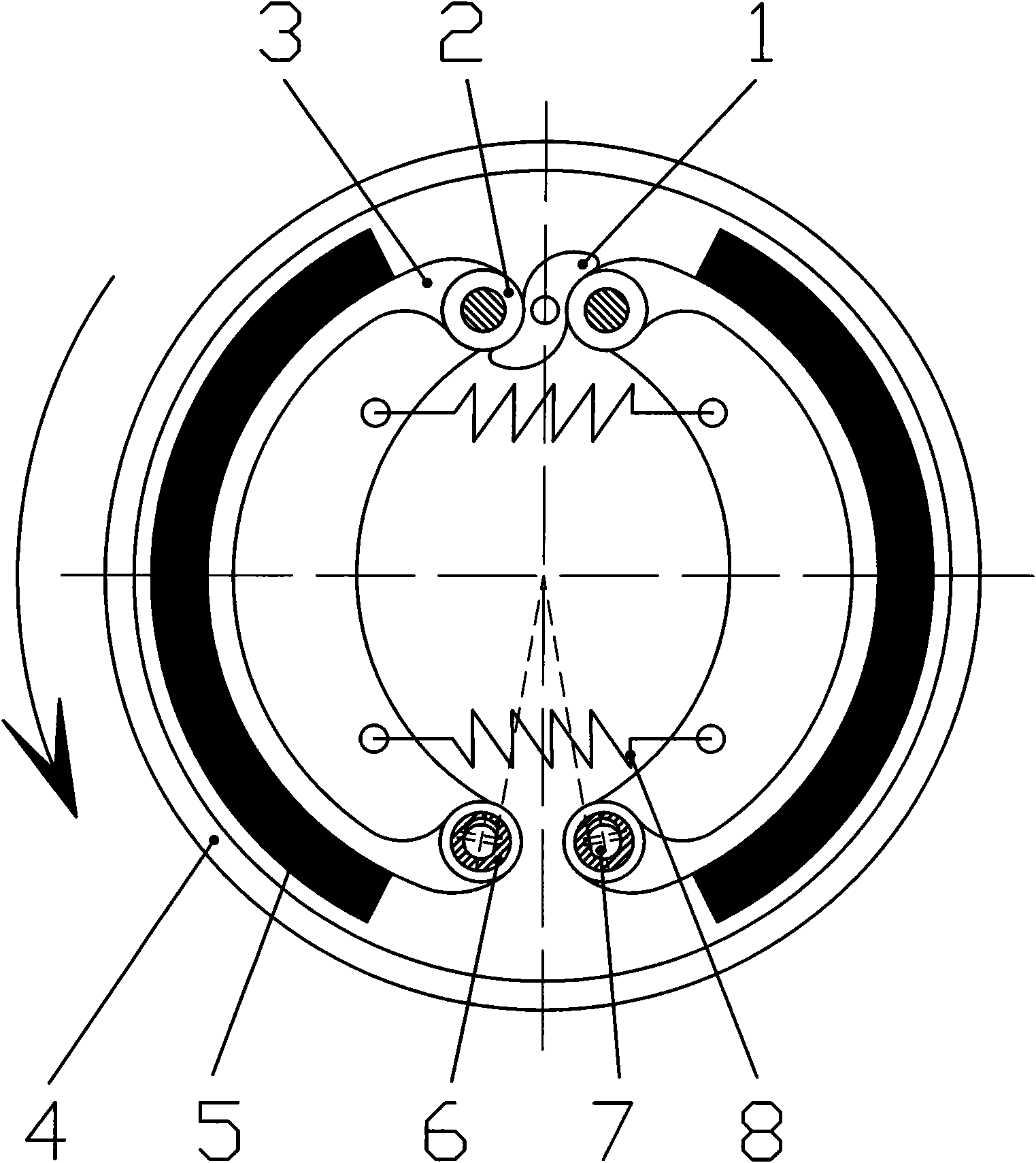

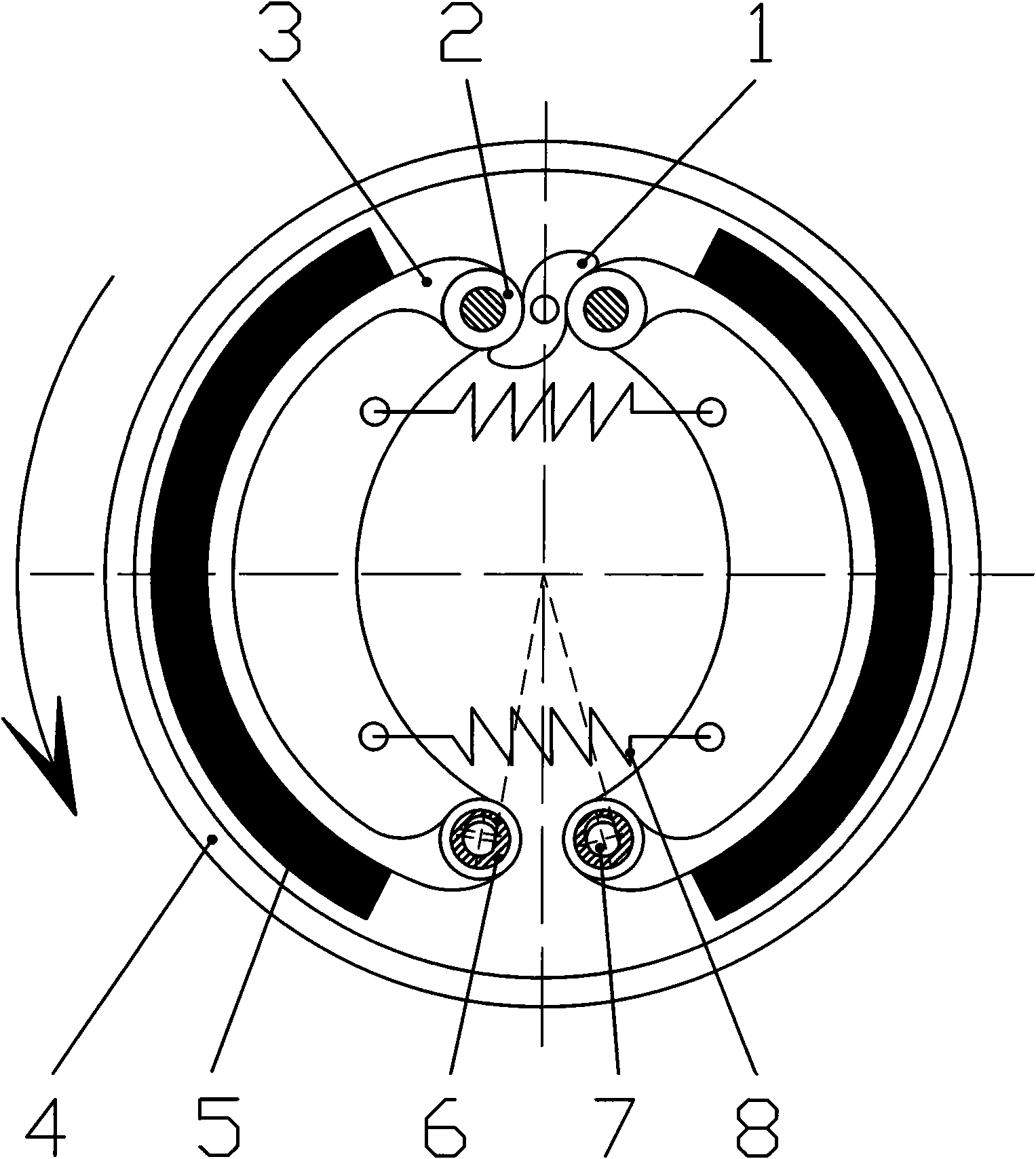

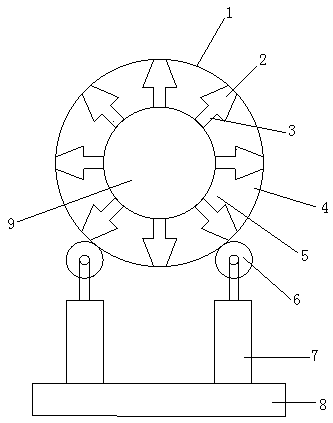

Drum brake

InactiveCN102374244ASolve for uniformitySolve the noiseBraking membersMechanically actuated drum brakesBrake torqueEngineering

The invention relates to a drum brake which aims to solve the problem that a brake shoe of the conventional drum brake can not be radially expanded, and further solve the problems of brake noise, dragging, squeal and locking. The technical scheme of the invention is as follows: the drum brake comprises a brake drum (4), a brake shoe (3), a friction plate (5), a driving device, a lining (6), a shoe plate shaft (7), and a reset device; the drum brake is characterized in that an outline with a certain guiding function is arranged on a part on which the shoe plate shaft is matched with the lining, and the guiding outline is arranged in a brake radial direction along which the brake shoe can be radially expanded, and the lining can slide with the brake shoe along the guiding outline of the shoe plate shaft, but can not rotate around the shoe plate shaft, and the brake shoe can rotate around the lining arranged in an end hole. The drum brake provided by the invention has the advantages that the drum brake is simple and easy, the drum brake can effectively solve the problems of uneven abrasion of the friction plate, brake noise, dragging, squeal and locking, meanwhile, and the drum brake has large brake torque.

Owner:BEIJING TINGYI BRAKING CO LTD

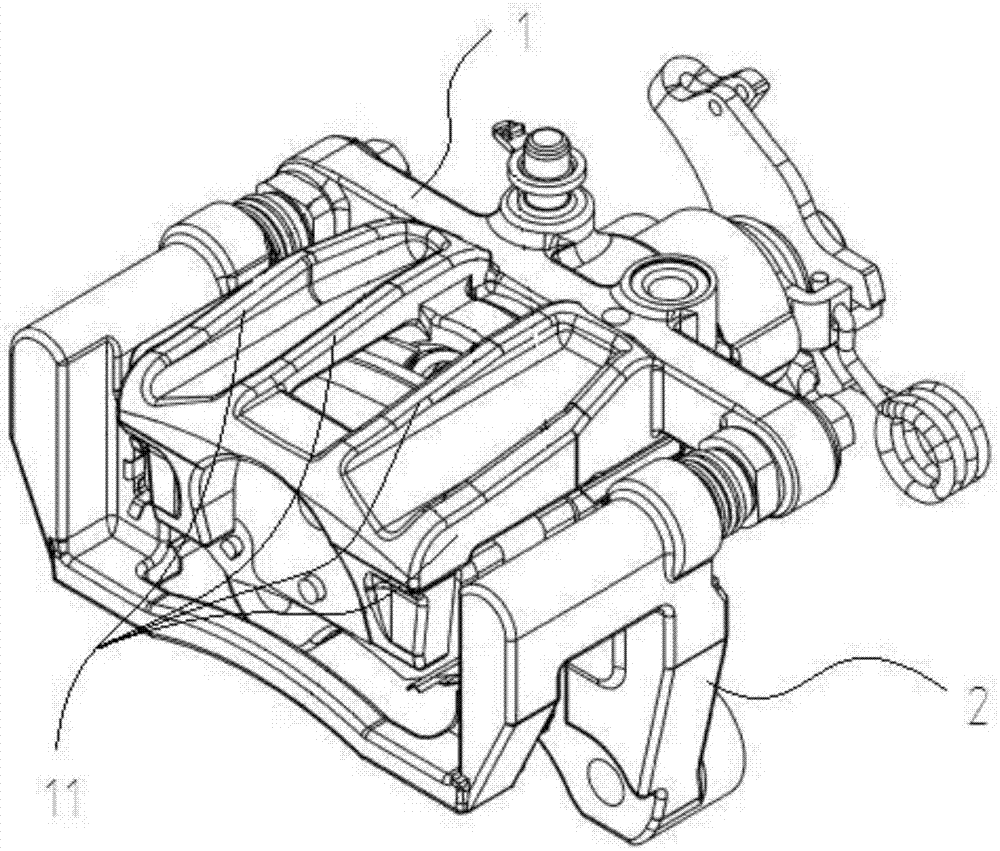

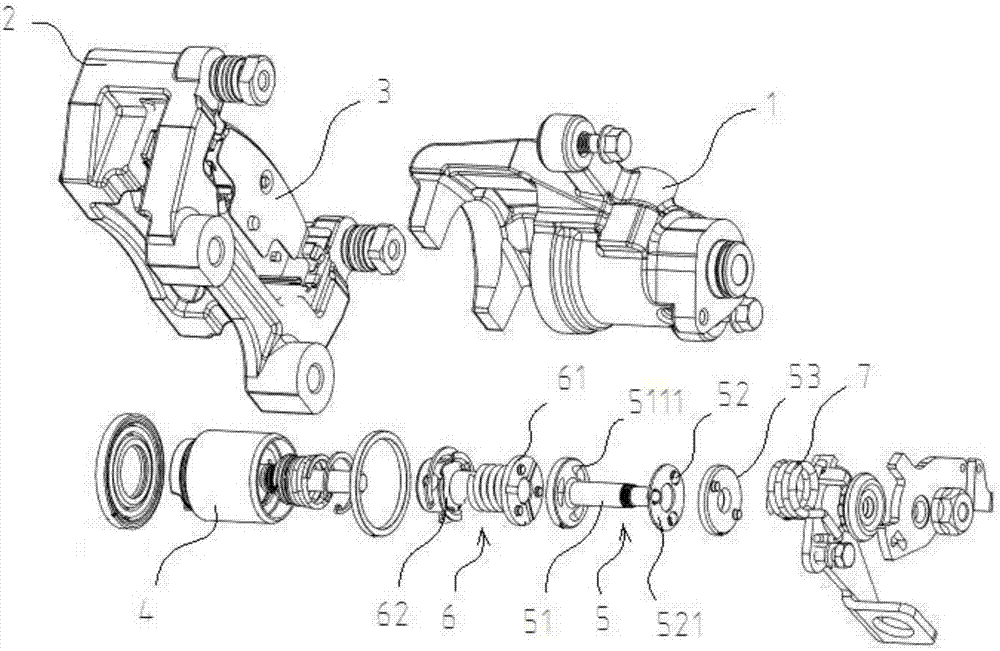

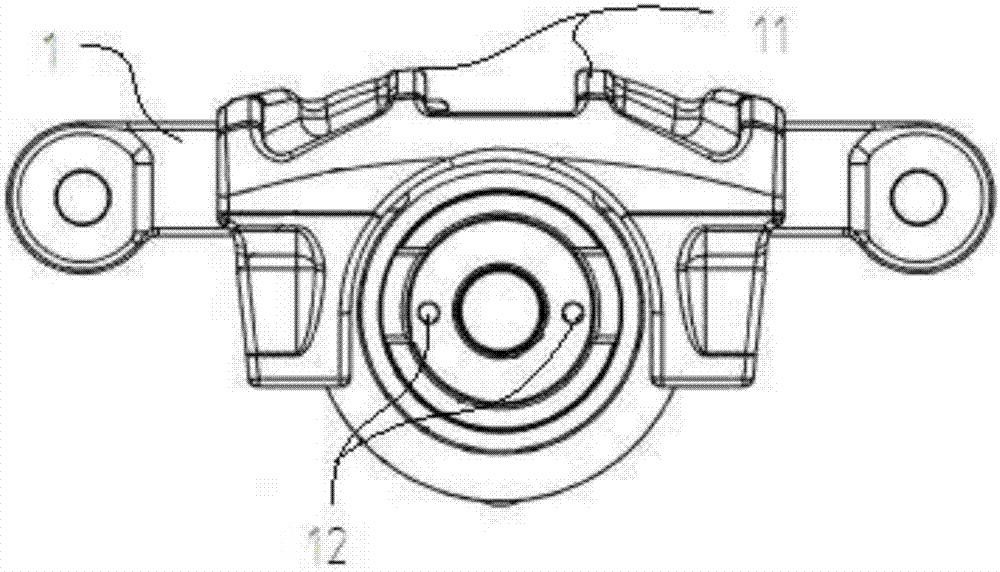

Integrated brake caliper

ActiveCN107956822APrevent rotationIncrease rotation speedNoise/vibration controlBrake actuating mechanismsControl theoryPiston

The invention provides an integrated brake caliper, and belongs to the technical field of vehicle braking. The integrated brake caliper comprises a brake support assembly provided with a friction plate structure and a brake shell connected with the brake support assembly; and a thrust assembly, an adjusting assembly and a piston are arranged in the brake shell. According to the integrated brake caliper, a limiting convex point and a limiting groove are arranged between the thrust assembly and the brake shell, and a connecting convex point and a connecting concave point are embedded and connected between the thrust assembly and the adjusting assembly, so that the layout space is reduced, the fit clearance is small, the parking endurance abrasion is small, the durability is better; meanwhile, a ball ramp structure and a multiple thread structure are adopted, so that the ejection effect of the piston is further improved, the mechanical transmission gap is shortened, and the braking performance is improved; the brake shell is a cast aluminum piece with reinforcing ribs, so that the weight is lighter; and the surface material of a silencing piece with a friction plate structure adoptsa rubber cloth ripple silencing piece so that the friction coefficient can be increased, the piston can be prevented from rotating, the parking performance is further improved, and the market competitiveness is improved.

Owner:WANXIANG QIANCHAO SHANGHAI AUTOMOTIVE SYST

Method for using slag cooler special for heat storage secondary combustion purifying device for treating solid waste for adsorbing VOCs waste gas

ActiveCN107013929AReduce heat lossStable temperature gradientLighting and heating apparatusIndefinite timeCombustion

The invention relates to the technical field of volatile organic compound waste gas treatment, in particular to a method for using a slag cooler special for a heat storage secondary combustion purifying device for treating solid waste for adsorbing VOCs waste gas. The method is characterized in that the slag ash slagging temperature ranges from 850 DEG C to 950 DEG C, and therefore a two-stage cooling technical scheme including jacket type air cooling spiral conveyor first-stage air cooling and roller slag cooling assembly second-stage water cooling is adopted, and it is guaranteed that gradient descent of the slag ash temperature is stable and gentle; therefore, it is guaranteed that when slagging is carried at indefinite time intervals, spiral blades in a jacket type air cooling spiral conveyor have no the problems that local temperature changes are large, and the spiral blades and the inner wall of an air cooling jacket are locked after thermal expansion; and a spiral slag crushing ream is designed to roll on the circumferential face of a rotary roller along with rotation of the rotary roller, scale on the inner wall of the rotary roller is swept in cycles, and the rotary roller is prevented from heat conducting coefficient reducing and local high temperature deformation.

Owner:山东天盛纤维素股份有限公司

Grinding process applied to high-precision and easy-to-assemble hub unit

The invention relates to a grinding process applied to a high-precision easy-to-assemble hub unit, and belongs to the technical field of hub unit machining. The grinding process comprises the following steps that a spline hole of a hub flange is machined and formed to serve as an axis reference, an inner ring clamping groove of the hub flange is machined, and an outer ring flange and a flange holeof the outer ring flange are roughly turned according to the axis reference; then the nesting process of an inner ring and the hub flange is completed through an oil press; a motor sliding air cylinder seat at the front end of a machine base drives an inner locking notch and channel grinding assembly to be inserted into the outer ring flange, and a motor sliding air cylinder seat at the side endof the machine base drives an outer locking notch and channel grinding wheel to be close to the outer side end of the hub flange with the inner ring; and the outer locking notch and channel grinding wheel conducts displacement grinding from the outer wall of the hub flange with the inner ring, and the inner locking notch and channel grinding assembly grinds a locking notch and a channel in the outer ring flange. The grinding process has the advantages of good operation stability, high precision and long service life, and the problem that the machining coaxiality of locking notches and channelsof an outer ring flange, an inner ring and a hub flange is poor is solved.

Owner:浙江丰波机电科技有限公司

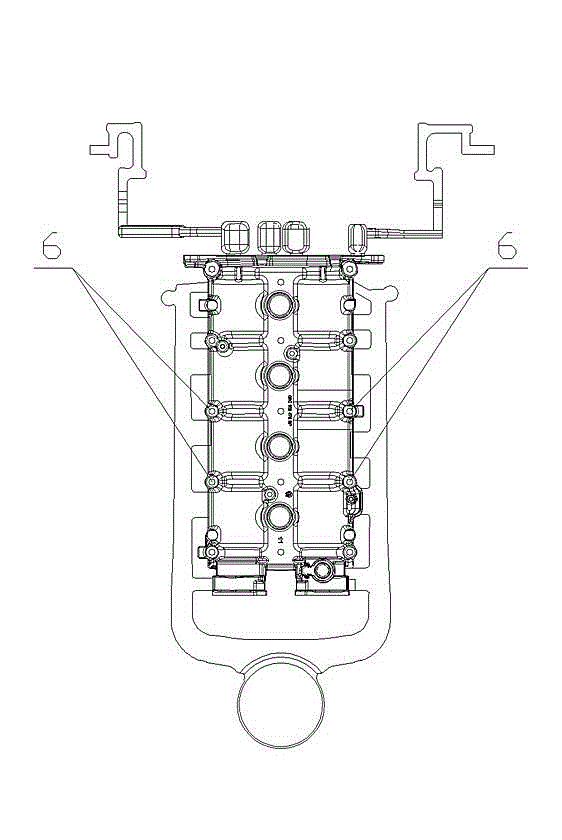

Bilateral filling gating system

The invention discloses a bilateral filling gating system which comprises a stationary die and a movable die, wherein a stationary die insert and a movable die insert are also respectively connected onto the stationary die and the movable die, sliding block bushes which are matched with the stationary die insert and the movable die insert are arranged, sliding blocks which are matched with the sliding block bushes are arranged, the stationary die insert, the movable die insert and the sliding blocks commonly form a cavity, the sliding blocks can laterally move in the sliding block bushes, inclination angles alpha are arranged on the outlines of the sliding blocks along the movement direction of the sliding blocks, so the whole front ends of the sliding blocks are conical, and the value range of the inclination angles is 1-2 degrees; the bilateral filling gating system is characterized in that the left side and the right side of the cavity are respectively provided with flow gates 6; and a plurality of the flow gates 6 are arranged. The invention provides the bilateral filling gating system which has a simple structure and an ingenious design, adopts a synchronous bilateral filling mode, can shorten the filling process and time by a half, has small energy loss, and can obviously improve the casting quality and production efficiency.

Owner:DALIAN YAMING AUTOMOTIVE PARTS

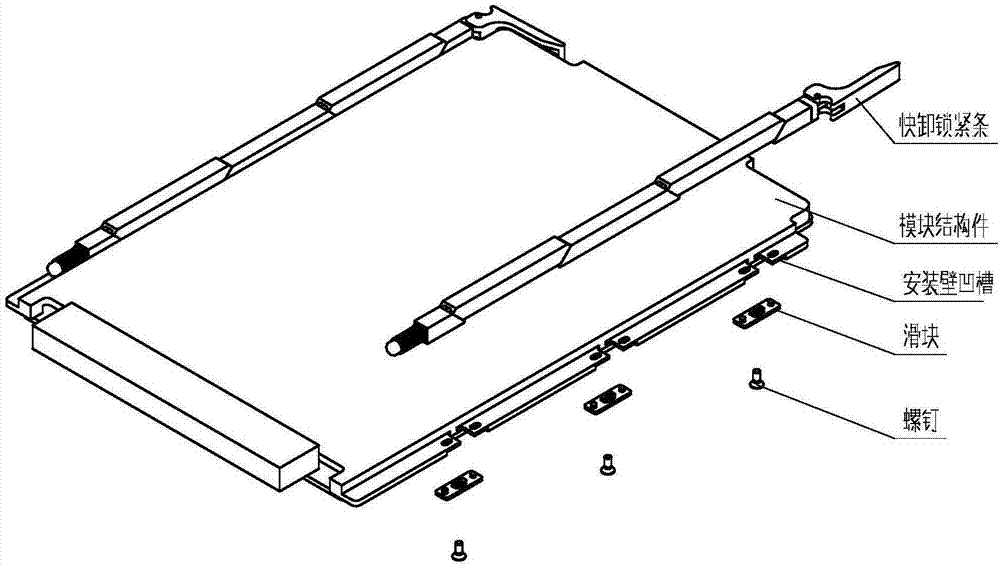

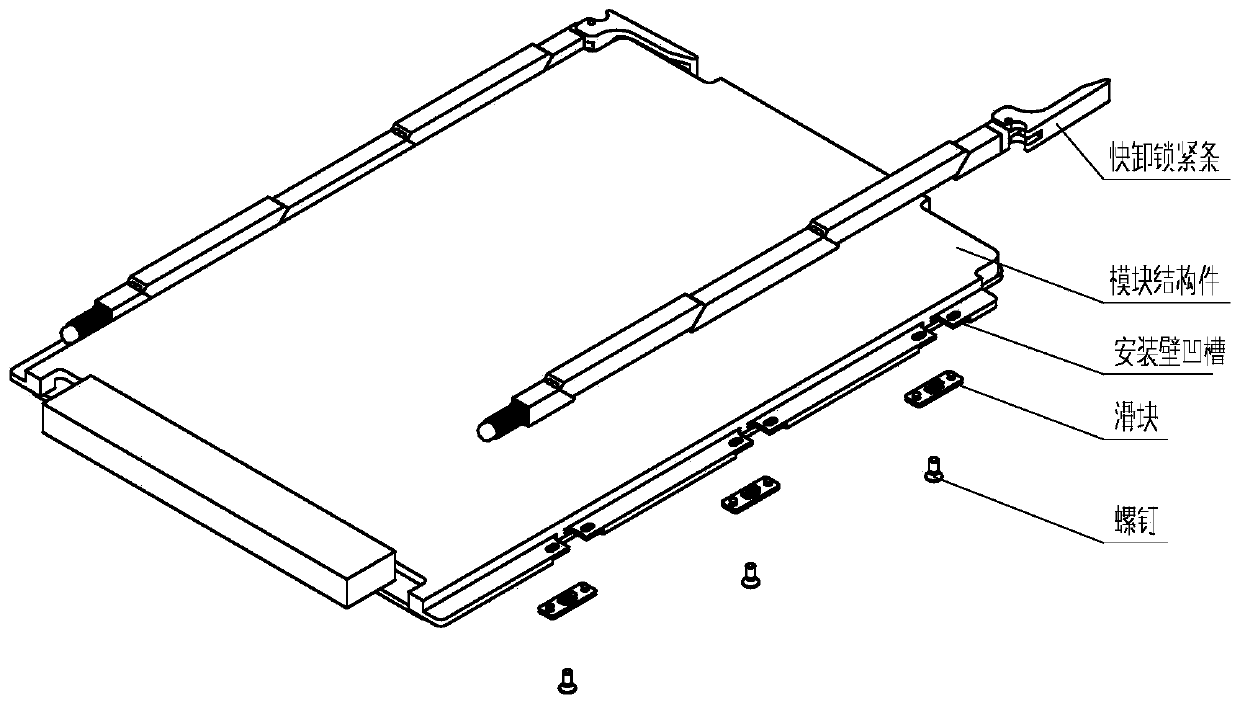

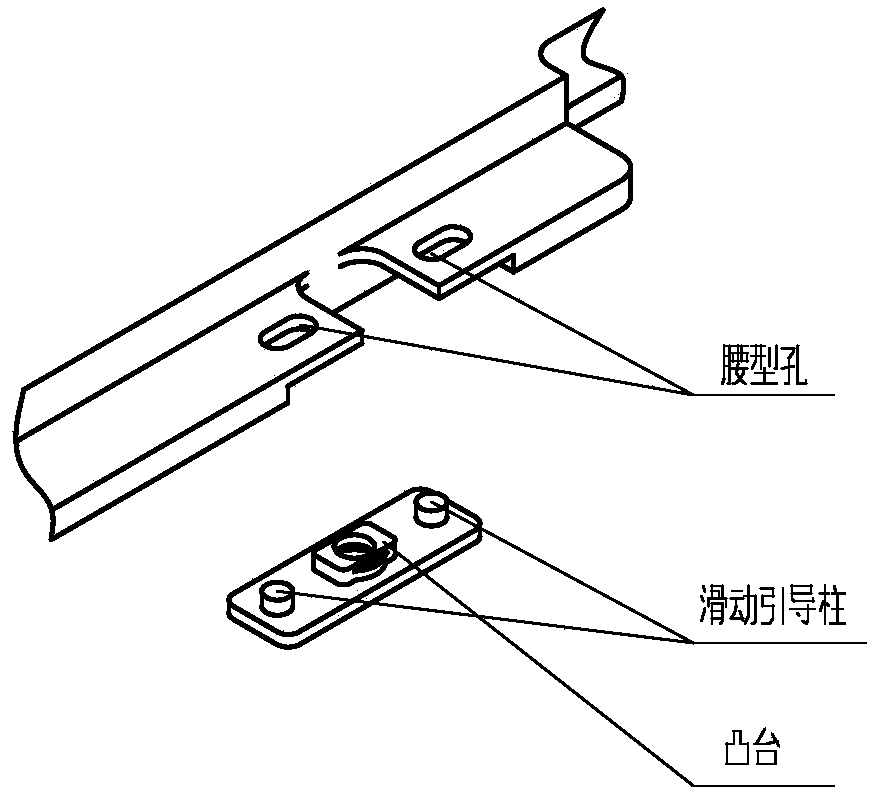

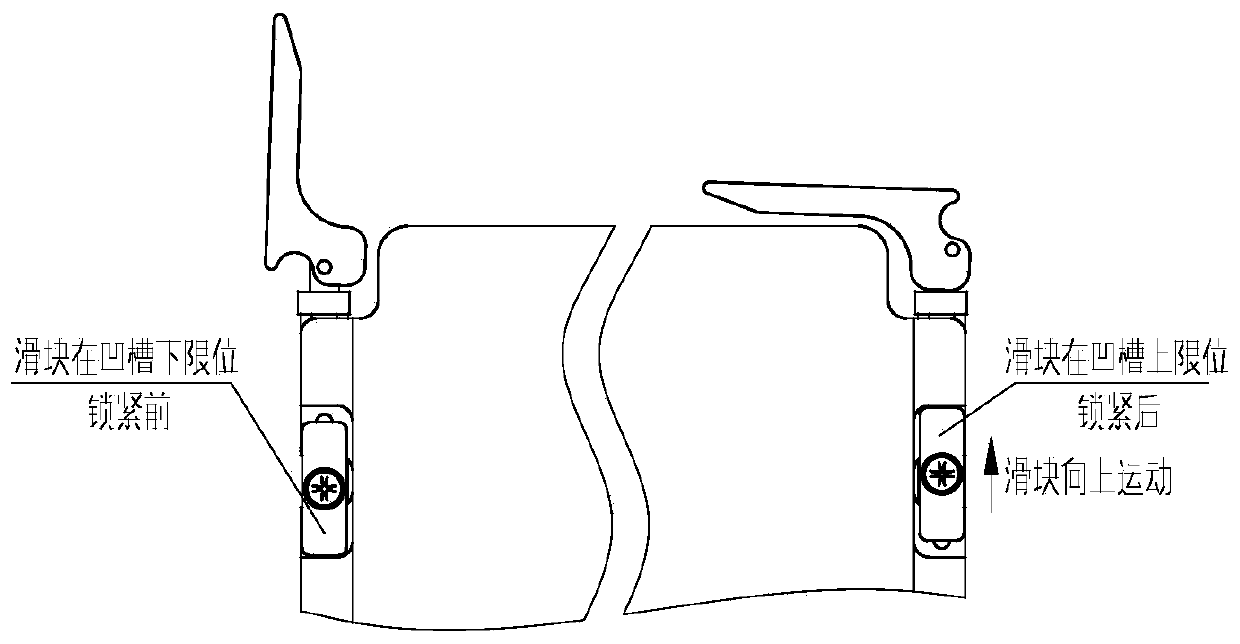

Locking strip float mounting mechanism and mounting method thereof

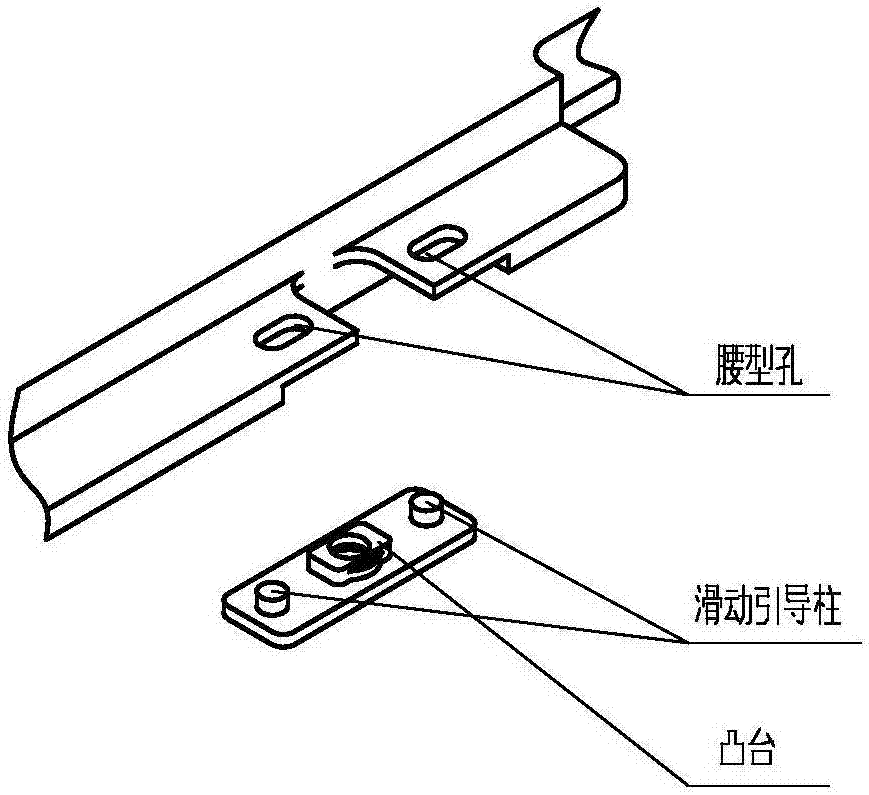

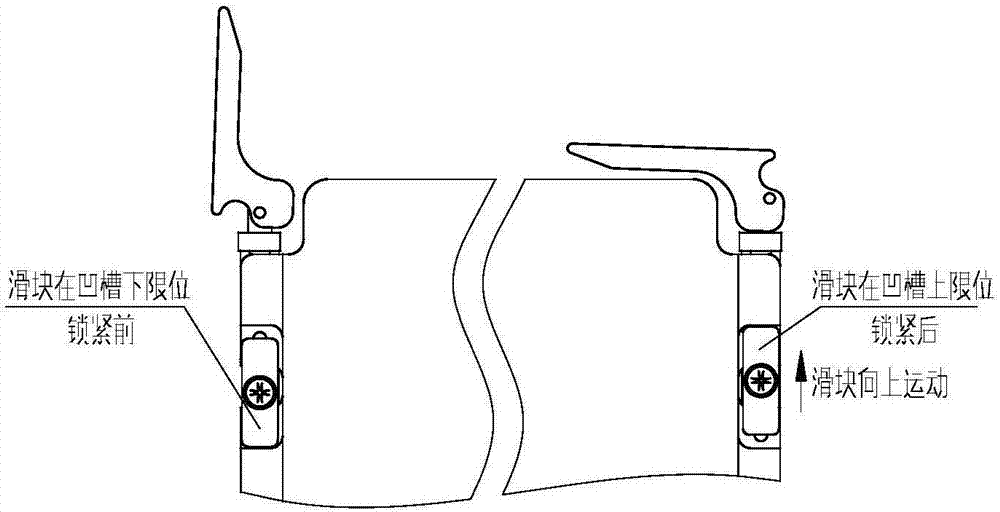

ActiveCN107979940APrevent lockOnly positive extrusionClamping/extracting meansComputer moduleMechanical engineering

The invention belongs to the technical field of electronic equipment mechanical structures, and relates to a locking strip float mounting mechanism and a mounting method thereof. A float mounting mechanism is employed, grooves and slide blocks are arranged in mounting walls of a module structure, locking strips can be mounted on the module structure in a float manner, only a positive extrusion force is generated between each locking strip and a corresponding guide-track groove, the locking strip and the corresponding guide-track groove do not generate sliding friction, and locking of the locking strips is avoided. The locking strip float mounting mechanism is simple in structure and convenient to use, and can effectively overcome the locking problem of locking strip wedge blocks.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

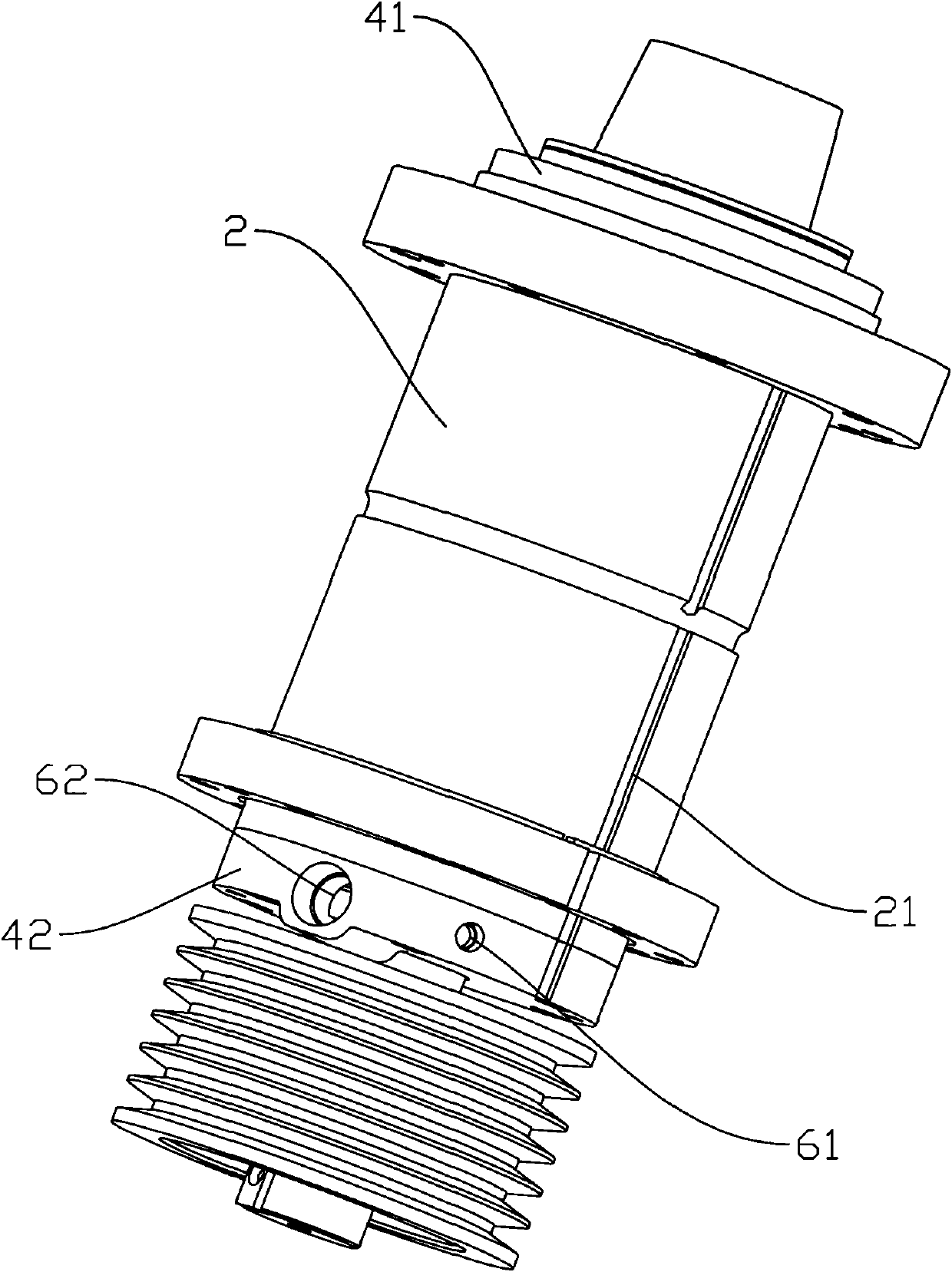

Wire passing sealing locking device

PendingCN110285268AAchieving tightnessTo achieve the effect of lockingPipesEngineeringMechanical engineering

Owner:中国人民解放军军事科学院防化研究院

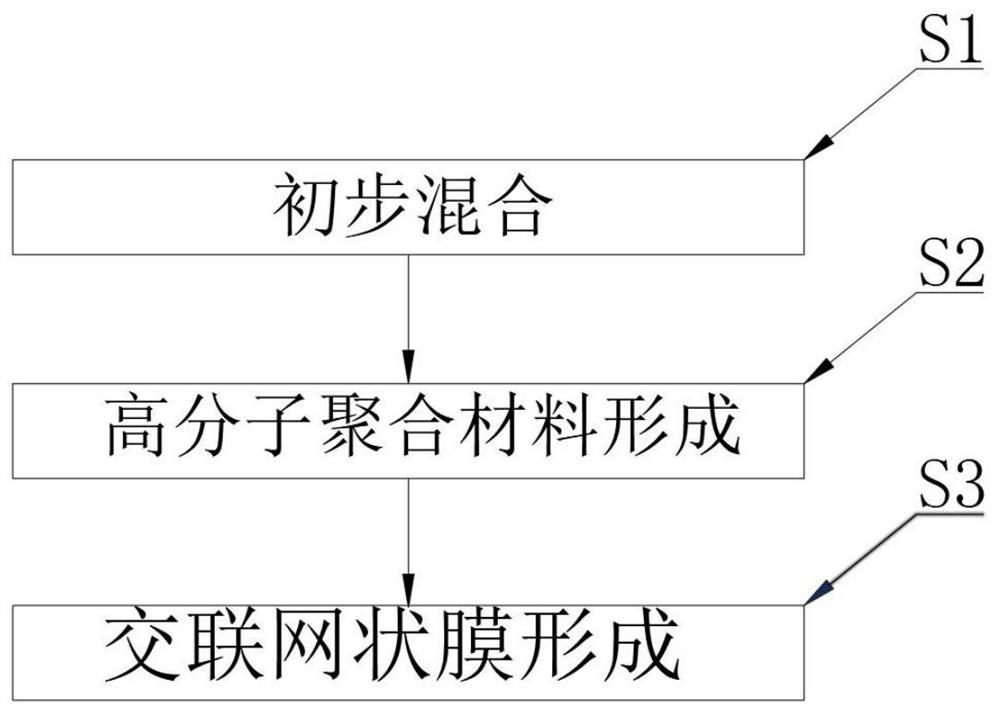

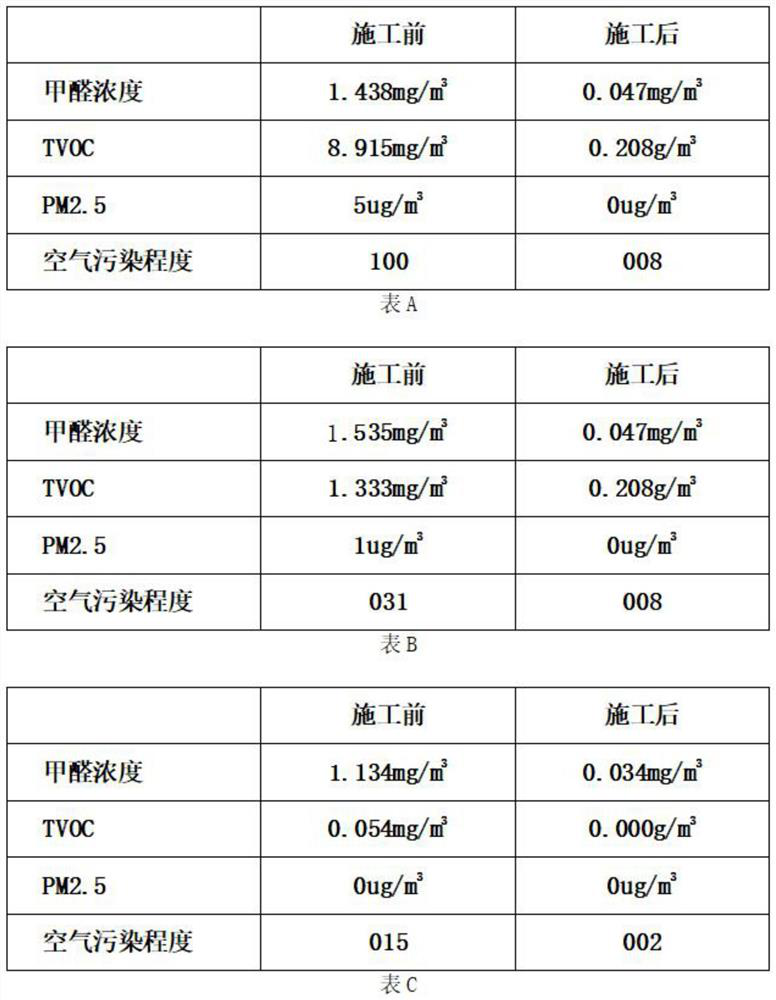

Indoor closed space complex gas pollutant source purification agent and application thereof

PendingCN112619408AIncreased persistenceMembrane structure and hardness enhancementDispersed particle separationAir quality improvementPeptideChemistry

The invention discloses an indoor closed space complex gas pollutant source purification agent and application thereof. Firstly, a high-molecular polymer and unsaturated higher fatty acid are effectively mixed; under the action of a catalyst, an emulsifying agent and a dispersing agent, a uniformly dispersed macromolecular polymeric material is formed; and the macromolecular peptide polymer and the unsaturated higher fatty acid are gradually spread along with volatilization of water molecules in air, and due to different molecular weights, composite crossed multi-layer films with different effects are gradually formed to form a cross-linked net-shaped film formed by a bottom-layer decomposition film, a middle-layer multi-layer protection film and an upper-layer macromolecular polymer, so that release of gaseous pollutants is prevented. The sustainability of the agent is improved, the membrane structure and the hardness are enhanced, volatilization of pollutants can be rapidly solved by forming the multi-membrane structure, harmful gas is locked, O-C=O, C-NH2, H2O and CHO are firmly cross-linked and tightly combined with a macromolecular polymeric material, damage caused by external force is not likely to happen, and the strength of the multi-membrane structure is improved.

Owner:SHANGHAI YONGYI ENVIRONMENT ALEERING CO LTD

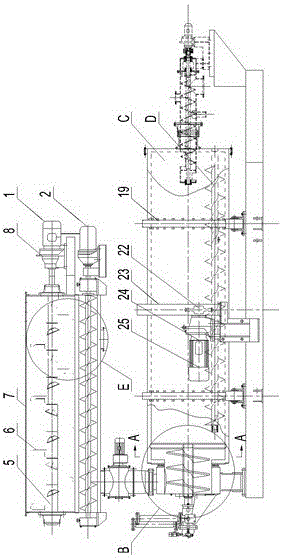

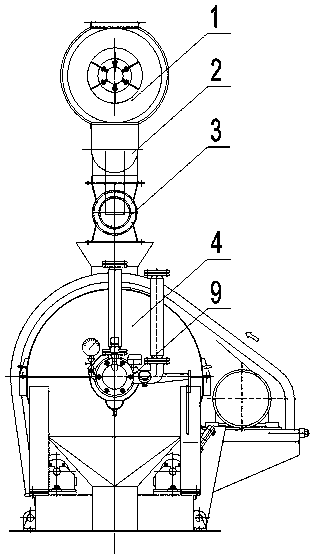

Special slag cooler for heat storage secondary combustion purification plants for treating and adsorbing VOCs (volatile organic compounds) waste gas and solid waste

ActiveCN106838948AThe temperature gradient drops and stabilizesReduce air leakage coefficientLighting and heating apparatusVolatile organic compoundSlag

The invention relates to the field of technologies for treating volatile organic compound waste gas, in particular to a special slag cooler for heat storage secondary combustion purification devices for treating and adsorbing VOCs (volatile organic compounds) waste gas and solid waste. The special slag cooler is characterized by comprising an ash blowing machine, a jacket type air-cool spiral conveyor, an air shutdown valve and a drum type slag cooling assembly. According to the technical scheme of secondary slag ash cooling, the special slag cooler has the advantages that stable and gentle temperature gradient descent of slag ash can be guaranteed by primary air cooling of the jacket type air-cool spiral conveyor and secondary water cooling of the drum type slag cooling assembly, and accordingly the problems of great local temperature variation of spiral blades in existing jacket type air-cool spiral conveyors during irregular interval slag discharge and locking of the spiral blades and the inner wall of air-cool jackets after the spiral blades are thermally expanded can assuredly solved; designed spiral slag breaking hinges can roll in circumferential surfaces of rotary drums along with rotation of the rotary drums, accordingly, slag on the inner walls of the rotary drums can be cleaned in cycles, and reduction of heat conductivity coefficients of the rotary drums and local high-temperature deformation of the rotary drums can be prevented.

Owner:FAREAST KINGSTAR CHEM

A method of using a special cold slag machine for treating adsorption vocs waste gas solid waste heat storage secondary combustion purification device

ActiveCN107013929BReduce heat lossStable temperature gradientLighting and heating apparatusHeat conductingSlag

The invention relates to the technical field of volatile organic compound waste gas treatment, in particular to a method for using a slag cooler special for a heat storage secondary combustion purifying device for treating solid waste for adsorbing VOCs waste gas. The method is characterized in that the slag ash slagging temperature ranges from 850 DEG C to 950 DEG C, and therefore a two-stage cooling technical scheme including jacket type air cooling spiral conveyor first-stage air cooling and roller slag cooling assembly second-stage water cooling is adopted, and it is guaranteed that gradient descent of the slag ash temperature is stable and gentle; therefore, it is guaranteed that when slagging is carried at indefinite time intervals, spiral blades in a jacket type air cooling spiral conveyor have no the problems that local temperature changes are large, and the spiral blades and the inner wall of an air cooling jacket are locked after thermal expansion; and a spiral slag crushing ream is designed to roll on the circumferential face of a rotary roller along with rotation of the rotary roller, scale on the inner wall of the rotary roller is swept in cycles, and the rotary roller is prevented from heat conducting coefficient reducing and local high temperature deformation.

Owner:山东天盛纤维素股份有限公司

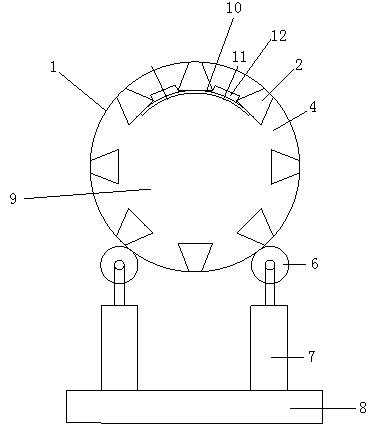

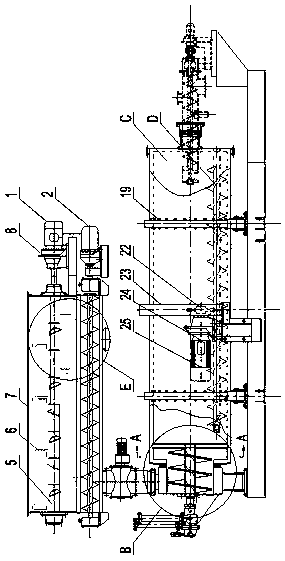

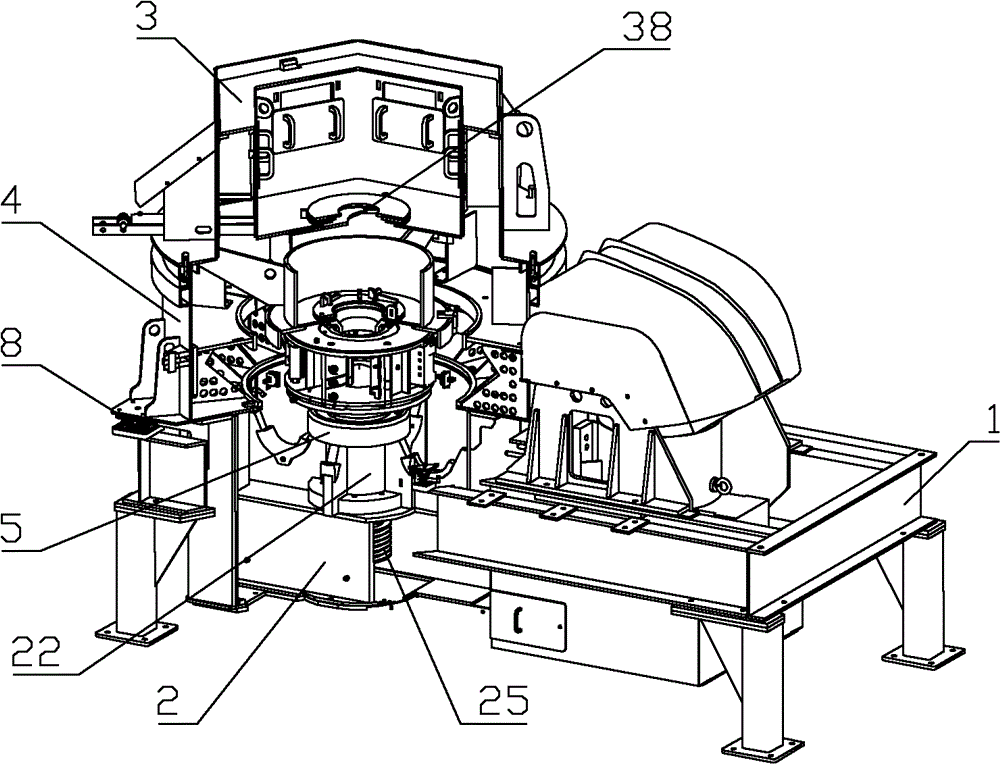

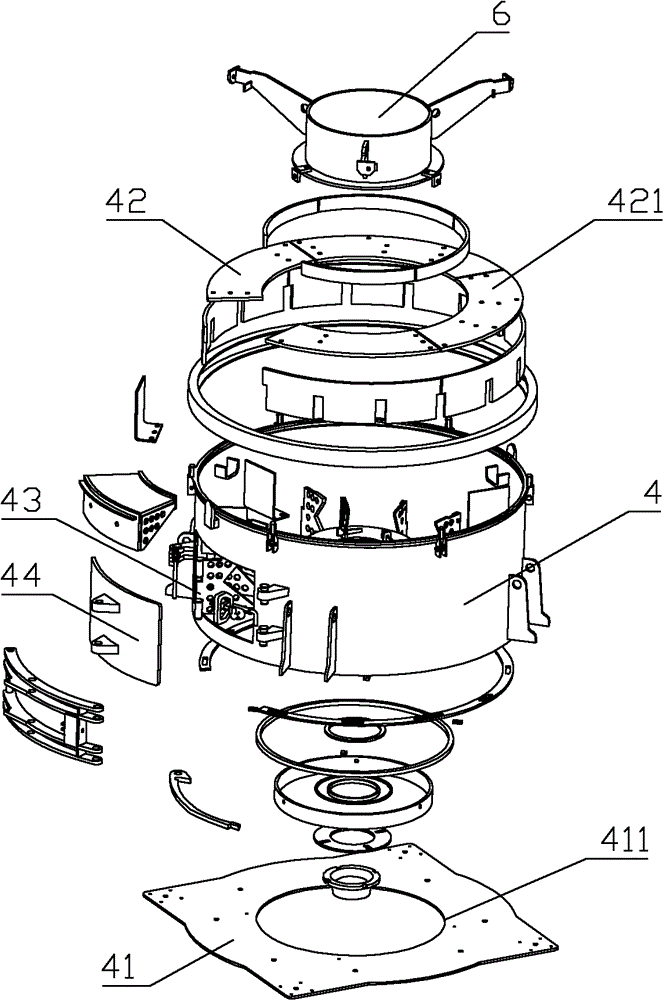

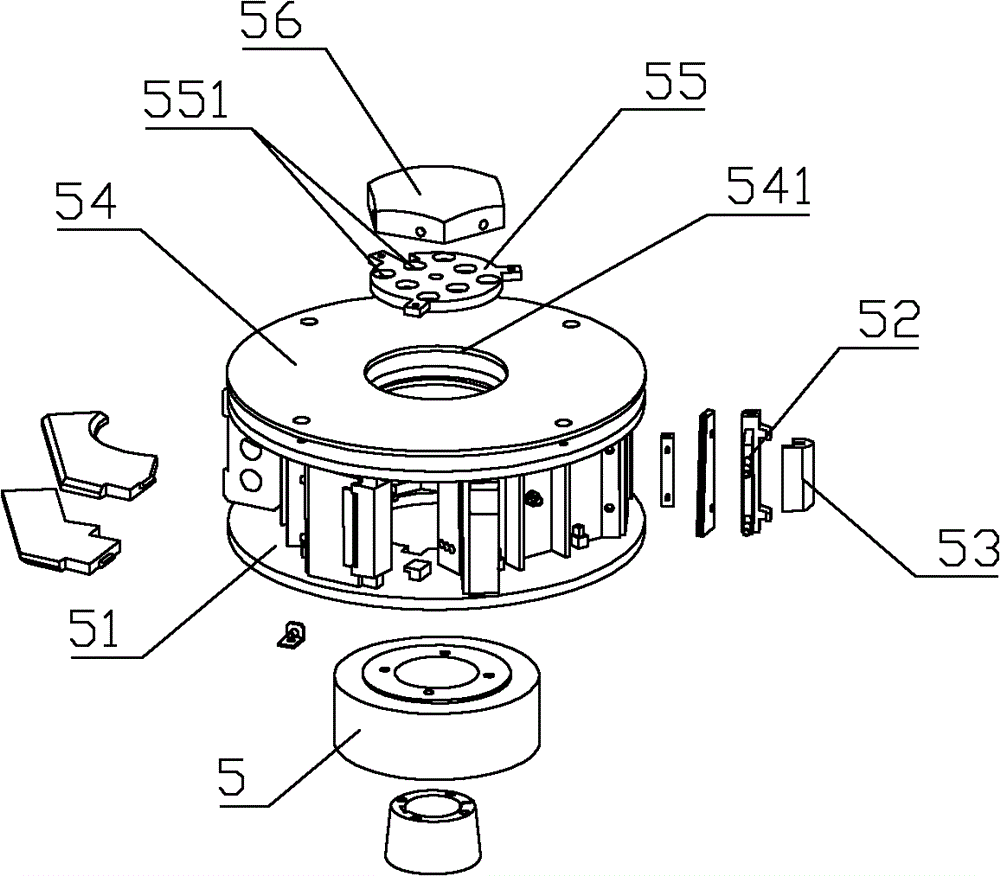

Automatic companion stone embedding and lining autogenous grinder

PendingCN110252471ADoes not affect strengthReduce weightGrain treatmentsMineral particlesEngineering

The invention relates to an automatic companion stone embedding and lining autogenous grinder which is formed by a motor, a speed reducer part, a transmission part, a support foundation part and a shell part. The shell part is formed by at least one section of shell unit. The automatic companion stone embedding and lining autogenous grinder is characterized in that one end of the shell unit is a feed end; the other end of the shell unit is a discharge end; a shell liner is arranged on the inner wall of the shell unit and is formed by grid sections uniformly distributed on the circumference at intervals; a grid section groove is formed between each two adjacent grid sections; a cross section of each grid section is characterized in that the end in the direction toward the center of the shell unit is wide, and the end in the direction toward the inner wall of the shell unit is narrow; a cross section of each grid section groove is characterized in that the end in the direction toward the center of the shell unit is narrow, and the end in the direction toward the inner wall of the shell unit is wide; the horizontal surface in the length direction of each grid section is narrow at the feed end and wide at the discharge end; and the horizontal surface in the length direction of each grid section groove is wide at the feed end and narrow at the discharge end. The automatic companion stone embedding and lining autogenous grinder has the advantages of light liner weight, capabilities on automatically selecting applicable mineral particles to be inlaid into a liner groove so as to substitute lining and assist grinding, and capabilities on automatically locking stones and retreating and supplementing stones.

Owner:内蒙古尾得选矿科技有限公司

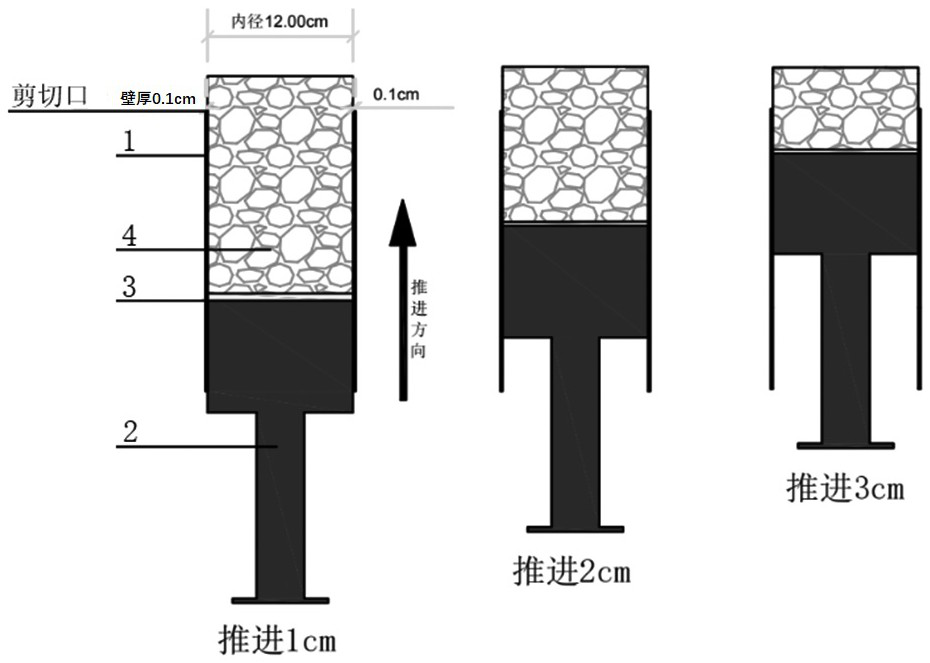

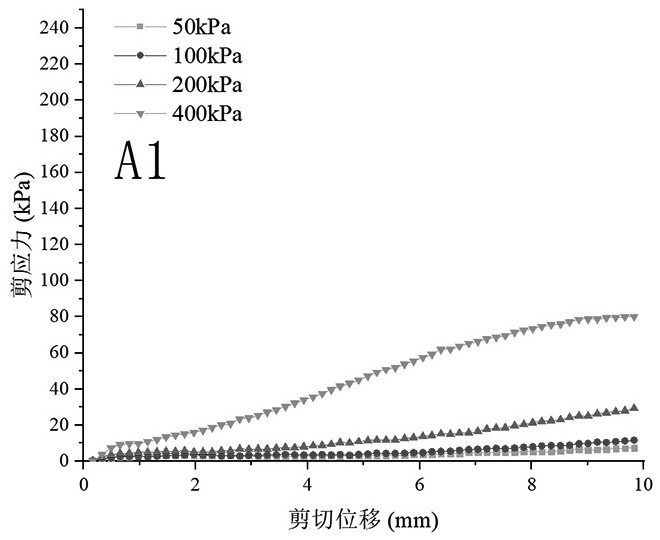

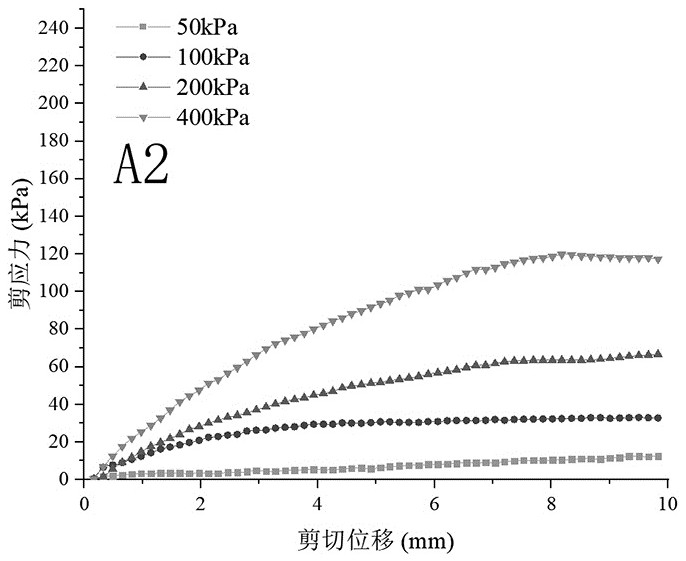

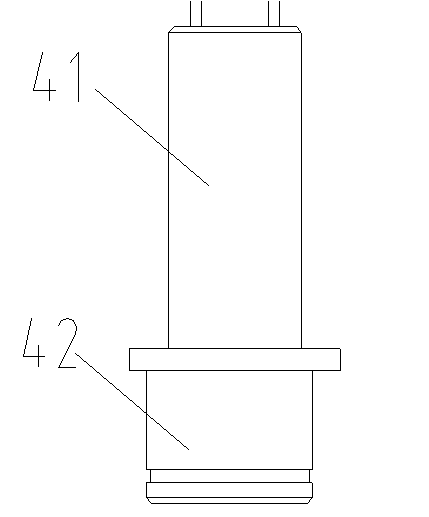

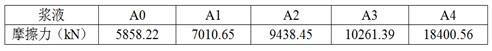

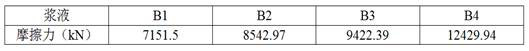

A Configuration Method of Low Shear Strength Grouting Material in Shield Excavation Gap

ActiveCN113788665BSolve the lockMeet performance requirementsUnderground chambersTunnel liningFilling materialsStructural engineering

Owner:BEIJING URBAN CONSTR GROUP +2

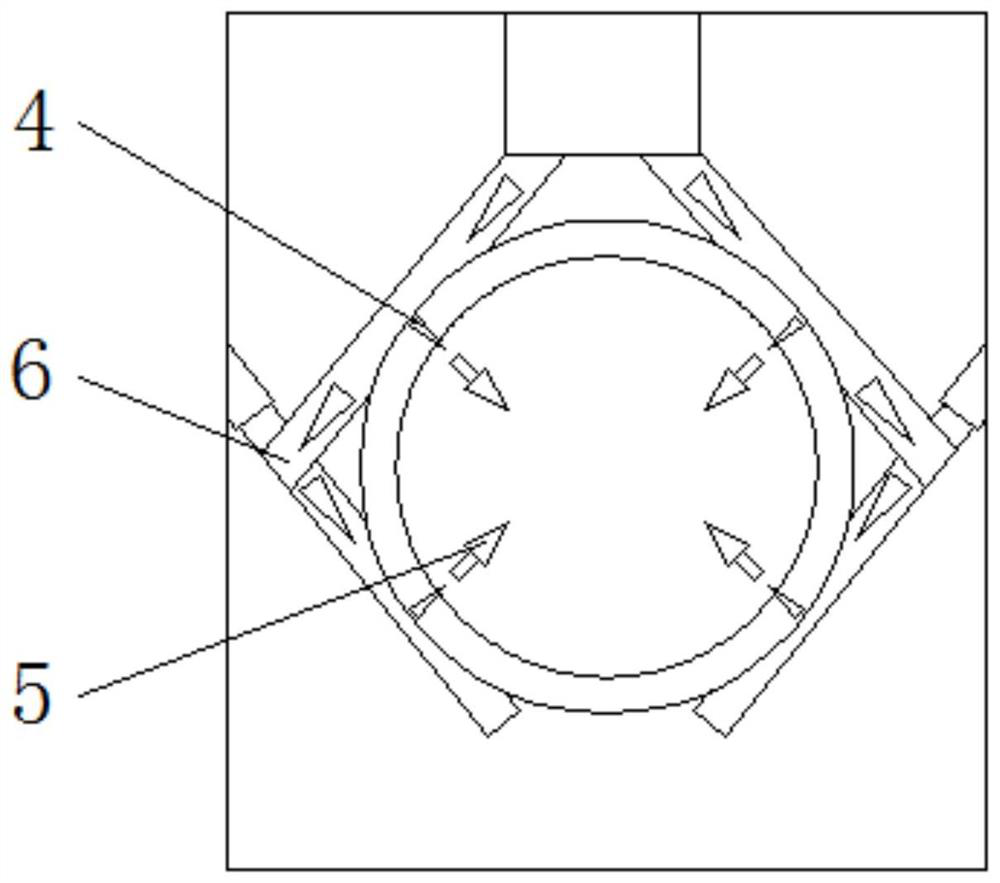

Novel hydraulic breaker oil way with function of preventing piston from being stuck

InactiveCN112726706AReduce hydraulic clamping force and frictionResolve locks and strainsMechanical machines/dredgersEngineeringCylinder block

The invention discloses a novel hydraulic breaker oil way with the function of preventing a piston from being stuck, and relates to the technical field of hydraulic breaker oil ways. According to the technical scheme, the novel hydraulic breaker oil way is characterized by comprising a middle cylinder body and a rear cylinder body, the middle cylinder body is fixedly connected with the rear cylinder body, the piston is arranged in the middle cylinder body, the piston penetrates through the rear cylinder body, an oil way is arranged in the middle cylinder body, and hydraulic oil in the oil way in the middle cylinder body flows into the middle cylinder body from a middle cylinder hole formed in the middle cylinder body in multiple symmetrical directions; and the novel hydraulic breaker oil way has the the effects that oil ways are arranged in the middle cylinder body and the rear cylinder body, the hydraulic oil in the oil ways is input into the middle cylinder body and the rear cylinder body in the multiple symmetrical directions, so that the periphery of the piston is stressed uniformly, uniform centripetal pressure is formed, it is guaranteed that the piston is positioned at an axis symmetric space position in the middle cylinder hole, a uniform circumferential oil film is formed, and therefore the piston easily does reciprocating motion in the oil film, hydraulic clamping force and friction force are reduced, and the phenomena of locking and pulling damage of the piston and the middle cylinder hole are solved.

Owner:JIANGSU LIBOSHI MACHINERY

Conveying device for wood floor

Owner:苏州豪特景精密机械有限公司

Preparation method of low-shear-strength grouting material for shield excavation gap

ActiveCN113788665ASolve the lockMeet performance requirementsUnderground chambersTunnel liningFilling materialsSlurry

The invention discloses a preparation method of a low-shear-strength grouting material for a shield excavation gap. The preparation method comprises the following steps: selecting a grouting material; preliminarily designing multiple groups of grouting materials with different water cement ratios and multiple groups of grouting materials with different swelling-water ratios; manufacturing a plurality of groups of grouting material test pieces; testing the shear strength of each group of test pieces to obtain the optimal water-cement ratio and the optimal swelling-water ratio of the grouting material; adding bentonite and water into a stirrer according to the optimal swelling-water ratio, conducting stirring, fully and uniformly conducting mixing, conducting standing, and fully conducting swelling; measuring water glass with required baume degree, adding the water glass into expanded bentonite slurry, and uniformly conducting stirring; and adding cement powder, and continuously conducting stirring uniformly to finish the preparation. The filling problem of the excavation gap in shield construction is studied, and the problem that a shield body is locked by a conventional shield body grouting material can be solved; and a novel filling material configuration method is adopted, the pumping requirement in grouting equipment is met, and meanwhile high shear strength is achieved.

Owner:BEIJING URBAN CONSTR GROUP +2

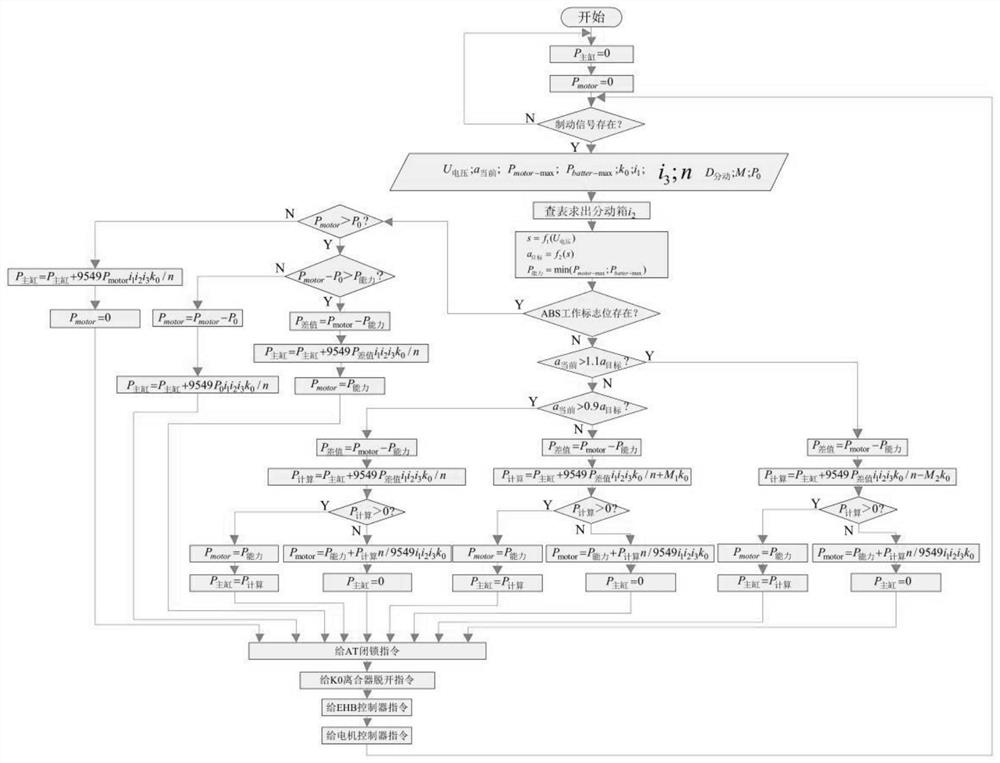

A braking energy recovery control method

ActiveCN112406825BNo overshooting of braking forceSmooth brakingElectrodynamic brake systemsBraking systemsBrake torqueEnergy recovery

The invention relates to the technical field of automobile control methods, in particular to a braking energy recovery control method. When the car is under braking conditions, the relevant signals are used to judge whether the total braking torque of the previous cycle has been adjusted, so as to determine the total braking torque of this cycle; when the vehicle controller does not receive the working flag signal , obtain the current target braking deceleration and current braking deceleration of the vehicle, obtain the first limit value and second limit value of this braking cycle through the current target braking deceleration, and compare the current braking deceleration with the first limit value value and the second limit value, the vehicle controller assigns the current cycle electric brake and the current cycle hydraulic brake under the premise of prioritizing the electric brake according to the comparison result; the first limit value is smaller than the second limit value. In the braking energy recovery of the present invention, electric braking is applied first, and the insufficient part is supplemented by hydraulic braking, so that the energy in the braking process is recovered to the greatest extent, the energy recovery is more efficient, and the vehicle is smoother in the braking process.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

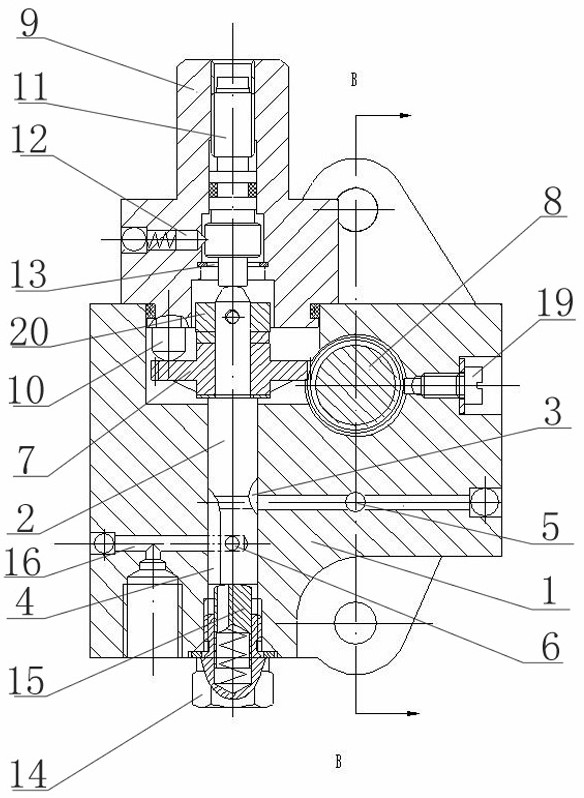

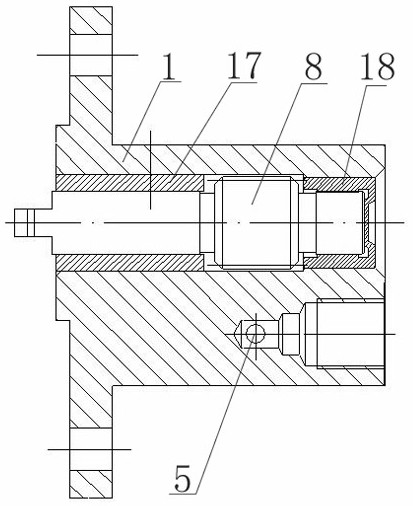

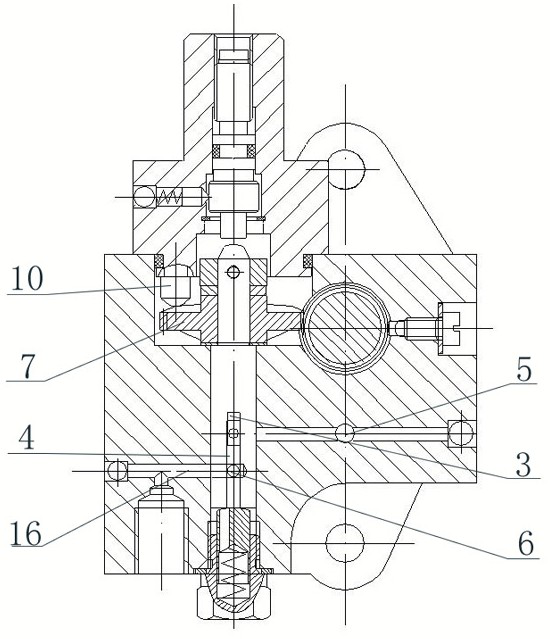

High temperature resistant miniature adjustable plunger lubricating flow pump

ActiveCN109139174BTo offer comfortSolve the lockPositive displacement pump componentsPressure lubrication with lubrication pumpTurbineOil intake

The invention relates to a lubricating liquid flow pump, specifically a high-temperature-resistant miniature adjustable plunger-type lubricating flow pump, which solves the problems of the existing lubricating liquid flow pumps with large flow rate, uninterrupted liquid supply and variable variables. The scheme includes a pump body, a pump There is a piston rod in the body, the upper end of the piston rod is covered with a special-shaped turbine, and a worm is also worn. There is an oil inlet and an oil outlet on the pump body. There is a pump cover on the pump body. There are horizontal oil guide grooves and vertical oil guide grooves. Advantages: 1. The end face of the special-shaped turbine cooperates with the ejector pin, and the helical gear cooperates with the worm to realize the rotation and axial piston movement at the same time, decelerating the pump fluid; 2. Quantitatively adjust the amount of lubricating fluid pumped through the adjustment shaft; 3. Two The four oil outlets supply liquid intermittently in turn, which is convenient for synchronously providing lubricating liquid for the engine and other systems; 4. Reasonable selection of materials can solve the problem of locking of paired friction pairs under high temperature and improve the reliability of high temperature work.

Owner:SHANXI PINGYANG IND MACHINERY

Discharging and feeding equipment

PendingCN111409920AAdjustable connection rangeAvoid stickingPackagingLoading/unloadingMechanical engineeringBuffer zone

The invention relates to the technical field of conveying equipment and provides discharging and feeding equipment. The discharging and feeding equipment comprises a shell body, a feeding spiral and an anti-material-jamming structure. A feeding hole is formed in the shell body; a feeding cavity is constructed in the shell body; a buffer zone is arranged in the feeding cavity; the feeding spiral ispositioned in the feeding cavity; a feeding passage is arranged between the feeding spiral and the feeding hole; the feeding passage and the buffer zone are arranged in parallel in the feeding direction of the feeding spiral; the anti-material-jamming structure is positioned between the feeding passage and the buffer zone; and the anti-material-jamming structure moves to adjust the communicationrange between the feeding passage and the buffer zone. The discharging and feeding equipment can solve the problem of feeding spiral locking caused by particles; and the structure is novel and practical, the manufacturing is simple, the cost is low and the service life is long.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

A locking bar floating installation mechanism and installation method

ActiveCN107979940BPrevent lockOnly positive extrusionClamping/extracting meansEngineeringMechanical engineering

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

Main shaft system of vertical shaft type sand maker

The invention discloses a main shaft system of a vertical shaft type sand maker, comprising a main shaft and a shaft sleeve, wherein the main shaft is positioned in the shaft sleeve through a bearing; bearing covers combined by axial positioned bearings are arranged at the upper end and the lower end of the shaft sleeve; a sealing structure is arranged between the bearing cover and the main shaft; and a lubricating structure is arranged on the shaft cover and comprises a thin oil inlet, an oil return hole and a grease inlet which are arranged on the side wall body of the bearing cover. The main shaft system has reasonable, novel and unique structure and operates stably at high rotating speed; by lubricating and combining thin oil with grease, the problem that the main shaft is locked can be effectively solved and the service lives of the bearing and other parts can be prolonged; and in addition, during bearing assembly, the bearing sleeve is electromagnetically heated so as to ensure the assembly precision and bring convenience to the assembly process.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

Brake protection structure device

InactiveCN107697039ASolve skid and sideslipSolve the lockBraking element arrangementsBrake coolingInstabilityEngineering

The invention discloses a brake protection structure device, which comprises a gearbox, an oil discharge hole, a brake, a fastening bolt, a fixing pipe, a front bracket, and a hydraulic shock absorber, and is characterized in that the gear oil in the gearbox is fixed The pipe and the oil drain hole flow out; the fixed pipe is provided with a fixed tapered pipe sleeve, and the fastening bolt is fixed on the tapered pipe sleeve; the upper part of the front bracket has a fixed pipe, and the lower part is provided with a hydraulic shock absorber device. The invention has the advantages of simple structure, simple operation, good heat dissipation effect, effectively solves the problems of wheel slipping, side slipping, locking, unstable braking, etc., keeps the sliding rate of the wheel within the optimal range, is safe and reliable, and has good vibration reduction and braking effects it is good.

Owner:郭晓伟

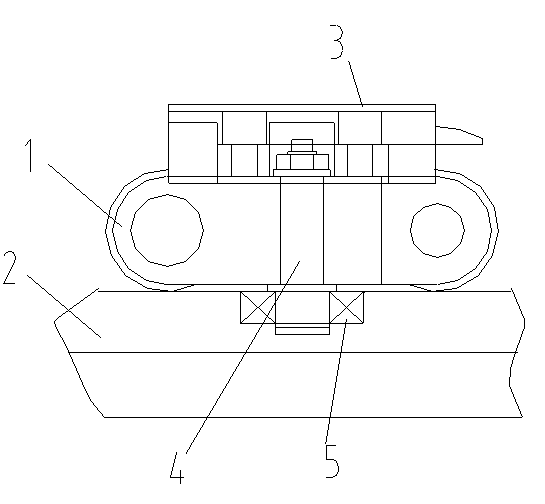

High-temperature-resistant minisize adjustable plunger-type lubrication flow pump

ActiveCN109139174ATo offer comfortSolve the lockPositive displacement pump componentsPressure lubrication with lubrication pumpEngineeringAbnormal shaped

The invention relates to a lubrication liquid flow pump, in particular to a high-temperature-resistant minisize adjustable plunger-type lubrication flow pump. The problem that an existing lubricationliquid flow pump is high in flow, cannot liquid intermittently and cannot achieve variable flow are solved. According to the scheme, the high-temperature-resistant minisize adjustable plunger-type lubrication flow pump comprises a pump body, a piston rod is arranged in the pump body, a special-shaped turbine is fixedly arranged at the upper end of the piston rod in a sleeving mode, a worm penetrates through the special-shaped turbine, a pump body is provided with an oil inlet and an oil outlet as well as a pump cover, an ejector pin is supported on the pump cover, and the piston rod is provided with a horizontal oil guide channel and a vertical oil guide channel. The high-temperature-resistant minisize adjustable plunger-type lubrication flow pump has the advantages that 1, the end face ofthe special-shaped turbine is matched with the ejector pin and is further matched with the worm through helical teeth, rotaton and axial piston movement are both achieved, and pump liquid is decelerated; 2, an adjusting shaft is used to achieve quantitative adjustment of the pumping amount of lubrication liquid; 3, the two oil outlets supply the liquid in turn, so that the lubrication liquid is supplied to an engine and other systems synchronously; and 4, by reasonably selecting materials, the problem of locking of a pairing friction pair under high temperature is solved, and the high-temperature operation reliability is improved.

Owner:SHANXI PINGYANG IND MACHINERY

A leak-proof device for the gluing mechanism of an edge banding machine

ActiveCN104138826BReduce storageWon't enterLiquid surface applicatorsCoatingsRotational axisDevice leakage

The invention discloses an anti-leakage device for a glue application mechanism of an edge banding machine, comprising a glue supply box, a glue application shaft, a rubber supply wheel seat, a sealing cover installed between the rubber supply wheel seat and the glue application shaft, and an O-shaped sealing ring , Bearing; Wherein, the gluing shaft includes the gluing shaft working part and the gluing shaft connecting part fixedly connected to each other; the outer wall surface of the gluing shaft working part is provided with a helical lift whose helical direction is opposite to the gluing shaft rotation direction. Groove, the aforementioned sealing cover is used to accept the leaked glue; during the rotation of the glue shaft, the glue is actively lifted up from the receiving groove and the slender gap to the glue supply box by rotating the lifting groove; effectively avoiding the glue from entering In the case of locking inside the bearing, even if the sealing element is slightly worn, the normal operation of the equipment can still be guaranteed, and only the O-ring is replaced during maintenance, and there is no need to replace the high-temperature bearing. The maintenance cost is lower and effective. It solves the problems of bearing locking and maintenance troubles that often occur in traditional gluing devices.

Owner:NANXING MACHINERY CO LTD

A special cold slag machine for treating adsorption vocs waste gas solid waste heat storage secondary combustion purification device

ActiveCN106838948BReduce heat lossStable temperature gradientLighting and heating apparatusCombustionSlag

The invention relates to the field of technologies for treating volatile organic compound waste gas, in particular to a special slag cooler for heat storage secondary combustion purification devices for treating and adsorbing VOCs (volatile organic compounds) waste gas and solid waste. The special slag cooler is characterized by comprising an ash blowing machine, a jacket type air-cool spiral conveyor, an air shutdown valve and a drum type slag cooling assembly. According to the technical scheme of secondary slag ash cooling, the special slag cooler has the advantages that stable and gentle temperature gradient descent of slag ash can be guaranteed by primary air cooling of the jacket type air-cool spiral conveyor and secondary water cooling of the drum type slag cooling assembly, and accordingly the problems of great local temperature variation of spiral blades in existing jacket type air-cool spiral conveyors during irregular interval slag discharge and locking of the spiral blades and the inner wall of air-cool jackets after the spiral blades are thermally expanded can assuredly solved; designed spiral slag breaking hinges can roll in circumferential surfaces of rotary drums along with rotation of the rotary drums, accordingly, slag on the inner walls of the rotary drums can be cleaned in cycles, and reduction of heat conductivity coefficients of the rotary drums and local high-temperature deformation of the rotary drums can be prevented.

Owner:FAREAST KINGSTAR CHEM

Vertical-shaft sand making machine

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

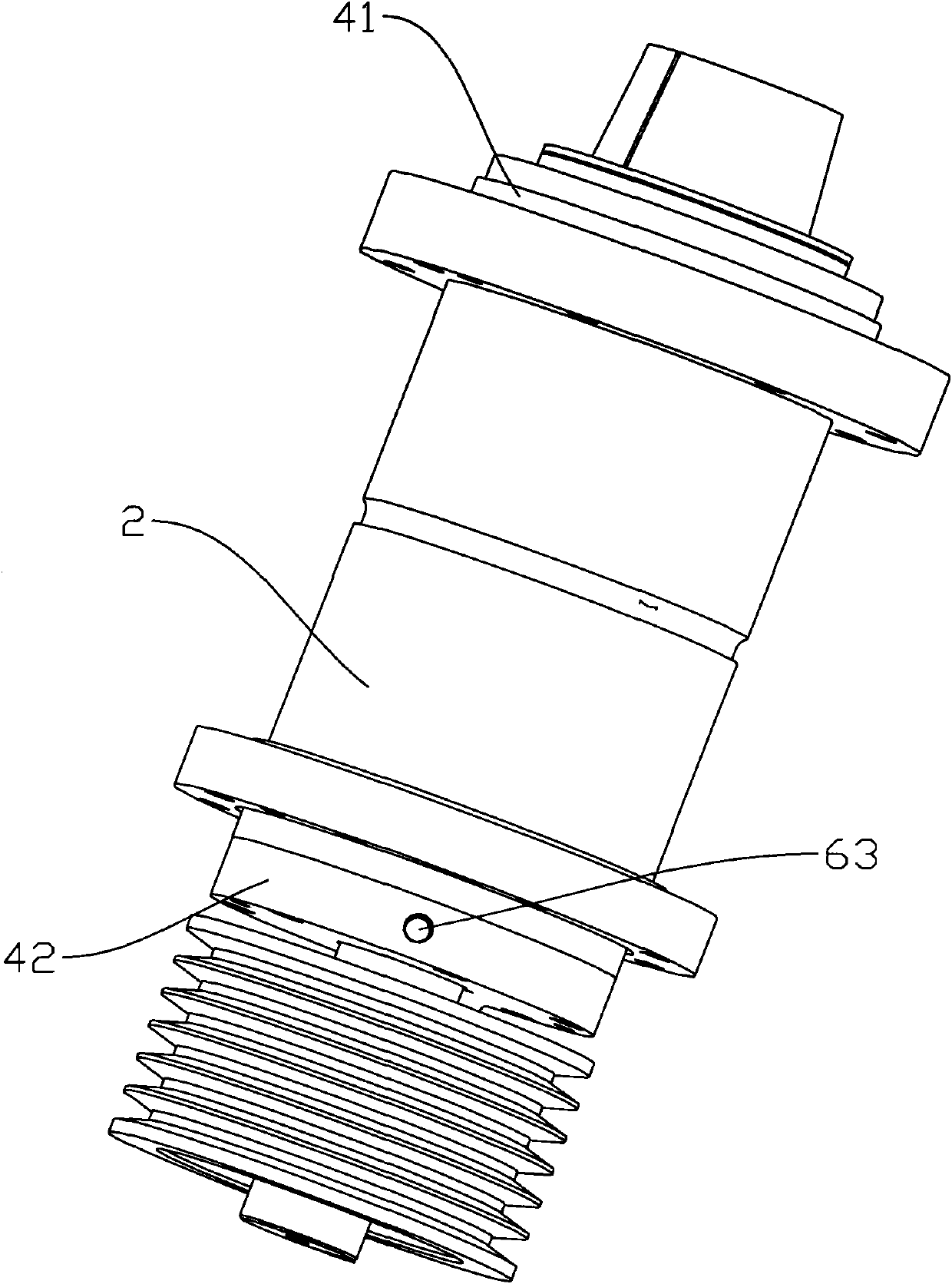

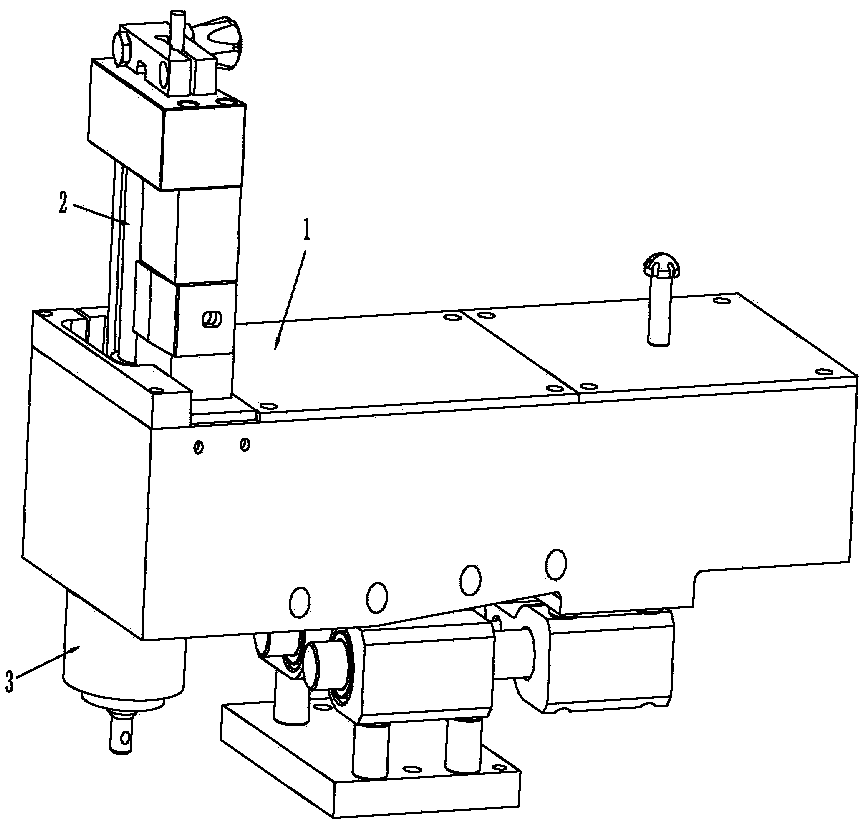

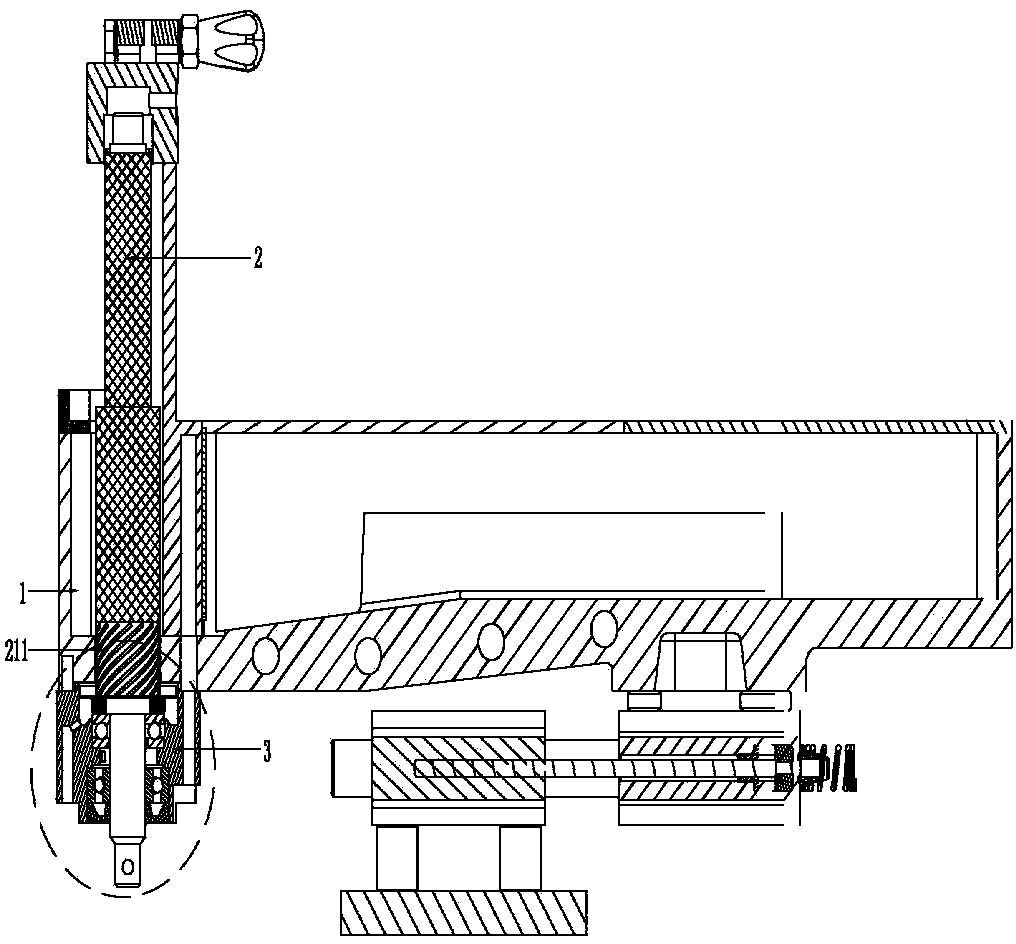

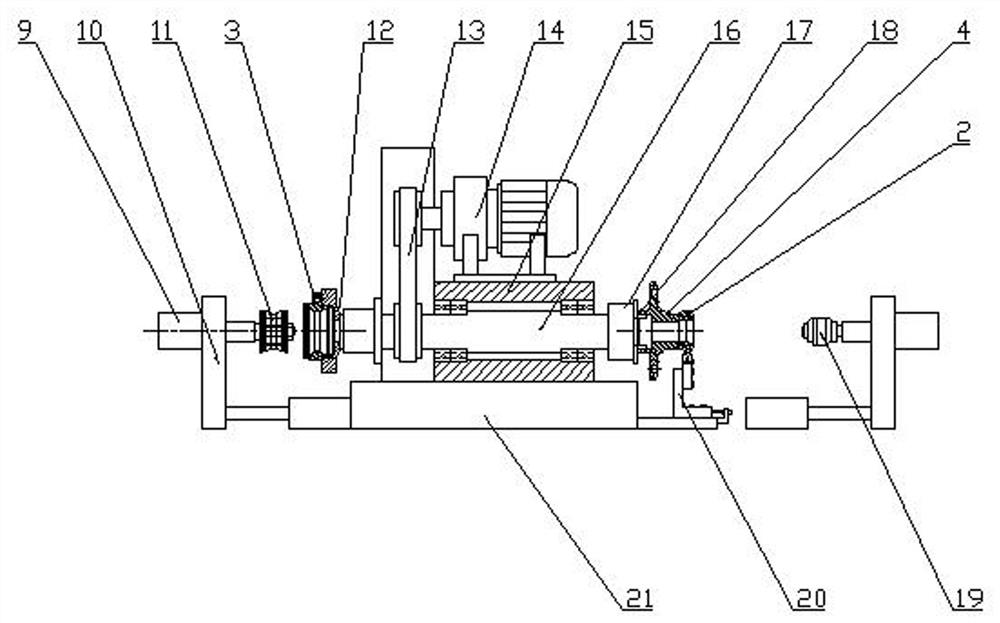

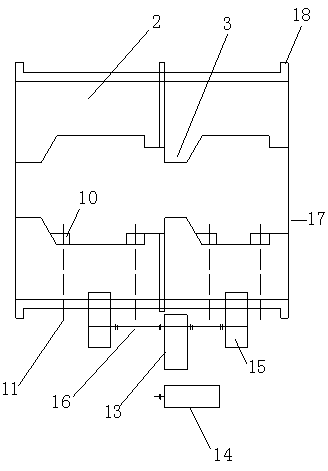

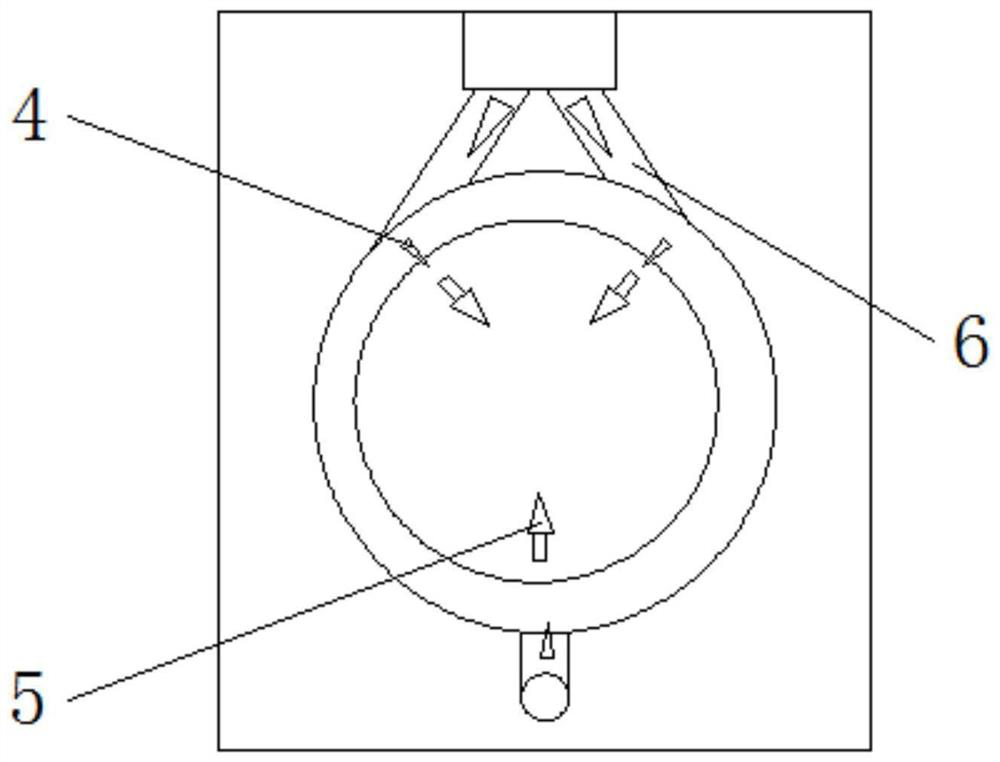

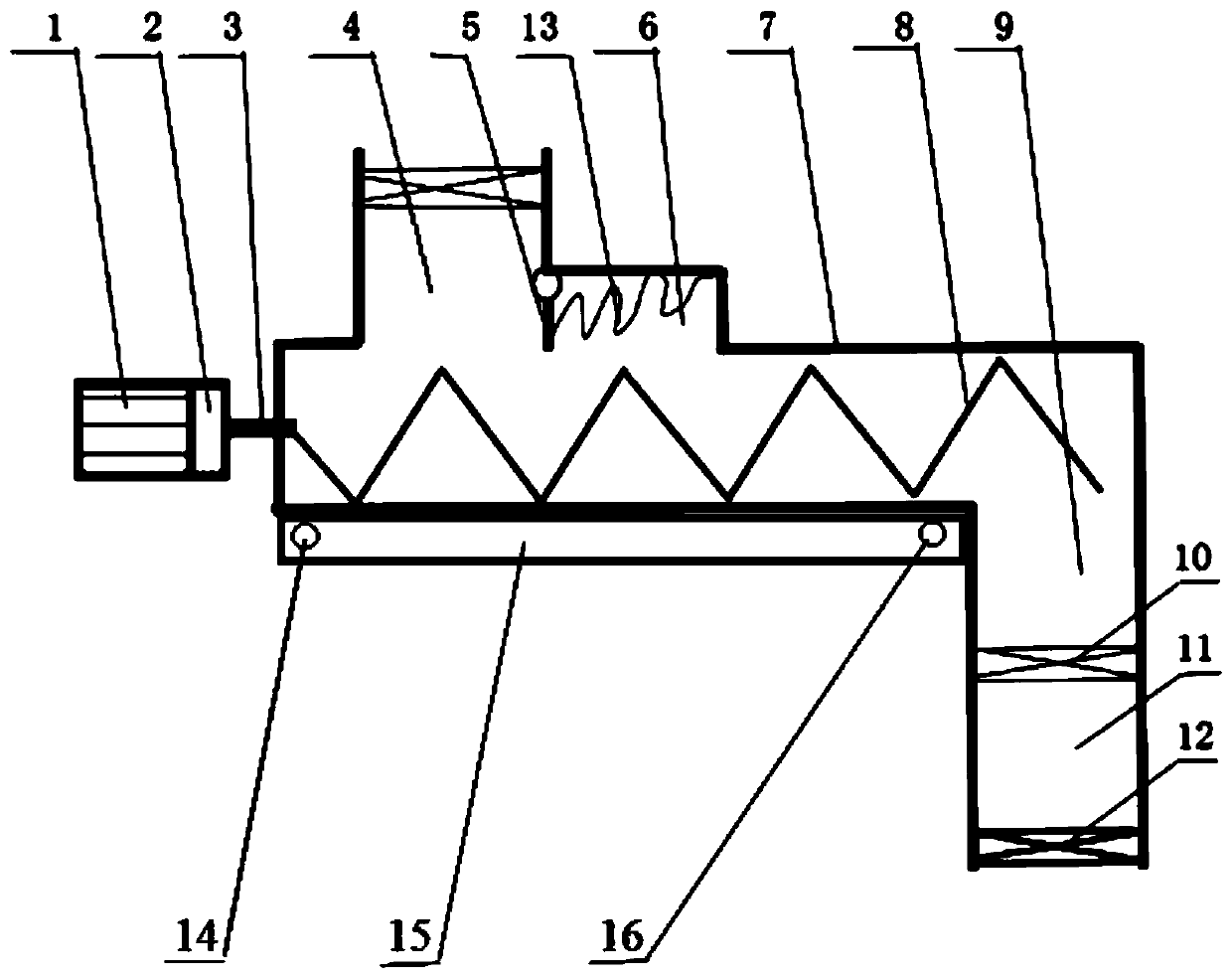

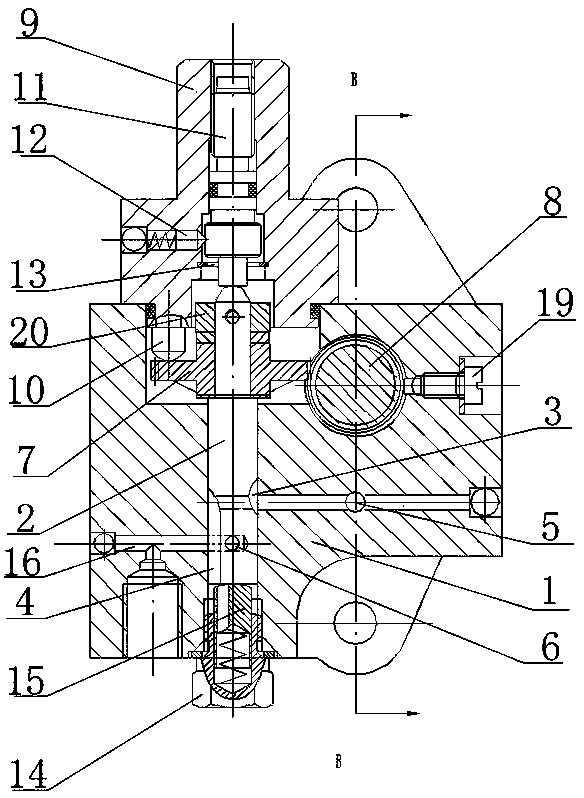

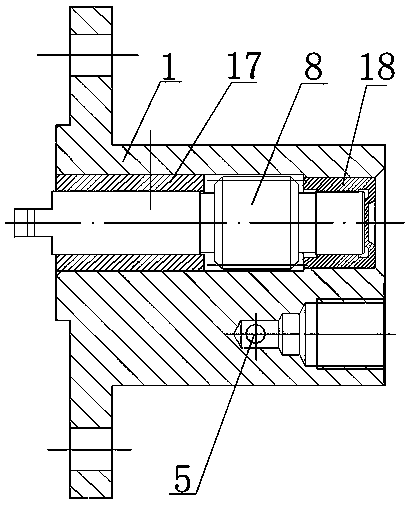

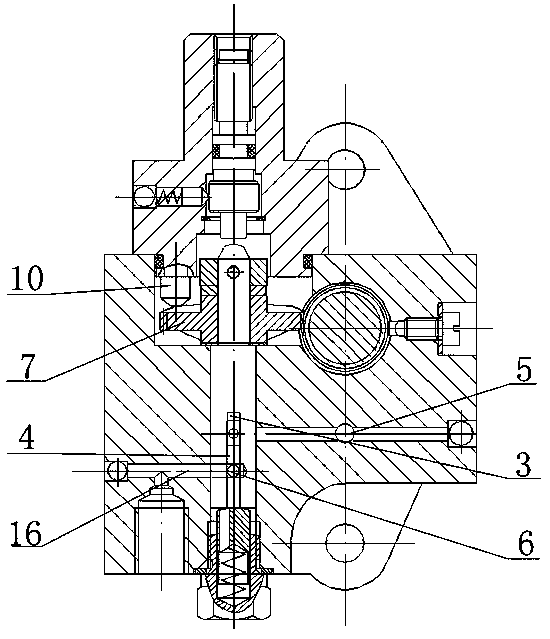

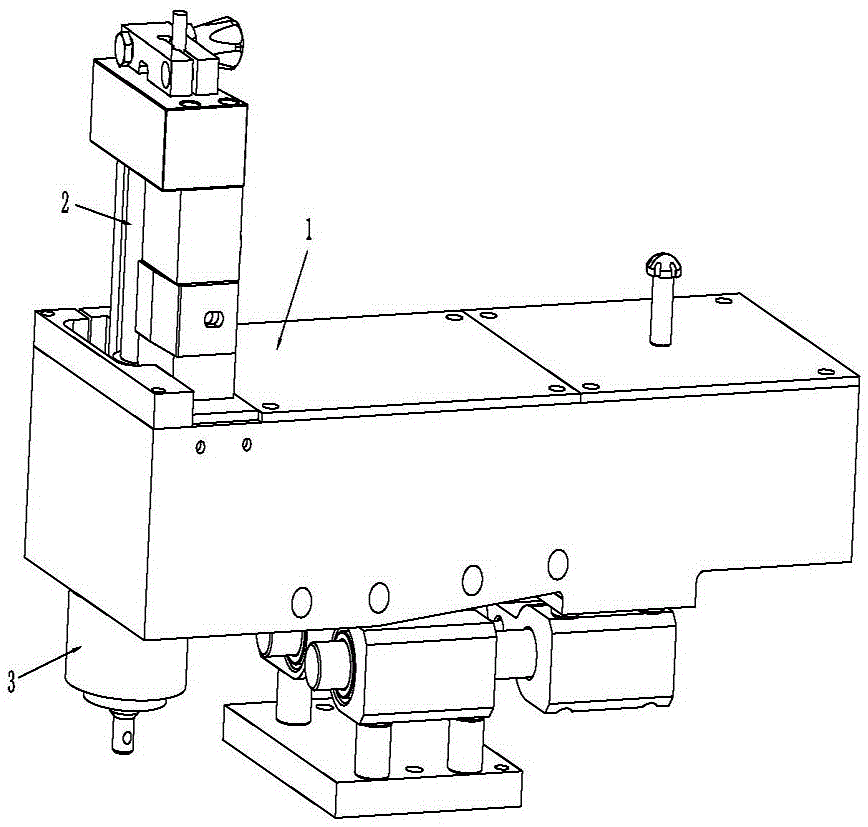

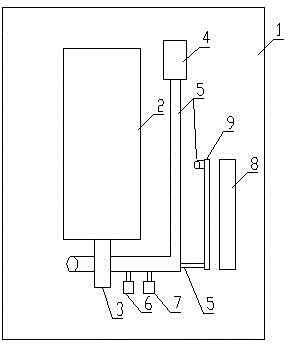

Hydraulic device for miniature numerical control machine tool

InactiveCN104084809ASolve the lockImprove job stabilityServomotorsPositioning apparatusNumerical controlDrive motor

The invention relates to a hydraulic device for a miniature numerical control machine tool, which consists of an oil tank (1), an oil supply device and an oil way cooling device, wherein the oil supply device comprises a drive motor (2), an oil pump (3), a single-head solenoid valve (4), an oil pipe (5), a pressure regulating valve (6) and a pressure gauge (7); the oil way cooling device comprises the oil pipe (5), a cooling fan (8) and a heat-radiating plate (9). The hydraulic device is characterized in that the oil supply device is arranged at the middle part of the oil tank (1), and the oil way cooling device is arranged on the right of the oil tank (1). The hydraulic device has the benefits that the locking problem of a rotary oil cylinder is solved through replacing an original air pressure way with oil pressure; moreover, the hydraulic device has a simple and light structure, and the working stability of the numerical control machine tool is also effectively improved.

Owner:JIANGSU AIBO MACHINERY MFG

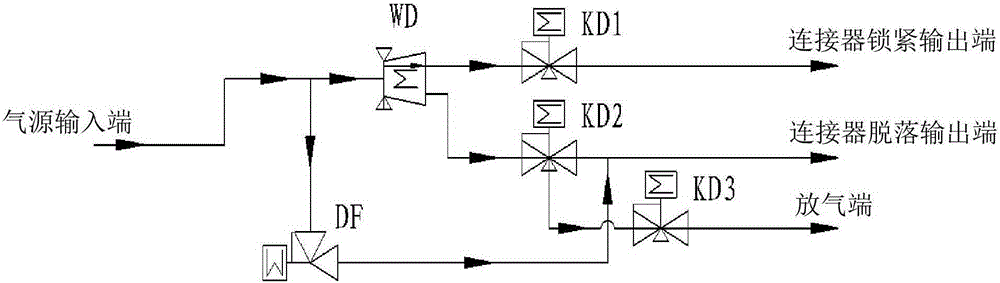

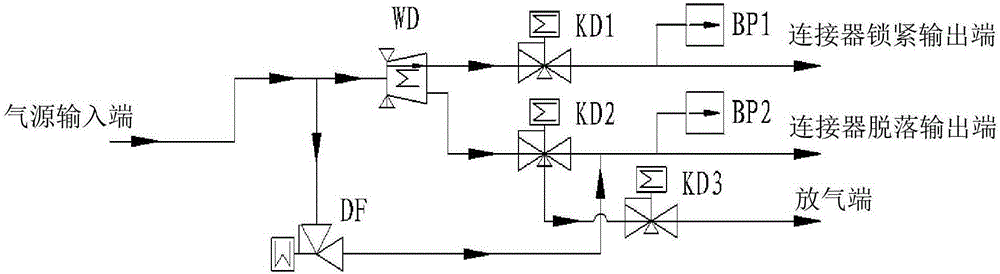

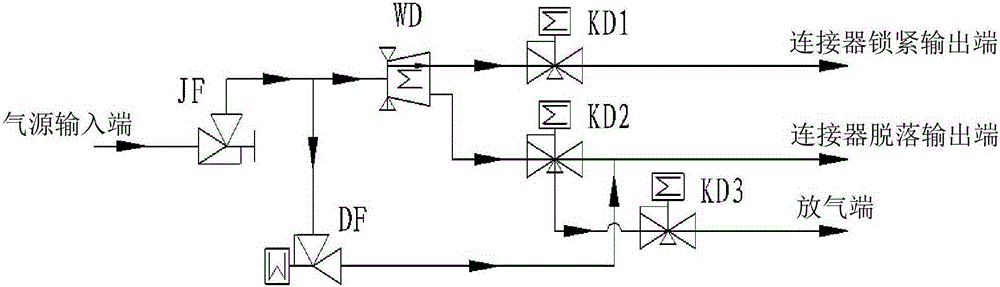

Gas supply circuit used for controlling low-temperature gas-liquid connector

The invention provides a gas supply circuit used for controlling a low-temperature gas-liquid connector. The gas supply circuit comprises a gas source input end, a two-position five-way electromagnetic valve, a first normally-open electromagnetic valve, a second normally-open electromagnetic valve, a connector locking output end, a connector disengagement output end, a third normally-open electromagnetic valve, a two-position two-way electromagnetic valve, and a gas exhaust end. The first end of the two-position five-way electromagnetic valve is connected with the gas source input end. The first end of the first normally-open electromagnetic valve is connected with the second end of the two-position five-way electromagnetic valve. The first end of the second normally-open electromagnetic valve is connected with the third end of the two-position five-way electromagnetic valve. The connector locking output end is connected with the second end of the first normally-open electromagnetic valve. The connector disengagement output end is connected with the second end of the second normally-open electromagnetic valve. The first end of the third normally-open electromagnetic valve is connected with the third end of the second normally-open electromagnetic valve. The first end of the two-position two-way electromagnetic valve is connected with the gas source input end. The second end of the two-position two-way electromagnetic valve is connected with the second end of the second normally-open electromagnetic valve. The gas exhaust end is connected with the second end of the third normally-open electromagnetic valve. According to the gas supply circuit, the design of redundant backup of the two-position five-way electromagnetic valve is provided for coping with possible failures, and the reliability of the gas supply circuit is improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com