Automatic companion stone embedding and lining autogenous grinder

A self-grinding machine, automatic technology, applied in grain processing and other directions, can solve the problems of large consumables, weakened potential energy, high replacement and maintenance costs, achieve the effect of fixed structure and simple replacement, reduce production wear costs, and overcome the effects of large production consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

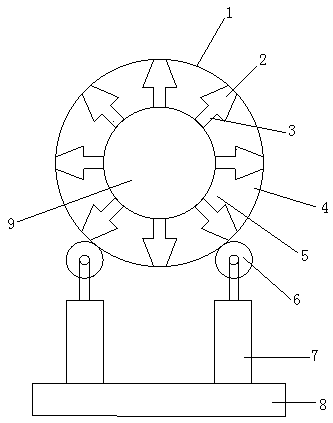

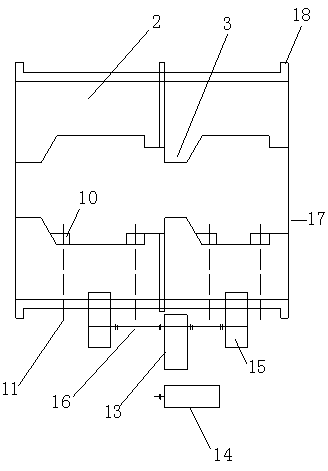

[0044] Refer to attached figure 1 , 2 , the present invention includes a motor 14, a reducer 13, a drive wheel 15, a transmission shaft 16, a supporting base, and a cylinder, wherein: the cylinder is composed of at least one section of cylinder unit 1, and one end of the cylinder unit is a feed end, The other end is the discharge end, and a cylinder liner is installed on the inner wall of the cylinder unit. The cylinder liner is composed of grate bars 2 evenly spaced on the circumference, and grate grooves 4 are formed between adjacent grate bars. The cross section is: the end is wide toward the center of the cylinder unit, and the end is narrow toward the inner wall of the cylinder unit; the cross section of the grate groove is: the end is narrow toward the center of the cylinder unit, and the end is wide toward the inner wall of the cylinder unit. The cross-section of the groove is arc-shaped toward the inner wall of the cylinder unit; the horizontal surface in the length d...

Embodiment 2

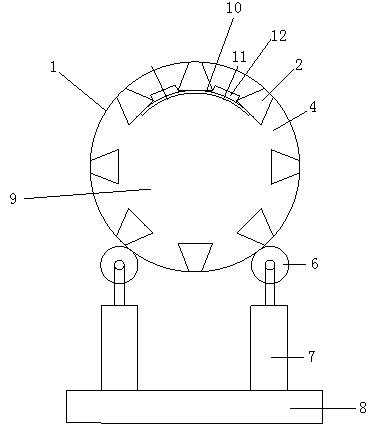

[0048] Refer to attached image 3 , On the basis of embodiment 1, remove the croissor plate that grate bar central direction discharge end is provided with. Start the motor to make the cylinder part rotate, and the solid waste metallurgical slag or the slag and iron after preliminary classification of the iron remover are continuously fed into the feed port and feed end of the self-milling machine. The mineral accumulation at the feed port is higher than that at the discharge end, and the rotating cylinder throws the minerals in a high circulation cycle, and the moving minerals and the minerals and the companion stone liner are extruded, rubbed, and excavated, and the minerals are crushed and soft. Minerals are first finely crushed, slag and iron are stripped, and the product is pushed from the feed end to the discharge end under the continuous feeding and overflow promotion, and is discharged from the body for the next stage of processing.

[0049] Simultaneously, under the ...

Embodiment 3

[0051] Aggregate shaping or supporting screening:

[0052] Refer to attached image 3 , 4 , on the basis of Embodiment 2 or 1, the cylinder part is composed of more than one cylinder unit, and the last cylinder unit is connected to the previous cylinder unit in reverse, that is: the discharge end of the last cylinder unit is connected to the front The discharge end of a cylinder unit is connected, and the rear section of the cylinder liner is exposed outside the shell of the cylinder unit, so that the grate groove is horizontal, the feed end is narrow, and the discharge end is wide. The exposed part of the cylinder liner can be wrapped with another layer of screen. The gap between the grate bars of the exposed part of the liner of the cylinder forms the third discharge port 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com